Abstract

The polynomial model proposed by Frye–Morris is generally used to predict the moment-rotation behaviour of eight types of angle connections. The problem with the Frye–Morris model is that it either overestimates or underestimates the connection stiffness as it was developed by assimilating only few test results. A nominal air-gap distance of 10 mm is provided between beam and column, while assembling the connections for fabrication conveniences. This air-gap distance has considerable influence on the connection behaviour observed from the previous studies and an improved polynomial model was suggested for top and seat-angle connection based on the numerical parametric studies by considering the air-gap distance as an additional size parameter. In line with this, the Frye–Morris model for double web-angle connection is also modified based on numerical parametric studies. A new equation is proposed based on the Frye–Morris procedure with air gap as an additional parameter. The proposed equation is compared with the experimental results and Frye–Morris model and is found to be in close agreement.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Semi-rigid connections are a class of connections that fall between the rigid and flexible connections. The fact that simple connections do have some degree of rotational rigidity led to the developments in the semi-rigid connections. Similarly, rigid connections do experience some degree of joint deformation and this can be utilized to reduce the joint design moments. Several research studies have been reported dealing with the effect of connection behaviour on steel frames. But in the past two decades, the incorporation of semi-rigid behaviour into steel connection design has attracted attention since modelling the real behaviour of the connections leads to more reliable designs and economies in construction. Much of the knowledge needed to apply semi-rigid behaviour for design has been derived from detailed finite element analysis (FEA) of bolted connections. However, if one considers the large number of variables related to connection geometry, connection components and constitutive relationships for their materials, the task of deriving simplified guidelines for the incorporation of semi-rigid behaviour into design is a formidable analytical assignment. This task is further complicated by the need to treat the problem in three dimensions to consider nonlinear geometric and material effects. Thus, the aspect of semi-rigid design has been a research tool rather than a design tool.

Review of literature

Various researchers have conducted experimental and numerical studies on different types of connections. Exclusive details of experiments on bolted double web-angle (DWA) connection are not available in literature. Frye and Morris (1975) developed a polynomial expression to predict the behaviour of different types of connections based on experimental studies. Mullin and Astanch (1988) conducted several tests on double web-angle beam-to-column connections, which were bolted to a beam web and welded to a column flange and concluded that double angle-web connections can be divided into three distinct regions of behaviour during loading: a tee-hanger region, a shear beam region and a compression region. Kishi and Chen (1990) developed the moment-rotation relationship of semi-rigid steel beam-to-column connections and reported that the power model is simple to use and provides a realistic representation of the actual moment-rotation behaviour of each connection type with angles, and can be easily implemented in a second-order frame analysis. Barakat and Chen (1991) proposed models associated with the simplified analysis procedure for un-braced flexible steel frames. Richard et al. (1993) presented a method for modelling connection moment-rotation curves. Abdalla and Chen (1995) expanded the existing database of semi-rigid steel connections and compared the experimental moment-rotation curves with several analytical models describing these curves. Kim and Chen (1998) provided a practical method for design of Type partially restrained (PR) construction for design office use and presented the three-parameter power model for connection moment-rotation curves. Yang et al. (2000) carried out FEA of double web-angle connections welded to the beam web and bolted to the column flange subjected to axial tensile loads, shear loads and a combination of both. The loads were increased monotonically and steel angles with three different thicknesses were analysed and concluded that the thickness of angle has a tremendous influence on the response of the connection. Kishi et al. (2001) examined four FE models to find the one that best estimates M–θ r characteristics of top- and seat-angle with double web-angle connections using ABAQUS and recommended the use of power model. Hong et al. (2001) studied the double web-angle connections, which were subjected to monotonic axial tensile loading, shear loading and combined loading to establish the effects of the bolt gauge distances and angle thickness using ABAQUS. Tests proved that an excessive reduction of gauge distance and increase of angle thickness cause an earlier failure because of stress concentration. Pucinotti (2001) proposed a simplified mechanical model for top- and seat- and web-angle connection. The application of model and its comparisons with experimental curves and Eurocode application have revealed the excellent quality of the simplified model. Citipitioglu et al. (2002) gave a methodology for modelling the moment-rotation response of top- and seat-angle (TSA) connection with and without web angles using ABAQUS. Lee and Moon (2002) proposed a two parameter log model to describe the nonlinear M–θ relationship of semi-rigid connections. The proposed model accurately describes the M–θ behaviour of all connections by controlling shape parameters α and n. Hong et al. (2002) studied the nonlinear behaviour of a double web-angle and double-channel beam-to-column connection subjected to shear loads. Komuro et al. (2004) established a numerical analysis method for evaluating M–θ r relations of top- and seat-angle with or without web angles under monotonic loading. Taufik and Xiao (2005) presented a three-dimensional finite element methodology to predict the behaviour of TSA connection with mild carbon steel and high-strength steel and found that stress–strain curve is a very important parameter for accurate prediction of angle-bolted connection behaviour with high-strength steel. Yang and Lee (2006) studied the moment-rotation relationship of a double angle connection and proposed two simplified analytical models for predicting the initial stiffness and ultimate connection moment which were the most influential parameter affecting connection behaviour. Based on the study, they summarized that the Wu–Chen equation provides a more accurate connection behaviour than any other similar equation. Prabha et al. (2008) investigated the applicability of Frye and Morris (1975) polynomial model to predict the behaviour of TSA connection. The numerical parametric studies conducted by varying the air-gap distance between beam and the column showed that the FE model with air gap is flexible than the model without air-gap distance. A new model has been proposed for the moment-rotation behaviour of TSA connection including a new size parameter, the air gap.

As observed from the literature, various models have been developed in this regard such as polynomial model, power model, linear model, two/three parametric model, Wu–Chen, Ang–Morris and Richard model. Simple formulae for semi-rigid design are generally not presented in many codes of practice. However, Indian code (IS:800 2007) has adopted a simple polynomial model given by Frye and Morris (1975) for the design of semi-rigid frames. This model has the disadvantage that it requires a large number of experimental data to evaluate the power of exponents of size parameters that influence the connection behaviour. As experimental studies are expensive and time consuming, analytical simulations are generally preferred. But, these analytical models need to be validated. Recent advances in computing technique have led to the development and use of general purpose FEA software, which simplifies the problem. The validated model can be used to simulate a number of expensive experiments by varying the most significant size parameters that affects the connection behaviour.

The present work evaluates the Frye and Morris (1975) polynomial model for the design of DWA connection. The moment-rotation behaviour of bolted DWA connections is studied by varying three key parameters: cleat angle thickness, depth of angle and the gauge distance. The effect of air gap between the beam web and column flange is considered as it is found to affect the connection stiffness to a great extent (Prabha et al. 2008). Numerical simulations are carried out using the commercial FEA software package, ABAQUS. To validate the numerical model, test details and the results of previous experimental work conducted by Raman 2005 on DWA connection are used. The results from the numerical parametric studies are then used to modify the Frye and Morris (1975) model for DWA connections with air gap as an additional size parameter.

Review of previous experimental work on DWA connections (Raman 2005)

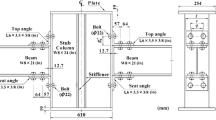

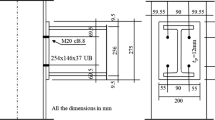

The experimental details of DWA connection tested previously (Raman 2005) are discussed below briefly. The experimental set-up for double web-angle connection is illustrated in Fig. 1.

Experimental set-up details

The set-up consists of two beams of length 1 m each connected to a central column of height 650 mm. The beams and column were made of Universal Beam (UB) steel sections 306.6 × 165.7 × 11.8 × 6.7 × 46.1 of ultimate tensile strength of 410 MPa. Indian Standard angle of size ISA 65 × 65 × 6 and length of 180 mm is used as double web angle. An air-gap distance of 10 mm is provided between beam and column. The test specimen is given the id DWA-6-180, in which 6 represents the thickness of angle in mm and 180 is the length of angle in mm. In order to simulate the simply supported conditions, one side of the beam was supported on hinge and other on roller. High-strength friction grip (HSFG) bolts of 16 mm diameter and 8.8 grade were used to connect the ends of beam web to the central stub column. The bolts were tightened by a pre-torque of 214 Nm. The present set-up has the advantage that column does not rotate, but only displaces up and down and the relative rotation between the column and beam is mainly due to connection deformation. Dial gauges of least count 0.01 mm were placed at every quarter effective span of the beam to measure the deflection. Strain gauges were pasted at various locations to measure the strain variation. Inclinometer was used to measure the relative rotation between the beam and column. The load was applied over the centre of the stub column with the help of a 60 T capacity hydraulic jack. Dial gauge, inclinometer and strain gauge readings are noted periodically up to collapse load.

Experimental observations and results

Two stages were identified in DWA connection before failure occurs, first stage was before air gap closure between beam and column and the second stage after air gap closure. In the first stage, the load was carried by the torsion of flange leg, web leg moves like a rigid body and tension face of the web leg yielded. In the second stage, load was carried by the compressive thrust on web of column and tension in flange leg bolts. Finally the connection was failed by tearing of web angle. The photographic view of the deformed shape of the connection and the angle failure is shown in Fig. 2a, b. The moment-rotation curve obtained from the experiment is shown in Fig. 3. The maximum value of ultimate moment was recorded as M u = 40 kN m and the ultimate rotation recorded for the test specimen was 0.14 rad. The failure modes of test specimens exhibited angle yielding that indicates the failure was governed by excessive yielding of the angle material, resulting in excessive rotation beyond acceptable rotation limits (normally 0.03–0.05 rad for semi-rigid connections), which causes significant loss in connection stiffness. The testing was stopped when any further increase in load cycles did not result in much gain in strength (i.e., moment), but it led to a very rapid increase in rotation. The first slip observed in the curve is due to the pre-tensioning of bolts and the second slip is due to the web leg moves like rigid body which lead to close the air gap between beam and the column. After this point, there was a gradual increase in moment due to the closure of air gap and torsion of the flange leg started. Six strain gauges were used to measure the strain variation. First one is pasted in the compression face of the flange leg named as S1, second in the tension face of the web leg named as S2, third in the tension face of the flange leg named as S3, fourth in the compression face of the web leg named as S4, fifth in the compression face of flange leg parallel to the axis of the column and sixth in the tension face of the flange leg parallel to the column axis. The location of strain gauges and its variation with the applied load is shown in Fig. 4. It can be observed that strain variation in the web leg (S2 and S4) is lower (less than 1000 µm) because of the web leg moves like rigid body. The higher strains (18,000 µm) are recorded in S1 and S3 due to the tension yielding of angle leg.

FEA of DWA connection

Three-dimensional (3D) elasto–plastic nonlinear FEA has been conducted for evaluating the moment-rotation behaviour of DWA connections. The test details given in the previous section are used to develop the FE model.

Model description

FE model of DWA connection is shown in Fig. 5. The beam, column and connection components are modelled using eight-noded solid elements with reduced order integration (C3D8R). This element is characterized by eight nodes having 3° of freedom at each node, i.e., translations in the x, y and z directions. HSFG bolts of class 8.8 and diameter of 16 mm are used for the connection. An air gap of 10 mm is considered between beam and column. In order to simplify the model, the bolts and bolt heads are idealized as circular instead of hexagonal. Washers and fillets in the angle are not modelled to reduce the complexity. A clearance of 1.5 mm is allowed between the bolt shank and bolt hole. A number of trail models have been analysed by varying the number of elements. Based on the computational effort, convergence of the solution and by comparing with the experimental results, the final arrangement of mesh and elements have been decided. The mesh size is controlled appropriately to enable surface to surface contact and easy convergence of the solution. The FE model is made to mimic the behaviour of the actual connection by giving proper interaction between various surfaces. In order to simulate the simple supported conditions, one side of beam is given roller support and other as hinge support. After applying all boundary conditions, nonlinear analysis is carried out by considering both geometric and material nonlinearities.

Contact modelling

The modelling of contacts between various components plays a major role in the performance of the connection. The bolt pre-tension and friction are the most critical parameters. The forces are transmitted by friction between members as a result of bolt pre-tensioning. The contact pairs are web angles to beam web/column flange, bolt shank to bolt hole, and bolt head to respective components. Out of these, the contact between bolt shank and bolt hole is frictionless, whereas the others are friction contact. The interaction consists of two components, one normal to the surface and the other tangential to the surface. The tangential component consists of relative motion between the surfaces and frictional shear stress, if connection is made up of HSFG bolts. Hard contact is given between the surfaces, i.e., the surfaces separate, when the contact pressure between them becomes zero or negative. While in contact the normal and shear forces are transmitted from one surface to another. Thus, a suitable value of friction coefficient should be given such that the frictional forces resist relative sliding of the surface. To simulate the exact connection behaviour, finite sliding contact pair definition is given between the two surfaces, one of which is the master and other is slave surface. The master surface should be a discontinuous surface and the surface intersecting the master is called slave surface.

Material model

Steel is assumed to behave as an elasto–plastic material in tension with following material parameters: Young’s Modulus E = 200 GPa, yield stress f y = 250 MPa and Poisson’s ratio μ = 0.3. The material properties of the steel members are given in Table 1. The stress–strain behaviour of steel specimens obtained from the tension coupon test (Fig. 6a) is represented by trilinear constitutive model (Fig. 6b) in the numerical study. Stress–strain data can be given in a tabular form as input in ABAQUS. The hardening behaviour is defined using plastic strain values, which have zero value at yield stress, corresponding to stress in steel at that particular point. The yield and ultimate strength of bolt are decided based on the nominal properties of 8.8 grade bolts. The stress–strain behaviour of bolts is represented by the bilinear constitutive model (Fig. 6c) in the numerical study.

Comparison of results and validation of FE model

The loading and boundary conditions of DWA connection are shown in Fig. 7. One end of each beam is connected on either side of the column flange and the other end is suitably supported in order to simulate simply supported conditions. The model is analysed in two steps. In pre-tension step, each bolt is pre-tensioned with a force of 70,000 N equivalent to the experimental torque of 214 Nm on a pre-selected section of the bolt shank. In the second step, pressure load is applied on the top of central stub column. The results of FE model and experiment (Specimen ID. DWA-6-180) are compared based on the following three criteria: connection failure, moment-rotation behaviour, deformation and stress distribution in DWA connection. The failure mode of FE model is found to be in good agreement with the experimental observations. The deformed shape of connection at the ultimate stage is given in Fig. 8. The moment-rotation curves obtained from FEA are compared with the experimental results in Fig. 9. The connection moment is evaluated by multiplying the reaction force with the distance between beam support point and face of the column flange. It is seen that the initial slip due to bolt pre-tensioning predicted by FE model and experiment is quiet similar. The second slip due to the closure of air gap is also very well captured by the FE model. The discrepancy in the ultimate moment capacity between experimental results and FEA is found to be only 3 %. As the failure load and mode of failure agree reasonably well, this model is adopted for further parametric studies.

Comparison of Frye and Morris (1975) model with FEA results

The Frye and Morris (1975) polynomial model is used to obtain the moment-rotation behaviour of different semi-rigid connections. The general form is given by

where M is the moment at the joint in kNm, K is the standardization constant, which depends on the connection geometry and type, and \(C_{1} , \;C_{2} ,\; C_{3}\) are curve fitting constants. For DWA connection, the curve fitting constants are given as \(C_{1} = 1.64 \times 10^{3} , \;C_{2} = 1.03 \times 10^{14} , \;C_{3} = 8.18 \times 10^{25}\) and K = d −2.4a t −1.81a g 0.15, where d a is the depth of angle in mm, t a is the thickness of angle in mm, and g is the gauge distance in mm.

The moment-rotation curves predicted by Frye–Morris model (1975) and FE model are plotted for the specimen DWA-6-180. The Frye–Morris model (1975) does not take into account the air-gap distance between beam and column, whereas the FE model (DWA-6-180) considers an air-gap distance of 10 mm. The comparison of moment-rotation behaviour (Fig. 10) clearly shows that the Frye and Morris (1975) model prediction is highly stiffer than the FE model. This stiff behaviour can be attributed to the fewer number of test results based on which the original equation was developed and the ignorance of air gap parameter makes the connection stiffer. Hence it is clear that the exponents of the various size parameters in the Frye–Morris model needs a revision and further modification.

Comparison of Frye–Morris model (1975) with FE model

Parametric studies

The size parameters that influence the behaviour of double web angle are depth of angle (d a), thickness of angle (t a), gauge distance (g) and the air-gap distance (a g) between the beam and column. Using the validated FE model, parametric studies have been conducted by varying the above parameters. Twelve FE models are developed by varying the air-gap distance between beam and column (0, 7, 10 mm), angle length (180, 205, 230 mm), angle thickness (65 × 65 × 6, 65 × 65 × 8, 65 × 65 × 10 mm) and gauge distance (35, 37.5, 40 mm). The results of the parametric studies are discussed below.

Effect of air gap on the connection behaviour

Three FE models have been developed to study the variation of air gap on the connection behaviour, one without air gap and other two with air gaps of 7 and 10 mm between the beam web and column flange. The graph showing the comparison of connection behaviour with varying air gaps is shown in Fig. 11. It is observed that the initial stiffness remains similar up to a rotation of 0.5° irrespective of the air-gap distance. The first slip observed in all the FE models is due to the initial pre-tension force in the bolts. Beyond this point, there is considerable difference in stiffness as the air gap varies. The model without air gap is stiffer than the models with air-gap distance of 7 and 10 mm, because the model without air gap is already in contact with the column flange, whereas in the other models there is an additional slip due to the closure of air-gap distance before coming into contact with the column flange. There is an appreciable increase in the moment capacity for the specimen without air gap. As mentioned earlier, the Frye–Morris model (1975) does not take into account of the air gap as size parameter. Based on this study, it is proposed to incorporate a new size parameter, air gap (a g), in the equation to determine the standardization constant.

Effect of angle length on the connection behaviour

Three FE models have been developed by varying the angle length as 180, 205 and 230 mm to study the effect of angle length on connection behaviour. An air-gap distance of 10 mm is considered in all the FE models. It was observed that as the angle length increases, the connection stiffness varies proportionately (Fig. 12). However, the initial stiffness remains similar for all the three cases up to a rotation of 0.5°, after which the stiffness increases with increase in angle length. Due to minor changes in the angle length, significant variation is not observed in the moment capacity.

Effect of angle thickness on the connection behaviour

Three FE models have been developed by varying the angle thickness as 6, 8 and 10 mm to study the effect of angle thickness on the connection behaviour. An air-gap distance of 10 mm is considered in all the FE models. The graph showing the variation of angle thickness is shown in Fig. 13. The initial connection stiffness remains constant up to 0.25° rotation after which there is an increase in connection stiffness as well as moment carrying capacity for the higher thickness angle specimens. Also as the thickness increases, failure mode changes from tearing of angle to the end tearing of beam as the thicker angles exhibit a stiff nature.

Effect of gauge length on the connection behaviour

Three FE models have been developed by varying the gauge distance as 35, 37.5 and 40 mm to study the effect of variation of gauge distance on connection behaviour. An air-gap distance of 10 mm is considered in all the FE models. The graph showing the variation of gauge distance is shown in Fig. 14. It is observed that the initial stiffness remains almost similar up to 2° rotation (till the air gap closure) after which there is a slight variation in the stiffness. As the gauge distance decreases, the stiffness increases. Slight variation in gauge does not cause pronouncing changes in the moment carrying capacity of the connection.

Proposed modifications to existing Frye and Morris (1975) model

An improved polynomial model to predict the moment-rotation behaviour of DWA connections is developed based on the procedure given by Frye and Morris (1975) using the results from numerical studies. The moment-rotation relationship is given as

where moment (M) is expressed in kNm and all other size parameters are expressed in mm. The standardization constant for double web angle is given by

A number of parametric studies have been conducted to predict the moment-rotation behaviour of DWA connections. Based on the parametric studies, it is found that the air-gap distance between beam web and column flange has pronounced effects on the stiffness and moment-rotation behaviour. Therefore, it is proposed to include air gap a g as an additional size parameter in the prediction of moment-rotation relationship. The modified standardization constant K can be expressed as

The modified moment-rotation characteristics of the DWA connection can be obtained by substituting its altered size parameters in the standardization equation. The improved values of a1, a2, a3, a4 obtained from the parametric studies are −1.55, −1.14, 0.81 and 0.39, respectively. Hence, the proposed standardization constant K (Eq. 3) becomes

After determining all size parameters, exponent ‘aj,’ standardized moment-rotation (KM vs.\(\theta_{\text{r}}\)), graph is plotted for all the cases. Finally, the curve fitting constant C 1, C 2, and C 3 of the standardized moment-rotation relation is determined by the least square curve fitting technique. The values of the constants obtained in various cases are presented in Table 2.

With the average values of C 1 = 75.043348, C 2 = −1583.238, C 3 = 98160.033, Eq. (1) becomes

where θ r is the relative rotation in degrees, M is the moment in kNm and all other size parameters are in mm.

The improved Frye–Morris model is then compared with the experimental result (Specimen ID. DWA-6-205) and Frye–Morris model (1975) as shown in Fig. 15. It is found that the improved model compares well with the experiment than the Frye–Morris model (1975) which is very stiff. The results of the numerical studies (Specimen ID. DWA-6-180, DWA-8-180) are further used to evaluate the Frye and Morris (1975) model and proposed model. The comparison of initial stiffness predicted by the above mentioned methods is given in Table 3. The comparison of M–θ r curves (Figs. 16, 17) shows that the connection stiffness is highly overestimated by Frye–Morris model and the proposed model agrees well with the numerical results with an average error of around 15 %. This may be attributed to the fact that air gap is taken as an additional size parameter in the proposed model to find the connection stiffness. The proposed model is suitable for the connections with dominant failure mode of angles. From the literature, it is observed that no model has been proposed with air gap as a size parameter for DWA connections.

Comparison of proposed model with experiment, FE model and Frye–Morris model (1975)

Comparison of proposed model with FE model (DWA-6-180) and Frye–Morris model (1975)

Comparison of proposed model with FE model (DWA-8-180) and Frye–Morris model (1975)

Summary and conclusions

A nominal air-gap distance considered between beam the web and column flange in beam-column connections has considerable influence on the connection behaviour (Prabha et al. 2008). In the present study, the suitability of Frye and Morris (1975) polynomial model suggested by IS:800 (2007) in predicting the moment-rotation relationship of DWA connection is analysed by comparison with the previous test results available. The comparison study shows the stiffer prediction of the M–θ r behaviour by Frye Morris (1975) model, as it was developed by assimilating only few test results and also does not consider the air-gap distance between the beam and column, which provides considerable flexibility to the connection. Since the Indian Code IS:800 (2007) for steel design suggests the Frye and Morris (1975) polynomial model to predict the M–θ behaviour of various connections, an attempt has been made to modify the model by taking into account the air-gap distance for the better prediction. A systematic numerical parametric studies have been conducted by varying the most influencing parameters that affect the connection behaviour such as air-gap distance, angle thickness, angle length and the gauge distance. Before conducting the parametric studies, the FE model is validated by comparison with the known test results (Raman 2005) based on the connection failure mode, moment-rotation behaviour and moment capacity. The results obtained from the numerical parametric studies are used to modify the model with a new additional size parameter, i.e., air-gap distance. The improved Frye–Morris model is then compared with the experiment and Frye–Morris model (1975), which does not consider the air-gap distance. The comparison shows that the improved model presented a best fit with the experimental results than the Frye–Morris model (1975) model. Hence, the improved Frye–Morris model will be suitable for studies where air-gap distance is also taken into account.

References

Abdalla KM, Chen WF (1995) Expanded data base of semi-rigid steel connections. Comput Struct 56(4):553–564

Barakat M, Chen WF (1991) Design analysis of semi-rigid frames: evaluation and implementation. Eng J AISC 28:55–64

Citipitioglu AM, Haj-Ali RM, White DW (2002) Refined 3D finite element modeling of partially restrained connections including slip. J Constr Steel Res 58:995–1013

Frye MJ, Morris AG (1975) Analysis of flexibility connected steel frame. Can J Civ Eng 2:280–291

Hong K, Yang JG, Lee SK (2001) Parametric study of double angle framing connections subjected to shear and tension. J Constr Steel Res 57(7–12):997–1013

Hong K, Yang JG, Lee SK (2002) Moment-rotation behaviour of double angle connections subjected to shear load. Eng Struct 24:125–132

IS: 800 (2007) Code of practice for general construction in steel. Bureau of Indian Standards, New Delhi

Kim Y, Chen WF (1998) Practical analysis for partially restrained frame design. J Struct Eng 124:736–749

Kishi N, Chen WF (1990) Moment-rotation relations of semi-rigid connections with angles. J Struct Eng 116:1813–1834

Kishi N, Ahmed A, Yabuki N (2001) Nonlinear finite element analysis of top- and seat-angle with double web-angle connections. Struct Eng Mech 12(2):201–214

Komuro M, Chen WF, Kishi N (2004) Elasto–plastic FE analysis on moment-rotation relations of top- and seat-angle connections. In: Connections in steel structures, Amsterdam, June 3–4, pp 111–120

Lee SS, Moon TA (2002) Moment rotation model of semi rigid connections with angles. Eng Struct 24(2):227–237

Mc Mullin KM, Astanch A (1988) Analytical and experimental studies of double-angle framing connections. Report no. UCB/SEMM-88/14. Department of Civil Engineering, University of California, Berkeley

Prabha P, Marimuthu V, Arul Jayachandran S, Seetharaman S, Raman N (2008) An improved polynomial model for top and seat-angle connection. Int J Steel Compos Struct 8(5):403–421

Pucinotti R (2001) Top and seat and web angle connections: prediction via mechanical model. J Constr Steel Res 57(6):663–696

Raman M (2005) Analytical & experimental investigations on semi-rigid steel connections. ME thesis, Malnad College of Engineering, Hassan

Richard MR, Hsia W-K, Chmielowiec M (1993) Moment rotation curves for double framing angles. Comput Struct 30:485–494

Taufik S, Xiao RY (2005) 3D finite element prediction of angle bolted connection with high strength steel. Adv Steel Struct 2:1775–1782

Yang JG, Lee GY (2006) Analytical models for the initial stiffness and ultimate moment of a double angle connection. Eng Struct 29:542–551

Yang JG, Murry TM, Plant RH (2000) Three-dimensional finite element analysis of double angle connections under tension and shear. J Constr Steel Res 54:227–244

Acknowledgments

The authors thank Dr. Nagesh R. Iyer, Director, CSIR-Structural Engineering Research Centre, Chennai, for his constant support and encouragement. This paper is published with the kind permission of the Director, Structural Engineering Research Centre (SERC), Chennai, India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Prabha, P., Rekha, S., Marimuthu, V. et al. Modified Frye–Morris polynomial model for double web-angle connections. Int J Adv Struct Eng 7, 295–306 (2015). https://doi.org/10.1007/s40091-015-0100-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40091-015-0100-y