Abstract

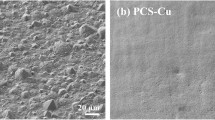

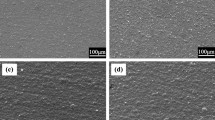

Void formation is a critical reliability concern for solder joints in electronic packaging. The control of microstructures and the quantity of impurities in Cu electroplated films significantly affect void formation at the joint interface, but studies investigating these factors are rare. In this study, three Cu films (denoted as A, B, and C) are fabricated using an electroplating process. The Cu A film has a faceted grain texture embedded with twin boundaries, while Cu B and C films have similar columnar textures. After thermal aging at 200 °C for 1000 h, the SAC 305 (Sn-3.0Ag-0.5Cu) solder joints with Cu A and B films exhibit robust interfacial structures without voids. However, microstructural collapse is observed in the solder joint of SAC 305/Cu C, where many crevices are formed parallel to the interface. Based on the microanalysis, the concentration of impurities is higher in Cu C than in Cu A and B. Moreover, discrete voids rather than continuous crevices are present in the SAC305/Cu C system when the impurity concentration in Cu C is reduced. The findings demonstrate that impurity control in Cu electroplated film is critical for the control of void/crevice formation in electronic solder joints.

Similar content being viewed by others

References

H. Lee, Y.A. Wang, C.M. Chen, Development of nanotwins in electroplated copper and its effect on shear strength of tin/copper joint. J. Alloys Compd. 765, 335–342 (2018). https://doi.org/10.1016/j.jallcom.2018.06.247

Y.-A. Shen, C. Chen, Effect of Sn grain orientation on formation of Cu6Sn5 intermetallic compounds during electromigration. Scr. Mater. 128, 6–9 (2017). https://doi.org/10.1016/j.scriptamat.2016.09.028

L. Yin, F. Wafula, N. Dimitrov, P. Borgesen, Toward a better understanding of the effect of Cu electroplating process parameters on Cu3Sn voiding. J. Electron. Mater. 41, 302–312 (2012). https://doi.org/10.1007/s11664-011-1764-0

H. Lee, T.-Y. Yu, H.-K. Cheng, K.-C. Liu, P.-F. Chan, W.-P. Dow, C.-M. Chen, Impurity incorporation in the Cu electrodeposit and its effects on the microstructural evolution of the Sn/Cu solder joints. J. Electrochem. Soc. 164, D457–D462 (2017). https://doi.org/10.1149/2.1171707jes

T.-Y. Yu, H. Lee, H.-L. Hsu, W.-P. Dow, H.-K. Cheng, K.-C. Liu, C.-M. Chen, Effects of Cu electroplating formulas on the interfacial microstructures of Sn/Cu joints. J. Electrochem. Soc. 163, D734–D741 (2016). https://doi.org/10.1149/2.0091614jes

W.L. Chiu, C.M. Liu, Y.S. Haung, C. Chen, Formation of nearly void-free Cu3Sn intermetallic joints using nanotwinned Cu metallization. Appl. Phys. Lett. 104, 171902 (2014). https://doi.org/10.1063/1.4874608

P.-F. Chan, H. Lee, S.-I. Wen, M.-C. Hung, C.-M. Chen, W.-P. Dow, Effect of copper grain size on the interfacial microstructure of a Sn/Cu joint. ACS Appl. Electron. Mater. 2, 464–472 (2020). https://doi.org/10.1021/acsaelm.9b00720

P.-C. Chiang, Y.-A. Shen, S.-P. Feng, C.-M. Chen, Electrodeposition of twinned Cu with strong texture effect on voiding propensity in electroplated Cu solder joints. J. Electrochem. Soc. 167, 162516 (2021). https://doi.org/10.1149/1945-7111/abd517

J.Y. Juang, C.L. Lu, K.J. Chen, C.C.A. Chen, P.N. Hsu, C. Chen, K.N. Tu, Copper-to-copper direct bonding on highly (111)-oriented nanotwinned copper in no-vacuum ambient. Sci. Rep. 8, 13910 (2018). https://doi.org/10.1038/s41598-018-32280-x

C.M. Liu, H.W. Lin, Y.S. Huang, Y.C. Chu, C. Chen, D.R. Lyu, K.N. Chen, K.N. Tu, Low-temperature direct copper-to-copper bonding enabled by creep on (111) surfaces of nanotwinned Cu. Sci. Rep. 5, 9734 (2015). https://doi.org/10.1038/srep09734

C.M. Liu, H.W. Lin, Y.C. Chu, C. Chen, D.R. Lyu, K.N. Chen, K.N. Tu, Low-temperature direct copper-to-copper bonding enabled by creep on highly (1 1 1)-oriented Cu surfaces. Scr. Mater. 78–79, 65–68 (2014). https://doi.org/10.1016/j.scriptamat.2014.01.040

H.-Y. Hsiao, C.-M. Liu, H. Lin, T.-C. Liu, C.-L. Lu, Y.-S. Huang, C. Chen, K.N. Tu, Unidirectional growth of microbumps on (111)-oriented and nanotwinned copper. Science 336, 1007–1010 (2012). https://doi.org/10.1126/science.1216511

Z. Zheng, P.-C. Chiang, Y.-T. Huang, W.-T. Wang, P.-C. Li, Y.-H. Tsai, C.-M. Chen, S.-P. Feng, Study of grain size effect of Cu metallization on interfacial microstructures of solder joints. Microelectron. Reliab. 99, 44–51 (2019). https://doi.org/10.1016/j.microrel.2019.05.018

Y. Liu, J. Wang, L. Yin, P. Kondos, C. Parks, P. Borgesen, D.W. Henderson, E.J. Cotts, N. Dimitrov, Influence of plating parameters and solution chemistry on the voiding propensity at electroplated copper–solder interface. J. Appl. Electrochem. 38, 1695–1705 (2008). https://doi.org/10.1007/s10800-008-9618-z

J.Y. Wu, H. Lee, C.H. Wu, C.F. Lin, W.P. Dow, C.M. Chen, Effects of electroplating additives on the interfacial reactions between Sn and Cu electroplated layers. J. Electrochem. Soc. 161, D522–D527 (2014). https://doi.org/10.1149/2.0821410jes

H. Lee, S.-T. Tsai, P.-H. Wu, W.-P. Dow, C.-M. Chen, Influence of additives on electroplated copper films and their solder joints. Mater. Charact. 147, 57–63 (2019). https://doi.org/10.1016/j.matchar.2018.10.029

Y.C. Chu, C. Chen, N. Kao, D.S. Jiang, Effect of Sn grain orientation and strain distribution in 20-μm-diameter microbumps on crack formation under thermal cycling tests. Electron. Mater. Lett. 13, 457–462 (2017). https://doi.org/10.1007/s13391-017-7041-5

S. Liu, T. Song, W. Xiong, L. Liu, Z. Liu, S. Huang, Effects of Ag on the microstructure and shear strength of rapidly solidified Sn–58Bi solder. J. Mater. Sci. Mater. Electron. 30, 6701–6707 (2019). https://doi.org/10.1007/s10854-019-00981-2

Acknowledgements

The authors acknowledge the financial support of the Ministry of Science and Technology of Taiwan through Grant No. MOST-106-2221-E-005-066-MY3. Chih-Ming Chen thanks the financial support of the “Innovation and Development Center of Sustainable Agriculture” from The Featured Areas Research Center Program within the framework of the Higher Education Sprout Project by the Ministry of Education (MOE) in Taiwan. Yu-An Shen thanks the Ministry of Science and Technology of Taiwan under Project 109-2222-E-035-008-MY2.

Funding

The funding was supported by Ministry of Science and Technology, Taiwan (Grant Nos.: MOST-106-2221-E-005-066-MY3 and MOST 109-2222-E-035 -008 -MY2) and Ministry of Education.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chiang, PC., Shen, YA. & Chen, CM. Effects of impurities on void formation at the interface between Sn-3.0Ag-0.5Cu and Cu electroplated films. J Mater Sci: Mater Electron 32, 11944–11951 (2021). https://doi.org/10.1007/s10854-021-05824-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-05824-7