Abstract

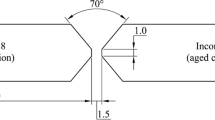

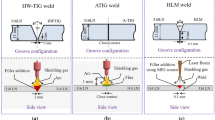

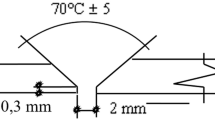

The improvement and optimization of post-weld treatments in the case of austenitic 316L stainless steels are, to a large extent, a condition of the service life of the associated structures. In this regard, mechanical brushing and heat treatment are post-weld techniques dedicated to the assembly of mechanically welded structures applicable in the aeronautics, food, and transport sectors. In this study, two techniques are applied to welded joints: mechanical brushing and heat treatment at high temperature. The base material is austenitic stainless steel with molybdenum (AISI316L) in sheet of 5-mm thick. The adopted welding process is Arc Welding under Metal Inert Gas (MIG). Monotonic Tensile test, micro-hardness measurement, low cycle fatigue, micro-hardness measurement, and MES (scanning electron microscopy) observation were conducted in order to qualify the welded, brushed, and heat-treated weldment. Compared with the welded and brushed samples, the treatment with heat annealing specimen maintains the longest lifetime and the lowest consolidation stress ± 0.4% imposed strain rate and 10−3/s as displacement speed. The annealing heat treatment has a softening effect on the welded structure during the test of the cycle fatigue; this is consistent with the micro-hardness levels measured in the weldment.

Similar content being viewed by others

References

Kirkhope KJ, Bell R, Caron L, Basu RI, Ma KT (1999) Weld detail fatigue life improvement techniques. Part 1. Mar Struct 12(6):447–474

Haagensen P, Maddox S (2013) IIW recommendations on methods for improving the fatigue strength of welded joints: IIW-2142-110. Woodhead Publishing

Kim IT, Kim HS, Dao DK et al Fatigue resistance improvement of welded joints by bristle roll-brush grinding. Int J Steel Struct 18(5):1631–1638

Ben Fredj N, Sidhom H, Braham C (2006) Effect of the cryogenic wire brushing on the surface integrity and the fatigue life improvement of the AISI 304 stainless steel ground components. In: Fracture of nano and engineering materials and structures. Springer, Dordrecht, pp 1303–1304

Weiss B, Stickler R (1972) Metallurgical Transformation A 3:851–866

Schwind M, Kallqvist J et al (2000) σ-phase precipitation in stabilized austenitic stainless steels. Acta Mater 48:2473–2481

Hert D, Lebrun JP (1996) Int J Fatigue 18(1):60

Yamauchi K (2002) Metallurgical Material Transformations A 33A:174

Liu F, Hwang YH, Nam SW (2006) The effect of post weld heat treatment on the creep-fatigue behavior of gas tungsten arc welded 308L stainless steel. Mater Sci Eng A 427(1–2):35–41

Valensi F (2007) Contribution to the study of phenomena related to anodic and cathodic effects in MIG-MAG welding. Physics. University of Orleans. France. fftel-00449180f (https://tel.archives-ouvertes.fr/tel-00449180/document)

Sylwia Zielinska. Physical properties of MIG-MAG plasma. Process Engineering. University of Orléans, 2005. France. fftel-00458799f (https://tel.archives-ouvertes.fr/tel-00458799/document )

Guizani H, Nasser MB, Tlili B, Oueslati A, Chafra M (2019) Finishing and quality of mechanically brushed 316L stainless steel welded joints using MIG process: hardness modeling by L9 TAGUCHI design. Int J Adv Manuf Technol 105(1–4):1009–1022

R. N. GUNN. Duplex stainless steels. 2000

P. LACOMBE, B. BAROUX, G. BERANGER. Stainless steels.1990

Lippold JC D.J. Kotecki, Welding metallurgy of stainless steel

Riad Badji (2008) Influence of high temperature heat treatments on the evolution of texture and microstructure of 2205 duplex stainless steel welds. Mechanics of materials [physics.class-ph]. Paris-Nord University - Paris XIII. France. <tel-00806333> (https://tel.archivesouvertes.fr/file/index/docid/806333/filename/PhD_Badji_2008.pdf )

Kožuh S, GOJI M (2009) Mechanical properties and microstructure of austenitic stainless steel after welding and post-weld heat treatment. Kovove Materiarly 47:253–262

Safrany JS Techniques of the engineer-treaty metallic materials . M 1(630):1–22

Kamariah MSIN, Harun WSW, Khalil NZ, Ahmad F, Ismail MH, Sharif S (2017) Effect of heat treatment on mechanical properties and microstructure of selective laser melting 316L stainless steel. In IOP Conference Series: Materials Science and Engineering (Vol. 257, No. 1, p. 012021). IOP Publishing

Montero Sistiaga M, Nardone S, Hautfenne C, Van Humbeeck J (2016) Effect of heat treatment of 316L stainless steel produced by selective laser melting (SLM). In: Proceedings of the 27th Annual International Solid Freeform Fabrication Symposium-An Additive Manufacturing Conference, pp 558–565

Yadollahi A, Shamsaei N, Thompson SM, Seely DW (2015) Effects of process time interval and heat treatment on the mechanical and microstructural properties of direct laser deposited 316L stainless steel. Mater Sci Eng A 644:171–183

Imandoust A, Zarei-Hanzaki A, Heshmati-Manesh S, Moemeni S, Changizian P (2014) Effects of ferrite volume fraction on the tensile deformation characteristics of dual phase twinning induced plasticity steel. Mater Des 53:99–105

Kocijan A, Merl DK, Jenko M (2011) The corrosion behaviour of austenitic and duplex stainless steels in artificial saliva with the addition of fluoride. Corros Sci 53(2):776–783

Friedel J Dislocations pergamon, New York, p 274

Kchaou Y (2015) A comparative study of the mechanical properties of superaustenitic and duplex welded joints in pressure vessels. Dhd, ISAE-ENSMA, Poitiers, France

Ward AL Thermal and irradiation effects on the tensile and creep-rupture properties of weld-deposited type 316 stainless steel. Nuclear Technol 24(2):201–215

Goodwin GM, Cole NC, Slaughter GM Study of ferrite morphology in austenitic stainless steel weldments. Welding Res Suppl (United States)

Gugelev BM Mechanism of the deformation and fracture of austenitic-ferritic weld metal. Automat Weld 22(7):20–23

Ivanov KM, Petrov GL The thermal embrittlement of chromium-nickel austenitic-ferritic weld metals when aged at temperatures below 500°C. Welding Research Abroad:79–85

Yarkovoi V, Muromtsev B, Komissarov V Long time strengths of parent metal and welded joints in Khl8N9 and Khl6N9M2 steels. Automat Weld 22(6):40–43

Heuschkel J Time-temperature dependence of austenitic stainless steel welded joint components. Welding J 35:12

De Baglion L (2011) Low cycle fatigue behaviour and damage of a type 304L austenitic stainless steel, as a function of environment (vacuum, air, primary water PWR) at 300 degrees Celsius. Dhd, ISAE-ENSMA, ISAE-ENSMA, Poitiers, France

Prasad R, Rama R (1995) Effect of welding parameters and gas composition on ferrite content of austenitic weld and clad metals. Prakt Metallogr 32(6):312–324

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission XIII - Fatigue of Welded Components and Structures

Rights and permissions

About this article

Cite this article

Guizani, H., Tlili, B. & Chafra, M. Experimental characterization and fatigue behavior of thermally and mechanically treated 316L stainless steel MIG-welded joints. Weld World 65, 67–78 (2021). https://doi.org/10.1007/s40194-020-00997-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-020-00997-x