Abstract

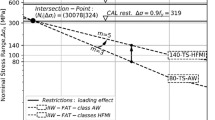

Within the structural durability evaluation of welded structures under spectrum loading, the influence of overloads on the fatigue life due to special events during service must also be considered. For this, butt welds and transverse stiffeners manufactured from the steel grades S355N/M, 690Q and 960Q were submitted to Gaussian spectra without and with superimposed overload spectra. The overloads harmed only the low-strength joints under pulsating bending. In all the other cases investigated, with low-, medium- and high-strength steels under fully reversed and pulsating loadings, a significant decrease of fatigue life was not observed; on the contrary, a significant increase of fatigue life could even be observed. This behaviour is explained by modelling the notch stresses and strains in the weld toes with the appertaining cyclic elastic-plastic material law and considering the local residual stresses. The modelling comprised also the crack propagation behaviour. Not only the fatigue life to crack initiation but also the crack propagation life is increased by the overload spectra.

Similar content being viewed by others

Abbreviations

- a :

-

Amplitude, crack depth

- c inital :

-

Surface crack length

- D :

-

Damage sum

- e :

-

Elongation

- eq :

-

Equivalent

- F :

-

Load

- f :

-

Frequency, failure

- G :

-

Gauss

- K :

-

Stress intensity

- k, k’:

-

Slope of the S-N line (curve), slope of the prolongation

- l :

-

Longitudinal

- L s , L so :

-

Sequence length, overload sequence length

- k M :

-

Mean-stress sensitivity

- M k :

-

Correction function for considering stress concentration

- m :

-

Mean, exponent of Paris-Erdogan equation

- N, N̄ :

-

Number of cycles, constant and variable amplitude loading

- N k :

-

Fatigue life at knee point

- n :

-

Nominal

- OL:

-

Overload

- P s :

-

Probability of survival

- R,R̄ :

-

Load or stress ratio, R = F min /F max or σ min /σ max for constant and variable amplitude loading

- r :

-

Rupture, radius

- T σ, T̄ σ :

-

Fatigue strength scatter between P s = 10 and 90 %, for constant and variable amplitude loading

- t, s :

-

Thickness

- Y :

-

Correction function for crack propagation

- Δ:

-

Range

- ε:

-

Strain

- σ, σ̄:

-

Stress, constant and variable amplitude loading

- σak :

-

Knee point of the S-N line

References

Sonsino C.M., Kaufmann H., Demofonti G., Riscifuli S., Sedlacek G., Müller C., Hanus F. and Wegmann, H.G.: High-strength steels in welded state for lightweight constructions under high and variable stress peaks, European Commission, EUR Report no. 19989EN, 2001, ISBN: 92-894-1588-6.

Kaufmann H., Sonsino C.M., Demofonti G. and Riscifuli S.: High-strength steels in welded state for light-weight constructions under high and variable stress peaks, Steel Research International, 2008, vol. 79, no. 5, pp. 382–389.

Hobbacher A.: IIW Recommendations for fatigue design of welded joints and components, Doc. IIW-1823, WRC Bulletin 520, Welding Research Council, Inc., New York, 2009.

Eurocode no. 3: Design of steel structures, Part 1.1: General rules and rules for buildings ENV 1993-1-1: 1992, Brussels.

Radaj D., Sonsino C.M. and Fricke W.: Fatigue assessment of welded joints by local approaches, Woodhead Publishing, Cambridge, 2006, 2nd extended Edition.

Puthli R., Herion S., Bergers J., Sedlacek G., Müller C., Störzel J., Höhler S., Bucak Ö. and Lorenz J.: Beurteilung des Ermüdungsverhaltens an Krankonstruktionen bei Einsatz hoch- und ultrhochfester Stähle, Evaluation of the fatigue behaviour of crane constructions manufactured by high- and ultrahigh-strength steels, FOSTA-Report no. P 512, Düsseldorf, 2006 (in German).

Sonsino C.M.: Fatigue testing under variable amplitude loading, International Journal of Fatigue, 2007, vol. 29, no. 6, pp. 1080–1089.

Jung L. and Zenner H.: Einfluss von Überlasten und Kollektivänderungen auf die Lebensdauer von Schweißverbindungen, Influence of overloads and change of spectrum shape on fatigue life of welded joints, Schweißen und Schneiden, 1995, vol. 47, no. 6, pp. 488–493 (in German).

Haibach E.: Betriebsfestigkeit — Verfahren und Daten zur Bauteilberechnung, Structural durability — Methods and data for component design, VDI — Verlag, Düsseldorf, 2002, 2nd Edition (in German).

Sonsino C.M.: Effect of residual stresses on the fatigue behaviour of welded joints depending on loading conditions and welded geometry, International Journal of Fatigue, 2009, vol. 31, no. 1, pp. 88–101.

Sonsino C.M.: A consideration of allowable equivalent stresses for fatigue design of welded joints according to the notch stress concept with the reference radii rref = 1.00 and 0.05 mm, Welding in the World, 2009, vol. 53, no. 3/4, pp. R64–R75.

Nitschke- Pagel Th. and Wohlfahrt H.: Einfluss von Eigenspannungen auf die Dauerschwingfestigkeit von Schweißverbindungen, Influence of residual stresses on the fatigue limit of welded joints, in: DVS-Report no. 133, 1991, pp. 101-107 (in German).

Payne J.G. and Porter-Gof, R.F.: Experimental residual stress distributions in welded tubular T-nodes, in: Proceedings of the International Conference on Fatigue and Crack Growth in Offshore Structures, London, the Institution of Mechanical Engineers, 1986, pp. 109–116.

Shijve J.: Fatigue of structures and materials, Kluwer Academic Publishers, AH Dordrecht, 2001.

Berger C., Blauer J.G., Hodulak L. and Pyttel B.: Bruchmechanischer Festigkeitsnachweis für Maschinenbauteile (FKM Richtlinie Bruchmechanik), Fracture mechanics assessment of machine components (FKM Guideline Fracture Mechanics), Forschungskuratorium für Maschinenbau (FKM), Frankfurt a. M., 2004, 2nd Edition (in German).

Koçak M., Webster S., Janosch J.J., Ainsworth R.A. and Koers R.: FITNET FITNESS-FOR-SERVICE (FFS) Procedure, Annex — Volume 2, Revision MK8, GKSS Research Centre Geesthacht, 2008.

Olivier R. and Ritter W.: Wöhlerlinienkatalog für Schweissverbindungen aus Baustählen, Catalogue of SN-Curves for welded steel joints, Part 1–4, FraunhoferInstitute for Structural Durability LBF, Darmstadt, Report no. 151, 1979–1982, ISSN 0721-5320 (in German).

Wheeler O.E.: Spectrum loading and crack growth, Transactions ASME, Journal of Basic Engineering, 1972, vol. 94, pp. 181–186.

Willenborg J., Engle R.M. and Wood H.A.: A crack growth retardation model using an effective stress concept, TM71-1-FBR, Wright-Patterson Air Force Base, Dayton, Ohio, 1971.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Sonsino, C.M., Kau Fmann, H., Wagener, R. et al. Interpretation of Overload Effects Under Spectrum Loading of Welded High-Strength Steel Joints. Weld World 55, 66–78 (2011). https://doi.org/10.1007/BF03321544

Published:

Issue Date:

DOI: https://doi.org/10.1007/BF03321544