Abstract

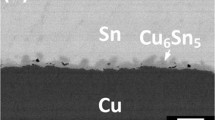

The reliability of flip-chip Sn/Cu solder joint strongly depends on Kirkendall voids, since it affects the mechanical properties of the solder joints. In this paper, the formation of Kirkendall voids (KVs) at the interface of Sn/Cu joints was investigated by changing various Cu substrates, namely, high-purity Cu (HP Cu), electroplated Cu (EP Cu), and vacuumed-sputtered Cu (VS Cu). It is found that the KVs did not appear at the Sn/HP Cu interface even after aging at 180 °C for 720 h. A large number of voids were observed at the Cu3Sn/Cu interface in Sn/EP Cu and Sn/VS Cu joints during a short aging time. The size of voids formed in the Sn/EP Cu was larger relative to that in Sn/VS Cu. The formation of different voids at the Sn/Cu joints can be attributed to three factors, i.e., diffusion paths for Cu atoms increased from Sn/HP Cu, Sn/EP Cu, and Sn/VS Cu, different impurities (S, Cl, et al.) in Cu substrates, and different stress states at the Cu3Sn/Cu interface.

Similar content being viewed by others

References

Baheti VA, Kashyap S, Kumar P, Chattopadhyay K, Paul A (2017) Bifurcation of the Kirkendall marker plane and the role of Ni and other impurities on the growth of Kirkendall voids in the Cu–Sn system. Acta Mater 131:260–270

Liashenko OY, Lay S, Hodaj F (2016) On the initial stages of phase formation at the solid Cu/liquid Sn-based solder interface. Acta Mater 117:216–227

Yang Y, Lu H, Yu C, Li Y (2011) Void formation at the interface in Sn/Cu solder joints. Microelectron Reliab 51(12):2314–2318

Buchovecky E, Jadhav N, Bower AF, Chason E (2009) Finite element modeling of stress evolution in Sn films due to growth of the Cu6Sn5 intermetallic compound. J Electron Mater 38(12):2676–2684

Yin L, Borgesen P (2011) On the root cause of Kirkendall voiding in Cu3Sn. J Mater Res 26(3):455–466

Yu J, Kim JY (2008) Effects of residual S on Kirkendall void formation at Cu/Sn–3.5Ag solder joints. Acta Mater 56(19):5514–5523

Park JY, Seo W, Yoo S, Kim YH (2017) Effect of Cu electroplating parameters on microvoid formation and high-speed shear strength in Sn-3.0Ag-0.5Cu/Cu joints. J Alloys Compd 724(15):492–500

Kim JY, Yu J (2008) Effects of residual impurities in electroplated Cu on the Kirkendall void formation during soldering. Appl Phys Lett 92(9):947–1262

Kim J, Kim H (2010) Effects of organic additives on preferred plane and residual stress of copper electroplated on polyimide. Mater Chem Phys 120(2):341–347

Cho MG, Kang SK, Shih DY, Lee HM (2007) Effects of minor additions of Zn on interfacial reactions of Sn-Ag-Cu and Sn-Cu solders with various Cu substrates during thermal aging. J Electron Mater 36(11):1501–1509

Peter B, Liang Y, Pericles K (2011) Assessing the risk of “Kirkendall voiding” in Cu3Sn. Microelectron Reliab 51(4):837–846

Zou J, Mo L, Wu F, Wang B (2010) Effect of Cu substrate and solder alloy on the formation of Kirkendall voids in the solder joints during thermal aging. International Conference on Electronic Packaging Technology & High Density Packaging IEEE :944–948

Yin L, Dimitrov N, Borgesen P (2012) Toward a better understanding of the effect of Cu electroplating process parameters on CuSn voiding. J Electron Mater 41(2):302–312

Liu Y, Wang J, Yin L, Kondos P, Parks C, Borgesen P, Henderson DW, Cotts EJ, Dimitrov N (2008) Influence of plating parameters and solution chemistry on the voiding propensity at electroplated copper–solder interface. J Appl Electrochem 38(12):1695–1705

Tu KN, Thompson RD (1982) Kinetics of interfacial reaction in bimetallic Cu-Sn thin films. Acta Metall 30(5):947–952

Kim S, Yu J (2012) Recrystallization-induced void migration in electroplated cu films. Scripta Mater 67(4):312–315

Porter DA, Easterling KE, Sherif M (1992) Phase transformations in metals and alloys, 2nd edition. Ref User Serv Q 1(2):245

Kumar S, Handwerker CA, Dayananda MA (2011) Intrinsic and interdiffusion in Cu-Sn system. J Phase Equilib Diff 32(4):309–319

Cheng EH, Kuo TT, Wang CC, Wu WH (2012) Inhibiting the growth of Cu3Sn and Kirkendall voids in the Cu/Sn-Ag-Cu system by minor Pd alloying. Electron Mater Lett 8(5):495–501

Song JY, Yu J, Lee TY (2004) Effects of reactive diffusion on stress evolution in Cu–Sn films. Scripta Mater 51(2):167–170

Weinberg K, Böhme T, Müller WH (2009) Kirkendall voids in the intermetallic layers of solder joints in MEMS. Comput Mater Sci 45(3):827–831

Funding

This project is supported by the National Natural Science Foundation of China (Grant Nos. 51805316 and 51605276), Shanghai Science and Technology Development Funds (18FY1424900), and Shanghai Science and Technology Committee Innovation Grant (17JC1400600 and 17JC1400601).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission VII - Microjoining and Nanojoining

Rights and permissions

About this article

Cite this article

Chen, J., Yang, J., Zhang, Y. et al. Effect of substrates on the formation of Kirkendall voids in Sn/Cu joints. Weld World 63, 751–757 (2019). https://doi.org/10.1007/s40194-019-00704-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-019-00704-5