Abstract

We propose a solar cell design using the combination of titanium dioxide (TiO2) and graphite as active photon absorbing materials. TiO2 absorbs photons of nearly ultraviolet wavelengths to produce electron–hole pairs, while graphite is expected to absorb photons of longer wavelengths. Although many authors have claimed that graphite is a semimetal, we observed that a model of a solar cell containing TiO2 only as the active material behaves exactly the same as a model containing graphite only as the active material. Additionally, we observed that a model of a solar cell made using a composite of TiO2 and graphite as the active material had much higher efficiency than solar cells made using TiO2- or graphite-only active materials. Although the highest efficiency we report here is approximately 1 %, our proposed solar cell structure is promising for mass application, especially in low-income settings, owing to its easy and flexible fabrication, and easy large-scale application.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In recent years, many attempts have been made to produce solar cells using cheaper materials, and easily applied and readily scalable methods, because the manufacturing process consists of only a few simple steps: spraying of TiO2 suspension on the TCO’s surface, electroplating of metallic bridges, adhesion of polymer electrolyte, and fixing a counter electrode [1–5]. Although the efficiency of our solar cells does not match the efficiency of presently applied solar cells, our solar cells might compete with presently applied solar cells economically, especially when considering factors such as production and maintenance costs and efficiency.

Although the application of TiO2 in solar cells is not new, the principle and implementation of its application in presently applied solar cells and in our proposed model greatly differ. The commonly used structure is a dye-sensitized solar cell [6], with TiO2 used as a conductive medium for the transport of electrons from the dye to the electrode. In the proposed structure, TiO2 particles play the role of a photon absorber and the produced electrons are transported to the electrode through metallic bridges.

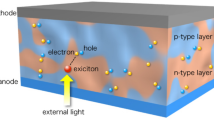

We used TiO2 as an active material that absorbs photons and converts them into electric current. This material has a band gap around 3.2–3.8 eV, allowing the effective absorption of ultraviolet light. Only a few electron–hole pairs are produced when the material is illuminated by the solar spectrum. To enlarge the absorption band of TiO2, the doping of pure TiO2 with V, Cr, Mn, Fe, Ni, or Au [7, 8] and Pt, Rh, Au, Pd, Ni, or Ir [9] has been reported. The cited studies claim that the band gap of TiO2 is reduced by doping, resulting in an increase in visible-spectrum absorption and, thus, higher solar cell performance. Instead of doping pure TiO2, we have tried using impure (low-grade) TiO2, which is found in nature [10]. Previously, we have demonstrated that impure TiO2 has a wider absorption spectrum [1–4, 9] than pure TiO2 and have applied the material in developing solar cells [1–5].

In addition to the absorption band, the lifetime of electron–hole pairs produced in the TiO2 must be considered because it directly determines the photon-to-current conversion. The lifetime of an electron–hole pair in TiO2 is very short and potentially limits the efficiency of photon-to-current conversion. The electron and hole in anatase TiO2 undergo non-exponential decay, where the whole population decays within in a few nanoseconds and the electron population persists for periods up to microseconds [11].

In previous works we deposited copper particles in the space between TiO2 particles to suppress electron–hole recombination and observed greatly improved efficiency [1–5]. The formation of metal (Cu) and semiconductor (TiO2) produces a high Schottky barrier that facilitates electron capture by the metal. Vorontsov reported that Pt-TiO2 has the highest Schottky barrier and a longer electron–hole separation time [12, 13]. Similarly, the Cu-TiO2 contact in the present work might lengthen the lifetime of electron–hole pair separation and allow enough time for electrons to migrate into the metal and transport through the copper bridge. Hoffmann et al. stated that although the electron–hole pair lifetime is only a few nanoseconds, it is long enough for electrons to migrate to the TiO2 surface and then be captured by the metal [14].

The conduction band and valence band of TiO2 are produced by different orbitals. The valence band is developed by the d-orbital while the conduction band is developed by the s-p hybridized orbital [15]. This leads to different parity of the electron and hole pair, which suppresses the recombination probability.

In the present work, we propose a method of further improving the efficiency of TiO2-based solar cells by adding particles capable of absorbing visible light. A mixture containing such particles and TiO2 particles is expected to absorb more photons, with wavelengths approximately ranging from the ultraviolet to the red region. Previous investigations aimed to devise a strategy for improving solar cell efficiency using materials with different absorption bands. Kim et al. added a low-band-gap material to a main absorbing material to improve the efficiency of a plastic-based solar cell [16]. Peet et al. developed a tandem solar cell by combining the functions of low- and high-band-gap materials to widen the absorption range and observed improved efficiency [17]. The important difference between the previous method and the method reported here is the use of a cheap material and simple processing.

In the present work, we mix graphite particles with TiO2 particles. The use of graphite as a conducting and catalytic counter electrode for dye-sensitized solar cells has improved efficiency [18]. However, to our knowledge, the use of graphite as a photon-absorbing material in a solar cell has not been investigated. Graphite is a semimetal with a valence and conduction band that overlap by around 0.03 eV [19, 20].

Method

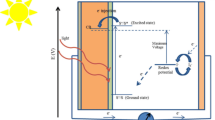

The structure of the solar cell reported here is schematically shown in Fig. 1. The solar cell is composed of fluorine-doped tin oxide (FTO) as a transparent electrode, photon-absorbing particles, a polymer electrolyte and a counter electrode. We trialed three composites as photon absorbing particles: TiO2 only, graphite only, and a mixture of graphite and TiO2. We also deposited a copper bridge in the space between particles to facilitate electron transport [1–5].

First, we made suspensions of TiO2 only, graphite only, and TiO2/graphite mixtures with different weight ratios in distilled water. The powders were homogeneously stirred in distilled water for 1 h. The homogeneous suspension was then sprayed (30 times) onto the FTO surface, and heated at 200 °C to produce a thick film. The film was then heated at temperatures of 100, 200, and 300 °C for 20 min to evaporate water and to create better contact between the film and FTO surface.

We deposited copper in the space between particles by electroplating. Electroplating was conducted in a bath containing electrolyte liquid. The temperature of the bath was 55 °C. The electrolyte liquid was made by dissolving 14.999 g of CuSO4 into 120 ml of distilled water. A copper rod (99.99 % purity) was used as an anode, and the composite film as a cathode. The deposition time was controlled to be 10 s, the voltage was 5 V DC, and the separation of the anode and cathode was 2 cm.

A polymer electrolyte was made by dissolving 0.18 g LiOH (Kanto, Japan) in a beaker containing 10 ml distilled water and by dissolving 1.8 g polyvinyl alcohol (PVA) (Bratachem, Indonesia) in another beaker containing 20 ml distilled water. Each beaker was then stirred for 1 h. Subsequently, the LiOH solution was mixed with the PVA solution and stirred for 3 h at 100 °C to produce a gel-like electrolyte. The electrolyte was smeared manually on the film surface. Aluminum, used as a counter electrode, was then affixed to the opposite side of the electrolyte using a clamper on both sides of the cell. The thickness of overall solar cell structure is around 3 mm, including FTO and aluminium counter electrode, and the cross section area is 1 cm2.

The morphology was observed using a scanning electron microscope (SEM) (JEOL JSM-6360LA, operated at 20 kV). A current–voltage (IV) meter (Keithley 617) was used to measure the performance of the solar cell. The measurements were made under illumination. The measurements were set up under XENOPHOT 64653 HLX ELC 24 V, 250 W GX5.3 OSRAM lamp illumination with light intensity of 900 lumens (45 W/m2) and the light intensity was measured using a lux meter.

Results and discussion

We first analyzed the I–V behavior of solar cells containing TiO2 only, graphite only, and a mixture of TiO2/graphite as the photon-absorbing material as shown in Fig. 2. All samples contained deposited Cu as an electron bridge to the FTO electrode. It is interesting to observe that the I–V behavior of the solar cell containing graphite as the active material was similar to that of the solar cell containing TiO2 as the active material. The efficiency of the solar cell containing TiO2 was only 0.03 % while that of the solar cell containing graphite was a much higher 0.12 %. A further increase in efficiency was achieved with a mixture of TiO2 and graphite as the active material. Using a weight ratio of 8 % of graphite relative to TiO2, efficiency of 0.27 % was achieved as displayed in Fig. 2.

Current–voltage characteristics of solar cells containing an active layer of TiO2 only (triangle), graphite only (circle) and a mixture of TiO2/graphite (square) with a graphite/TiO2 ratio of 8 %w/w. The fill factors and efficiencies of the solar cells are 0.33 and 0.03 %, 0.29 and 0.12 %, and 0.26 and 0.27 % for cells containing TiO2 only, graphite only, and a mixture of TiO2/graphite, respectively

It is clear that the mixture of TiO2 and graphite achieved higher efficiency. However, the maximum observed efficiency of 0.27 % remains low. Achieving a much higher efficiency remains a challenge. To this end, we investigated the deposition of multiple absorbing layers. Our basic assumption was that some of the radiation penetrating the solar cell was not converted into electricity. Thickening the active layer may maximize the photon absorption and thus improve the efficiency of conversion. We used an active layer of the TiO2/graphite mixture with a weight ratio (graphite/TiO2) of 8 %w/w. We deposited one, two, and three layers. Nair et al. confirmed the effects of film thickness on the structural, optical, and luminescence properties of TiO2 prepared by radio frequency magnetron sputtering [21]. We expect that the film thickness also affects the efficiency of the solar cell.

Figure 3 clearly shows that, compared with the case for one layer, two active layers provide higher efficiency at 1.09 %, with a fill factor of 0.28. One active layer is unable to absorb all photons, with some of the light penetrating the cells not being used to generate current. The realized efficiency was thus only 0.35 %. Using two layers maximizes photon absorption and achieves a greater light-to-current conversion (efficiency). Further increasing the number of layers reduces the efficiency; the efficiency was only 0.29 % for three layers. It is likely that the third layer did not receive any photons, with all photons being absorbed by the first and second layers. The creation of electrons and holes thus occurs optimally in the first and second layers.

Effect of the number of active layers on the current–voltage characteristic of the solar cells: (circle) one layer, (square) two layers, and (triangle) three layers. An active layer is composed of TiO2 and graphite with Cu particles deposited in the space between TiO2 and graphite particles. The measurement was made under a xenon lamp with illumination intensity of 37.38 W/m2

The number of electrons produced by the solar cell is nearly the same for two layers and for more than two active layers. However, the use of more than two layers adds more space for electrons to spread out and some move away from the electrode. This electron will have enough time to recombine again with a hole and does not take part in the generation of current. Consequently, the efficiency of the solar cell is reduced.

In this experiment we have used the illumination intensity of 37.38 W/m2 to determine the efficiency of the solar cells. We assume that the observed efficiency will be not much different when using different intensities. This assumption is based on the equation of the solar cell efficiency ε = (P max/P in) × 100 %, where P in is the power of illumination and P max is the maximum value of the multiplication of current and voltage. If the intensity of illumination is increased, the resulting current will change, and multiplication of the current and voltage which producing the maximum power increases. This conclusion is strongly supported by El-Shaer et al. report [22]. They investigated the dependence of current, voltage, fill factor, and efficiency on light intensity for mono C-Si and poly C-Si solar cell modules. The experiments were carried out in the light intensities between 0.2 and 1.0 of the sunlight’s intensity at temperature of 25 °C. They found the current increased linearly with light intensity. The voltage and efficiency of the solar cell module experienced a small rise with light intensity. They also investigated the fill factor dependency on light intensity and observed that the fill factor was nearly independent of light intensity.

To further assure the results, we measured directly the efficiency of the solar cells containing an active layer of TiO2 only at two different illumination intensities: 37.38 W/m2 and 213 W/m2. The results of measurement are displayed in Table 1. It appears that P max at intensities of 37.38 W/m2 and 213 W/m2 are 0.33 μVA and 2.68 μVA, respectively. The ratio of P max to intensity of illumination are 0.33/37.38 = 0.009 and 2.68/213 = 0.013 at intensities of 37.38 W/m2 and 213 W/m2 respectively. It might be concluded that different illumination intensities produced nearly the same efficiency.

Figure 4 shows the effect of number of spray layers on efficiency and I sc current. It appears that initially the efficiency increases with the number of layer and then decreased when further increasing the number of layers. Similar observations have been reported by other researchers, including for solar cells made from different materials. For example, Li et al. reported the effect of thickness on efficiency of solar cell made from poly(3-hexylthiophene) [23]. They observed that the efficiency initially rises with increasing thickness of the active layer and then dropped after reaching the optimum thickness. Zheng et al. investigated the effect of thickness of poly3-hexylthiophene:6,6-phenyl C61 butyric acid methyl ester P3HT:PCBM active layer on the solar cell efficiency [24]. They varied the thickness from 130 nm to 1200 nm and observed the efficiency initially increased with active layer thickness from 130 nm to 830 nm, and then decreased with active layer thickness when the thickness is above 830 nm. Islam et al. investigated the influence of thickness on the optical characteristics of the blend of poly (3-hexylthiophene) (P3HT) and Phenyl C61 butyric acid methylester (PCBM) used as an active material [25]. The active material was deposited on ITO by spin-coating method. They found that the absorption of the active layer increases with active layer thickness. Yu Xie et al. investigated the effects of thickness on light absorbance of P3HT:PCBM thin-films which is used as an active layer in polymer solar cells (PSCs) [26]. This active material was deposited using spray method. The thickness was varied from 60 nm to 80 nm. It is again confirmed that light absorbance increased with increasing active layer thickness.

Here we propose a simple model to explain the effect of the active layer thickness on the solar cell efficiency. The assumptions used in this model are the TiO2 films are homogeneous regardless of thickness and photoelectrons generated at any point will move in all directions with equal probability. It should be emphasized that the proposed model is just a simple qualitative models, merely to show that the efficiency indeed increases and then decreases with increasing the active layer thickness. Predictions from the model are also not confronted directly with the experimental data.

As an illustration, look at Fig. 5. Light comes from the left side with intensity I 0 penetrates the TCO and falls on the active layer to produce electron–hole pairs. If the cross-sectional dimension is very large compared to the thickness dimension, the generated electrons at any point can be considered to move to the right or the left directions only with equal probability. Electron moving to the left reaches to the electrode directly. Electron moving to the right will be reflected by the right edge of the active layer, and turns to the left toward the electrode. The electrons have a specific lifetime. Thus not all the electrons can reach the electrode due to recombination with holes during the trip. The efficiency of a solar cell is determined by the number of electrons reaching the electrode.

At position x measured from the left surface of the active layer, the light intensity drops to I(x) = I 0 e −αx with α is the absorption coefficient. The number of electrons generated in the active layer element with thickness dx is proportional to the intensity of the light falling on the elements and the element thickness, or

with γ is a constant. Assuming the cross section dimension is very large compared to the thickness dimension, the electrons generated in the element dx effectively flow in both directions (left and right). Half the electrons flow directly toward the electrode and the other half flow away from the electrode, reflected by the right edge of the active layer, and then flow back toward the electrode. If v is the average velocity of the electrons then the time required by electron to reach the electrode in the two directions of flow are t 1 = x/v and t 2 = (2D − x)/v, respectively.

The photogenerated electron in a semiconductor material has a lifetime, τ, namely the average life time of electrons in the material before recombining with holes. In the presence of this lifetime, the probabilities of electrons moving directly to the electrode and electrons which are reflected by the right edge of the active layer to reach the electrode are p 1 ∝ exp(−t 1/τ) and p 2 ∝ exp(−t 2/τ), respectively. Thus, the number of electrons generated by the elements dx reaching the electrode is proportional to

The efficiency of the solar cell is proportional to the total number of electrons reaching the electrode. Therefore,

with β is a new constant. If we define ξ = 1/αvτ, the efficiency can be written as

Figure 6 is an illustration of the calculation result using Eq. (4). As mentioned earlier, we are not confronting models with observational data. We only intend to show qualitatively that the efficiency initially rises then falls with increasing the active layer thickness. More accurate model that takes into account more factors that contribute to the efficiency and direct comparison with experimental data are being explored.

Illustration of the calculation results using the Eq. (4) for ξ = 0.15 and ξ = 0.25. Qualitatively it appears that efficiency increases and then decreases with increasing the active layer thickness

The maximum value of efficiency occurs at thicknesses that satisfies dε/dD = 0, or

which produces

An SEM image of a graphite film sprayed onto an FTO substrate is shown in Fig. 7a. The particles are of micrometer size. An SEM image of the graphite/TiO2 composite inserted with particles copper is shown in Fig. 7b. The average size of a TiO2 particle is approximately 160 nm, while the copper particles are larger than the TiO2 particles.

We also estimated the final thickness of the active layer after spraying several times on the TCO. Figure 8 is a SEM image TiO2/graphite results of 30 times spraying on the surface of the TCO. It appears from the image that the final thickness of the active layer is between 15 and 30 μm.

The ultraviolet–visible light characterization of the composite graphite/TiO2 film is presented in Fig. 9. The graphite/TiO2 film absorbs a wide range of the solar spectrum, from less than 400 nm to more than 850 nm. The film absorbs a wider solar spectrum than pure TiO2 does. Pure TiO2 only absorbs the solar spectrum below 400 nm. It is clear that the use of the active layer of graphite and TiO2 enhances the absorption in the visible region, despite the decrease in absorption in the ultraviolet region. This is important because the content of the ultraviolet light of the sun is less than 8 % [1] and most of the spectrum spread in the visible to the infrared region. Decrease of absorbance in the ultraviolet region and an increase in the absorbance in the visible region and longer wavelengths accumulatively increase efficiency.

Graphite has a wider band of absorption but this does not mean the absorbed photons were used to produce electron–hole pairs. However, we observed a strange phenomenon. Although graphite is a semimetal, its function is similar to that of TiO2 when applied to make solar cells having the structure reported in [1]. Why does a semimetal function similarly to a semiconductor? It remains unclear whether phenomena other than electron–hole pair production play a role in this. Garcia et al. found evidence for the semiconducting behavior of Bernal graphite with a narrow band gap [27], but it is unclear whether the graphite used in the present work exhibited semiconducting behavior.

We directly measured the absorbance of graphite used in this work. Figure 10a is Tauc plot of the UV spectrum of graphite used in this work. We estimated that the band gap is about 1.8 eV. This value is much greater than the values reported previous researchers of around 0.03 eV [19, 20]. We assume that this difference is caused by graphite we used in this work is not a graphite with a very high purity. This assumption is supported by EDX data as shown in Fig. 10b. It appears that the graphite that we have used a purity of only 90 % and there are about 10 % of other elements such as oxygen, aluminium, and silicon. The use of graphite with a low purity is intended to reduce material cost in the manufacturing of solar cell.

Further work is required to improve the properties of the presently proposed solar cell. Because the presently reported model’s efficiency is lower than that of commercial p–n junction or dye-sensitized solar cells, greatly improving the efficiency of our proposed model remains an important objective. Additionally, the stability of the solar cells (e.g., how long the solar cell can maintain its function before decaying) must be explored intensively.

Conclusion

We demonstrated that a design of solar cells having a TiO2/graphite mixture as an active (absorber) material can reach an efficiency of approximately 1.09 %, much higher than solar cells using TiO2 only (0.03 %) or graphite only (0.12 %) as the active material. Owing to its easy and flexible fabrication, and easy scaling up to very large areas, the reported solar cell model is promising for mass application, especially in low-income communities.

References

Saehana, S., Arifin, P., Khairurrijal, Abdullah, M.: A new architecture for solar cells involving a metal bridge deposited between active TiO2 particles. J. Appl. Phys. 111, 123109 (2012)

Saehana, S., Yuliza, E., Arifin, P., Khairurrijal, Abdullah, M.: Dye-sensitized solar cells (DSSC) from black rice and its performance improvement by depositing interconnected copper (copper bridge) into the space between TiO2 nanoparticles. Mater. Sci. Forum 737, 43–53 (2013)

Yuliza, E., Saehana, D., Rahman, D.Y., Rosi, M., Khairurrijal, Abdullah, M.: Enhancement performance of dye-sensitized solar cells from black rice as dye and black ink as counter electrode with inserting copper on the space between TiO2 particles by using electroplating method. Mater. Sci. Forum 737, 85–92 (2013)

Saehana, S., Prasetyowati, R., Hidayat, M.I., Arifin, P., Khairurrijal, Abdullah, M.: Efficiency improvement in TiO2-particle based solar cells after deposition of metal in spaces between particles. Int. J. Basic Appl. Sci. 12, 15 (2011)

Rokhmat, M., Wibowo, E., Sutisna, Yuliza, E., Khairurrijal, Abdullah, M.: Enhancement of TiO2 particles based-solar cells efficiency by addition of copper(ii) nitrate and post-treatment with sodium hydroxyde. Adv. Mater. Res. 1112, 245–250 (2015)

O’regan, B., Gratzel, M.: A low-cost, high-efficiency solar cell based on dye-sensitized colloidal TiO2 films. Nature 353, 737–740 (1991)

Serpone, N., Pelizzetti, E.: Photocatalys, fundamental and application. Wiley, New York (1989)

Li, X.Z., Li, F.B.: Study of Au/Au3+ -TiO2 photocatalysts toward visible photooxidation for water and wastewater treatment. Environ. Sci. Technol. 35, 2381–2387 (2001)

Wang, Y., Cheng, H., Zhang, L., Hao, Y., Ma, J., Xu, B., Li, W.: The preparation, characterization, photoelectrochemical and photocatalytic properties of lanthanide metal-iondoped TiO2 nanoparticles. J. Mol. Cat. A Chem. 151, 205–216 (2000)

Abdullah, M., Nurmawarti, I., Khairurrijal.: Very wide band absorption of sunlight spectra using titanium dioxide particles with distributed band gap. J. Nanosains Nanoteknol. 3, 10–14 (2010)

Yamada, Y., Kanemitsu, Y.: Determination of electron and hole lifetimes of rutile and anatase TiO2 single crystals. Appl. Phys. Lett. 101, 133907 (2012)

Vorontsov, A.V., Savinov, E.N., Jin, Z.S.: Influence of the form of photodeposited platinum on titania upon its photocatalytic activity in CO and acetone oxidation. J. Photochem. Photobiol. A 125, 113–117 (1999)

Li, F.B., Li, X.X.: The enhancement of photodegradation efficiency using Pt–TiO2 catalyst. Chemosphere 48, 1103–1111 (2001)

Hoffmann, M.R., Martin, S.T., Choi, W., Bahnemann, D.W.: Environmental Applications of Semiconductor Photocatalysis. Chem. Rev. 95, 69–96 (1995)

Banerjee, S., Gopal, J., Muraleedharan, P., Tyagi, A.K., Raj, B.: Physics and chemistry of photocatalytic titanium dioxide: visualization of bactericidal activity using atomic force microscopy. Curr. Sci. 90, 1378–1383 (2006)

Kim, J.Y., Lee, K., Coates, N.E., Moses, D., Nguyen, T.Q., Dante, M., Heeger, A.J.: Efficient tandem polymer solar cells fabricated by all-solution processing. Science 317, 222–225 (2007)

Peet, J., Kim, J.Y., Coates, N.E., Ma, W.L., Moses, D., Heeger, A.J., Bazan, G.J.: Efficiency enhancement in low-bandgap polymer solar cells by processing with alkane dithiols. Nature Mater. 6, 497–500 (2007)

Sengupta, R., Bhattacharya, M., Bandyopadhyay, S., Bhowmick, A.K.: A review on the mechanical and electrical properties of graphite and modified graphite reinforced polymer composites. Prog. Polym. Sci. 36, 638–670 (2011)

McClure, J.W.: Band structure of graphite and de haas-van alphen effect. Phys. Rev. 108, 612 (1957)

McClure, J.W.: Energy band structure of graphite. IBM J. Res. Dev. 8, 255 (1964)

Nair, P.B., Justinvictor, V.B., Daniel, G.P., Joy, K., Thomas, P.V.: Influence of film thickness and annealing atmosphere on the structural, optical and luminescence properties of nanocrystalline TiO2 thin films prepared by RF magnetron sputtering. J. Mater. Sci. Mater. Electron. 24, 2453–2460 (2013)

El-Shaer, A., Tadros, M.T.Y., Khalifa, M.A.: Effect of light intensity and temperature on crystalline silicon solar modules parameters. Int. J. Emerg. Technol. Adv. Eng. 4, 311 (2014)

Li, G., Shrotriya, V., Yao, Y., Yang, Y.: Investigation of annealing effects and film thickness dependence of polymer solar cells based on poly(3-hexylthiophene). J. Appl. Phys. 98, 043704 (2005)

Zeng, L., Tang, C.W., Chen, S.H.: Effects of active layer thickness and thermal annealing on polythiophene: fullerene bulk heterojunction photovoltaic devices. Appl. Phys. Lett. 97, 053305 (2010)

Islam, MdS, Islam, MdE, Ismail, ABMd, Baerwolff, H.: Influence of thickness and annealing temperature on the optical properties of spin-coated photoactive P3HT:PCBM blend. Opt. Photon. J. 3, 28–32 (2013)

Xie, Y., Gao, S., Eslamian, M.: Fundamental study on the effect of spray parameters on characteristics of P3HT:PCBM active layers made by spray coating. Coatings 5, 488–510 (2015)

García, N., Esquinazi, P., Barzola-Quiquia, J., Dusari, S.: Evidence for semiconducting behavior with a narrow band gap of Bernal graphite. New J. Phys. 14, 053015 (2012)

Acknowledgments

This work was supported by a research Grant from the Ministry of Research and Higher Education of the Republic of Indonesia (contract no. 310y/I1.C01/PL/2015) and fellowship grand from Indonesia Endowment Fund for Education (LPDP).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Rahman, D.Y., Rokhmat, M., Yuliza, E. et al. New design of potentially low-cost solar cells using TiO2/graphite composite as photon absorber. Int J Energy Environ Eng 7, 289–296 (2016). https://doi.org/10.1007/s40095-016-0213-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40095-016-0213-5