Abstract

This paper discusses the bearing capacity and settlement response of granular columns with and without geosynthetic encasement using the currently available design procedure. The design procedure is modified to include the influence of the geosynthetic encasement. The key parameters influencing the load bearing capacity and settlement are studied through comprehensive parametric analyses. The results portray the advantage of geosynthetic encased granular columns in enhancing the bearing capacity and reducing the settlements compared to granular columns without encasement. Different installation patterns of granular columns were considered in this investigation. The maximum bearing capacity improvement and settlement reduction are observed with granular columns installed in triangular plan arrangement. The hexagonal pattern results in the lowest area replacement ratio and also the lowest improvement factors. It is shown that with geosynthetic encasement, the performance with hexagonal pattern could be improved to match with other more efficient patterns like square and triangular. Some selected results are validated through detailed finite element results. A quick assessment of the settlement improvement with geosynthetic encapsulated granular columns is possible with the design charts presented.

Similar content being viewed by others

Abbreviations

- \( a_{s} \) :

-

Area replacement ratio

- \( A_{g} \) :

-

Area of the intervening soil in the unit cell

- \( A_{\text{cell}} \) :

-

Area of the unit cell

- \( C \) :

-

Constant applied for a given granular column arrangement

- \( C_{u} \) :

-

Undisturbed undrained shear strength of the soft clay

- \( D \) :

-

Diameter of the granular column

- \( m \) :

-

Deformability ratio

- \( {\text{Mor}}\;J \) :

-

Modulus of the geosynthetic encasement

- \( K_{0} \) :

-

At-rest earth pressure coefficient in the soft clay soil

- \( S \) :

-

Spacing of the granular column at c/c

- \( q_{\text{safe}} \) :

-

Safe bearing pressure of the foundation soil

- \( Q \) :

-

Overall safe load on each column and its tributary soil

- \( \sigma_{v} \) :

-

Limiting axial stress in the column

- \( \sigma_{v*} \) :

-

Limiting axial stress in the column after geosynthetic encasement

- \( \sigma_{rL} \) :

-

Limiting radial stress

- \( \Delta \sigma_{3} \) :

-

Additional confinement offered by the geosynthetic encasement

- \( \Delta \sigma_{r0} \) :

-

Increase in mean radial stress

- \( \sigma_{v0} \) :

-

Average initial effective vertical stress

- \( \varphi_{c} \) :

-

Angle of internal friction of the granular column material

- \( \varphi_{s} \) :

-

Angle of internal friction of the foundation soil

- \( \beta \) :

-

Settlement reduction ratio

- \( \beta^{ - 1} \) :

-

Improvement factor

- \( \varepsilon_{a} \) :

-

Allowable axial strain in the geosynthetic

- OGC:

-

Ordinary granular column

- EGC:

-

Encased granular column

- PVD:

-

Prefabricated vertical drain

References

IRC: 113-2013, Guidelines for the design and construction of Geosynthetic Reinforced Embankments on Soft Subsoils. Indian Roads Congress, Highway Research Board, New Delhi, India

IRC (1995) State of the art: High embankments on soft ground—Part B Ground Improvement. Edited and Published by Secretary, IRC Highway Research Board, New Delhi, pp 25–60

Aboshi H (1979) The compozer, a method to improve characteristics of soft clays by inclusion of large diameter sand columns. In: Proceedings of 1st international conference on soil reinforcement, vol 1, pp 211–216

Afshar JN, Ghazavi M (2014) Experimental studies on bearing capacity of geosynthetic reinforced stone columns. Arab J Sci Eng 39(3):1559–1571

Barksdale RD, Bachus RC (1983) Design and construction of stone columns. Report No. FHWA/RD-83/026, Federal Highway Administration Office of Engineering and Highway Operations Research and Development, Washington

Brauns J (1978) Initial bearing capacity of stone columns and sand piles. In: International symposium on soil reinforcing and stabilizing techniques in engineering practice, vol 1, pp 497–512

Fattah MY, Al-Neami MA, Al-Suhaily AS (2017) Estimation of bearing capacity of floating group of stone columns. Eng Sci Technol Int J 20(3):1166–1172

Greenwood DA (1970) Mechanical improvement of soils below ground surface. In: Proceedings of institution of civil engineers proc, London, UK, pp 11–22

Hughes JMO, Withers NJ (1974) Reinforcing of soft cohesive soils with stone columns. Ground Eng 7(3):42–49

Malarvizhi SN, Ilamparuthi K (2004) Load versus settlement of clay bed stabilized with stone and reinforced stone columns. In: 3rd Asian regional conference on geosynthetics, pp 322–329

Shahu JT, Reddy YR (2011) Clayey soil reinforced with stone column group: model tests and analyses. ASCE J Geotech Geoenviron Eng 137(12):1265–1274

Vesic AS (1972) Expansion of cavities in infinite soil mass. J Soil Mech Found Div 98(SM3):265–290

Watts KS, Johnson D, Wood LA, Saadi A (2000) An instrumented trial of vibro ground treatment supporting strip foundations in a variable fill. Geotechnique 50(6):699–708

Baumann V, Bauer GEA (1974) The performance of foundations on various soils stabilized by the Vibro-compaction method. Can Geotech J 11(4):509–530

Priebe H (1978) Abschätzung des Scherwiderstandes eines durch Stopfverdichtung verbesserten Baugrundes. Die Bautech 55(9):281–284

Priebe HJ (1995) The design of vibro replacement. Ground Eng 28(10):31

Goughnour RR, Bayuk AA (1979) A field study of long term settlements of loads supported by stone columns in soft ground. In: Proceedings of international conference on soil reinforcement: reinforced earth and other techniques, Paris, vol 1, pp 279–286

Goughnour RR (1983) Settlement of vertically loaded stone columns in soft ground. In: Proceedings of 8th European conference on soil mechanics and foundation engineering, Helsinki, Finland, vol 1, pp 235–240

Van Impe W (1983) Improvement of settlement behaviour of soft layers by means of stone columns. In: Proceedings of the 8th European conference on soil mechanics and foundation engineering: improvement of ground, vol 1, pp 309–312

Borges JL, Domingues TS, Cardoso AS (2009) Embankments on soft soil reinforced with stone columns: numerical analysis and proposal of a new design method. Geotech Geol Eng 27(6):667–679

Hughes JMO, Withers NJ, Greenwood DA (1975) A field trial of the reinforcing effect of a stone column in soil. Geotechnique 25(1):31–44

Datye KR, Nagaraju SS (1975) Installation and testing of rammed stone columns. In: Proceedings of IGS specialty session, 5th Asian regional conference on soil mechanic and foundation engineering, Bangalore, India, pp. 101–104

Balaam NP, Booker JR (1981) Analysis of rigid rafts supported by granular piles. Int J Numer Anal Meth Geomech 5(4):379–403

Rao BG, Ranjan G (1985) Settlement analysis of skirted granular piles. ASCE J Geotech Eng 111(11):1264–1283

Rao PJ, Kumar S, Bindumadhava (1992) Experimental studies on stone columns. In: Indian Geotechnical Conference, pp 97–107

Bergado DT, Singh N, Sim SH, Panichayatum B, Sampaco CL, Balasubramaniam AS (1990) Improvement of soft Bangkok clay using vertical geotextile band drains compared with granular piles. Geotext Geomembr 9(3):203–231

Muir Wood D, Hu W, Nash DF (2000) Group effects in stone column foundations: model tests. Geotechnique 50(6):689–698

Sivakumar V, McKelvey D, Graham J, Hughes D (2004) Triaxial tests on model sand columns in clay. Can Geotech J 41(2):299–312

Black J, Sivakumar V, Madhav MR, McCabe B (2006) An improved experimental test set-up to study the performance of granular columns. Geotech Test J 29(3):193–199

Ambily AP, Gandhi SR (2007) Behavior of stone columns based on experimental and FEM analysis. ASCE J Geotech Geoenviron Eng 133(4):405–415

Najjar SS, Sadek S, Maakaroun T (2010) Effect of sand columns on the undrained load response of soft clays. ASCE J Geotech Geoenviron Eng 136(9):1263–1277

Fattah MY, Shlash KT, Al-Waily MJ (2013) Experimental evaluation of stress concentration ratio of model stone columns strengthened by additives. Int J Phys Model Geotech 13(3):79–98

Noor Muneerah PG, Haji Jeludin DK, Sivakumar V, O’Kelly BC, Mackinnon PA (2015) Experimental observations of settlement of footings supported on soft clay reinforced with granular columns: laboratory model study. ASCE J Geotech Geoenviron Eng 142(1):04015063

Gupta P, Sharma JK (2018) Settlement analysis of non-homogeneous single granular pile. Indian Geotech J 48(1):92–101

Indian Standard, I.S., 15284 2003. Design and construction for ground improvement—Guidelines. Part 1: Stone columns. Bureau of Indian Standards, New Delhi, India

Chummar AV (2000) Ground improvement using stone columns: problems encountered. In: An international conference on geotechnical and geological engineering, GeoEng2000, Melbourne, Australia

McKenna JM, Eyre WA, Wolstenholme DR (1975) Performance of an embankment supported by stone columns in soft ground. Geotechnique 25(1):51–59

Van Impe W, Silence P (1986) Improving of the bearing capacity of weak hydraulic fills by means of geotextiles. In: International conference on geotextiles, pp 1411–1416

Alexiew D, Sobolewski J, Pohlmann H (2000) Projects and optimized engineering with geogrids from “ non-usual” polymers. In: Proceedings of the 2nd European geosynthetics conference, Bologna, pp 239–244

Murugesan S, Rajagopal K (2006) Geosynthetic-encased stone columns: numerical evaluation. Geotext Geomembr 24(6):349–358

Murugesan S, Rajagopal K (2009) Studies on the behavior of single and group of geosynthetic encased stone columns. ASCE J Geotech Geoenviron Eng 136(1):129–139

Yoo C (2010) Performance of geosynthetic-encased stone columns in embankment construction: numerical investigation. J Geotech Geoenviron Eng 136(8):1148–1160

Pulko B, Majes B, Logar J (2011) Geosynthetic-encased stone columns: analytical calculation model. Geotext Geomembr 29(1):29–39

Raithel M, Kempfert HG (1999) Bemessung von geokunststoffummantelten Sandsäulen. Bautechnik 76(11):983–991

Almeida MSS, Hosseinpour I, Riccio M (2013) Performance of a geosynthetic-encased column (GEC) in soft ground: numerical and analytical studies. Geosynth Int 20(4):252–262

Almeida MS, Hosseinpour I, Riccio M, Alexiew D (2015) Behavior of geotextile-encased granular columns supporting test embankment on soft deposit. J Geotech Geoenviron Eng 141(3):04014116

Ali K, Shahu JT, Sharma KG (2012) Model tests on geosynthetic-reinforced stone columns: a comparative study. Geosynth Int 19(4):292–305

Alkhorshid NR, Araújo GLS, Palmeira EM (2018) Behavior of geosynthetic-encased stone columns in soft clay: numerical and analytical evaluations. Soils Rocks 41(3):333–343

Khabbazian M, Kaliakin VN, Meehan CL (2015) Column supported embankments with geosynthetic encased columns: validity of the unit cell concept. Geotech Geol Eng 33(3):425–442

Hosseinpour I, Riccio M, Almeida MS (2019) Field measured poisson’s ratio of geotextile-encased granular column. In: Proceedings of the Institution of Civil Engineers-Ground Improvement, London, UK, pp 1–7

Hosseinpour I, Soriano C, Almeida MS (2019) A comparative study for the performance of encased granular columns. J Rock Mech Geotech Eng 11(2):379–388

Alexiew D, Raithel M (2015) Geotextile Encased Columns (GEC): case studies over twenty years. In: Indraratna B, Jian C, Rujikiatkamjorn C (eds) Ground improvement case histories: embankments with special reference to consolidation and other physical methods. Elsevier, Amsterdam, Netherlands

Raithel M, Kempfert HG (2000) Calculation models for dam foundations with geotextile coated sand columns. In: ISRM International Symposium. International Society for Rock Mechanics and Rock Engineering

Zhang L, Zhao M (2014) Deformation analysis of geotextile-encased stone columns. ASCE Int J Geomech 15(3):1–10

IS 8009-2 (1980) Indian Standard – Code of practice for calculation of settlement of foundations. In: Part 2 Deep foundations subjected to symmetrical static vertical loading. Bureau of Indian Standards, New Delhi, India

Henkel DJ, Gilbert GD (1952) The effect measured of the rubber membrane on the triaxial compression strength of clay samples. Geotechnique 3(1):20–29

Miranda M, Da Costa A, Castro J, Sagaseta C (2017) Influence of geotextile encasement on the behaviour of stone columns: laboratory study. Geotext Geomembr 45(1):14–22

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Section A: Design of OGCs as per IS 15284 Part 1 (2003) [35]

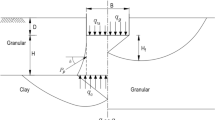

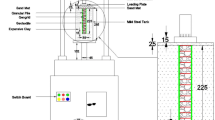

Detailed calculations for estimating the bearing capacity and settlement reduction factors are given in this section. The foundation soil is assumed to be 10 m thick having an undrained cohesive strength of 5 kPa. The Ko of the soil was assumed to be 0.50. The granular columns are assumed to be of 600 mm diameter and aggregate having friction angle of 36°. The columns are assumed to be provided at a c/c spacing of 1.2 m in triangular pattern. The geosynthetic is assumed to have tensile modulus of 500 kN/m at 5% strain. The settlement is assumed to be limited to 5% of soil thickness. The saturated unit weight of soil is assumed to be 20 kN/m3, and the water table is at ground level.

Step-1 Capacity Based on Bulging of the Ordinary Granular column

Initial effective radial stress \( \sigma_{r0} \) = \( K_{0} \sigma_{v0} \) = 0.5 \( \times \) 10 \( \times \) 2 \( \times 0.6 = 6 \;{\text{kPa}} \)

Limiting radial stress \( \sigma_{rL} \) = \( \left( {\sigma_{r0} + 4C_{u} } \right) \) = \( \left( {6 + 4 \times 5} \right) = 26 \;{\text{kPa}} \)

The limiting axial stress in the column \( \sigma_{v} = \sigma_{rL} \times K_{{p_{\text{col}} }} = 26 \times 3.85 = 100.14 \;{\text{kPa}} \)

Safe load on the stone column Q1 (with factor of safety of 2) \( = \frac{{\left( {\sigma_{v} \frac{\pi }{4} D^{2} } \right)}}{2} = \frac{{\left( {100.14 \times 0.7854 \times 0.6^{2} } \right)}}{2} = 14.16 \;{\text{kN}} \)

Step-2 Capacity Based on Surcharge Effect

The safe bearing pressure of the soil with a factor of safety of 2.5, \( q_{\text{safe}} = C_{u} N_{c} /2.5 \)

The increase in mean radial stress due to surcharge

The increase in the safe load of the stone column Q2 \( = \left( {\frac{{Kp_{\text{col}} \Delta \sigma_{r0} A_{s} }}{2}} \right) = \left( {\frac{3.85 \times 6.85 \times 0.283}{2}} \right) = 3.73 \;{\text{kN}}. \)

Step-3 Capacity Based on Bearing Support Provided by the Intervening Soil

Effective area of unit cell area for triangular pattern = \( 0.866\;{\text{S}}^{2} \).

Area of the intervening soil \( A_{g} = 0.866\;{\text{S}}^{2} - \frac{{\pi D^{2} }}{4} = 0.866\left( {2 \times 0.6} \right)^{2} - 0.283 = 0.964 \;{\text{m}}^{2} \).

Safe load taken by the intervening soil Q3 = \( q_{\text{safe}} A_{g} = 10.28 \times 0.964 = 9.91 \;{\text{kN}} \) for triangular pattern.

Overall safe load on each unit cell = \( \left( {Q_{1} + Q_{2} + Q_{3} } \right) = 27.80 \).

Section B: Modification to IS 15284 Part 1 (2003) [35]

The additional confinement \( \Delta \sigma_{3} \) offered by the geosynthetic encasement is quantified by the equation proposed by Henkel and Gilbert [56].

.

This additional confinement is summed up with the modified limiting radial stress \( \sigma_{rL*} = \left( {\sigma_{r0} + 4C_{u} + \Delta \sigma_{3} } \right) = 6 + 20 + 44.42 = 70.42 \;{\text{kPa}} \).

The modified limiting axial stress in the column \( \sigma_{v*} = \sigma_{rL*} \times K_{{p_{\text{col}} }} = 70.42 \times 3.85 = 271.1 \;{\text{kPa}}. \)

Now, the safe load on the geosynthetic encased stone column Q1* (with factor of safety of 2) \( = \frac{{\left( {\sigma_{v*} \frac{\pi }{4} D^{2} } \right)}}{2} = \frac{{\left( {271.1 \times 0.7854 \times 0.6^{2} } \right)}}{2} = 38.33 \;{\text{kN}} \).

Overall safe load that can be applied on each unit cell area = \( \left( {Q_{1*} + Q_{2} + Q_{3} } \right) = 51.97\;{\text{kN}} \).

Section C: Settlement of the Soft Clay Treated with OGC and EGC based on IS 15284 Part 1 (2003) [35]

The settlement of the granular column-treated ground is estimated using the stress concentration ratio (n) and the area replacement ratio as. The stress concentration ratio is obtained as per the equation indicated below,

The stress concentration ratio for OGC,

Similarly, stress concentration factor for \( {\text{EGC }} = \left( {\frac{{\left( {272.1 + \left( {6.85 \times 3.85} \right)} \right)/2.5}}{10.28}} \right) = \, 11.57 \)

Area replacement ratio = 0.7854 × 0.62/(0.866 × 1.22) = 0.227.

Then the settlement reduction ratio is computed from the calculated stress concentration ratio (n) and area replacement ratio (as) as per [32].

For EGC, \( \beta = \frac{{S_{t} }}{S} = \frac{1}{{1 + \left( {n - 1} \right)a_{s} }} = \frac{1}{{1 + \left( {11.57 - 1} \right)0.227}} = 0.29 \),

The settlement of the treated soil is 53% of the total settlement of the untreated soil in the case of OGC and 29% in the case of EGC.

The corresponding improvement factors (1/\( \beta \)) as per (42) are 1.89 and 3.45, respectively, for OGC and EGC.

Rights and permissions

About this article

Cite this article

Jayarajan, J., Karpurapu, R. Bearing Capacity and Settlement Response of Ordinary and Geosynthetic Encased Granular Columns in Soft Clay Soils: Analysis and Design Charts. Indian Geotech J 51, 237–253 (2021). https://doi.org/10.1007/s40098-020-00457-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40098-020-00457-9