Abstract

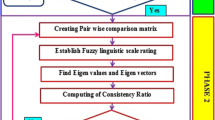

Nanosheet-based catalysts were used as additives in engine fuels to enhance the engine performance characteristics. In this research, graphene oxide nanosheets (GON) were used as a catalyst to Aegle marmelos (AM) bio-oil/diesel opus at 20 and 30 gm/l. The operating characteristics of a direct injection diesel engine powered by GON fuel blends were compared with A20 and diesel (B0). All test fuel blends (A20, A20G20 and A20G30) have been analyzed for the mutual effects of varying engine load (W) and compression ratio (CR) in test engine via experimental investigation and fuzzy prediction approach. With the augmentation of GON concentration in the blend, reduction in hydrocarbon (HC), carbon monoxide (CO), and soot emissions is observed along with increased oxides of nitrogen (NOx) and carbon dioxide (CO2) emission. The engine performance was also enhanced with augmenting in GON addition with fuel blends. Engine parameters were precisely predicted by the fuzzy model (trapezoidal mf, Mamdani FIS and centroid-weighted average). The developed fuzzy model predicted the engine operating attributes with a greater coefficient of determination (R2 = 0.91) and correlation coefficients (R = 0.95). The fuzzy validation outcomes endorse the adaptability of the developed model with better accuracy and depict that AM bio-oil nanoadditive opus is a good alternative for diesel in transportation fleets.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

Abbreviations

- AM:

-

Aegle marmelos

- A20:

-

20% AM bio-oil + 80% B0

- A20G20:

-

20% AM bio-oil + 80% B0 + GON 20 mg/l

- A20G30:

-

20% AM bio-oil + 80% B0 + GON 30 mg/l

- ASTM:

-

American Society for Testing and Materials

- BSFC:

-

Break specific fuel consumption (kg/kW hr)

- BTE:

-

Break thermal efficiency (%)

- CeO2 :

-

Cerium oxide

- CI:

-

Compression ignition

- CO:

-

Carbon monoxide (%)

- CO2 :

-

Carbon dioxide (%)

- CNT:

-

Carbon nanotube

- CR:

-

Compression ratio

- CV:

-

Calorific value

- B0:

-

Diesel

- FB:

-

Fuel blend

- FIS:

-

Fuzzy inference system

- GO:

-

Graphene oxide

- GON:

-

Graphene oxide nanosheet

- HC:

-

Hydrocarbons (ppm)

- IC:

-

Internal combustion

- mf:

-

Membership function

- MgO:

-

Magnesium oxide

- NOx:

-

Nitrogen oxide (ppm)

- O2 :

-

Oxygen

- ppm:

-

Parts per million

- R:

-

Correlation coefficient

- R2 :

-

Coefficient of determination

- TiO2 :

-

Titanium oxide

- VCR:

-

Variable compression ratio

- W:

-

Engine load

References

Shaafi, T., Sairam, K., Gopinath, A., Kumaresan, G., Velraj, R.: Effect of dispersion of various nanoadditives on the performance and emission characteristics of a CI engine fuelled with diesel, biodiesel and blends—a review. Renew. Sustain. Energy Rev. 49, 563–573 (2015)

Ramakrishnan, P., Kasimani, R., Peer, M.S., Rajamohan, S.: Assessment of n-pentanol/Calophyllum inophyllum/diesel blends on the performance, emission, and combustion characteristics of a constant-speed variable compression ratio direct injection diesel engine. Environ. Sci. Pollut. Res. 25(14), 13731–13744 (2018)

Venugopal, P., Kasimani, R., Chinnasamy, S.: Prediction and optimization of CI engine performance fuelled with Calophyllum inophyllum diesel blend using response surface methodology (RSM). Environ. Sci. Pollut. Res. 25(25), 24829–24844 (2018)

Razmara, M., Bidarvatan, M., Shahbakhti, M., Robinett, R., III.: Optimal exergy-based control of internal combustion engines. Appl. Energy 183, 1389–1403 (2016)

Paramasivam, B., Kasimani, R., Rajamohan, S.: Characterization of pyrolysis bio-oil derived from intermediate pyrolysis of Aegle marmelos de-oiled cake: study on performance and emission characteristics of CI engine fueled with Aegle marmelos pyrolysis oil-blends. Environ. Sci. Pollut. Res. 25(33), 33806–33819 (2018)

Praveen, A., Rao, G.L.N., Balakrishna, B.: Performance and emission characteristics of a diesel engine using Calophyllum inophyllum biodiesel blends with TiO2 nanoadditives and EGR. Egypt. J. Pet. 27(4), 731–738 (2018)

Sakthivel, G., Sivaraja, C., Ikua, B.W.: Prediction OF CI engine performance, emission and combustion parameters using fish oil as a biodiesel by fuzzy-GA. Energy 166, 287–306 (2019)

Sharma, A., Murugan, S.: Effect of blending waste tyre derived fuel on oxidation stability of biodiesel and performance and emission studies of a diesel engine. Appl. Therm. Eng. 118, 365–374 (2017)

Rajamohan, S., Kasimani, R.: Analytical characterization of products obtained from slow pyrolysis of Calophyllum inophyllum seed cake: study on performance and emission characteristics of direct injection diesel engine fuelled with bio-oil blends. Environ. Sci. Pollut. Res. 25(10), 9523–9538 (2018)

Alagu, R., Sundaram, E.G.: Preparation and characterization of pyrolytic oil through pyrolysis of neem seed and study of performance, combustion and emission characteristics in CI engine. J. Energy Inst. 91(1), 100–109 (2018)

Kalargaris, I., Tian, G., Gu, S.: Combustion, performance and emission analysis of a DI diesel engine using plastic pyrolysis oil. Fuel Process. Technol. 157, 108–115 (2017)

Sekhar, S.C., Karuppasamy, K., Sathiyamoorthy, K.: The impact of various nano additives blended with diesel and biodiesel on DI diesel engine performance, combustion and emission parameters-a mini-review. Asian Journal of Research in Social Sciences and Humanities 7(2), 483–496 (2017)

Suganthi, L., Iniyan, S., Samuel, A.A.: Applications of fuzzy logic in renewable energy systems–a review. Renew. Sustain. Energy Rev. 48, 585–607 (2015)

Krishnamoorthi, M., Malayalamurthi, R.: Availability analysis, performance, combustion and emission behavior of bael oil-diesel-diethyl ether blends in a variable compression ratio diesel engine. Renewable Energy 119, 235–252 (2018)

Kumaravel, S., Murugesan, A., Vijayakumar, C., Thenmozhi, M.: Enhancing the fuel properties of tyre oil diesel blends by doping nano additives for green environments. J. Clean. Product. 240, 118128 (2019)

Halim, S.A., Swithenbank, J.: Characterisation of Malaysian wood pellets and rubberwood using slow pyrolysis and microwave technology. J. Anal. Appl. Pyrol. 122, 64–75 (2016)

Pradhan, D., Bendu, H., Singh, R., Murugan, S.: Mahua seed pyrolysis oil blends as an alternative fuel for light-duty diesel engines. Energy 118, 600–612 (2017)

Suriapparao, D.V., Pradeep, N., Vinu, R.: Bio-oil production from Prosopis juliflora via microwave pyrolysis. Energy Fuels 29(4), 2571–2581 (2015)

Oliveira, T., Cardoso, C., Ataide, C.: Fast pyrolysis of soybean hulls: analysis of bio-oil produced in a fluidized bed reactor and of vapor obtained in analytical pyrolysis. J. Therm. Anal. Calorim. 120(1), 427–438 (2015)

Sogancioglu, M., Yel, E., Ahmetli, G.: Pyrolysis of waste high density polyethylene (HDPE) and low density polyethylene (LDPE) plastics and production of epoxy composites with their pyrolysis chars. J. Clean. Prod. 165, 369–381 (2017)

Lam, S.S., Liew, R.K., Cheng, C.K., Rasit, N., Ooi, C.K., Ma, N.L., Ng, J.-H., Lam, W.H., Chong, C.T., Chase, H.A.: Pyrolysis production of fruit peel biochar for potential use in treatment of palm oil mill effluent. J. Environ. Manage. 213, 400–408 (2018)

Paramasivam, B., Kasimani, R., Rajamohan, S.: Experimental assessment and multi-response optimization of diesel engine performance and emission characteristics fuelled with Aegle marmelos seed cake pyrolysis oil-diesel blends using Grey relational analysis coupled principal component analysis. Environ. Sci. Pollut. Res. 26(7), 6980–7004 (2019)

Jeyakumar, N., Narayanasamy, B., John, K., Kathiresh, Markus Solomon, J.: Preparation, characterization and effect of calcium carbonate and titanium dioxide nano additives on fuel properties of tire oil diesel blend. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects 40(15), 1798–1806 (2018)

Vinukumar, K., Azhagurajan, A., Vettivel, S., Vedaraman, N., Lenin, A.H.: Biodiesel with nano additives from coconut shell for decreasing emissions in diesel engines. Fuel 222, 180–184 (2018)

Chaichan, M.T., Kadhum, A.A.H., Al-Amiery, A.A.: Novel technique for enhancement of diesel fuel: Impact of aqueous alumina nano-fluid on engine’s performance and emissions. Case studies in thermal engineering 10, 611–620 (2017)

Tamilvanan, A., Balamurugan, K., Vijayakumar, M.: Effects of nano-copper additive on performance, combustion and emission characteristics of Calophyllum inophyllum biodiesel in CI engine. J. Therm. Anal. Calorim. 136(1), 317–330 (2019)

Patel, H.K., Kumar, S.: Experimental analysis on performance of diesel engine using mixture of diesel and bio-diesel as a working fuel with aluminum oxide nanoparticle additive. Therm. Sci. Eng Progr. 4, 252–258 (2017)

Bhowmik, S., Panua, R., Ghosh, S.K., Paul, A., Debroy, D.: Prediction of performance and exhaust emissions of diesel engine fuelled with adulterated diesel: An artificial neural network assisted fuzzy-based topology optimization. Energy Environ. 29(8), 1413–1437 (2018)

Quesada, L., Pérez, A., Godoy, V., Peula, F., Calero, M., Blázquez, G.: Optimization of the pyrolysis process of a plastic waste to obtain a liquid fuel using different mathematical models. Energy Convers. Manage. 188, 19–26 (2019)

Sharma, S.K., Das, R., Sharma, A.: Improvement in the performance and emission characteristics of diesel engine fueled with jatropha methyl ester and tyre pyrolysis oil by addition of nano additives. J. Braz. Soc. Mech. Sci. Eng. 38(7), 1907–1920 (2016)

Sachuthananthan, B., Krupakaran, R., Balaji, G.: Exploration on the behaviour pattern of a DI diesel engine using magnesium oxide nano additive with plastic pyrolysis oil as alternate fuel. Int. J. Ambient Energy 42(6), 701–712 (2019)

Baranitharan, P., Ramesh, K., Sakthivel, R.: Multi-attribute decision-making approach for Aegle marmelos pyrolysis process using TOPSIS and Grey Relational Analysis: Assessment of engine emissions through novel Infrared thermography. J. Clean. Prod. 234, 315–328 (2019)

Kavimani, V., Prakash, K.S., Thankachan, T.: Surface characterization and specific wear rate prediction of r-GO/AZ31 composite under dry sliding wear condition. Surf. Interfaces 6, 143–153 (2017)

Kavimani, V., Prakash, K.S.: Tribological behaviour predictions of r-GO reinforced Mg composite using ANN coupled Taguchi approach. J. Phys. Chem. Solids 110, 409–419 (2017)

Sudhagar, S., Sakthivel, M., Mathew, P.J., Daniel, S.A.A.: A multi criteria decision making approach for process improvement in friction stir welding of aluminium alloy. Measurement 108, 1–8 (2017)

Latha, B., Senthilkumar, V.: Analysis of thrust force in drilling glass fiber-reinforced plastic composites using fuzzy logic. Mater. Manuf. Processes 24(4), 509–516 (2009)

Lerkkasemsan, N., Achenie, L.E.: Pyrolysis of biomass–fuzzy modeling. Renew. Energy 66, 747–758 (2014)

Lerkkasemsan, N.: Fuzzy logic-based predictive model for biomass pyrolysis. Appl. Energy 185, 1019–1030 (2017)

Sakthivel, R., Ramesh, K., Purnachandran, R., Shameer, P.M.: A review on the properties, performance and emission aspects of the third generation biodiesels. Renew. Sustain. Energy Rev. 82, 2970–2992 (2018)

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

P.Baranitharan considered the research concept, designed the research methodology and wrote the original draft of this manuscript. S. Kumanan, V. Kavimani and M.Varatharajulu contributed to providing supervision of this manuscript's draft.

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Appendices

Appendix

Rule No. IF–THEN rules

-

1.

If (EngineLoad is LOW) and (CompressionRatio is LOW) and (FuelBlend is LOW) then (BSFC is HIGH)(BTE is LOW)(CO is HIGH)(HC is HIGH)(CO2 is LOW)(NOx is LOW)(Smoke is HIGH)

-

2.

If (EngineLoad is LOW) and (CompressionRatio is LOW) and (FuelBlend is MEDIUM) then (BSFC is HIGH)(BTE is LOW)(CO is HIGH)(HC is HIGH)(CO2 is LOW)(NOx is LOW)(Smoke is HIGH)

-

3.

If (EngineLoad is LOW) and (CompressionRatio is LOW) and (FuelBlend is HIGH) then (BSFC is HIGH)(BTE is LOW)(CO is HIGH)(HC is HIGH)(CO2 is LOW)(NOx is LOW)(Smoke is MEDIUM)

-

4.

If (EngineLoad is LOW) and (CompressionRatio is MEDIUM) and (FuelBlend is LOW) then (BSFC is HIGH)(BTE is LOW)(CO is HIGH)(HC is HIGH)(CO2 is LOW)(NOx is LOW)(Smoke is HIGH)

-

5.

If (EngineLoad is LOW) and (CompressionRatio is MEDIUM) and (FuelBlend is MEDIUM) then (BSFC is HIGH)(BTE is LOW)(CO is HIGH)(HC is HIGH)(CO2 is LOW)(NOx is LOW)(Smoke is HIGH)

-

6.

If (EngineLoad is LOW) and (CompressionRatio is MEDIUM) and (FuelBlend is HIGH) then (BSFC is HIGH)(BTE is LOW)(CO is MEDIUM)(HC is MEDIUM)(CO2 is LOW)(NOx is LOW)(Smoke is MEDIUM)

-

7.

If (EngineLoad is LOW) and (CompressionRatio is HIGH) and (FuelBlend is LOW) then (BSFC is HIGH)(BTE is LOW)(CO is MEDIUM)(HC is HIGH)(CO2 is LOW)(NOx is LOW)(Smoke is HIGH)

-

8.

If (EngineLoad is LOW) and (CompressionRatio is HIGH) and (FuelBlend is MEDIUM) then (BSFC is HIGH)(BTE is LOW)(CO is LOW)(HC is HIGH)(CO2 is MEDIUM)(NOx is LOW)(Smoke is MEDIUM)

-

9.

If (EngineLoad is LOW) and (CompressionRatio is HIGH) and (FuelBlend is HIGH) then (BSFC is MEDIUM)(BTE is LOW)(CO is LOW)(HC is MEDIUM)(CO2 is MEDIUM)(NOx is LOW)(Smoke is LOW)

-

10.

If (EngineLoad is MEDIUM) and (CompressionRatio is LOW) and (FuelBlend is LOW) then (BSFC is MEDIUM)(BTE is MEDIUM)(CO is HIGH)(HC is HIGH)(CO2 is MEDIUM)(NOx is MEDIUM)(Smoke is HIGH)

-

11.

If (EngineLoad is MEDIUM) and (CompressionRatio is LOW) and (FuelBlend is MEDIUM) then (BSFC is MEDIUM)(BTE is MEDIUM)(CO is MEDIUM)(HC is HIGH)(CO2 is MEDIUM)(NOx is MEDIUM)(Smoke is MEDIUM)

-

12.

If (EngineLoad is MEDIUM) and (CompressionRatio is LOW) and (FuelBlend is HIGH) then (BSFC is MEDIUM)(BTE is MEDIUM)(CO is MEDIUM)(HC is MEDIUM)(CO2 is MEDIUM)(NOx is MEDIUM)(Smoke is MEDIUM)

-

13.

If (EngineLoad is MEDIUM) and (CompressionRatio is MEDIUM) and (FuelBlend is LOW) then (BSFC is MEDIUM)(BTE is MEDIUM)(CO is MEDIUM)(HC is HIGH)(CO2 is MEDIUM)(NOx is MEDIUM)(Smoke is HIGH)

-

14.

If (EngineLoad is MEDIUM) and (CompressionRatio is MEDIUM) and (FuelBlend is MEDIUM) then (BSFC is MEDIUM)(BTE is MEDIUM)(CO is MEDIUM)(HC is HIGH)(CO2 is MEDIUM)(NOx is MEDIUM)(Smoke is MEDIUM)

-

15.

If (EngineLoad is MEDIUM) and (CompressionRatio is MEDIUM) and (FuelBlend is HIGH) then (BSFC is LOW)(BTE is MEDIUM)(CO is LOW)(HC is MEDIUM)(CO2 is MEDIUM)(NOx is MEDIUM)(Smoke is LOW)

-

16.

If (EngineLoad is MEDIUM) and (CompressionRatio is HIGH) and (FuelBlend is LOW) then (BSFC is MEDIUM)(BTE is MEDIUM)(CO is LOW)(HC is MEDIUM)(CO2 is MEDIUM)(NOx is HIGH)(Smoke is MEDIUM)

-

17.

If (EngineLoad is MEDIUM) and (CompressionRatio is HIGH) and (FuelBlend is MEDIUM) then (BSFC is MEDIUM)(BTE is MEDIUM)(CO is LOW)(HC is LOW)(CO2 is MEDIUM)(NOx is HIGH)(Smoke is MEDIUM)

-

18.

If (EngineLoad is MEDIUM) and (CompressionRatio is HIGH) and (FuelBlend is HIGH) then (BSFC is LOW)(BTE is MEDIUM)(CO is LOW)(HC is LOW)(CO2 is MEDIUM)(NOx is HIGH)(Smoke is LOW)

-

19.

If (EngineLoad is HIGH) and (CompressionRatio is LOW) and (FuelBlend is LOW) then (BSFC is LOW)(BTE is HIGH)(CO is MEDIUM)(HC is HIGH)(CO2 is MEDIUM)(NOx is HIGH)(Smoke is HIGH)

-

20.

If (EngineLoad is HIGH) and (CompressionRatio is LOW) and (FuelBlend is MEDIUM) then (BSFC is LOW)(BTE is HIGH)(CO is MEDIUM)(HC is MEDIUM)(CO2 is HIGH)(NOx is HIGH)(Smoke is MEDIUM)

-

21.

If (EngineLoad is HIGH) and (CompressionRatio is LOW) and (FuelBlend is HIGH) then (BSFC is LOW)(BTE is HIGH)(CO is LOW)(HC is MEDIUM)(CO2 is HIGH)(NOx is HIGH)(Smoke is LOW)

-

22.

If (EngineLoad is HIGH) and (CompressionRatio is MEDIUM) and (FuelBlend is LOW) then (BSFC is LOW)(BTE is HIGH)(CO is LOW)(HC is HIGH)(CO2 is HIGH)(NOx is HIGH)(Smoke is MEDIUM)

-

23.

If (EngineLoad is HIGH) and (CompressionRatio is MEDIUM) and (FuelBlend is MEDIUM) then (BSFC is LOW)(BTE is HIGH)(CO is LOW)(HC is MEDIUM)(CO2 is HIGH)(NOx is HIGH)(Smoke is MEDIUM)

-

24.

If (EngineLoad is HIGH) and (CompressionRatio is MEDIUM) and (FuelBlend is HIGH) then (BSFC is LOW)(BTE is HIGH)(CO is LOW)(HC is LOW)(CO2 is HIGH)(NOx is HIGH)(Smoke is LOW)

-

25.

If (EngineLoad is HIGH) and (CompressionRatio is HIGH) and (FuelBlend is LOW) then (BSFC is LOW)(BTE is HIGH)(CO is LOW)(HC is LOW)(CO2 is HIGH)(NOx is HIGH)(Smoke is LOW)

-

26.

If (EngineLoad is HIGH) and (CompressionRatio is HIGH) and (FuelBlend is MEDIUM) then (BSFC is LOW)(BTE is HIGH)(CO is LOW)(HC is LOW)(CO2 is HIGH)(NOx is HIGH)(Smoke is LOW)

-

27.

If (EngineLoad is HIGH) and (CompressionRatio is HIGH) and (FuelBlend is HIGH) then (BSFC is LOW)(BTE is HIGH)(CO is LOW)(HC is LOW)(CO2 is HIGH)(NOx is HIGH)(Smoke is LOW)

Rights and permissions

About this article

Cite this article

Paramasivam, B., Kumanan, S., Kavimani, V. et al. Fuzzy-based prediction of compression ignition engine distinctiveness powered by novel graphene oxide nanosheet additive diesel–Aegle marmelos pyrolysis oil ternary opus. Int J Energy Environ Eng 13, 683–701 (2022). https://doi.org/10.1007/s40095-021-00458-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40095-021-00458-1