Abstract

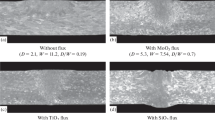

Advanced A-TIG method was conducted to increase the weld penetration and compared with the conventional TIG welding process. A two-pipeline setup was designed to apply Ar + CO2 mixed gas as the outer layer, while pure argon was applied as the inner layer to prevent any consumption of the tungsten electrode. The results indicate that the presence of active gas in the molten pool led to the change in the temperature coefficient of surface tension so that the Marangoni convection turns inward and forms a deep weld zone. The increase in gas flow rate causes a decrease in the weld efficiency which is attributed to the increase in oxygen content in the weld pool and the formation of a thicker oxide layer on the weld surface. Moreover, the stir and the temperature fluctuation, led by double shielding gas, create more homogeneous nucleation sites in the molten pool so that a fine grain microstructure was obtained.

Similar content being viewed by others

References

W. Lucas, M.H. Rodwell, Weld. Revolut. 8, 185 (1987)

S.P. Lu, H. Fujii, K. Nogi, J. Mater. Sci. 26, 170 (2010)

B. Arivazhagan, M. Vasudevan, J. Manuf. Process. 18, 55 (2015)

A.R. Khalifeh, A. Dehghan, E. Hajjari, Acta Metall. Sin. (Engl. Lett.) 26, 721 (2013)

M. Manikandan, N. Arivazhagan, M. Nageswara Rao, G. Madhusudhan Reddy, Acta Metall. Sin. (Engl. Lett.) 28, 208 (2015)

Y.L. Xu, Z.B. Dong, Y.H. Wei, C.L. Yang, Theor. Appl. Fract. Mech. 48, 2178 (2007)

P. Vasantharaja, M. Vasudevan, J. Nucl. Mater. 421, 117 (2012)

K. Tseng, C. Hsu, J. Mater. Process. Technol. 211, 503 (2011)

T. Wen, S. Liu, S. Chen, L. Liu, C. Yang, Trans. Nonferr. Met. Soc. China 25, 397 (2015)

Q. Zhu, Y. Lei, Y. Wang, W. Huang, B. Xiao, Y. Ye, Fusion Eng. Des. 89, 2964 (2014)

A. Bîrdeanu, C. Ciucă, A. Puicea, J. Mater. Process. Technol. 212, 890 (2012)

T. Cunha, C. Enrique, Ultrasonics 56, 201 (2015)

S.H. Zhang, Y.F. Shen, H.J. Qiu, Opt. Laser Technol. 48, 381 (2013)

B. Emde, M. Huse, J. Hermsdorf, S. Kaierle, V. Wesling, L. Overmeye, Phys. Proc. 56, 646 (2014)

S.P. Lu, H. Fujii, H. Sugiyama, M. Tanaka, K. Nogi, Metall. Mater. Trans. A 34, 1901 (2003)

C.R. Heiple, P. Burgardt, Weld. J. 64, 159 (1985)

S.P. Lu, H. Fujii, K. Nogi, T. Sato, Sci. Technol. Weld. Join. 12, 689 (2007)

Y. Zou, R. Ueji, H. Fujii, Mater. Sci. Eng. A 620, 140 (2015)

S.P. Lu, M.P. Qin, W.C. Dong, J. Mater. Process. Technol. 213, 229 (2013)

M. Häßler, S. Rose, U. Füssel, H.I. Schneider, C. Werner, Weld. World Le Soudage Dans Le Monde 59, 71 (2015)

Y. Morisada, H. Fujii, X.K. Ni, Mater. Des. 54, 526 (2014)

ASFMH Committee, G.F. Vander Voort, Metallography and microstructures, in ASM Handbook, vol. 9 (ASM International, Materials Park, OH, 2004)

D.S. Howse, W. Lucas, Sci. Technol. Weld. Join. 5, 189 (2000)

H. Taimatsu, K. Nogi, K. Ogino, J. High. Temp. Soc. 18, 14 (1992)

D.J. Li, S.P. Lu, D.Z. Li, Y.Y. Li, J. Mater. Sci. Technol. 30, 922 (2014)

M. Tanaka, M. Ushio, J.J. Lowke, Vacuum 73, 381 (2004)

C.C. Silvaa, H.C. de Mirandaa, H.B. de Sant’Anab, J.P. Fariasa, Mater. Charact. 60, 346 (2009)

J. Brooks, J. Williams, A. Thompson, Metall. Trans. A 14, 1271 (1983)

X.J. Di, S.J. Deng, B.S. Wang, Mater. Des. 66, 169 (2015)

J.W. Elmer, S.M. Allen, T.W. Eagar, Metall. Trans. A 20, 2106 (1989)

Author information

Authors and Affiliations

Corresponding author

Additional information

Available online at http://link.springer.com/journal/40195

Rights and permissions

About this article

Cite this article

Nakhaei, R., Khodabandeh, A. & Najafi, H. Effect of Active Gas on Weld Shape and Microstructure of Advanced A-TIG-Welded Stainless Steel. Acta Metall. Sin. (Engl. Lett.) 29, 295–300 (2016). https://doi.org/10.1007/s40195-016-0381-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40195-016-0381-6