Abstract

Synthesis of metal nanoparticles from the metal salts by reduction with plant extracts in water, without any additional stabilizing or capping agents is a green and eco-friendly method. In the present work, aqueous extract of the bark of Terminalia arjuna was utilized to synthesize T. arjuna-conjugated palladium nanoparticles (TA-PdNPs) from palladium chloride. The dark brown colour indicating the formation of TA-PdNPs appeared within 3 h without heating but, on heating colour appeared almost instantly. The synthesized TA-PdNPs are characterized by UV spectroscopy, HRTEM and XRD studies. The TA-PdNPs were utilized as efficient catalyst for Heck and Suzuki type C–C coupling reactions and degradation of organic dyes in aqueous medium at room temperature.

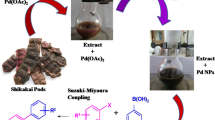

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Metal nanoparticles have drawn a great attention of scientific community due to a combination of their shape and size dependent unique properties like chemical, physical, theromodynamic, optical, electronic etc. and these have found increasing applications in pharmacology, bio-diagnostics, medicine, drug-delivery, catalysis, coatings, solar cells, purification of water, etc. [1,2,3,4,5,6,7,8,9]. Palladium nanoparticles are highly interesting than other transition metal nanoparticles for their usefulness in both homogeneous as well as heterogeneous catalysis due to their high surface-to-volume ratio and high surface energy. Use of palladium nanoparticles as a catalyst for various C–C coupling reactions such Suzuki and Heck coupling reactions has been highly exploited in organic synthesis [10,11,12,13,14,15]. Palladium nanoparticles have also been used as a catalyst in hydrogenation of alkenes, alkynes, allyl and benzyl alcohols and hydrogenolysis of allylic and benzylic ethers [16,17,18]. However, the examples of the utilization of phytochemical-conjugated PdNPs in C–C coupling reactions and degradation of dyes are rare [19,20,21].

Water pollution has been a great concern in modern civilization due to contamination of natural water mainly by human activities. For example, use of different colouring textile dyes which are toxic in nature pollute water through drainage [22]. So detoxification or transformation of these dyes into a non dangerous substance is a challenge. Palladium nanoparticles can be utilized for the reductive degradation of dyes [23]. Several methods have been developed and modified to synthesize metal nanoparticles. But, use of toxic chemicals in those methods, limits their application. Use of non-toxic bio molecules to synthesize Pd nanoparticles without using hazardous chemicals under mild reaction conditions is a greener and environment-friendly method [24,25,26,27,28,29]. Among the various methods reported for the synthesis of the palladium nanoparticles, a bottom-up synthetic strategy by the plant extract-mediated reductive method, involving reduction of Pd(II) to Pd(0) by phytochemicals, has gained profound significance in recent years due to the renewable and non-toxic nature of the phytochemicals, mild reaction condition, eco-friendly aqueous medium etc. The advantage of this method is that, additional stabilizers are not required to synthesize PdNPs which is important to sustain active surface of PdNPs and prevent generation of less active black palladium [30] and here the plant extract itself acts as a stabilizer. The leaf extracts of Chrysophyllum cainito [31], xanthan gum [32], Glycine max leaf [33], Cinnamomum camphora leaf [34], Hippophae rhamnoides Linn leaf [9] have been utilized for synthesis of PdNPS. Terminalia arjuna is a well known medicinal plant and its stem bark is rich in various plant secondary metabolites such as terpenoids, flavonoids including polyphenols, steroids and glycosides [35,36,37,38,39,40,41,42,43]. Herein, we report the synthesis PdNPs using the bark extract of T. arjuna. The polyphenols acted as reducing and stabilizing agents for the synthesis of T. arjuna-conjugated PdNPs (TA-PdNPs). Characterization of TA-PdNPs was carried out by Surface Plasmon resonance (SPR) spectroscopy, High-resolution transmission electron microscopy (HRTEM) and X-Ray diffraction studies. The synthesized TA-PdNPs were utilized as an excellent catalyst for C–C coupling reactions (Suzuki and Heck coupling without phosphine) and reductive degradation of dyes (methylene blue and rhodamine-B) in aqueous medium.

Experimental

Materials and instruments

Details of materials used and instruments required to characterize TA-PdNPs are discussed in supporting information.

Preparation of Terminalia arjuna bark extract

Dried T. arjuna bark (30 g) was powdered and boiled with 200 mL of distilled water for 15 min and then filtered through Whatman 1 filter paper. The concentration of the extract was 6000 mg L−1, as determined by evaporation of 1 mL of the extract that contained 6 mg of the dried extract.

Synthesis of palladium nanoparticles

Palladium nanoparticles (TA-PdNPs) were synthesized by heating the mixture of palladium chloride solution (0.4 mL, 5.019 mM) and the bark extract of T. arjuna at 60–70 °C for 2 min. Then the reaction mixture was kept at room temperature for 1 h. We have prepared a series of TA-PdNPs containing different concentration of the bark extract of T. arjuna ranging from 200 to 1600 mg L−1. Palladium chloride solution (0.4 mL, 5.019 mM each) was added to each vial and the final volume was made up to 2 mL thereby keeping the concentration PdNPs fixed (1.004 mM).

C–C coupling reactions

Suzuki and Heck coupling reactions were carried out by following a procedure reported by us previously [31].

Dye degradation

Catalytic efficiency of stabilized TA-PdNPs towards reductive degradation of dyes was investigated by reduction of two chemical dyes methylene blue (MB) and rhodamine-B (Rh-B) with sodium borohydride (16.5 mM). The reduction reaction was monitored by UV spectroscopy.

Results and discussion

Characterization of TA-PdNPs

UV studies

We synthesized palladium nanoparticles (TA-PdNPs) using T. arjuna bark extract and palladium chloride (0.4 mL, 5.019 mM). UV–visible spectroscopic study was carried out to confirm the synthesis of TA-PdNPs. The aqueous palladium chloride solution (1.00 mM) showed absorption band at 234 nm, arises due to charge transfer between chloride ion to Pd (II) [44]. On addition of palladium chloride solution to T. arjuna bark extract, a characteristic continuous surface plasmon resonance (SPR) band in the UV–visible region was also observed indicating the formation of TA-PdNPs (Fig. 1). At first, the intensity of SPR band increased up to 400 mg L−1 concentration of the bark extract and no further increase in the intensity of the SPR band was observed with increasing concentration of the bark extract. These observations indicated that, with gradual increase in concentration of the bark extract, formation of TA-PdNPs increased and at 400 mg L−1 concentration of the bark extract, formation of TA-PdNPs was complete. This is probably due to the fact that the total phytochemicals present in the bark extract were sufficient to reduce and stabilize all the Pd(II) ions present in the palladium chloride solution (1.004 mM, 2 mL) [45].

UV–Visible spectra of: a bark extract of T. arjuna, b aqueous PdCl2, c–g colloidal TA-PdNPs synthesized with 200, 400, 800, 1200, 1600 mg L−1 concentrations of T. arjuna bark extract, respectively. Inset: photograph of the vials containing plant extract, Pd (II) solution and colloidal PdNPs stabilized by 200, 400, 800, 1200, 1600 mg L−1 concentrations of T. arjuna bark extract (after 22 h of mixing, from left to right)

HRTEM studies

HRTEM analysis of TA-PdNPs synthesized with the bark extract concentration of 800 mg L−1 was carried out to study its morphology. Most of the of TA-PdNPs particles were spherical-shaped having 4–16 nm size along with a few other types of shapes like hexagonal, triangular etc. (Fig. 2a, b). The average size of the nanoparticles was 8.94 nm (Fig. 2c) as determined from the diameter of 74 TA-PdNPs. The particles were highly stable because no precipitation was observed even on standing the colloids at room temperature for several weeks. The HRTEM images showed that particles were of discrete entities and did not agglomerate on standing. This observation also indicated the high stability of TA-PdNPs. Elemental analysis by Energy Dispersive X-ray (EDX) of TA-PdNPs confirmed the presence of Pd metal along with carbon and oxygen atoms (Fig. 2e) that indicated the presence of organic molecules from the bark extract. The semi-transparent regions observed in the HRTEM images also indicated the presence of phytochemicals. The recorded SAED pattern showed Debye–Scherrer rings which are representation of planes of Pd-crystal (Fig. 2d). The crystallinity of TA-PdNPs was also supported by XRD studies (discussed below).

XRD studies

Powdered x-ray diffraction studies of synthesized TA-PdNPs were carried out by coating the colloidal samples on a glass slide and then allowing the removal of the volatiles initially in air and then under reduced pressure. The characteristic reflections at 2θ = 40.2°, 46.3°, 67.9° and 81.6° for 111, 200, 220 and 311 planes confirmed the crystalinity of TA-PdNPs (Fig. 3). These values agreed with reported fcc crystalline palladium, JCPDS file No. 05-0681 [46, 47]. The additional peaks also observed at 2θ = 51.5°, 58.2°, 66° and 70.2° by X-ray diffraction studies might be due to the phytochemicals present in the TA-PdNPs [48].

Mechanism of the formation of TA-PdNPs

The bark of T. arjuna is rich in polyphenolic compounds [35]. Taking a o-dihydroxyphenolic compound as a representative, a schematic representation of a plausible mechanism for the synthesis and stabilization of TA-PdNPs is shown in Fig. 4. Pd(II) ions can form chelate complex with the polyphenolic compounds present in the bark extract of T. arjuna. A five-membered chelate ring is formed by the adjacent hydroxyl groups of the polyphenolic compounds. The chelated ortho-dihydroxy groups are then oxidized to quinones with concomitant reduction of Pd(II) to Pd(0) because of the very high oxidation–reduction potential of Pd(II). Collision of Pd(0) atoms leads to the formation of PdNPs and the synthesized PdNPs are stabilized by polyphenolic compounds as well as the quinones.

Applications

C–C coupling reactions

We have carried out two C–C coupling reactions viz., ‘Suzuki’ and ‘Heck’ reactions to investigate the efficiency of synthesized TA-PdNPs as a catalyst.

-

(a)

Suzuki Reaction

Suzuki reaction was carried out using iodobenzene (0.5 mmol), phenylboronic acid (0.77 mmol) and K2CO3 (1 mmol) as a base in the presence of TA-PdNPs (0.079 mol % with respect to iodobenzene) as catalyst in water at 100 °C (Fig. 5a). The reaction was complete after 9 h and the isolated yield of purified product was 99.3%. The catalytic turn over number (TON) and the turn over frequency (TOF) for Suzuki reaction were calculated to be 1241 and 138 h−1, respectively.

-

(b)

Heck Reaction

Heck reaction was performed using iodobenzene (1 mmol), methyl acrylate (1.5 mmol), Et3N as base and TA-PdNPs (0.11 mol % with respect to iodobenzene) as catalyst in 1:1 DMF–water mixture at 90 °C (Fig. 5b). The reaction was complete in 5 h and the yield of the purified product was 95.5%. The catalytic turn over number (TON) and the turn over frequency (TOF) for Heck reaction were calculated to be 996 and 190 h−1, respectively.

Dye degradation

To test whether the colloidal TA-PdNPs can be utilized as a catalyst for the degradation of toxic pollutants, we chose the sodium borohydride reduction of two toxic chemical dyes methylene blue (MB) and rhodamine-B (Rh-B) as model reactions.

-

(a)

Reduction of methylene blue dye

On treatment of an aqueous solution of methylene blue (0.5 mM) with sodium borohydride (16.5 mM), the position of the absorption band at 663 nm did not change and only a minute decrease in intensity of this band was observed with time (Fig S5a). This was due to very slow rate of reduction the dye because of for large kinetic energy barrier for the reduction reaction. But after addition of colloidal TA-PdNPs (0.1 mL) synthesized from bark extract of T. arjuna (800 mg L−1) to reaction mixture, the colour of dye as well as absorption band at 663 nm disappeared within fraction of second due to the formation of leuco methylene blue [49]. For the calculation of rate constant we tried to slow down the rate of reaction by diluting the colloidal TA-PdNPs by ten times (100 μL of colloidal TA-PdNPs diluted to 1 mL in distilled water) and on addition of this diluted TA-PdNPs (0.1 mL) to reaction mixture, the colour of dye also disappeared within a few seconds. Then again the colloidal TA-PdNPs was diluted to 100 times and the reaction completed in 9 min (Fig. 6) on addition of 0.075 mL diluted TA-PdNPs to reaction mixture. Similarly, on addition of 0.05 mL of 100 times diluted TA-PdNPs to reaction mixture the absorption band at 663 nm decreases slowly and completely disappear in 15 min (Fig. S6). For these reduction reactions the calculated rate constants were 0.141 min−1 and 0.139 min−1 (Fig. S8c and S8d), respectively, which are consistent with previous reports [50]. The catalytic turn over number (TON) and the turn over frequency (TOF) for the degradation of methylene blue were calculated to be 133 and 14.8 min−1, respectively.

-

(b)

Reduction of Rhodamine-B dye

On treatment of an aqueous solution of rhodamine-B (0.5 mM) with sodium borohydride (16.5 mM) at room temperature, the absorption band at 553 nm did not change its position. A very slow decrease in intensity of the absorption band was observed with time due to slow reduction of rhodamine-B with sodium borohydride (Fig S5b). But when colloidal TA-PdNPs (0.1 mL) synthesized from bark extract of T. arjuna (800 mg L−1) was added to reaction mixture the absorption band at 553 nm as well as the pink colour disappeared in fraction of a second due to the formation of colourless leuco rhodamine-B [51]. Hence, for calculating rate constant we tried to slow down the rate of the reaction by diluting the stabilized TA-PdNPs. By addition of 0.1 mL of both 10 times as well as 100-times diluted TA-PdNPs to reaction mixture the colour of reaction mixture disappeared within few seconds and rate could not be calculated. So the stabilized TA-PdNPs were further diluted. After 500 times dilution of TA-PdNPs, the reaction was completed in 9 min by addition of 0.1 mL of diluted TA-PdNPs (Fig. 7). Similarly, on addition of 0.05 mL of 500-times diluted TA-PdNPs to reaction mixture the absorption band at 553 nm decreases slowly and completely disappear in 54 min (Fig. S7). For these reduction reactions the calculated rate constants were 0.52 min−1 and 0.062 min−1 (Fig. S8a and S8b), respectively, which are also consistent with previous reports [52]. The catalytic turn over number (TON) and the turn over frequency (TOF) for the degradation of rhodamine-B were calculated to be 500 and 55 min−1, respectively.

Conclusions

Terminalia arjuna-conjugated PdNPs (TA-PdNPs) were synthesized using the non-toxic bark extract of T. arjuna and PdCl2 solution having average diameter of PdNPs of 8.9 nm. The small-sized aqueous colloidal TA-PdNPs were utilized as an efficient catalyst for the Suzuki and Heck type C–C coupling reaction under phosphine-free conditions in excellent yields making it useful in synthetic organic chemistry. Excellent catalytic activity of TA-PdNPs towards reductive degradation of dyes such as methylene blue and rhodamine-B in the presence of sodium borohydride has also been demonstrated in aqueous medium making it useful for the removal of toxic industrial pollutants.

References

Colomban, P.: The use of metal nanoparticles to produce yellow, red and iridescent colour, from bronze age to present times in lustre pottery and glass: solid state chemistry spectroscopy and nanostructure. J. Nano Res. 8, 109–132 (2009)

Becheri, A., Dürr, M., Nostro, P.L., Baglioni, P.: Synthesis and characterization of zinc oxide nanoparticles: application to textiles as UV-absorbers. J. Nanoparticle Res. 10, 679–689 (2008)

Mokkapati, S., Beck, F.J., Polman, A., Catchpole, K.R.: Designing periodic arrays of metal nanoparticles for light-trapping applications in solar cells. Appl. Phys. Lett. 95, 053115 (2009)

Yetisen, A.K., Qu, H., Manbachi, A., Butt, H., Dokmeci, M.R., Hinestroza, J.P., Skorobogatiy, M., Khademhosseini, A., Yun, S.H.: Nanotechnology in textiles. ACS Nano 10, 3042–3068 (2016)

Chng, L.L., Erathodiyl, N., Ying, J.: Nanostructured catalysts for organic transformations. Acc. Chem. Res. 46, 1825–1837 (2013)

Wunder, S., Lu, Y., Albrecht, M., Ballauff, M.: Catalytic activity of faceted gold nanoparticles studied by a model reaction: evidence for substrate-induced surface restructuring. ACS Catal. 1, 908–916 (2011)

Kelly, K.L., Coronado, E., Zhao, L.L., Schatz, G.C.: The optical properties of metal nanoparticles: the influence of size, shape, and dielectric environment. J. Phys. Chem. B. 107, 668–677 (2003)

Jain, P.K., Huang, X., El-Sayed, I.H., El-Sayed, M.A.: Noble metals on the nanoscale: optical and photothermal properties and some applications in imaging, sensing, biology, and medicine. Acc. Chem. Res. 41, 1578–1586 (2008)

Nasrollahzadeh, M., Sajadi, S.M., Maham, M.: Green synthesis of palladium nanoparticles using Hippophae rhamnoides Linn leaf extract and their catalytic activity for the Suzuki-Miyaura coupling in water. J. Mol. Catal. A Chem. 396, 297–303 (2015)

Mastalira, A., Kiralyb, Z., Patzkob, A., Dekanyb, I., Argentierec, P.L.: Synthesis and catalytic application of Pd nanoparticles in graphite oxide. Carbon 46, 1631–1637 (2008)

Zhang, J., Bai, X.: Microwave-assisted synthesis of Pd nanoparticles and their catalysis application for Suzuki cross-coupling reactions. Inorg. Nano Metal Chem. 47, 672–676 (2017)

Khazaei, A., Rahmati, S., Hekmatian, Z., Saeednia, S.: A green approach for the synthesis of palladium nanoparticles supported on pectin: application as a catalyst for solvent-free Mizoroki-Heck reaction. J. Mol. Catal. A Chem. 372, 160–166 (2013)

Bej, A., Ghosh, K., Sarkar, A., Knight, D.W.: Palladium nanoparticles in the catalysis of coupling reactions. RSC Adv. 6, 11446–11453 (2016)

Calò, V., Nacci, A., Monopoli, A., Cotugno, P.: Heck reactions with palladium nanoparticles in ionic liquids: coupling of aryl chlorides with deactivated olefins. Angew. Chem. Int. Ed. 48, 6101–6103 (2009)

Mandali, P.K., Chand, D.K.: Palladium nanoparticles catalyzed sonogashira reactions for the one-pot synthesis of symmetrical and unsymmetrical diarylacetylenes. Catal. Commun. 47, 40–44 (2014)

Wilson, O.M., Knecht, M.R., Garcia-Martinez, J.C., Crooks, R.M.: Effect of Pd nanoparticle size on the catalytic hydrogenation of allyl alcohol. J. Am. Chem. Soc. 128, 4510–4511 (2006)

Carsten, B., He, F., Son, H.J., Xu, T., Yu, L.: Stille polycondensation for synthesis of functional materials. Chem. Rev. 111, 1493–1528 (2011)

Shaik, M.R., Ali, Z.J.Q., Khan, M., Kuniyil, M., Assal, M.E., Alkhathlan, H.Z., Al-Warthan, A., Siddiqui, M.R.H., Khan, M., Adil, S.F.: Green synthesis and characterization of palladium nanoparticles using Origanum vulgare L. extract and their catalytic activity. Molecules 22, 165 (2017)

Majumdar, R., Tantayanon, S., Bag, B.G.: A Novel trihybrid material based on renewables: an efficient recyclable heterogeneous catalyst for C–C coupling and reduction reactions. Chem. Asian J. 11, 2406–2414 (2016)

Lakshmipathy, R., Reddy, B.P., Sarada, N.C., Chidambaram, K., Pasha, S.K.: Watermelon rind-mediated green synthesis of noble palladium nanoparticles: catalytic application. Appl. Nanosci. 5, 223–228 (2015)

Hazarika, M., Borah, D., Bora, P., Silva, A.R., Das, P.: Biogenic synthesis of palladium nanoparticles and their applications as catalyst and antimicrobial agent. Plos One (2017). https://doi.org/10.1371/journal.pone.0184936

Padhi, B.S.: Pollution due to synthetic dyes toxicity & carcinogenicity studies and remediation. IARAS 3, 940–955 (2012)

Banazadeh, A., Salimi, H., Khaleghi, M., Shafiei-Haghighi, S.: Highly efficient degradation of hazardous dyes in aqueous phase by supported palladium nanocatalyst—a green approach. J. Environ. Chem. Eng. 4, 2178–2186 (2016)

Anastas, P.T., Kirchhoff, M.M.: Origins, current status, and future challenges of green chemistry. Acc. Chem. Res. 35, 686–694 (2002)

Iravani, S.: Green synthesis of metal nanoparticles using plants. Green Chem. 13, 2638–2650 (2011)

Thakkar, K.N., Mhatre, S.S., Parikh, R.Y.: Biological synthesis of metallic nanoparticles. Nanomedicine 6, 257–262 (2010)

Verma, R.S.: Journey on greener pathways: from the use of alternate energy inputs and benign reaction media to sustainable applications of nano-catalysts in synthesis and environmental remediation. Green Chem. 16, 2027–2041 (2014)

Huang, X., Wu, H., Liao, X., Shi, B.: One-step, size-controlled synthesis of gold nanoparticles at room temperature using plant tannin. Green Chem. 12, 395–399 (2010)

Majumdar, R., Bag, B.G., Maity, N.: Acacia nilotica (Babool) leaf extract mediated size-controlled rapid synthesis of gold nanoparticles and study of its catalytic activity. Int. Nano Lett. 3, 53 (2013)

Balanta, A., Godard, C., Claver, C.: Pd nanoparticles for C–C coupling reactions. Chem. Soc. Rev. 40, 4973–4985 (2011)

Majumdar, R., Tantayanon, S., Bag, B.G.: Synthesis of palladium nanoparticles with leaf extract of Chrysophyllum cainito (Star apple) and their applications. Int. Nano Lett. 7, 267–274 (2017)

Kumari, A.S., Venkatesham, M., Ayodhya, D., Veerabhadram, G.: Green synthesis, characterization and catalytic activity of palladium nanoparticles by xanthan gum. Appl. Nanosci. 5, 315–320 (2015)

Petla, R.K., Vivekanandhan, S., Misra, M., Mohanty, A.K., Satyanarayana, N.: Soybean (glycine max) leaf extract based green synthesis of palladium nanoparticles. J. Biomater. Nanobiotechnol. 3, 14–19 (2012)

Yang, X., Li, Q., Wang, H., Huang, J., Lin, L., Wang, W., Sun, D., Su, Y., James Opiyo, B., Hong, L., Wang, Y., He, N., Jia, L.: Green synthesis of palladium nanoparticles using broth of Cinnamomum camphora leaf. J. Nanoparticle Res. 12, 589–1598 (2010)

Amalraj, A., Gopi, S.: Medicinal properties of Terminalia arjuna (Roxb.) Wight & Arn.: a review. J. Tradit. Complement. Med. 7, 65–78 (2017)

Chitte, R.R., Nagare, S.L., Date, P.K., Shinde, B.P.: Detection of phytoconstituents of medicinal plant Terminalia arjuna using chromatographic techniques. J. Chromatogr. 8, 4 (2017)

Viswanatha, G.L.S., Vaidya, S.K., Ramesh, C., Krishnadas, N., Rangappa, S.: Antioxidant and antimutagenic activities of bark extract of Terminalia arjuna. Asian Pac. J. Trop. Med. 3, 965–970 (2010)

Mandal, S., Patra, A., Samanta, A., Roy, S., Mandal, A., Das Mahapatra, T., Pradhan, S., Das, K., Nandi, D.K.: Analysis of phytochemical profile of Terminalia arjuna bark extract with antioxidative and antimicrobial properties. Asian Pac. J. Trop. Biomed. 3, 960–966 (2013)

Kaur, S.J., Grover, I.S., Kumar, S.: Modulatory effects of a tannin fraction isolated from Terminalia arjuna on the genotoxicity of mutagens in Salmonella typhimurium. Food Chem. Toxicol. 38, 1113 (2000)

Ahmad, M.S., Ahmad, S., Gautam, B., Arshad, M., Afzal, M.: Terminalia arjuna, a herbal remedy against environmental carcinogenicity: an in vitro and in vivostudy. Egypt. J. Med. Hum. Genet. 15, 61–67 (2014)

Momin, H.A.M., Satardekar, K.: Evaluation of phytochemicals, antioxidant and antiinflammatory screening of Terminalia arjuna. Ijppr. Hum. 8, 242–251 (2017)

Thomson, H.A.J., Ojo, O.O., Flatt, P.R., Abdel-Wahab, Y.H.A.: Aqueous bark extracts of Terminalia arjuna stimulates insulin release, enhances insulin action and inhibits starch digestion and protein glycation in vitro. Austin J. Endocrinol. Diabetes 1, 1001 (2014)

Shengule, S., Mishra, S., Bdhale, S.: Inhibitory effect of a standardized hydro ethanolic extract of Terminalia arjuna bark on alpha-amylase enzyme. Asian J. Pharm. Clin. Res. 11, 366–369 (2018)

Bel’skaya, O.B., Gulyaeva, T.I., Arbuzov, A.B., Duplyakin, V.K., Likholobov, V.A.: Interaction between Pt(IV) and Pd(II) chloro complexes in solution and on the γ-Al2O3 surface. Kinet. Catal. 51, 105–112 (2010)

Kora, A.J., Rastogi, L.: Green synthesis of palladium nanoparticles using gum ghatti (Anogeissus latifolia) and its application as an antioxidant and catalyst. Arab. J. Chem. (2015). https://doi.org/10.1016/j.arabjc.2015.06.02

Xiong, Y., McLellan, J.M., Yin, Y., Xia, Y.: Synthesis of palladium icosahedra with twinned structure by blocking oxidative etching with citric acid or citrate ions. Angew. Chem. Int. Ed. 46, 790–794 (2007)

Demir, M.M., Gulgun, M.A., Menceloglu, Y.Z., Erman, B., Abramchuk, S.S., Makhaeva, E.E., Khokhlov, A.R., Matveeva, V.G., Sulman, M.G.: Palladium nanoparticles by electrospinning from poly(acrylonitrile-co-acrylic acid) –PdCl2 solutions. Relation between preparation conditions, particle size and catalytic activity. Macromolecules 37, 1787–1792 (2004)

Rout, Y., Behera, S., Ojha, A.K., Nayak, P.L.: Green synthesis of silver nanoparticles using Ocimum sanctum (Tulashi) and study of their antibacterial and antifungal activities. J. Microbiol. Antimicrob. 4, 103–109 (2012)

Saikia, P., Miah, A.T., Das, P.P.: Highly efficient catalytic reductive degradation of various organic dyes by Au/CeO2-TiO2 nano-hybrid. J. Chem. Sci. 129, 81–93 (2017)

Li, S., Li, H., Liu, J., Zhang, H., Yang, Y., Yang, Z., Wanga, L., Wang, B.: Highly efficient degradation of organic dyes by palladium nanoparticles decorated on 2D magnetic reduced graphene oxide nanosheets. Dalton Trans. 44, 9193–9199 (2015)

Collins, A.M., Zhang, X., Scragg, J.J., Blanchard, G.J., Marken, F.: Triple phase boundary photovoltammetry: resolving rhodamine B reactivity in 4-(3-phenylpropyl)-pyridine microdroplets. ChemPhysChem 11, 2862–2870 (2010)

Hemmati, S., Mehrazin, L., Ghorban, H., Garakani, S.H., Mobaraki, T.H., Mohammadia, P., Veisi, H.: Green synthesis of Pd nanoparticles supported on reduced graphene oxide, using the extract of Rosa canina fruit, and their use as recyclable and heterogeneous nanocatalysts for the degradation of dye pollutants in water. RSC Adv. 8, 21020–21028 (2018)

Acknowledgements

CG thanks UGC for providing Faculty Development Programme (FDP). SNH, ACB and SKP thank UGC, New Delhi and SG thanks CSIR, New Delhi for research fellowships. BGB thanks India-Srilanka project (DST/INT/SL/P25/2016), SERB, India (EMR/2016/001123), UGC-MRPMAJOR-CHEM-2013-35629, UGC-SAP DRS II and DST-FIST New Delhi and Vidyasagar University for financial support and infrastructural facilities.

Funding

This study was funded by a Grant of the SERB, India (EMR/2016/001123), India–Srilanka project (DST/INT/SL/P25/2016), New Delhi.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Garai, C., Hasan, S.N., Barai, A.C. et al. Green synthesis of Terminalia arjuna-conjugated palladium nanoparticles (TA-PdNPs) and its catalytic applications. J Nanostruct Chem 8, 465–472 (2018). https://doi.org/10.1007/s40097-018-0288-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40097-018-0288-z