Abstract

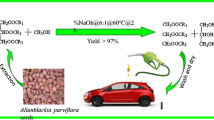

A catalyst-free and environmentally friendly process was employed for the production of biodiesel from sea mango seed oil. This oil is non-edible and contains several fatty acids such as palmitic acid (C16), trans-9-elaidic acid (C18:1t), oleic acid (C18:1), linoleic acid (C18:2), and linolelaidic acid (C18:2n6t). The in situ extraction and transesterification of the oil were carried at the subcritical methanol–water condition. The effect of reaction temperature and time on the yield of biodiesel was studied. The maximum yield of biodiesel was 98.58% and achieved at 200 °C, 40 bar and reaction time of 6 h. The ratio among sea mango seed, methanol, and water was 2:10:1.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

A large number of studies on biodiesel production have been conducted due to its potential to reduce the dependence of fossil-based liquid fuel [1] and to lessen the CO2 emission from the transportation sector [2]. Aside from reducing the net CO2 emission, biodiesel is also known for its biodegradability [3], non-toxicity [4], and low emission profile of SO x [5] and other pollutants, such as CO x , hydrocarbon, NO x [6], and low particulate matter [7]. Biodiesel is a renewable biofuel. Thus, it is environmentally friendly [8]. Rashid et al. [9] defined biodiesel as mono-alkyl esters derived from vegetable oils/animal fats by a chemical process called the transesterification process [9]. However, vegetable oils/animal fats may contain high free fatty acid (FFA) and water [10] that may cause the formation of soap during the reaction [11].

Due to the lack of non-consumable resources of vegetable oils and animal fats as raw materials for biodiesel production, in the early studies of biodiesel production high-quality food-grade oils were used as the starting materials. In the USA, biodiesel is produced in industrial scale using soybean oil as the raw material, while palm oil is used to produce biodiesel in Malaysia [12]. However, the use of edible feedstock creates several economic and environmental issues, the competition between crop land used for food production and biodiesel can become intense especially in developing and less develop countries with food shorage problems [12,13,14]. Non-edible and non-conventional feedstocks have been selected to substitute edible feedstocks for biodiesel production, and in this study we utilized sea mango (Cerbera odollam), which is known as a poisonous fruit as the raw material for biodiesel preparation.

Sea mango is a tree of the Apocynaceae family. The seed of this poisonous fibrous-kernelled fruit contains a significant amount of oil [15]. The presence of non-edible oil in sea mango makes it a potential candidate for use as non-edible feedstock for biodiesel production [15]. Kansedo et al. [16] studied the production of biodiesel from sea mango seed using sulfated zirconia catalyst. They found that the yield of FAME from sea mango seed could reach up to 83% via an ex situ method. Unfortunately, the use of the conventional method of biodiesel production has some drawbacks, such as the high price of the catalyst, the high cost of the pre-treatment process, and slow reaction time [17].

Water is environmentally friendly and the cheapest solvent for many kinds of processes [18]; however at ambient condition, water is not a suitable solvent or reactant for organic compounds due to its high polarity, and it also cannot be used as extracting agent for non-polar compounds. Studies have found out that by increasing its temperature and pressure, water can be utilized as an extracting agent. Water in the liquid state condition at temperature above the atmospheric boiling point and below the critical temperature (374 °C) is called as subcritical water (SubCW) [19], and at this condition water can be used as extracting and reaction media for many kinds of reaction systems with or without the presence of catalyst [20].

In the present, there is no study on the utilization of in situ subcritical methanol–water for the production of biodiesel from sea mango seed oil without the presence of a catalyst. One of the main drawbacks of using catalyst, especially homogeneous catalyst, is the difficulty in the purification step, which often requires a complicated procedure and at the end will affect the cost of production itself [21]. In this study, we utilized the non-catalytic process for the production of biodiesel from sea mango seed.

This study aimed to find the best condition for the manufacture of biodiesel from sea mango seed with the non-catalytic process using subcritical water and methanol. The effects of temperature and reaction time on the yield of biodiesel were studied at constant pressure (40 bar) and a constant mass ratio among methanol, water, and sea mango seed (10:1:2).

Materials and methods

Materials

Sea mango seeds were collected from several streets in Surabaya, East Java, Indonesia. The sea mango seeds were repeatedly washed using tap water to remove dirt and other impurities and subsequently dried at 100 °C for 24 h. The dry sea mango seed was pulverized in Junke and Kunkel hammer mill. The chemicals used in this study such as n-hexane (90%) and anhydrous methanol (99.9%) were purchased from Merck, Germany. Ultrapure N2 gas (99.9%) was obtained from Aneka Gas Pty. LTD. The reference standard mix of (Supelco) fatty acid methyl esters (FAMEs) consists of C14–C22 fatty acids and was purchased from Sigma-Aldrich Co. USA. All the chemicals were used without any further purification.

Analysis of sea mango seed oil mass fraction

The oil mass fraction in the sea mango seed was determined by Soxhlet extraction method. Forty-five grams of dried powder of sea mango seeds was placed in a porous bag made of durable filter paper. n-Hexane was used as the extracting solvent. 250 ml of n-hexane was placed in a round bottom flask, and then the flask was attached to the Soxhlet extractor. Subsequently, the flask was heated until the n-hexane evaporated and the vapors condensed in the condenser. The liquid n-hexane then trickled back into the extraction chamber containing the sea mango seed powder, and the oil was extracted from the seed powder. When the level of liquid in the extraction chamber rose to the top of the siphon tube, n-hexane in the extraction chamber flowed back into the flask. This process was repeated many times until a drop of solvent from the siphon tube did not leave a residue when evaporated.

The liquid from the Soxhlet extractor was evaporated using IKA RV10 B rotary evaporator to remove n-hexane, and the mass of oil obtained was weighed using Mettler Toledo analytical balance.

The chemical characteristics of sea mango seed oil used in this study are given in Table 1.

In situ subcritical methanol transesterification

In situ subcritical water methanol transesterification of sea mango seed oil was carried out in a laboratory-scale high-pressure batch reactor (150 cm3, temperature limit: 100–300 °C, pressure range: 0–80 bar). The stainless steel reactor was equipped with an external heater, a pressure gauge, and a thermos controller to maintain the system at the desired temperature. The ratio of methanol, sea mango seed powder, and distilled water was 10:2:1, this ratio was based on the stoichiometry of transesterification reaction between triglycerides and methanol. The reactor was closed with its cap using M8 screws, and it was heated at a rate of 20 °C min−1 to the desired temperatures (140, 160, and 180 °C). The temperatures were kept constant for specific times (4, 5, and 6 h). To keep the temperature and pressure constant, it was controlled by a PID-type controller with an uncertainty of ± 1 °C and pressure gauge to monitor the pressure at 40 bar. The schematic diagram of the subcritical reactor is given in Fig. 1. N2 gas was injected into the reactor to maintain the pressure of the system and to ensure that water and methanol existed in the liquid form. During the reaction, the system was kept under constant stirring at 400 rpm using a magnetic stirrer. After the reaction was complete, the reactor was suddenly cooled to room temperature and the vent valve was opened to release nitrogen gas. The liquid was separated from the mixture using Whatman filter paper no. 41. The biodiesel was extracted from the filtrate using n-hexane in a separatory funnel, and then glycerol (bottom phase) was separated from the organic phase. The organic phase was evaporated using IKA RV 10 B rotary evaporator to remove n-hexane. The yield of biodiesel (FAMEs) was weighed and analyzed using gas chromatography.

Analysis of FAME in biodiesel

The content of fatty acid methyl ester in biodiesel was analyzed using Shimadzu gas chromatograph 2014. Gas chromatography was equipped with FID and 30 m × 0.25 mm DB-WAX capillary column; the film thickness was 0.25 μm. The analysis was conducted using helium as carrier gas at a linear velocity of 34 cm s−1 and the injector temperature was kept constant at 250 °C, while the FID temperature was kept at 300 °C. The column temperature was programmed at 120 °C for 3 min, and then heated to 300 °C with a heating rate of 20 °C min−1 and kept at 300 °C for 2 min. The amount of the sample injected into the column was 1 μl with 1:100 split ratio. Other physical and chemical properties of the biodiesel were determined by the ASTM D6751 method.

Results and discussion

Oil content of sea mango seed

To determine the oil content of the sea mango seeds, the extraction of oil from sea mango seeds was conducted using the Soxhlet extraction procedure. The extraction experiments were conducted three times, and the results are given in Table 2. High oil content in the sea mango seed (average 48.72 wt. %) indicates that this unedible seed is a suitable precursor for biodiesel production.

Effect of reaction temperature on FAME yields

The yield of biodiesel obtained from the transesterification of sea mango oil using subcritical water–methanol at various temperatures and reaction time is summarized in Table 3. From this table, it can be seen that the maximum yield of biodiesel was 98.58%. The highest yield of the biodiesel was obtained at a temperature of 200 °C and reaction time of 6 h. At 200 °C, the increase in the reaction time gave no significant effect on the yield of biodiesel. In the in situ production of biodiesel, temperature played a significant role in the yield of biodiesel as indicated in Table 3. At temperature 140 °C and reaction time of 4 h, the yield of biodiesel was 14.08% and increased almost two times when the temperature was increased to 160 °C. At subcritical condition, the increase in temperature decreased the polarity of methanol, leading to increase in the miscibility of sea mango oil in methanol. With the increase of the miscibility of oil in methanol, the amount of oil extracted from the solid interior of mango seed also increases. The oil and methanol become one homogeneous phase [22]. The transesterification reaction of sea mango oil with methanol is reversible and endothermic; therefore, with the increase of temperature and miscibility of oil in methanol (become one phase), the rate of transesterification reaction to form fatty acid methyl ester also increases. The esterification reaction also occurred simultaneously in this process due to the 6.4% free fatty acid contained in sea mango seed oil as shown in Table 1. The high content of free fatty acid in the feedstock was not a problem for biodiesel production using the subcritical water methanol process, because no alkaline catalyst was used in this process that may cause a saponification reaction and give a low yield of biodiesel.

Effect of water on FAME yields

The addition of water into the subcritical system also plays an important role. When water was added to the system, the biodiesel yield rose to 98.58%. This value is ~ 26% higher compared to biodiesel yield from water-free process under similar conditions (200 °C, 40 bar for 6 h). Silva et al. [23] investigated the effect of water addition on biodiesel production from Jatropha curcas L. oil under supercritical ethanol. In the water-free system, the maximum fatty acid ethyl ester obtained was about 80%, and when 10% water was introduced to the process the yield became 87%. It was reported that the presence of water would stimulate the parallel reactions of transesterification and decrease the decomposition degree of fatty acid [23,24,25]. At subcritical condition, the dielectric constant of water is lower than at standard pressure and ambient temperature. Therefore, the water is easily dissociated into H3O+ and OH−. With the presence of excess H3O+, the system becomes acidic. The presence of H3O+ (hydroxonium) in the system represents the nature of the proton in aqueous solution, and this proton subsequently acts as a catalyst for the transesterification process at the temperature below the critical point of the mixture [26] and reduce the reaction time to achieve the same biodiesel yield.

Effect of reaction time on FAME yields

In general, the reaction time gives a positive effect on the yield of biodiesel as seen in Table 3. The longer the reaction time, the higher is the yield of biodiesel. As mentioned before, the transesterification reaction to produce biodiesel is an endothermic and reversible process; it requires energy to shift the reaction toward the biodiesel product (fatty acid methyl ester). With the increase of reaction time, the energy added to the system also increases and more energy is available to shift the reaction toward the formation of fatty acid methyl ester. Since the reaction was maintained at subcritical condition under nitrogen environment without the presence of any catalyst, the oxidation or secondary reaction of the biodiesel product did not occur. Therefore, the yield increased with the increase of reaction time.

FAME content in biodiesel

It has been reported that sea mango seed mainly contains oleic acid (48.1%), followed by palmitic acid (30.3%), linoleic acid (17.8%), and stearic acid (3.8%) [27]. GC analysis showed that sea mango seed oil contains several fatty acids such as palmitic acid (C16), trans-9-elaidic acid (C18:1t), oleic acid (C18:1), linoleic acid (C18:2), and linolelaidic acid (C18:2n6t). During the transesterification reaction with methanol, these fatty acids were converted to their esters [C16 (methyl palmitate), C18:1t (trans-9-elaidic methyl ester), C18:1c (cis-9-oleic methyl ester), C18:2 (methyl linoleate), C18:2n6t (methyl ester)]. The fatty acid methyl ester (FAME) compositions in the biodiesel obtained from sea mango seed oil are given in Table 4.

Fuel properties of biodiesel

The physical and chemical characteristics of the biodiesel such as density, kinematic viscosity, flash point, cetane number, and acid number were determined according to the ASTM standard. The density was determined by ASTM D1298, and the kinematic viscosity was determined using ASTM D445-10. ASTM D93 was employed for the determination of the flash point of the biodiesel. The cetane number was determined by ASTM D613, which is a standard method for the determination of the cetane number of diesel fuel oil. The values of chemical and physical characteristics of the biodiesel are given in Table 5.

In a combustion chamber, the density of the biodiesel plays an essential role since it determines the mass of the biodiesel injected into the chamber [28]. The standard density of biodiesel at 15 °C is in the range of 860–900 kg m−3. The density of the biodiesel obtained in this study is in the range of 881.6–887.5 kg m−3. These values are in the range of the standard density of biodiesel. The kinematic viscosity strongly influences the volatilization and atomization of the biodiesel upon injection in the combustion chamber. This physical property also influences the engine life. The higher viscosity enhances the fuel spray penetration, resulting in the improvement of air–fuel mixing. However, fuel with high viscosity tends to form a deposit in the engine and reduce the combustion efficiency [20, 28, 29]. Nevertheless, fuel with low viscosity may not provide sufficient lubrication in the combustion system [28]. The ASTM kinematic viscosity standard for biodiesel is 1.9–6.0 cSt (mm2 s−1), and the kinematic viscosity of the sea mango biodiesel is in the range of 2.89–3.01 cSt.

Flash point is one of the essential characteristics of biodiesel. This physical property relates to the ignition of biodiesel. The moderate value of a flash point is required for the safety of handling and storage. Since the flash point of the biodiesel produced in this study is above the minimum value of the ASTM standard, this biodiesel is safe for handling and storage for a period of time. Cetane number is an index that measures the combustion quality of diesel fuel during compression ignition [28]. This index strongly influences the performance of the engine during fuel combustion and exhaust emission. The low value of cetane number causes difficulties in the startup of the engine and, during combustion, produces noise in the engine and smokes of exhaust gas. The cetane number of biodiesel produced in this study is higher than the minimum value of the ASTM standard D6751. The compositions of fatty acids in the feedstock or raw material also have significant effect on the cetane number of the biodiesel product. If the oil contains a high percentage of saturated fatty acid, the value of cetane number of the resulting biodiesel is high. On the contrary, a low value of cetane number will be obtained if the oil contains a significant amount of unsaturated fatty acids [20, 30].

One of the crucial properties of biodiesel is the acid number. The acid number indicates the quantity of free fatty acids and mineral acids present in the biodiesel. High acid number causes corrosion problem in the engine and fuel injectors [28]. The degradation of biodiesel during storage will increase the acid number; therefore, this property can be used as a measure of biodiesel degradation. The acid number of biodiesel obtained in this experiment is in the range of 330–415 mg kg−1. The values are still in the inadmissible range, since the maximum acid number allowed in the ASTM D6751 is 500 mg kg−1.

Conclusion

In this study, the biodiesel was produced from non-edible seed oil using the subcritical methanol-water process. The sea mango seed, which contains highly toxic compounds, was used as the source of the non-edible oil. The in situ extraction and transesterification of the oil were carried out without the presence of acid or base catalyst. This process drastically reduces the production cost, since it does not require extraction and separation of the catalyst. However, the main disadvantage of this process is that the transesterification reaction must be conducted at high temperature and pressure. The maximum FAME yield of 98.58% was obtained at 200 °C, at a pressure of 40 bar and reaction time of 6 h.

References

Kouzu M, Hidaka J (2011) Transesterification of vegetable oil into biodiesel catalyzed by CaO: a review. Fuel 93:1–12

Olivares-Carrillo P, Quesada-Medina J (2011) Synthesis of biodiesel from soybean oil using supercritical methanol in a one-step catalyst-free process in batch reactor. J Supercrit Fluids 58:378–384

Mariano AP, Tomasella RC, de Oliveira LM, Contiero J, de Angelis DF (2008) Biodegradability of diesel and biodiesel blends. Afr J Biotechnol 7:1323–1328

Innocent DS, Sylvester PO, Yahaya MF, Nwadike I, Okoro LN (2013) Comparative analysis of biodiesel and petroleum diesel. IJERN 1:1–8

Szybist JP, Song J, Alam M, Boehman AL (2007) Biodiesel combustion, emissions and emission control. Fuel Process Technol 88:679–691

Idusuyi NP, Ajide OO, Abu R (2012) Biodiesel as an alternative energy resource in Southwest Nigeria. IJST 2:323–327

Moser BR (2012) Preparation of fatty acid methyl esters from hazelnut, high-oleic peanut and walnut oils and evaluation as biodiesel. Fuel 92:231–238

Kaur M, Ali A (2011) Lithium ion impregnated calcium oxide as nanocatalyst for the biodiesel production from karanja and jatropha oils. Renew Energy 36:2866–2871

Rashid U, Rehman HA, Hussain I, Ibrahim M, Haider MS (2011) Muskmelon (Cucumis melo) seed oil: a potential non-food oil source for biodiesel production. Energy 36:5632–5639

Gashaw A, Teshita A (2014) Production of biodiesel from waste cooking oil and factors affecting its formation: a review. IJRSE 3:92–98

Alptekin E, Canakci M (2011) Production of biodiesel from waste cooking oil and factors affecting its formation: a review. Fuel 90:2630–2638

Fan X, Burton R (2009) Recent development of biodiesel feedstocks and the applications of glycerol: a review. Open Fuels Energy Sci J 2:100–109

Karatay SE, Dönmez G (2011) Microbial oil production from thermophile cyanobacteria for biodiesel production. Appl Energy 88:3632–3635

Kumar A, Sharma S (2010) Non-edible oilseeds as biodiesel feedstock for meeting energy demands in India. Renew Sustain Energy Rev 15:1791–1800

Gaillard Y, Krishnamoorthy A, Bevalot F (2004) Cerbera odollam: a ‘suicide tree’ and cause of death in the state of Kerala, India. J Ethnopharmacol 95:123–126

Kansedo J, Lee KT, Bhatia S (2009) Cerbera odollam (sea mango) oil as a promising nonedible feedstock for biodiesel production. Fuel 88:1148–1150

White K, Lorenz N, Potts T, Penney WR, Babcock R, Hardison A, Canuel EA, Hestekin JA (2011) Production of biodiesel fuel from tall oil fatty acids via high temperature methanol reaction. Fuel 90:3193–3199

Li CJ, Chen L (2006) Organic chemistry in water. Chem Soc Rev 35:68–82

Liang X, Fan Q (2013) Application of sub-critical water extraction in pharmaceutical industry. MSCE 1:1–6

Gunawan F, Kurniawan A, Gunawan I, Ju YH, Ayucitra A, Soetaredjo FE, Ismadji S (2014) Synthesis of biodiesel from vegetable oils wastewater sludge by in situ subcritical methanol transesterification: process evaluation and optimization. Biomass Bioenergy 69:28–38

Bernal JM, Lozano P, Garcia-Verdugo E, Burguete MI, Sánchez-Gómez G, López-López G, Vaultier MPM, Luis SV (2012) Supercritical synthesis of biodiesel. Molecules 17:8696–8719

Glišić SB, Skala DU (2010) Phase transition at subcritical and supercritical conditions of triglycerides methanolysis. J Supercrit Fluids 54:71–80

Silva C, Colonelli TAS, Silva EA, Cabral VF, Oliveira JV, Cardozo-Filho (2014) Continuous catalyst-free production of ester from Jatropha curcas L. oil under supercritical ethanol. Braz J Chem Eng 31(3):727–735

Vieitez I, Silva C, Borges GR, Corazza FC, Oliveira JV, Grompone MA, Jachmanián I (2008) Continuous production of soybean biodiesel in supercritical ethanol–water mixtures. Energy Fuels 22:2805–2809

Abdala ACA, Colonelli TAS, Trentini CP, Oliveira JV, Cardozo-Filho L, Silva EA, Silva C (2014) Effect of additives in the reaction medium on noncatalytic ester production from used frying oil with supercritical ethanol. Energy Fuels 28:3122–3128

Pitzer KS (1982) Self-ionization of water at high-temperature and the thermodynamic properties of the ions. J Phys Chem 86:4704–4708

Sarin A (2012) Biodiesel: production and properties. RSC Publishing, Cambridge, p 170

Margaretha YY, Prasetyo HS, Ayucitra A, Ismadji S (2012) Calcium oxide from Pomacea sp. shell as a catalyst for biodiesel production. Int J Energy Environ Eng 3:33

Xue J, Grift TE, Hansen AC (2011) Effect of biodiesel on engine performances and emissions. Renew Sustain Energy Rev 15:1098–1116

Yoshiyuki K (2000) Effects of fuel cetane number and aromatics on combustion process and emissions of a direct injection diesel engine. JSAE Rev 21:469–475

Acknowledgements

The financial support from NTUST through the Joint Research Collaboration Program is highly acknowledged. The first and second authors also acknowledge the partial support of the Directorate of Higher Education (DIKTI) through the Student Creativity Research Program.

Author information

Authors and Affiliations

Contributions

JL and MBR conducted the experiments, FES performed statistical analysis, YHJ drafted the manuscript, and SI performed the experiment design and corrected the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Lie, J., Rizkiana, M.B., Soetaredjo, F.E. et al. Production of biodiesel from sea mango (Cerbera odollam) seed using in situ subcritical methanol–water under a non-catalytic process. Int J Ind Chem 9, 53–59 (2018). https://doi.org/10.1007/s40090-018-0138-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40090-018-0138-3