Abstract

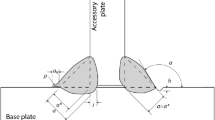

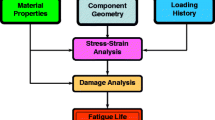

The starting point of the investigations presented in this paper is the simplified consideration of mean and residual stresses as well as the complete disregard of the complex failure mechanisms in the common fatigue standards and guidelines. An improved fatigue life assessment for welded components, which includes the crack initiation and propagation phase is the scope of this paper. The crack initiation phase is considered using the strain–life approach. The crack propagation life, starting from a technical crack of a depth of a = 0.5 mm, is derived by the application of linear–elastic fracture mechanics. In this two–phase approach, the mean and residual stresses are considered by using damage parameters for the initiation phase and effective stress intensity factors for the propagation phase. With this approach, a better understanding can be obtained of the influence of mean– and residual stresses and their influence on the course (slope k and knee point N k ) of the S–N curve. With this information to hand, a more reliable fatigue assessment can be achieved than is possible with the common standards and guidelines. With the proposed two-phase approach, higher permissible stresses can be allowed in the design phase, leading to resource-efficient, lightweight constructions.

Similar content being viewed by others

References

Hobbacher A (ed) (2009) Recommendations for fatigue design of welded joints and components. Welding Research Council, Bulletin 520

Radaj D (1996) Int J Fatigue 18(3):153–170

Zerbst U, Madia M, Eufinger J, Bruder T (2012) DVM Bericht 139: Werkstoffe und Fügeverfahren - Neue Herausforderungen für die Betriebsfestigkeit

Maddox S (1971) Procs. conf. fatigue of welded structures

Maddox S (1975) Int J Fract 11(3):389

Mohaupt U, Burns D, Kalbfleisch J, Vosikovsky O, Bell R (1987) Steel in marine structures. In: Proceedings of the 3rd international ECSC offshore conference on steel in marine structures (SIMS ’87), Delft, the Netherlands, 15–18 June . Elsevier, Amsterdam

Verreman Y, Nie B (1991) Fatigue fract Eng Mater Struct 14(2–3):337

Olivier R, Koettgen VB (1991) Schweißverbindungen II - Untersuchung zur Einbindung eines neuartigen Zeit- und Dauerschwingfestigkeitsnachweises von Schweißverbindungen aus Stahl in Regelwerke. Vorhaben Nr. 128, Heft Nr. 180. Forschungkuratorium Maschinenbau (FKM)

Hobbacher A (2008) International institute of welding JWG-XIII-XV-197-08

Lassen T, Recho N (2009) Int J Fatigue 31:70

Darcis P, Lassen T, Recho N (2006) Weld J 85(1):19

Chen N, Lawrence F (1998) Advances in Fatigue Crack Closure Measurement and Analysis: Second Volume. In: McClung R (ed). American Society for Testing and Materials ASTM, pp 351–367

Dimitrakis S, Lawrence F (1999) FCP report no. 184, improving the fatigue life of weldments with longitudinal attachments. Tech. rep., College of Engineering, University of Illinois

Chattopadhyay A, Glinka G, El-Zein M, Qian J, Formas R (2011) Weld World 55:2

Hou CY, Charng JJ (1997) Int J Fatigue 19(7):537

Hou C, Chen N, Lawrence FV (1994) FCP report no. 166, computer simulation of weldment fatigue life. Tech. rep., Collage of Engineering, University of Illinois

Lawrence F, Ho NJ, Mazumdar P (1981) Annu Rev Mater Sci 11:401

Lihavainen VM (2006) A novel approach for assessing the fatigue strength of ultrasonic impact treated welded structures. Ph.D. thesis, Lappeenranta University of Technology

Remes H (2008) Strain-based approach to fatigue strength assessment of welded joints. Ph.D. thesis, Helsiki University of Technology

Schaumann P, Keindorf C (2010) Stahlbau 79:34

Verreman Y, Nie B (1996) Fatigue Fract Eng Mater Struct 19(6):669

Peterson R (1959) Metal fatigue. McGraw-Hill, New York. Critical distance

Neuber H (1937) Kerbspannungslehre, Grundlagen für genaue Spannungsberechnung. Verlag von Julius Springer, Berlin

Seeger T (1996) Stahlbau Handbuch 1 Teil B. Stahlbau-Verlagsgesellschaft mbH Köln

Boukharouba T, Tamine T, Niu L, Chehimi C, Pluvinage G (1995) Eng Fract Mech 52(3):503

Lazzarin P, Livieri P (2001) Int J Fatigue 23:225

Lazzarin P, Berto F, Gomez F, Zappalorto M (2008) Int J Fatigue 30:1345

Schütz W (1967) Zeitschrift für Flugwissenschaft 15:407

Smith K, Watson P, Topper T (1970) J Mater 5:767

Harter J, AFGROW Users Guide And Technical Manual AFRL-VA-WP-TR-2008-XXXX. Air Force Research Lab WPAFB OH (2008)

Haibach E, Seeger T (1998) Materialwiss Werkstofftech 29:199

Sonsino CM, Bruder T, Baumgartner J (2010) Weld World 54:375

Bruder T, Störzel K, Baumgartner J, Hanselka H (2012) Int J Fatigue 34(1):86

Gurney T (1977) Residual stresses in welded constructions and their effects. In: International Conference, 15–17 November, London. The Welding Institute, Abington Hall, pp 151– 163

Ohta A, Maeda Y, Mawari T, Nishijima S, Nakamura H (1986) Int J Fatigue 8(3):147

Taylor D (1999) Int J Fatigue 21:413

Neuber H (1968) Konstruktion 20(7):245

Kuguel R (1961) 64th Annual Meeting of the Society (ASTM), pp 732–744

Sonsino CM (1995) Int J Fatigue 17(1):55

Topper T, Wetzel R, Morrow J (1967) Report no. NAEC-ASL-1114: Neuber’s rule applied to fatigue of notched specimens. Tech. rep., Aeronautical Structures Laboratory

Albrecht P, Yamada K (1977) J Struct Div 103(2):377

Glinka G, Shen G (1991) Eng Fract Mech 40(6):1135

Sonsino CM (2009) Int J Fatigue 31:88

Sonsino CM, Kaufmann H, Wagener R, Fischer C, Eufinger J (2011) Weld World 55(11–12):66

Baumgartner J, Bruder T (2013) Weld World 57:841

Varfolomeev I, Moroz S, Brand M, Siegele D, Baumgartner J IWM Bericht w 17/2011: Lebensdauerbewertung von Schweißverbindungen unter besonderer Berücksichtigung von eigenspannungen

Baumgartner J (2013) Schwingfestigkeit von Schweißverbindungen unter Berücksichtigung von Schweißeigenspannungen und Größeneinflüssen. Ph.D. thesis, Technische Universität Darmstadt

Vormwald M (2011) Materials Testing 53:98

Maddox S (1976) Welding research international 6(5)

Radaj D (1985) Gestaltung und Berechnung von Schweißkonstruktionen, Ermüdungsfestigkeit. Verlag für Schweißtechnik, DVS

Hensel J, Nitschke-Pagel T, Schönborn S, Dilger K (2012) International institute of welding XIII-2441-12

Acknowledgments

Parts of the investigations presented here were supported by financial funding from Federal Ministry of Economics and Technology BMWi over the AiF e.V. (Arbeitsgemeinschaft industrieller Forschungsvereinigungen ”Otto von Guericke” e.V.) under the grant 15.913N. Technical and scientific support during the project was given by the German Welding Society DVS (Forschungsvereinigung Schweißen und verwandte Verfahren e. V.) in the working group FA9 (Design and Assessment). The author would like to thank the AiF, the DVS, and the members of the FA9 for their support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission XIII - Fatigue of Welded Components and Structures

Rights and permissions

About this article

Cite this article

Baumgartner, J. Enhancement of the fatigue strength assessment of welded components by consideration of mean and residual stresses in the crack initiation and propagation phases. Weld World 60, 547–558 (2016). https://doi.org/10.1007/s40194-016-0304-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-016-0304-1