Abstract

Petrol frequently contains the additive methyl tertiary butyl ether (MTBE). Because of its significant health risks, MTBE pollution of surface and ground water is a severe concern for the environment. Highly porous physically activated carbons, particularly CO2-activated carbon (CO2-AC) and steam-activated carbon (Steam-AC), were obtained from date stones as potential eco-friendly adsorbents for MTBE from contaminated water. The chemical composition, microstructure, textural, and structural characteristics of adsorbents were characterised by elemental analysis, SEM, N2 sorption, XRD, and FTIR. The adsorption process evaluation based on the initial MTBE concentration, liquid-to-solid ratio, and equilibrium contact time. CO2-AC and steam-AC adsorbents have high surface areas of 819.5 m2/g, and 567.7 m2/g, respectively. At 40 °C, CO2-AC has an adsorption capability of 181.36 mg/g. The adsorption result was best fitted by the Freundlich model. The two-step intraparticle diffusion process prevailed the adsorption process, and the pseudo-second-order model presented an optimal fit for the adsorption kinetics models. Spontaneous physical adsorption was endothermic when CO2-AC adsorbs at 40 °C because ∆G was − 6.34 kJ/mol. Finally, the water quality improved and the salt content, the alkalinity, and the hardness decreased with the use of CO2-AC as an environmentally friendly adsorbent for removing MTBE from the polluted water.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

To improve fuel quality, oxygenates, such as ethers and alcohols, have taken the role of manganese and lead compounds, which are known to have harm effects on the living organisms and environment. One of the most often utilised oxygenates as gasoline additives is methyl tertiary butyl ether (MTBE), a compound produced from reaction of methanol and isobutylene. MTBE enhances octane ratings by ensuring the complete combustion of fuel. Recently, a high amount of MTBE is being used (approximately 15% of total fuel volume) because it improves fuel properties and its low price (Naser Sheykhaoleslami et al. 2016; Zhang et al. 2018; Ekinci 2021). Due to its restricted soil adsorption, high water solubility, and slowly biodegradability, MTBE readily penetrates groundwater. In 2000, both US Environmental Protection Agency (EPA) and the International Agency for Research on Cancer (IARC) categorised MTBE as a danger to humans (Hua et al. 2023). From MTBE properties, the undesirable effects on the environment have been exposed. MTBE could leak into the soil, surface water, or groundwater and pollute them. Dissolved MTBE will not degrade biologically; hence, it will build up in the ecosystem. When human exposed to MTBE, it may lead to headaches, nausea, dizziness, and irritation of the respiratory system in addition to many other types of cancer (McGregor 2006). MTBE has been identified as a contaminant that may cause cancer by EPA. The MTBE level in drinking water should be kept between 20 and 40 ppb in order to limit the toxin's potential impacts on human health and to prevent issues with taste and odour associated to water resources (USEPA 2008). Gearbox pipes, leak from gasoline storage tanks, tank spills, and truck accidents are among the primary sources of MTBE contamination. MTBE released by automobile exhaust would travel through the soil and atmosphere before ending up in underground waters. MTBE is readily absorbed by groundwater due to its high solubility in water (43,000–54,300 mg/L) and low absorption by soil (when compared to other hydrocarbons with gasoline content) (Zadaka-Amir et al. 2012; Levchuk et al. 2014).

Physico-chemical characteristics and qualities of MTBE make its removal or remediation from aquifers or groundwater difficult, costly, and time-consuming. Globally, groundwater remediation is crucial for both human health and water supply in locations where groundwater is an essential source of water supply, generally because of a lack of surface water or lakes (Hou et al. 2014, 2015; Pepino Minetti et al. 2017). MTBE removal from water is critical since it affects both human health and the environment. MTBE has been eliminated from aqueous systems using a variety of methods, including adsorption, biological treatment, air stripping, and sophisticated oxidation processes (Naser Sheykhaoleslami et al. 2016).

Adsorption is of practical and novel options that is monetarily feasible for eliminating MTBE from aqueous solutions, owing to its simplicity, reasonable operational requirements, and economic viability. Activated carbon, different zeolites, and synthetic resins are examples of porous materials that are employed as MTBE adsorbents (Ji et al. 2009; Abbasi et al. 2020).

Because of their microporosity, high surface area, versatile surface modification to adsorb specific contaminants, and renewability, solid adsorbents, particularly activated carbon, are still the most essential and beneficial adsorbents for eliminating pollutants (produced from solid agricultural waste). Furthermore, gaseous and liquid contaminants can be adsorbed by activated carbons.

Carbon precursors include peat, coal, numerous agricultural products, and wood. Due to their accessibility, sustainability, and potential for economic advantage, agricultural by-products in particular have received great interest recently in the process of making activated carbon. A large source of agricultural waste is date stones (DS), which have little economic value. Additionally, the FAO reported that Egypt is the country that produces the most dates globally. The estimated annual production is 1.5 million tonnes, or 17.7% of the estimated 7.5 million tonnes global production (Ebiad et al. 2020). DS use as a carbon source material is therefore economically advantageous. In addition, date stones are thought to be environmentally harmful waste (Sekirifa et al. 2013). Date’s main ingredients are cellulose (57%), crude fibre and ash (5%), hemicellulose (23%) and lignin (15%), with date stones accounting for roughly 10% of the fruit's overall weight.

Depending on the application, the preparation methods for activated carbon could be physical or chemical. The high-temperature pyrolysis of a carbonaceous substance in an inert atmosphere (N2, Ar, etc.) is known as carbonisation, and it is the first step in the physical process. Later, thermal activation is carried out at an appropriate temperature (700–1000 °C) using an activated agent (oxidising gas), such as water vapour, carbon dioxide, or both of them. The raw material is thermally decomposed after being impregnated with chemicals like ZnCl2, NaOH, KOH, H2SO4, and H3PO4 to achieve chemical activation.

The procedure takes place in one step at a high temperature (400–600 °C). Physical activation has the main benefit of not incorporating impurities from the activating agent, as opposed to chemical activation. As a result, the physical method is more environmentally friendly than the chemical process. In contrast to chemical activation, which can harm the pore structure, CO2 and steam activation may promote the development of meso/microporous structures and protect the biomass's natural related pore network (Heo and Park 2018; Jiang et al. 2020).

In this work, the major goal is to manufacture of physically activated carbons from date stone using steam and CO2 as an oxidising agent, and their application as adsorbents for environmentally removing MTBE from polluted water.

Materials and methods

Preparation of date carbonised (DC)

To remove any adhering pollutants, the date stones (DS) were first cleaned with deionised water, heated at 105 °C for 24 h, and then grounded and sieved to a diameter of 1–2 mm. Then, a quartz tubular reactor (450 mm length and 40 mm diameter) was placed in a horizontal heated furnace (Nabertherm, Germany) to heat 100 g of washed date stones. The sample was heated from ambient to 600 °C at a rate of 10 °C/min while being held under a flow of nitrogen (100 mL/min) for three hours. After being ground, the accumulated char was sieved.

Preparation of steam-activated carbon (Steam-AC)

30 g of the carbonised product were transferred to the horizontal tubular furnace for steam activation. The sample was heated to 900 °C at a rate of 10 °C/min under nitrogen gas (100 mL/min). When the temperature reached 900 °C, the nitrogen gas was connected to a deionised boiling water flask to produce nitrogen gas saturated with steam. Hold the steam flow for 20 min while adjusting the burn-off percentage. The tubular furnace was cooled to room temperature using a nitrogen gas flow. Activated carbon has been generated by grinding and sieving, to calculate the burn-off percentage. After steam activation, weight differences were used to calculate the yield percentages. The activation burn-off percentage was determined as follows:

Wa and Wc are the weights of carbons after and before steam activation, respectively. The burn-off was found to be 40%.

Preparation of CO2-activated carbon (CO2-AC)

30 g of the carbonised product were added to the horizontal furnace for CO2 activation. The sample was heated at a rate of 10 °C/min from room temperature to 850 °C under nitrogen flow (100 mL/min). When the temperature reached 850 °C, the flow of N2 and CO2 was alternated for 90 min at a rate of 100 mL/min, and then, the CO2 flow was turned back to N2 flow at the end of the reaction. Equation (1) was used to weight the produced activated carbon in order to calculate the burn-off percentage. A 35% burn-off was prepared. In order to conduct characterisation and adsorption evaluations, the samples were kept in a desiccator.

Adsorbent characterisation

The NOVA2000 gas sorption analyser from Quantachrome Corporation was used for evaluating N2 adsorption–desorption isotherms at − 196 °C and determine the morphology of generated activated carbons (ACs). Before starting, activated carbons were degassed under vacuum at 150 °C and 10−5 Torr to ensure a dry, spot-free surface for overnight. The adsorption isotherm relied on the correlation between the equilibrium relative pressures P/P° and the volume adsorbed (V cm3/g). The developed activated carbon conducted a thermogravimetric analysis (TGA) using a Thermo analyser [D-50] from Shimadzu, Japan, at a heating rate of 10 °C/min up to 1000 °C under nitrogen gas at a rate of 20 mL/min. Scanning electron microscopy (SEM) Field Emission Scanning Electron Microscope (ZEISS Sigma 300VP) (Carl Zeiss Microscopy Deutschland GmbH), a device with a 30 kV accelerating voltage. It was utilised for assessing the topography and surface morphology of generated activated carbons. They were enclosed with layer of gold to disperse the charge after being vacuum-dried for an entire night at roughly 105 °C. Using a Perkin-Elmer spectrum, Fourier transform infrared spectroscopies (FTIR) were carried out. One spectrometer with a range of 400–4000 cm−1. The samples were mixed with KBr in a 1:500 ratio, and then, they were compressed in a vacuum. The elemental analyser, Elementar—Vario EL cube, from Elementar Analysensysteme GmbH, examined the bulk contents of C, H, S, and N. The moisture and ash content of the manufactured ACs were measured in accordance with ASTM E 871(82) and ASTM D-1102(84) respectively. A Jenway pH metre (UK model 3510) was used to measure the supernatant's pH. The pH of the filtrate was measured after being shaken for 48 h with 0.2 g of the ACs in 25 mL of pre-boiled, distilled water. The pH readings of the obtained samples were assessed in accordance with Hassan et al. (Hassan et al. 2013).

Adsorption equilibrium studies

The MTBE adsorption capacity was measured using ASTM method D3860-98. Using drinking water, MTBE (Aldrich) was used to produce a stock solution with an initial concentration of 1000 ppm. The adsorption experiments were conducted in 50-ml DURAN bottles (SCHOTT, Germany) using 0.10 g of the produced ACs and 20 ml of the appropriate concentration of MTBE. The bottles were shaken at 250 rpm for three hours in a constant-temperature shaker bath. Three distinct temperatures (25, 35, and 40 °C) were used as the temperature ranges. The remaining adsorbates were filtered using filter sheets (Whatman No. 42) after the agitation period. 20 mL of 300 ppm MTBE solutions (pH 7.0) were combined with 0.10 g of adsorbents (adsorbent dosage: 5 g/L) and then shaken for three hours.

The kinetic investigation was then shaken for three hours at 250 rpm and 25 °C. The investigations were conducted at the specified intervals of 5, 15, 30, 45, 60, 90, 120 min. Once more, the experiments were carried out at two temperatures (35 and 40 °C).

Adsorption isotherms studied using Eight bottles containing 0.10 g of ACs and 20 mL of MTBE solution with initial diluent concentrations of (25, 50, 100, 150, 300, 600, 800, and 1000 ppm) and an initial pH of 7.0 were filled to determine the equilibrium adsorption. The bottles were then agitated by shaking at 250 rpm at 25 °C for two hours to ensure equilibrium. These investigations were also used to determine the adsorption's thermodynamic characteristics. At (35 °C and 40 °C), the same experiments were likewise conducted once again. Using a dose of prepared activated carbons of 0.1 g/20 mL.

Adsorbent dosage was studied by introduced multiple amounts of adsorbent (0.02, 0.05, 0.1, 0.15, 0.2, and 0.25 g) to 20 mL of 300 mg/L MTBE aqueous solutions and shaking for two hours at 25 °C., the impact of the ratio of solid to liquid was assessed.

The following estimates were made for the amount of MTBE removed (R %) and the adsorbed amount of MTBE per unit weight of adsorbent at the time (qt):

where W is the weight of adsorbent (g), Co is the initial MTBE concentration (mg/L), Ct is MTBE concentration at time t (mg/L) and V is the volume of solution (L).

Analytical methods

Headspace gas chromatography (HS-GC) is used to determine MTBE in an aqueous solution by extracting volatile components (such as MTBE) into the gas phase, and only the gas phase above the sample is introduced into the gas chromatographic column.

For all analyses, manual headspace apparatus (chromatec, model DRP 4, Russia) used to extract MTBE (as volatile component) from aqueous solution. Just prior to analysis, 5.0 mL of the aqueous solution was added in a 20-ml glass vial then the vial is sealed and heated to 70 °C with agitation for 20 min. After that, the MTBE was moved into gas phase above the aqueous sample then the gas-phase sample is removed from either the headspace vial with 1 mL gas-tight syringe, and the sample is introduced into the Gas Chromatograph (GC) model Crystal 9000 equipped with Flame Ionisation Detector (FID) was calibrated prior the analysis in the range of concentrations used in the batch investigations (25–1000 mg/L).

GC apparatus used a DB-1 fused silica capillary gas chromatography column (60 m length, 0.25 μm film thickness, and 0.25 mm internal diameter). Nitrogen gas was used as the carrier gas with a constant flows rate of 2 mL/min. The instrument setup was operated isothermally at a temperature of 50 °C for five minutes. Manual gas-tight syringe was injected gas-phase sample into the GC (fitted with a programmable temperature injector PTV), the PTV was set to 200 °C, split mode was 1:20, and the volatilised contents were taken. The MTBE peak has a retention time of 2.5 min. The GC/FID system was calibrated on a daily basis before the samples were analysed. To confirm the accuracy of the analysis, each headspace sample had at least three distinct analyses. A sample's results had a relative standard deviation of less than 3%.

To establish how the treatment process affected the quality of the water, anions and cations were measured according to ASTM D-4327 and D-6919, respectively. High-capacity columns (AS23 and CS12A) for anions and cations, respectively, are installed in the Thermo-DionexTM ICS-6000 Capillary HPICTM System. To assess the effectiveness of the suggested technique for treating the material, physical parameters such as density, specific gravity, and pH were evaluated both before and after treatment. The analysis of water samples was performed at the central analytical labs of the Egyptian Petroleum Research Institute (EPRI-central labs). Ion chromatography was used to determine anions and cations in accordance with ASTM D-4327 and 6919, respectively. DionexTM ICS-6000 Capillary HPICTM System (AS9 and CS12, respectively) for anions and cations. Atomic absorption spectrophotometer Analytik Jena Zeenit 700 p was used to assess the concentration of heavy metals by using the Atomic absorption method in accordance with ASTM D-4691.

Total Suspended Solids (T.S.S) and Total Dissolved Solids (T.D.S) were obtained according to ASTM D5907 Standard Test Methods for Filterable Matter (Total Dissolved Solids) and Nonfilterable Matter (Total Suspended Solids) in Water. Using a digital conductivity metre WTW 330I, in accordance with ASTM D-1125, conductivity and resistivity were assessed. As per ASTM D-1429, density and specific gravity were calculated. Using a combination glass electrode and a Mettler Toledo pH metre, pH was measured in accordance with ASTM D-1293. According to ASTM D-3875, alkaline species (CO3, OH, and HCO3) were measured. Using a digital turbidity metre model HACH 2100, the turbidity of water was measured in accordance with ASTM D1889-00.

Results and discussion

Adsorbent characterization

Elemental analysis and scanning electron microscopy (SEM)

The prepared activated carbons were characterised by elemental analysis to measure the per cent of carbon, hydrogen, nitrogen, and oxygen. Comparing the elemental analysis results before and after the preparation can confirm the successful preparation of the activated carbons. Scanning electron microscopy was used to study the surface of the prepared samples.

The results of the elemental analysis of date stone (DS), DC, Steam-AC, and CO2-AC are shown in Table 1. It is clear that Date stone (DS) has high content of oxygen, hydrogen, and nitrogen compared to DC, Steam-AC, and CO2-AC, Also having less carbon than the prepared adsorbents. This is due to the dehydration effect and polymeric deformation as a result of the activation by steam and carbon dioxide. The physical activation lowered H/C ratio from 0.330 (DS) to 0.008 (Steam-AC). The O/C ratio decreased as well, from 0.836 (DS) to 0.160 (CO2-AC) this results are consistent with previous studies (Martin-Martinez et al. 2018).

SEM pictures of the Steam-AC (a, b) and CO2-AC (c, d) adsorbents are shown in Fig. 1. SEM images of the activated carbon's surface revealed that it has irregular structures with cracks and crevices, as well as many grains of all sizes in sizable holes. These images showed amorphous and heterogeneous structures of the activated carbons. The development of pores was observed in Steam-AC and CO2-AC samples suggesting a high surface area and supporting the information provided by the surface area and porosity analysis. On the surface of date stone-activated carbon, the physical activation method (steam and CO2 activation) efficiently produced a substantial surface area with well-developed pores of various shapes and sizes. They are viewed as channels by the microporous network as well (Franciski et al. 2018). As mentioned before, the pores on the surface of the carbon were probably due to the activation process and to the catalytic effect of the steam and CO2 on the pyrolytic decomposition. SEM image (c, d) for CO2-AC sample showed many orderly pores over the surface with small size as compared to Steam-AC sample.

Textural analysis

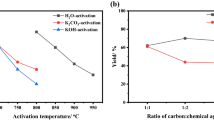

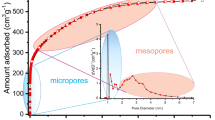

The pore structures and the surface areas of DC, Steam-AC, and CO2-AC were determined using the N2 adsorption/desorption technique, and the results are presented in Table 2 and Fig. 2. The adsorption isotherms of the DC and Steam-AC were classified according to the IUPAC as a combination of type IV and I (Thommes et al. 2015). Low relative pressures resulted in a fast rise in volume, which revealed type I isotherm-like adsorption in micropores. Type IV with the H4 hysteresis loop showed monolayer-multilayer adsorption followed by capillary condensation in tiny slit-like pores at moderate and high relative pressures, as depicted in Fig. 2.

These demonstrate that a mixture of micropores and mesopores were formed in the adsorbent for the DC and Steam-AC systems. The sample's CO2-AC isotherm is classified as type I (a), yet it displays a steep uptake at very low relative pressures due to micropore filling and a plateau or horizontal to the P/P° axis at medium and high pressures due to minute levels of nitrogen adsorption. This shows that the average width of the micropores is (< 1 nm) in the CO2-AC adsorbent.

A linear plot was used to obtain the Brunauer–Emmett–Teller (BET) equation's specific surface area SBET (m2/g), and a t-plot was used to get the micropore volume (Vmic) (cc/g) and the micropore surface area (Smic) (m2/g). The volume of N2 at saturation at p/p° ≈ 0.95 corresponds to the total pore volume (VT) (cc/g). The following equation could be used to determine the average pore radius (r–, nm):

The CO2-AC sample's SBET and Smic were 819.5 m2/g and 799.1 m2/g, respectively, based on the data analysis in Table 2. (i) 97.5% of the total surface area of CO2-AC sample was made up of micropores, which indicates that they predominate. Also, the (VT) and (Vmic) values were 0.3611 cc/g and 0.3113 cc/g, respectively. Additionally, the (Vmic) accounts for 86.2% of the total volume of pores. (ii) The average pore radius of the CO2-AC adsorbent is 0.88 nm. The bulk of pores are in the micropore region, according to the CO2-AC pore size distribution. (iv) The (SBET) and (Smic) values for the Steam-AC sample were 567.7 m2/g and 463.1 m2/g, respectively, with the surface area of the micropores making up 81.6% of the total surface area. Also, the (VT) and (Vmic) values were 0.3475 cc/g and 0.2343 cc/g, respectively. The Vmic also accounts for 67.4% of the total volume. (v) The average pore radius of the Steam-AC adsorbent is 1.22 nm, somewhat greater than that of the CO2-AC adsorbent. (vi) It is clear that steam activation causes microporosity to wide significantly more than carbon dioxide activation does. Because of this, CO2-AC has a lower outer surface (Smes) (m2/g) than Steam-AC, where the (Smes) of Steam-AC and CO2-AC were 104.6 m2/g and 20.4 m2/g respectively. The bulks of the pores in the steam-activated adsorbent, known as Steam-AC, are also in the micropore range according to the pore size distribution and the values of SBET, Smic, and Vmic are lower than CO2-AC (Molina-Sabio et al. 1996).

Structural characteristics

The characteristic structures of the activated carbons were investigated via XRD and FTIR. XRD is used to determine the crystallinity of the material and the phases of the structures. FTIR investigate the functional groups by vibration of the bonds of the functional groups.

Steam-AC sample diffractograms are shown in Fig. 3a. The XRD pattern of Steam-AC shows broad peaks and absence of sharp peak that revealed predominantly amorphous structure, where it is an advantageous property for well-defined porous adsorbents (Reddy et al. 2014). A strong broad peak centred at 25° and a weak broad peak centred at 44°. Here, small aromatic units arranged in the random order reflected the peak at 25° and attributed to the (002) reflection of a graphitic‒type lattice. In addition, the superposition of the (100) and (101) of a graphitic-type carbon structure reflected a weak peak centred around 44°. This means that the prepared activated carbon samples have a small degree of graphitisation (S. Kushwaha, G. Sreelatha 2013). Also, the broad peaks confirmed that the Steam-Ac has microporous structure and can be classified as non-graphitised carbon type (Tongpoothorn et al. 2010).

The FTIR spectra of DC, Steam-AC, and CO2-AC are shown in Fig. 3b. According to Saleh et al. (2017) and Eid (2018), all samples displayed a broad band at 3440 cm−1, which is due to the hydroxyl functional groups'–OH stretching vibration mode. The C-H stretching vibration for –CH2– and –CH3 was responsible for the two distinct peaks at 2853 and 2923 cm−1.The broadband at 1600 cm−1 was caused by the C=C stretching vibration of the keto-enol group and the aromatic quinone ring (László et al. 1997). The bands at 1450, 1400, and 1385 cm−1 were attributed to C–O stretching in carboxylate groups. In addition, the band at 1385 cm−1 is linked to the –CH3 deformation (Yang and Lua 2003; Ebiad et al. 2020). The appearance of new bands for steam-AC and CO2-AC at 1745 and 1720 cm−1 indicate the C=O stretching vibration in the carboxylic group, lactones, and anhydride. The appearance of the C=O is due to oxidising treatment of the carbon with steam and CO2, and this confirms the successful physical activation of the carbon samples. Bands between 850 and 440 cm−1 are thought to be responsible for alkene vibrations. Also, the C–O stretching in groups of acids, alcohols, phenols, ethers, and/or esters has a bandwidth between 1300 and 900 cm−1, with maxima at 1100 and 1046 cm−1 (Köseoʇlu and Akmil-Başar 2015). In addition, many weak bands with variable degrees of O–H group substitution or the out-of-plane bending mode of the C–H bending appeared in the 600–900 cm−1 range (Haggag et al. 2021). The bands at 2923 cm−1, 1428 cm−1, and 878 cm−1 are due to the aliphatic C–H stretching vibration, bending vibration, and out-of-plane bending vibration, respectively. At 620 cm−1, aromatic bonds (O–H) exhibit out-of-plane bending in all samples (Ma et al. 2020). Additionally, activated carbon samples have a band at 1400 cm−1 that might be brought on by bending (O–H) vibrations.

Surface chemistry

Surface acidity and basicity are significant factors in establishing the chemistry of the carbon adsorbent surface. The chemical and physical properties of DC, Steam-AC, and CO2-AC are listed in Table 3. The pH values of CO2-AC and steam-AC are 10.17 and 8.24, respectively. The majority of the important functional groups are present on these activated carbon surfaces (Steam-AC and CO2-AC) compared with the non-activated DC sample. Steam activation has a higher pH than carbon dioxide activation, because steam treatment only slightly decreases the content of acidic groups while somewhat increasing the content of basic groups (Zhang et al. 2014). Physically activated steam-AC and CO2-AC has high pHPZC values of 9.72 and 8.02, respectively, while DC sample has pHPZC of 6.38. Steam-AC and CO2-AC belong to the H-carbon type of basic activated carbon (Mondal et al. 2022). Therefore, the main functional groups are phenolic and lactonic.

Adsorption of MTBE from contaminated water

Effect of adsorbent dosage

The influence of activated carbon dosage on MTBE removal using Steam-AC sample, we introduced multiple amounts of adsorbent (0.02, 0.05, 0.1, 0.15, 0.2, and 0.25 g) to 20 mL of 300 mg/L MTBE aqueous solutions and shaking for two hours at 25 °C. We investigate the impact of the liquid-to-solid ratio (S/L ratio) is an important parameter affecting MTBE removal. Figure 4 demonstrates the amount of MTBE removal (R %) increases as the Steam-AC adsorbent dose increases. In case of Steam-AC, removal percentage of MTBE rose from 66% at 1 g/L to 84% at 5 g/L. Also, MTBE uptake (mg/g) decreased from 197.7 to 20.9 mg/g when the dosage increased from 1 to 12.5 g/L. This could be explained by an increase in the surface areas available for adsorption (as result of increase of adsorbent dosage) and increase the availability of adsorption sites (Husein 2013). The removal of MTBE efficiency percentage reached a plateau at 5 g/L of Steam-AC dosage and increasing the Steam-AC above 5 g/L did not affected the efficiency of the adsorption. Additionally, the dosage of Steam-AC adsorbent was increased causes some adsorption sites remained unsaturated through the removal process. Another potential cause is the high adsorbent dose-induced interparticle interactions, such as aggregation, which will reduce the overall surface area of the adsorbent and lengthen the diffusional path (Vijayalakshmi et al. 2016). It can be seen that the Steam-AC sample had an optimal MTBE removal capacity of 84% at a dose of adsorbent 5 g/L.

Adsorption kinetics of MTBE

Kinetic study provides information about the adsorption mechanism; it describes the rate of adsorbate uptake onto activated carbon and equilibrium time. The kinetic profiles of MTBE adsorption onto Steam-AC and CO2-AC adsorbents are shown in Fig. 5 (upper panel) at various contact periods and temperatures (25, 35, and 40 °C). As shown in figure, the rate of adsorption of MTBE rose rapidly for all at initial of removal process before slowing down and reaching equilibrium. At the three studied temperatures, CO2-AC adsorption reached equilibrium within the first 45 min, while Steam-AC grows more slowly and reaches a plateau after 90 min.

Between 0 and 45 min, the adsorption increased noticeably due to availability of free active sites on the adsorbent surface and high the MTBE content. After 45 min, there are only a very limited number of free active sites on the adsorbent surface, which is why we saw a gradual increase MTBE removal. The rapid kinetics had significant practical and financial relevance for CO2-AC and Steam-AC adsorbents for the high MTBE contamination because it allowed for reduced reactor capacities, assuring great efficiency and economy(Liadi et al. 2018).

The adsorption mechanism can be studied using a variety of adsorption kinetic models. According to Lagergren (Zhang et al. 2018), the pseudo-first-order (PFO) model is as follows:

where k1 is the rate constant of the pseudo-first-order process (min−1), and (qt) and (qe) are the amounts of MTBE adsorbed at time t and equilibrium (mg/g), respectively. The slope and intercept of the logarithmic plot of (qe–qt) against t were used to determine k1 and qe. The PFO kinetic model did not effectively account for the experimental data, as seen by the substantial discrepancy in (qe) between the estimated and resulted values. Table 4 provides a summary of the MTBE adsorption kinetic parameters, with an R2 correlation coefficient for the pseudo-first-order kinetic model of < 0.96.

The pseudo-second-order (PSO) kinetic model of McKay and Ho is represented as follows (Inal et al. 2009):

k2 is the pseudo-second-order rate constant (g/mg min) and qt and qe2 are the amounts of MTBE adsorbed at time t and equilibrium (mg/g), respectively. The slope and intercept of the plot of (t/qt) versus (t) can be used to empirically derive the PSO rate constant (k2) (Fig. 5, lower panel), and for all concentrations at all three temperatures, a very high correlation coefficient of > 0.99 was achieved. As a result, the estimated values of qe2 and the resulted (qe) measurements are most consistent with this kinetic model. These findings imply that the MTBE adsorption process on Steam-AC and CO2-AC follow the pseudo-second-order (PSO) model (Abbasi et al. 2020). This referring that, the adsorption process is controlled by chemisorption which involves valency forces through sharing (covalent force) or exchange of electron between sorbent and sorbate. The (qe) was generally 47.17, 52.08, and 53.48 mg/g at 25, 35, and 40 °C, respectively for MTBE adsorption over Steam-AC with PSO applied. We noticed that as the temperature rose, the adsorption capacity did too. In addition, the qe values for MTBE adsorption over CO2-AC were 57.8, 57.8, and 58.48 mg/g at 25, 35, and 40 °C, respectively. As a result of its larger surface area and predominance of micropores, CO2-AC exhibits a higher adsorption rate than Steam-AC.

Weber and Morris first presented the intraparticle diffusion model. They also asserted that the removal during adsorption (qt) is proportional to (t1/2) (Ekinci 2021).

(qt) (mg/g) is the amounts of MTBE adsorbed at time (t). The (Kid) (mg/g min0.5) is the intraparticle rate constant, and (C) (mg/g) is a constant related to the thickness of the boundary layer. The value of kid was obtained from the slope of a straight line and (C) is the intercept of plot (qt) versus (t0.5). With the values of the (kid) and (C) constants displayed in Table 4 and Fig. 6 (upper panel), it was discovered that the adsorption process consists of two steps. The second segment of the line, which is more gradual, represents progressive adsorption, which is the diffusion-controlled adsorption process occurring inside the particle. The sharper line represents external surface adsorption. The absence of a line across the origin suggested that intraparticle diffusion is not the rate-controlling step in MTBE removal. Instead, the impact of film diffusion is apparent (Chen et al. 2010; Sakr et al. 2023).

It is essential to differentiate between film and particle diffusion for design concepts. The Boyd kinetic equation (Chen et al. 2010) was used to determine which step of the adsorption process was the slowest.

where F is the fractional achievement of equilibrium at a time (t) and B(t) is a mathematical function of F.

Here, (qe) and (qt) denote, respectively, the equilibrium and time-at-time adsorption concentrations. Reichenberg (Haggag et al. 2021) came to the subsequent estimates:

The data in Table 4 can both be examined for linearity by graphing (B(t)) versus time (t), as seen in the lower panel of Fig. 6. If the plots are linear and cross the origin, particle-diffusion mechanisms govern the process of adsorption. The data demonstrate that film diffusion regulates the MTBE adsorption process on the Steam-AC and CO2-AC adsorbents at 25, 35, and 40 °C. As a result of the plot lines not commencing at the beginning (Chen et al. 2010). External mass transfer predominantly controls the rate-limiting process for the analysed solute concentration range (Kumar et al. 2005).

Adsorption isotherms

When determining the maximum adsorption capacity, adsorption isotherms have played a significant role. We plotted the equilibrium concentration (Ce) (mg/L) versus the amount of MTBE that was adsorbed onto Steam-AC and CO2-AC adsorbents at three different temperatures (25, 35, and 40 °C), as seen in the top panel of Fig. 7. The adsorption isotherm of Steam-AC and CO2-AC adsorbents is classified as H-type based on the isotherm's form, curves, and Giles classification. H type refers to an excess of basic surface groups that, according to Mondal et al. (2022), causes substantial MTBE adsorption at higher pH levels without any competition. In this model, adsorption starts out rather fast and only gradually achieves equilibrium at high concentrations.

The adsorption data were analysed using the Freundlich, Langmuir, Dubinin–Radushkevich (D–R), and Temkin isotherm equations. The isotherm equation based on the Langmuir adsorption model was most frequently used. The Langmuir isotherm equation is defined linearly in Dibaji et al. (2023).

The monolayer capacity is (qm) (mg/g), the Langmuir constant is (b) (L/mg), the quantity adsorbed at equilibrium is (qe) (mg/g), and the equilibrium concentration is (Ce) (mg/L). The maximum adsorption capacity (qm), (mg/g) was calculated using the slope of the plot of (Ce/qe) versus (Ce). As shown in Table 5, a lower correlation value (R2) of less than 0.95 indicates that Langmuir's model does not adequately fit linear data.

Table 5's lower correlation coefficient (R2) values, which ranged from 0.6176 to 0.7695, show that the Steam-AC adsorbent is not a good candidate for MTBE adsorption. The affinity between the adsorbent and adsorbate is further demonstrated by the Langmuir adsorption constant (b). The low heat of adsorption capacity is shown by the negligibly tiny amount of b results (0.004–0.009 L/mg) (Pongkua et al. 2020).

The equilibrium parameter (RL), a dimensionless constant, can be used to set the fundamental characteristics of the Langmuir isotherm and is expressed as follows:

where (Co) is the highest initial MTBE concentration in the solution (mg/L), (RL) is a predictor of an isotherm's favourability. According to Khan et al. (2010), (RL) > 1 implies an undesired adsorption, RL = 1 denotes a linear adsorption, 0 < (RL) < 1 denotes a favourable adsorption, and RL) = 0 denotes an irreversible adsorption. The (RL) values for the adsorption of MTBE on Steam-AC and CO2-AC adsorbents reached 0.0299 at 40 °C (Table 5). This highlights how the MTBE adsorption process is efficient by the activated carbons (Steam-AC and CO2-AC adsorbents).

According to the Freundlich model, adsorption occurs on an adsorbent surface, which is heterogeneous in nature and thereafter, a multilayer coverage over the surface gets formed. In this case, adsorption active sites have different energy values. Thus, distribution of adsorption over the surface is non uniform. Hence, active adsorption centres associated with maximum energy adsorbs the molecules first and subsequently for the centres with less and less energy (Debnath and Das 2023).

The Freundlich isotherm is generated by the assumption that the heat of adsorption is dispersed unevenly along the surface of a heterogeneous surface (Dehghani Kiadehi et al. 2017).

The (KF) (mg/g) and (n) is the Freundlich constants relating to adsorption intensity and adsorption capacity and (qe) is the quantity of MTBE sorbed at equilibrium (mg/g) (Ce) is the liquid's equilibrium solute amount (mg/L).

The Freundlich isotherm has the following linear expression:

where (kF) (L/mg), the equilibrium constant, is related to the adsorption capacity. Here, the surface heterogeneity factor (1/n) could be investigated the adsorbent-adsorbate interaction intensity. When 1/n value lies between 0 < (1/n) < 1, it indicates favourable adsorption. Further, if its value is close to 0, the surface can be more heterogeneous in nature. Again if the value is (n) < 1, the process is said to be chemical, whereas it would be physical adsorption if (n) > 1 (Zhang et al. 2005; Debnath and Das 2023).

The Freundlich constants n and KF were determined from the slope and intercept of a line drawn between (log qe) and (log Ce). Table 5 shows correlation coefficients as well as the Freundlich constants KF and n. According to the high values of the correlation coefficient (R2), which for CO2-AC adsorbent at 40 °C reached 0.9949 and (R2) for Steam-AC at 35 °C is 0.9889 (Fig. 7 lower panel), the prepared activated carbons exhibited correlation coefficient values of (R2) > 0.95. These high values of correlation coefficient (R2) indicate the Freundlich model better goodness of fit than Langmuir isotherm model. Hence, it confirms that multilayer adsorption of MTBE occur on the CO2-AC and Steam-AC surfaces.

According to Table 5, the values of the slope (1/n) have been found as 0.876 and 0651 for Steam-AC and CO2-AC at 40 °C, respectively, which lies in the range of 0 < (1/n) < 1, and hence, it reflects the favourable adsorptive removal of MTBE by physical-activated carbons. Also, as the values of (n) are equal to 1.142 and 1.536 for Steam-AC and CO2-AC at 40 °C, respectively, it confirms the physical adsorption of MTBE on the Steam-AC and CO2-AC adsorbents (Debnath and Das 2023).

(KF) constant value increases from 7.002 to 9.397 mg/g for CO2-AC sample with increase the temperature of the adsorption process from 25 to 40 °C. These reflect the adsorbent's capacity to bind to the adsorbate increase with rise the temperature (Aivalioti et al. 2012).

The Temkin isotherm give useful information about the adsorption mechanism and hence, adsorbent–adsorbate interactions. Temkin model assumes that the adsorbent-adsorbate interactions lead to linear decrease in the heat of adsorption of all the molecules in the layer with surface coverage. Also, the adsorption is characterised by a uniform distribution of binding energies, up to some maximum binding energy (Mall et al. 2005; Haggag et al. 2021).

The Temkin isotherm equation stats that:

This is linearisable as:

(b) is related to heat of adsorption (J/mol), (B1) is a the differential surface capacity, (KT) is the equilibrium binding constant (L/mol), and ® is the universal gas constant (8.314 J/mol K). The slope and intercept of the Ln Ce versus qe. Plot were used to calculate the Temkin isotherm constants (KT) and (B1).

According to Table 5, the interaction between the adsorbate and adsorbent causes the heat of MTBE adsorption (b) to match the amount of MTBE covering the produced sample. For CO2-AC, as the temperature rose from 298 to 313 K, (b) values slightly increased from 0.0828 to 0.0835 kJ/mol. These indicate that the heat of MTBE adsorption onto the surface of CO2-AC was hence endothermic and favoured at a higher temperature (Hassan 2019). The correlation coefficient R2 ranges from 0.8591 to 0.9135 for CO2-AC. The Temkin isotherm equation typically offers a poor match to the Freundlich isotherm.

To determine whether the adsorption was chemical or physical, the Dubinin–Radushkevich (D–R) isotherm was used. The equilibrium values were then determined using the D–R Equation (Ekinci 2021). Equation is used to illustrate the D–R model's linearised version.

where (β) is the activity coefficient in relation to mean adsorption energy (mol2/J2) and (ɛ) is the Polanyi potential. Here, the Polanyi potential can be created using Eq. (19) (Foo and Hameed 2012).

Equation (19) can be used for calculating the mean adsorption energy, E (kJ/mol).

The values of the D–R constants are shown in Table 5. The correlation coefficient (R2) values for the Steam-AC and CO2-AC adsorbents ranged from 0.4721 to 0.5846. According to this, the D-R model was less fit than the Freundlich model. The adsorption potential, which is independent of temperature, is determined by the nature of the adsorbate and adsorbent. It was generally known that the Freundlich and Langmuir isotherms do not establish the adsorption mechanism (Wu et al. 2007).

When the free energy (E) in the D-R isotherm range between 8 and 16 kJ/mol, it indicates that the working mechanism is the chemical ion-exchange mechanism of adsorption. However, when the (E) value was < 8 kJ/mol, physical adsorption was taken into consideration. For studied activated carbons samples, the adsorption energies (E) ranged from 0.5 to 2.236 kJ/mol. These results demonstrate that MTBE is adsorbed onto the Steam-AC and CO2-AC via the physical adsorption process.

We compared our data to various adsorbents in literature, Table 6. The MTBE adsorption on physical-activated carbons, specifically CO2-AC and Steam-AC adsorbents, has higher values.

Adsorption thermodynamic parameters

The following equations were used to determine thermodynamic parameters such as enthalpy (∆H), entropy (∆S), and Gibbs free energy (∆G):

where (Cs) is the amount of MTBE adsorbed on the prepared samples per litre of the solution (mg/L) and Kd is the adsorption distribution coefficient. (Ce) is the equilibrium concentration of MTBE (mg/L). R is the gas constant (8.314 J/mol K), and (T) is the temperature in kelvin unit. The slope and intercept of Van't Hoff plots of (1/T) versus (ln Kd) were used to derive ∆H and ∆S. The thermodynamic properties presented in Table 7 make it abundantly evident that the CO2-AC adsorbent has the highest adsorption capacity. The negative (∆G) values confirm that the MTBE adsorption is spontaneous. The change in free energy for the MTBE adsorption by Steam-AC and CO2-AC adsorbents can be categorised as a physisorption process, with this process's change in free energy falling between − 4.45 and − 6.34 kJ mol−1(Ebiad et al. 2020; Masod et al. 2023).

According to earlier research (Ebiad et al. 2020), (∆G) for physisorption varies between − 20 and 0 (kJ mol−1) while it range between − 80 and − 400 (kJ mol−1) for chemisorption. The Steam-AC and CO2-AC positive (∆H) values (22.01 and 29.75 kJ/mol) indicate an endothermic MTBE adsorption process. Steam-AC and CO2-AC adsorbents have positive (∆S) values of 0.115 J/mole K and 0.084 J/mole K, respectively. These demonstrate an increase in the degree of freedom of the adsorbed species at the solid-solution interface. Because of increasing the freedom, the activation energy barrier is broken, mobility is increased, and the intraparticle diffusion rate is subsequently increased (Mahdavian and Raouf 2010; Khoshand et al. 2018).

Physico-chemical properties of the decontaminated water

Table 8 lists the results of analyses performed on water samples both before and after CO2-AC treatment. It can be shown that employing CO2-AC adsorbent to remove MTBE from water contaminated with 50 ppm of MTBE as a starting concentration results in a minor decrease (7.31%) in T.D.S content. Additionally, when MTBE was removed from water contaminated with 500 ppm of MTBE using CO2-AC adsorbent, the TDS content was decreased by 19.83%.

Additionally, reductions in alkalinity of 72.22% and 71.09%, as well as a decrease in water hardness of 11.49% and 13.83%, were found. Thus, after using CO2-AC as an environmentally friendly adsorbent to remove MTBE from contaminated water, water quality has improved and shows lower salt content, alkalinity, and hardness.

Conclusion

The successful preparation of highly porous physically activated carbons (ACs), specifically CO2-activated carbon (CO2-AC) and Steam-activated carbon (Steam-AC), from date stones were accompanied by burn rates of approximately 33% and 40%, respectively. To remove MTBE from contaminated water via environmentally feasible processes, CO2-AC and Steam-AC were used for the adsorption of MTBE from polluted drinking water. The produced ACs have a high surface area (819.5 m2/g for CO2-AC and 567.7 m2/g for Steam-AC) and pore radii between 0.88 and 1.22 nm. The prepared ACs' microstructure revealed that they have well-developed pores. According to the kinetics data of the adsorption process, a pseudo-second-order model best fits the adsorption mechanism. The experimental equilibrium adsorption results were fitted using the Dubinin–Radushkevich (D–R) isotherm model, Temkin, Freundlich, and Langmuir. The outcomes of the MTBE adsorption onto Steam-AC and CO2-AC were best explained by the Freundlich model with favourable adsorption. For CO2-AC and Steam-AC, the maximal adsorption capacities at 40 °C were 181.36 mg/g and 149.08 mg/g, respectively. The estimated thermodynamic parameters (∆G, ∆H, and ∆S) demonstrated that the prepared ACs' spontaneously adsorb MTBE as confirmed by ∆G's negative values. Additionally, it is implied that the adsorption process is endothermic by positive enthalpy values. Greater distribution (randomness) at the solid/solution interface as demonstrated by positive values of entropy, speeds up the adsorption process. Finally, using CO2-AC as an environmentally friendly adsorbent to remove MTBE from contaminated water, improve the quality of the treated water as shown by lower salt content, alkalinity, and hardness of the treated water.

References

Abbasi F, Samaei MR, Azhdarpoor A et al (2020) Removal, optimization and kinetic modeling of high concentration of methyl tertiary butyl ether from aqueous solutions using copper oxide nanoparticles and hydrogen peroxide. Desalin Water Treat 181:278–288. https://doi.org/10.5004/dwt.2020.25032

Abu-Lail L, Bergendahl JA, Thompson RW (2010) Adsorption of methyl tertiary butyl ether on granular zeolites: Batch and column studies. J Hazard Mater 178:363–369. https://doi.org/10.1016/j.jhazmat.2010.01.088

Aivalioti M, Pothoulaki D, Papoulias P, Gidarakos E (2012) Removal of BTEX, MTBE and TAME from aqueous solutions by adsorption onto raw and thermally treated lignite. J Hazard Mater 207–208:136–146. https://doi.org/10.1016/j.jhazmat.2011.04.084

Chen DZ, Zhang JX, Chen JM (2010) Adsorption of methyl tert-butyl ether using granular activated carbon: equilibrium and kinetic analysis. Int J Environ Sci Technol 7:235–242. https://doi.org/10.1007/BF03326133

Debnath S, Das R (2023) Strong adsorption of CV dye by Ni ferrite nanoparticles for waste water purification: fits well the pseudo second order kinetic and Freundlich isotherm model. Ceram Int 49:16199–16215. https://doi.org/10.1016/j.ceramint.2023.01.218

Dehghani Kiadehi A, Ebadi A, Aghaeinejad-Meybodi A (2017) Removal of methyl tert-butyl ether (MTBE) from aqueous medium in the presence of nano-perfluorooctyl alumina (PFOAL): experimental study of adsorption and catalytic ozonation processes. Sep Purif Technol 182:238–246. https://doi.org/10.1016/j.seppur.2017.03.039

Dibaji Y, Zilouei H, Bazarganipoor M (2023) Removal of MTBE from aqueous solution using reduced graphene oxide/Fe3O4 nanocomposite. Environ Nanotechnol Monit Manag 20:100842. https://doi.org/10.1016/j.enmm.2023.100842

Ebiad MA, Abd El-Hafiz DR, Masod MB (2020) β-FeOOH/C nanocomposite for elemental mercury removal as a new approach to environmental and natural gas processes. J Nat Gas Sci Eng. https://doi.org/10.1016/j.jngse.2020.103383

Eid ME (2018) Polyethylenimine-functionalized magnetic amorphous carbon fabricated from oil palm leaves as a novel adsorbent for Hg (II) from aqueous solutions. Egypt J Pet 27:1051–1060. https://doi.org/10.1016/j.ejpe.2018.03.007

Ekinci EK (2021) Mesoporous magnesia sorbent for removal of organic contaminant methyl tert-butyl ether (MTBE) from water. Sep Sci Technol 00:1–11. https://doi.org/10.1080/01496395.2021.1960861

Foo KY, Hameed BH (2012) Factors affecting the carbon yield and adsorption capability of the mangosteen peel activated carbon prepared by microwave assisted K2CO3 activation. Chem Eng J 180:66–74. https://doi.org/10.1016/j.cej.2011.11.002

Franciski MA, Peres EC, Godinho M et al (2018) Development of CO2 activated biochar from solid wastes of a beer industry and its application for methylene blue adsorption. Waste Manag 78:630–638. https://doi.org/10.1016/j.wasman.2018.06.040

Ghadiri SK, Nabizadeh R, Mahvi AH et al (2010) Methyl tert-butyl ether adsorption on surfactant modified natural zeolites. Iran J Environ Heal Sci Eng 7:241–252

Haggag EA, Masod MB, Abdelsamad AA et al (2021) Kinetic studies on the adsorption of uranium on a mesoporous impregnated activated carbon. Egypt J Chem 64:1371–1385. https://doi.org/10.21608/EJCHEM.2020.50611.3039

Hassan AF (2019) Synthesis of carbon nano-onion embedded metal–organic frameworks as an efficient adsorbent for cadmium ions: kinetic and thermodynamic studies. Environ Sci Pollut Res 26:24099–24111. https://doi.org/10.1007/s11356-019-05581-5

Hassan AF, Youssef AM, Priecel P (2013) Removal of deltamethrin insecticide over highly porous activated carbon prepared from pistachio nutshells. Carbon Lett 14:234–242. https://doi.org/10.5714/CL.2013.14.4.234

Heo YJ, Park SJ (2018) H2O2/steam activation as an eco-friendly and efficient top-down approach to enhancing porosity on carbonaceous materials: the effect of inevitable oxygen functionalities on CO2 capture. Green Chem 20:5224–5234. https://doi.org/10.1039/c8gc02570c

Hou D, O’Connor D, Al-Tabbaa A (2014) Comparing the adoption of contaminated land remediation technologies in the United States, United Kingdom, and China. Remediat J 25:33–51. https://doi.org/10.1002/rem.21413

Hou D, Al-Tabbaa A, Hellings J (2015) Sustainable site clean-up from megaprojects: lessons from London 2012. Proc Inst Civ Eng Eng Sustain 168:61–70. https://doi.org/10.1680/ensu.14.00025

Hua T, Feng J, Li S, Yan W (2023) A general review on the application of adsorption and oxidation combined processes on methyl tert-butyl ether removal. Int J Environ Sci Technol. https://doi.org/10.1007/s13762-023-04888-8

Hung HW, Lin TF (2006) Adsorption of MTBE from contaminated water by carbonaceous resins and mordenite zeolite. J Hazard Mater 135:210–217. https://doi.org/10.1016/j.jhazmat.2005.11.050

Hung HW, Lin TF, Baus C et al (2005) Competitive and hindering effects of natural organic matter on the adsorption of MTBE onto activated carbons and zeolites. Environ Technol 26:1371–1382. https://doi.org/10.1080/09593332608618607

Husein DZ (2013) Adsorption and removal of mercury ions from aqueous solution using raw and chemically modified Egyptian mandarin peel using raw and chemically modified Egyptian mandarin peel. Desalin Water Treat 51:6761–6769. https://doi.org/10.1080/19443994.2013.801793

Inal F, Yetgin S, Aksu GT et al (2009) Activated carbon adsorption of fuel oxygenates MTBE and ETBE from water. Water Air Soil Pollut 204:155–163. https://doi.org/10.1007/s11270-009-0034-8

Ji B, Shao F, Hu G et al (2009) Adsorption of methyl tert-butyl ether (MTBE) from aqueous solution by porous polymeric adsorbents. J Hazard Mater 161:81–87. https://doi.org/10.1016/j.jhazmat.2008.03.052

Jiang C, Yakaboylu GA, Yumak T et al (2020) Activated carbons prepared by indirect and direct CO2 activation of lignocellulosic biomass for supercapacitor electrodes. Renew Energy 155:38–52. https://doi.org/10.1016/j.renene.2020.03.111

Khan MA, Lee SH, Jeon BH (2010) Adsorption of DCM and MTBE from aqueous phase on granular activated carbons: a comparative study. Geosyst Eng 13:97–104. https://doi.org/10.1080/12269328.2010.10541315

Khoshand A, Bazargan A, Rahimi K (2018) Application of soils for removal of methyl tertiary butyl ether (MTBE) from aqueous solution: adsorption kinetics and equilibrium study. Desalin Water Treat 111:226–235. https://doi.org/10.5004/dwt.2018.22209

Köseoʇlu E, Akmil-Başar C (2015) Preparation, structural evaluation and adsorptive properties of activated carbon from agricultural waste biomass. Adv Powder Technol 26:811–818. https://doi.org/10.1016/j.apt.2015.02.006

Kumar KV, Ramamurthi V, Sivanesan S (2005) Modeling the mechanism involved during the sorption of methylene blue onto fly ash. J Colloid Interface Sci 284:14–21. https://doi.org/10.1016/j.jcis.2004.09.063

Kushwaha S, Sreelatha G (2013) Physical and chemical modified forms of palm shell: preparation, characterization and preliminary assessment as adsorbents. J Porous Mater 20:21–36. https://doi.org/10.1007/s10934-012-9571-4

László K, Bóta A, Nagyu LG (1997) Characterization of activated carbons from waste materials by adsorption from aqueous solutions. Carbon N Y 35:593–598. https://doi.org/10.1016/S0008-6223(97)00005-5

Levchuk I, Bhatnagar A, Sillanpää M (2014) Overview of technologies for removal of methyl tert-butyl ether (MTBE) from water. Sci Total Environ 476–477:415–433. https://doi.org/10.1016/j.scitotenv.2014.01.037

Liadi MA, Tawabini B, Shawabkeh R et al (2018) Treating MTBE-contaminated water using sewage sludge-derived activated carbon. Environ Sci Pollut Res 25:29397–29407. https://doi.org/10.1007/s11356-018-2737-0

Ma M, Ying H, Cao F et al (2020) Adsorption of Congo red on mesoporous activated carbon prepared by CO2 physical activation. Chin J Chem Eng 28:1069–1076. https://doi.org/10.1016/j.cjche.2020.01.016

Mahdavian L, Raouf M (2010) Thermodynamic and electronic investigation about remove of mtbe from environment by single-walled carbon nanotube (SWNT). Integr Ferroelectr 114:7–16. https://doi.org/10.1080/10584587.2010.488157

Mall ID, Srivastava VC, Agarwal NK, Mishra IM (2005) Removal of Congo red from aqueous solution by bagasse fly ash and activated carbon: Kinetic study and equilibrium isotherm analyses. Chemosphere 61:492–501. https://doi.org/10.1016/j.chemosphere.2005.03.065

Martin-Martinez M, Álvarez-Torrellas S, García J et al (2018) Exploring the activity of chemical-activated carbons synthesized from peach stones as metal-free catalysts for wet peroxide oxidation. Catal Today 313:20–25. https://doi.org/10.1016/j.cattod.2018.01.003

Martucci A, Braschi I, Bisio C et al (2015) Influence of water on the retention of methyl tertiary-butyl ether by high silica ZSM-5 and y zeolites: a multidisciplinary study on the adsorption from liquid and gas phase. RSC Adv 5:86997–87006. https://doi.org/10.1039/c5ra15201a

Masod MB, El-Fiqi A, Ebiad MA (2023) Encapsulation of activated carbon into calcium alginate microspheres toward granular-activated carbon adsorbents for elemental mercury capture from natural gas. Environ Sci Pollut Res 30:82199–82216. https://doi.org/10.1007/s11356-023-28176-7

McGregor D (2006) Methyl tertiary-butyl ether: studies for potential human health hazards. Crit Rev Toxicol 36:319–358. https://doi.org/10.1080/10408440600569938

Mirzaei A, Ebadi A, Khajavi P (2013) Kinetic and equilibrium modeling of single and binary adsorption of methyl tert-butyl ether (MTBE) and tert-butyl alcohol (TBA) onto nano-perfluorooctyl alumina. Chem Eng J 231:550–560. https://doi.org/10.1016/j.cej.2013.07.017

Molina-Sabio M, González MT, Rodriguez-Reinoso F, Sepúlveda-Escribano A (1996) Effect of steam and carbon dioxide activation in the micropore size distribution of activated carbon. Carbon N Y 34:505–509. https://doi.org/10.1016/0008-6223(96)00006-1

Mondal S, Aikat K, Halder G (2022) Sorptive uptake of Ranitidine hydrochloride by Parthenium hysterophorus based chemically treated N-biochar in static bed continuous flow system. Results Surf Interfaces 8:100071. https://doi.org/10.1016/j.rsurfi.2022.100071

Naser Sheykhaoleslami NS, Irani M, Gholamian R, Aliabadi M (2016) Removal of MTBE from aqueous solution using natural nanoclays of Iran. Desalin Water Treat 57:27259–27268. https://doi.org/10.1080/19443994.2016.1172512

Pepino Minetti RC, Macaño HR, Britch J, Allende MC (2017) In situ chemical oxidation of BTEX and MTBE by ferrate: pH dependence and stability. J Hazard Mater 324:448–456. https://doi.org/10.1016/j.jhazmat.2016.11.010

Reddy KSK, Al SA, Srinivasakannan C (2014) Gas-phase mercury removal through sulfur impregnated porous carbon. J Ind Eng Chem 20:2969–2974. https://doi.org/10.1016/j.jiec.2013.10.067

Rodeghero E, Pasti L, Sarti E et al (2017) Temperature-induced desorption of methyl tert-butyl ether confined on ZSM-5: an in situ synchrotron XRD powder diffraction study. Minerals. https://doi.org/10.3390/min7030034

Sakr AAE, Amr N, Bakry M et al (2023) Carbon disulfide removal from gasoline fraction using zinc-carbon composite synthesized using microwave-assisted homogenous precipitation. Environ Sci Pollut Res 30:82014–82030. https://doi.org/10.1007/s11356-023-27905-2

Saleh TA, Sulaiman KO, Al-Hammadi SA et al (2017) Adsorptive desulfurization of thiophene, benzothiophene and dibenzothiophene over activated carbon manganese oxide nanocomposite: with column system evaluation. J Clean Prod 154:401–412. https://doi.org/10.1016/j.jclepro.2017.03.169

Sekirifa ML, Hadj-Mahammed M, Pallier S et al (2013) Preparation and characterization of an activated carbon from a date stones variety by physical activation with carbon dioxide. J Anal Appl Pyrolysis 99:155–160. https://doi.org/10.1016/j.jaap.2012.10.007

Thommes M, Kaneko K, Neimark AV et al (2015) Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC technical report). Pure Appl Chem. https://doi.org/10.1515/pac-2014-1117

Tongpoothorn W, Sriuttha M, Homchan P et al (2010) Preparation of activated carbon derived from Jatropha curcas fruit shell by simple thermo-chemical activation and characterization of their physico-chemical properties. Chem Eng Res Des 89:335–340. https://doi.org/10.1016/j.cherd.2010.06.012

USEPA (2008) Chapter 13: MTBE. Regul determ support doc sel contam from second drink water contam candidate list (CCL 2) EPA report 815-R-08-012, pp 1–76

Vijayalakshmi K, Gomathi T, Latha S et al (2016) Removal of copper(II) from aqueous solution using nanochitosan/sodium alginate/microcrystalline cellulose beads. Int J Biol Macromol 82:440–452. https://doi.org/10.1016/j.ijbiomac.2015.09.070

Wu XW, Ma HW, Li JH et al (2007) The synthesis of mesoporous aluminosilicate using microcline for adsorption of mercury(II). J Colloid Interface Sci 315:555–561. https://doi.org/10.1016/j.jcis.2007.06.074

Yang T, Lua AC (2003) Characteristics of activated carbons prepared from pistachio-nut shells by physical activation. J Colloid Interface Sci 267:408–417. https://doi.org/10.1016/S0021-9797(03)00689-1

Zadaka-Amir D, Nasser A, Nir S, Mishael YG (2012) Removal of methyl tertiary-butyl ether (MTBE) from water by polymer–zeolite composites. Microporous Mesoporous Mater 151:216–222. https://doi.org/10.1016/j.micromeso.2011.10.033

Zhang F, Nriagu JO, Itoh H (2005) Mercury removal from water using activated carbons derived from organic sewage sludge. Water Res 39:389–395. https://doi.org/10.1016/j.watres.2004.09.027

Zhang Y-J, Xing Z-J, Duan Z-K, Wang Y (2014) Effects of steam activation on the pore structure and surface chemistry of activated carbon derived from bamboo waste. Appl Surf Sci 315:279–286. https://doi.org/10.1016/j.apsusc.2014.07.126

Zhang Y, Jin F, Shen Z et al (2018) Kinetic and equilibrium modelling of MTBE (methyl tert-butyl ether) adsorption on ZSM-5 zeolite: batch and column studies. J Hazard Mater 347:461–469. https://doi.org/10.1016/j.jhazmat.2018.01.007

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Editorial responsibility: M. Shabani.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bakry, M., El-Azab, W.I., El-Fiqi, A. et al. Eco-friendly removal of methyl tert-butyl ether from contaminated water using steam and CO2-activated carbons. Int. J. Environ. Sci. Technol. 21, 6597–6614 (2024). https://doi.org/10.1007/s13762-023-05431-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13762-023-05431-5