Abstract

China’s economic development is closely related to oil and gas resources, and the country is investing heavily in pipeline construction. Slope geological hazards seriously affect the long-term safe operation of buried pipelines, usually causing pipeline leakage, property and environmental losses, and adverse social impacts. To ensure the safety of pipelines and reduce the probability of pipeline disasters, it is necessary to predict and quantitatively evaluate slope hazards. While there has been much research focus in recent years on the evaluation of pipeline slope disasters and the stress calculation of pipelines under hazards, existing methods only provide information on the occurrence probability of slope events, not whether a slope disaster will lead to pipeline damage. Taking the 2015 Xinzhan landslide in Guizhou Province, China, as an example, this study used discrete elements to simulate landslide events and determine the risk level and scope for pipeline damage, and then established a pipe-soil coupling model to quantitatively evaluate the impact of landslide hazards for pipelines in medium- and high-risk areas. The results provide a reference for future pipeline disaster prevention and control.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Oil and gas pipelines figure prominently in China’s economic development. At the end of 2021, the total length of oil and gas pipelines in China had reached 150,000 km, and it is expected that the total length of China’s oil and gas pipeline network will reach 240,000 km by 2025 (Gao 2022). Around 70% of these long-distance pipelines pass through mountainous areas, such as in southwestern China, where they are subject to complex geological conditions with high hazard potential (Zhang, Shuai, et al. 2020). About 130,000 geological disasters occurred in China from 2009 to 2019, of which landslides accounted for 71% (Liang et al. 2021). Geological disasters often trigger pipeline accidents, leading to leakage and explosion (Wang and Pan 2017; Tang 2020; Xu et al. 2022). Landslides can deform or even rupture pipelines, resulting in serious leakage, property and environmental losses, and social impacts (Lee et al. 2009; Zheng et al. 2012; Zhou 2018; Vasseghi et al. 2021). To reduce the probability of pipeline disasters and determine the prevention and control measures, it is necessary to predict and quantitatively evaluate pipeline slope hazards.

Traditionally, most assessments of the scope of influence and risk level of pipeline geological hazards have relied on field-based topographic and geotechnical mapping (Topal and Akin 2009). However, this method is not only costly, but also poorly evaluated. More recently, developments in satellite, airborne, and ground monitoring technologies have driven research on remote, real-time monitoring of pipeline geological hazards (Leynes et al. 2005; Marinos et al. 2019; Yan, Xiong, et al. 2022). Real-time monitoring of landslides can provide early warnings for pipeline landslide hazards (Vasconez et al. 2010; Lombardi et al. 2016; Yan et al. 2019). The technical method of unmanned aerial vehicle (UAV) point cloud filtering can be used to identify dangerous areas of oil and gas pipelines (Gao et al. 2011; Yan et al. 2021). However, these systems only monitor the slope hazard, and they cannot determine whether and to what degree it impacts the pipeline. Whether the occurrence leads to pipeline damage needs further research.

For the risk assessment of pipeline slope disasters, various assessment models are used to assess the vulnerability of pipelines to landslides (Jamshidi et al. 2013; Xiong et al. 2020). Alvarado-Franco et al. (2017) presented quantitative mechanical models for evaluating landslide probability and pipeline failure probability. These assessment methods mainly consider topographic factors and do not consider the dynamic influence of landslide movement processes (He et al. 2021). In slope stability analysis, various methods that consider different factors have achieved good results in geotechnical engineering application (Bar et al. 2020; McQuillan et al. 2020; Karrech et al. 2021). Zhang et al. (2022) also proposed a dynamic prediction method of landslide displacement. However, the discrete element method can consider the dynamic process of sliding in the simulation process, and has achieved good results in the simulation of several typical landslide cases (An et al. 2020; Xia et al. 2021; Yan, Cui, et al. 2022). The landslide risk division method based on the calculation results of landslide movement processes has also been studied (An et al. 2020).

A separate strand of research has used analytical methods to investigate pipeline stress under the action of landslides (Rajani et al. 1995; Cocchetti et al. 2009; Yuan et al. 2015; Zahid et al. 2020), and experimental modeling to observe pipeline displacement (Calvetti et al. 2004; Rojhani et al. 2012; Feng et al. 2015). However, analytical methods and model experiments are usually based on ideal assumptions, which are quite different from real-world situations (Kunert et al. 2012; Almahakeri et al. 2019). With the rapid development of computer processing power, numerical analysis (primarily, finite element) of landslide-pipeline mechanical responses under different conditions has become a research focus (Liu et al. 2010; Zhu and Randolph 2010; Han and Fu 2020; Zhang, Meng, et al. 2020). Li et al. (2016) studied pipeline stress distribution under the limit equilibrium of the slope mass for lateral landslides. They found greatest stress concentration in the middle and edges of the sliding mass and established the limit length of the pipeline safely withstanding lateral landsliding. Kunert et al. (2012) modeled the stress state due to landslide-driven soil displacements along about 1 km of buried pipeline using a three-dimensional model constructed with the ABAQUS software. Other research has performed more detailed analyses of pipeline response to ground load, including the variation of pipeline Mises’s stress and landslide displacement, burial depth, and pipeline wall thickness (Han and Fu 2019; Liang et al. 2019). However, the simple finite element analysis approach ignores the influence of landslide movement on the pipeline, and it is difficult to link the slope hazard with the pipeline. Further research is needed to develop a method of predicting the danger of slope disasters to pipelines.

Based on the field investigation of the 2015 Xinzhan landslide in Guizhou, China, this study used discrete elements to simulate landslide occurrence to determine the danger and damage scope to pipelines. It further established a pipe-soil coupling model to quantitatively evaluate landslides in medium- and high-risk areas and the degree of pipeline damage from the disaster. The results provide a reference that can be used as guidance for risk prevention and management of pipeline slope disasters.

2 The Study Area

The Xinzhan landslide disaster site is located in Tongzi County, Zunyi City, Guizhou Province, China (longitude 106° 51′ 48″–106° 51′ 58″ E, latitude 28° 21′ 39″–28° 21′ 44″ N) (Fig. 1). After burial in January 2013, the X60 type pipeline was subject to continuous rainfall that caused cracking on the surface of the excavated slope and localized slumping. On 12 July 2015, continuous heavy rainfall induced a small landslide that overrode the pipeline in its lower and middle parts to a burial depth of about 1.5–2 m. The landslide stratum is mainly composed of Quaternary landslide filling residual silty clay, and the underlying bedrock comprises mudstone and sandy mudstone of the Upper Shaximiao Formation of the Middle Jurassic.

3 Methodology

To quantitatively evaluate the risk level and degree of landslide hazard, we used a discrete element method in MatDEM to numerically simulate landslides, and a finite element slope-pipe model to analyze pipeline stress and displacement. Field investigation was also undertaken to provide model input and ground-truthing data.

3.1 MatDEM Discrete Element Method

We used the matrix discrete element algorithm and three-dimensional contact algorithm of the MatDEM software to numerically simulate landslides (Liu et al. 2017). The MatDEM software can cement together elements with specific mechanical properties (Fig. 2a) and construct a variety of three-dimensional rock and soil bodies that conform to the real-world structure. Fracture and nonlinear deformation are simulated dynamically (Liu et al. 2013), following the law of conservation of energy and statistically analyzing changes in mechanical energy and heat during the simulation. In this study, the linear elastic contact method was used to establish the landslide model, and the bonding force between elements was determined by the normal spring force and the tangential spring force to represent the spring contact and the tangential spring contact (Liu et al. 2015).

where \({F}_{n}\) is the normal force; \({K}_{n}\) is the normal stiffness; \({X}_{n}\) is the normal relative displacement (Fig. 2b); \({F}_{s}\) is the shear force; \({K}_{s}\) is the tangential stiffness; and \({X}_{s}\) is the shear deformation (Fig. 2c).

The maximum normal force between particle elements satisfies:

where \({X}_{b}\) is the fracture deformation; when the external force of the element in the normal direction gradually increases to exceed \({F}_{nmax}\), the bond between the elements is broken and the tension ceases. The maximum tangential force that the unit cement can withstand meets:

where \({F}_{s0}\) is the initial shear force; and \({\mu }_{p}\) is the friction coefficient. In the actual simulation process, when the tangential force is greater than \({F}_{smax}\), the unit cement will also break, and the unit will be dislocated. At this stage, only sliding friction (\({-\mu }_{p}{F}_{n}\)) remains between the elements.

3.2 Finite Element Analysis of Slope-Pipe Coupling

Slope-pipe models are commonly used to analyze pipeline stress and displacement (Zhang et al. 2016; Han and Fu 2019; Yan et al. 2021), and this study used the ABAQUS software to establish a coupled slope-pipe model. The welding seam at the pipe connection is ignored in the modeling, and it is assumed that the pipe material is uniform and the distribution direction is constant. Only the influence of pipe wall thickness and internal pressure is considered. The Mohr-Coulomb model is adopted for landslide soil, and a linear elastic model for the pipeline. When a landslide occurs, the contact state between the pipe and the soil is always nonlinear with the soil displacement change. Therefore, the nonlinear contact finite element method is used to realize the pipe-soil connection by adding contact elements on the contact surface of the pipe and the soil. The interaction simulation (Kunert et al. 2012) can simulate the nonlinearity of the pipe-soil material, the nonlinear contact of the pipe-soil interface, and the large deformation of the pipe. The slope of the model is a free boundary, the bottom is fixed, and normal constraints are applied around it (Zhang et al. 2017; Zhang et al. 2018).

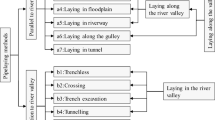

4 Pipeline Slope Disaster Risk Prediction System

At present, most studies of pipeline slope disasters focus on the monitoring and prevention of slope hazards and the failure of oil and gas pipelines. The quantitative evaluation system of pipeline landslide risk proposed in this study is divided into three parts: (1) field investigation (to uncover the on-site situation of disaster points); (2) pre-judgment (quantitative evaluation of pipeline landslide risk based on the movement process); and (3) risk evaluation (based on pipe-soil coupled pipeline force quantitative evaluation), as shown in Fig. 3. The evaluation system is demonstrated by application to the landslide hazard site at Xinzhan.

Flowchart showing the method for the quantitative prediction of pipeline slope disaster risk developed in this study; \({T}_{u}\) is the uniaxial tensile strength, \({C}_{u}\) is the uniaxial compressive strength, \({\sigma }_{a}\) is the pipe stress, and \({\sigma }_{s}\) is the minimum yield strength of the pipe material

4.1 Field Investigation

The purpose of the field investigation was to understand the basic situation of the pipeline site at Xinzhan, to provide input data for the modeling analysis, including information on the direction of the pipeline laying line, the buried depth of the pipeline, the properties of the surrounding soil, and the topography of the pipeline laying route in the mountainous area. The investigation also covered precision terrain, pipe material type, material parameters of the surrounding soil, and so on.

4.2 Hazard Risk Prediction

Before simulating the possible occurrence of landslides, the classification criteria of different risk levels were first determined. Then according to the impact of rainfall and weathering, we changed the parameters to estimate disaster risk.

4.2.1 Landslide Hazard Prediction

The MatDEM software was used to establish a slope model for the analysis of slope stability (Xie et al. 2021). The simulation considers the influence of rainfall and weathering on rock and soil strength by setting different material parameters (internal friction coefficient, tensile strength, compressive strength) (Xia et al. 2021), and analyzing kinetic energy, accumulation, and scraping of the landslide in each situation. An et al. (2020) developed a risk assessment method for single landslides based on the discrete element method that combines the maximum kinetic energy density and the maximum mass density to reliably delineate the landslide risk area. We built on this method, adding landslide silting hazards as a consideration. Landslide movement will cause the pipeline to be subject to higher kinetic energy, greater accumulation thickness will impart a greater static load on the pipeline, and scraping will cause the pipeline to be exposed or suspended. Therefore, two indicators, namely the landslide scraper/accumulation height H and the maximum kinetic energy density Q of the landslide, are considered to quantitatively evaluate the danger of the landslide to the pipeline, and to identify pipeline danger levels. The maximum burial thickness is calculated by subtracting the pre- and post-slip elevations of particles on the calculated grid nodes. The value ranges of different risk classification index parameters are shown in Table 1.

The formula for calculating the maximum kinetic energy density is:

where \({Q}_{ij}\) is the maximum kinetic energy density of the calculation grid; \({q}_{ij}^{t}\) is the kinetic energy of the calculation grid at time t; and \({s}_{ij}\) is the area of the calculation grid (i, j).

4.2.2 Multi-condition Motion Simulation of the Xinzhan Landslide

Field investigation showed that the landslide area consisted of silty clay and fully weathered mudstone debris with fragmented stones, mainly silty clay. The mechanical properties of the Xinzhan landslide material obtained through field sampling and laboratory tests, and the values of the material parameters obtained using the macro-micro conversion formula (Eqs. 6–10) (Liu et al. 2013), are shown in Table 2.

where \({K}_{n}\) and \({K}_{s}\) are the normal and shear stiffness of the particle, respectively; \(E\) is Young’s modulus; \(v\) is Poisson’s ratio; \({X}_{b}\) is the breaking displacement; \({T}_{u}\) is the uniaxial tensile strength; \(d\) is the particle diameter; \({F}_{s0}\) is the initial shear resistance; \({\mu }_{p}\) is the intergranular friction coefficient; \({C}_{u}\) is the uniaxial compressive strength; and \({\mu }_{i}\) is the internal friction coefficient.

Studies have shown that under the action of rainfall and weathering, soil strength (c, φ value) decreases to varying degrees. As a result, the macroscopic mechanical properties of the slope soil such as the internal friction coefficient \({\mu }_{i}\), uniaxial tensile strength \({T}_{u}\), and uniaxial compressive strength \({C}_{u}\) will change. In MatDEM, the micro-mechanical parameters of the model, such as initial shear resistance \({F}_{s0}\) and breaking displacement \({X}_{b}\), are mainly determined by substituting a conversion formula into the macro-mechanical properties of the material. Therefore, the internal friction coefficient \({\mu }_{i}\), uniaxial tensile strength \({T}_{u}\), and uniaxial compressive strength \({C}_{u}\) influence the landslide movement process. To consider the influence of parameter values on landslide simulation, the values of the three parameters are changed to consider the effects of rainfall and weathering on the landslide process (values for other parameters remain as in Table 2). Multiple groups of parameters were tested, and six groups with a degree of discrimination to illustrate the effect of different rock and soil properties on the landslide process were selected for modeling (as detailed in Table 3).

4.3 Quantitative Evaluation of Pipeline Risk

The slope instability process is simulated by the strength reduction method, and whether the pipeline is damaged is judged based on the allowable stress. Based on the topographic data of the disaster area, a pipe-soil coupling model was established for analysis and calculation.

4.3.1 Quantitative Evaluation of Pipeline Force

For low-risk areas, landslide occurrence holds no or minimal threat for pipeline safety. For medium- and high-risk areas, further analysis of pipe-soil coupling is needed to understand the mechanical response of the pipeline under the action of the landslide, and the impact of different slope conditions and pipeline stress levels in the most dangerous situation. We used the finite element method to carry out this analysis.

A range of external factors—such as rainfall, weathering, infiltration, and horizontal seismic force—act to decrease the shear strength of the soil body, reducing the internal friction angle and cohesion (Jia et al. 2014; Chen et al. 2021; Zhu et al. 2022). The strength reduction method can be used to simulate the entire process of slope stabilization to destabilization. The method reduces soil shear strength by reducing its material parameters (such as internal friction angle and cohesion) until the stress and slope reach a limit equilibrium state (Sun et al. 2021). For the Mohr-Coulomb model, the strength reduction factor can be expressed as:

where \({C}_{m}\) is the cohesion after strength reduction; \(C\) is the cohesion; \({F}_{r}\) is the strength reduction coefficient; \({\Phi }_{m}\) is the internal friction angle after strength reduction; and \(\varphi\) is the internal friction angle.

Following the Specification for Geological Hazards Risk Management of Oil and Gas Pipeline (SY/T 6828-2017),Footnote 1 the allowable stress of the pipeline under the action of the landslide is obtained by Eq. 13, and it is used to judge whether the pipeline is damaged.

where \({\sigma }_{a}\) is the pipe stress; \(\left[{\sigma }_{a}\right]\) is the allowable stress of the pipe; and \({\sigma }_{s}\) is the minimum yield strength of the pipe material.

In the simulation, if the stress on the pipeline does not exceed the allowable pipeline stress in the most dangerous landslide situation, the impact of projects to control the landslide can be taken into account, or the development trend of the landslide can be further observed. If the pipeline reaches the allowable stress in the most dangerous landslide situations, monitoring of pipeline stress at the slope, and monitoring and prevention of slope deformation can be considered. The threshold value for slope displacement monitoring can be based on the simulated critical state.

4.3.2 Establishment of a Pipe-Soil Coupling Model for the Xinzhan Landslide

Terrain data for the study area were first processed with the 3D modeling software Rhino to establish a 3D model with pipelines similar to the field situation, and then imported to the finite element software ABAQUS. The terrain model was then processed for computational analysis, including applying a tetrahedral mesh to the slope and the landslide area, and refining the pipeline crossing part and the surrounding soil mesh. The non-landslide area and the landslide bed mesh are appropriately sparse, and the pipeline is constructed with shell elements. The final model is shown in Fig. 4. Based on the site inspection, the Code for Design of Oil Transportation Pipeline Engineering (GB50253-2014)Footnote 2 was used to obtain the parameters of slope and pipeline, as shown in Tables 4 and 5. The stress state of the pipeline was obtained from the situation of the Xinzhan landslide, and the most dangerous situation simulated by discrete element.

5 Results and Analysis

Based on the discrete element and finite element method, the risk degree of the landslide to the pipeline was first determined, and then the stress and displacement of the pipeline at the disaster point were calculated by the pipe-soil coupling modeling analysis, and the influence of the landslide on the pipeline was quantitatively analyzed. This section introduces the key details of all the above results.

5.1 Xinzhan Landslide Simulation and Pipeline Risk Classification

First, the displacement and velocity of the landslide under various scenarios are compared and analyzed. Then, according to the results of the erosion, accumulation depth, and landslide kinetic energy density distribution during the whole movement process, the risk degree of the pipeline is divided.

5.1.1 Velocity and Displacement Analysis

Average velocity and displacement of the landslide for the six scenarios, based on different parameter settings, in the discrete element method analysis are shown in Fig. 5. The results show that average velocity and average displacement of the landslide decrease gradually as the friction coefficient and strength increase. In the most dangerous situation (Scenario 4), average speed reaches 10 m/s, displacement is about 160 m, and the rate of change of both is rapid.

5.1.2 Risk Classification Results

The erosion and accumulation depth of the landslide under the different scenarios is shown in Fig. 6, and the kinetic energy density distribution of the landslide during the whole movement process is shown in Fig. 7. Comparing the results of Scenarios 1–3 and 4–6, as the internal friction coefficient increases, landslide erosion and accumulation depth and area gradually decrease, as does the maximum kinetic energy density. Comparing Scenarios 1 and 4, 2 and 5, and 3 and 6, as intensity decreases, erosion and accumulation depth on the slope gradually increase, as does the maximum kinetic energy density.

In Scenario 4, the range of landslide scraping and accumulation is large, with an erosion depth of about 2–6 m and maximum stacking thickness of about 6 m (Fig. 6d), and the overall kinetic energy density is large, with a maximum kinetic energy density of 1.13 × 107 J/m2 (Fig. 7d). Near the pipeline, the slope was scraped to a depth of about 2 m; maximum kinetic energy density during movement was 3 × 106 J/m2, peaking in the middle of the landslide and gradually decreasing to both sides. This scenario may result in exposed or damaged pipes.

Using the simulation results for Scenario 4 (Figs. 6d and 7d) and the hazard classification standard, the pipeline hazard classification for Xinzhan (Fig. 8a) shows that pipeline damage is likely. Around 30 m of pipeline are classified as at high risk; landslide kinetic energy density in this area is high, and the pipeline is subjected to large impact forces. The field situation of local landslides induced by rainfall on 12 July 2015 (Fig. 8b–e) confirms the risk to this area of the pipeline. Further quantitative assessment of landslide impact on the pipeline is provided through the pipe-soil coupling simulation.

5.2 Pipeline Hazard Disaster Risk Assessment

Based on the most dangerous scenario, the stress and displacement of the pipeline at the disaster point and the displacement of the pipeline when the stress reaches the critical state were calculated by the pipe-soil coupling modeling analysis.

5.2.1 Impact of the Local Landslide

The finite element pipe-soil coupling model (Fig. 9) is based on a field survey of the Xinzhan landslide that shows the most severe deformation in about April 2015, mainly in the slip section of the wedge-shaped body. The simulation gives the maximum displacement of the small-scale landslide as 6.55 cm, located in the middle and lower parts (Fig. 9b). In this state, due to the influence of slope sliding force, the pipeline deformation mainly occurs in the landslide range (Fig. 9c). Pipeline deformation is largest at the central axis of the landslide, with a maximum of 0.25 cm, and decreases relatively symmetrically away from the central axis. Pipeline stress shows a different pattern, with highest values (maximum 206.7 MPa) at the edge of the landslide (Fig. 9d). Maximum stress coincides with the pipeline support area, although it is less than the allowable stress of the X60 pipeline under landslide action (415×0.8 = 332 MPa), so no damage occurs.

5.2.2 Impact of the Most Dangerous Landslide

The MatDEM simulation for the most dangerous conditions (Fig. 10) gives a landslide of about 170 m in length and a maximum width of 70 m. Under this scenario, landslide displacement is significantly larger, with a maximum of 454.4 cm (Fig. 10b). Pipeline displacement (up to 233 cm) and stress (598.2 MPa) are also high. Pipeline stress far exceeds the allowable stress, indicating that landslide occurrence in the most dangerous situation will lead to pipeline damage and impact pipeline transportation. The pattern of pipeline deformation is similar to the small landslide case, with highest values at the central axis of the landslide and gradually decreasing to both sides (Fig. 10c). Pipeline stress is concentrated in three areas, in the middle of the landslide and at the support areas on each side (Fig. 10d).

5.2.3 Critical State Landslide

The critical state parameters are assessed by continuously reducing the strength parameters of the soil material so that slope displacement increases (Fig. 11). When simulated pipeline stress reaches the critical value of 332 MPa, landslide displacement is 123.1 cm, and pipeline displacement is 63.28 cm. Under this state, the slope safety factor is 1.4, and the soil cohesion force and internal friction angle are 13.57 kPa and 14.57 °, respectively.

The results show that the most dangerous landslide case can lead to pipeline damage. The simulations provide guidance for rapid formulation of prevention and control projects based on the scope of the landslide. To reduce thrust, maximum stress value, and pipeline displacement, prevention and control measures should focus on the central axis of the landslide and pipeline support at the edge of the landslide area. Inspection and monitoring of the pipeline in the landslide area should be increased, so that once the landslide displacement critical value occurs, it can be rapidly reported, and the emergency plan enacted.

6 Discussion

Compared with the traditional field investigation and instrument monitoring methods (Topal and Akin 2009; Vasconez et al. 2010), our method directly uses free software (MatDEM and ABAQUS) to analyze and calculate after obtaining basic data, which does not require on-site construction and installation of instruments, is convenient to use, and is low in cost. It can quickly determine whether the danger point is likely to evolve into a landslide and calculate its impact on the pipeline. At present, the risk assessment of pipeline slope disasters is mostly based on the impact of topography and expert experience (Jamshidi et al. 2013; He et al. 2021), ignoring the impact analysis of the formation process of disasters on pipelines. In this study, MatDEM was first used to classify the dangerous area of the pipeline on the basis of considering the accumulation, erosion, and kinetic energy density of the landslide movement process, and then ABAQUS was used to quantify the impact of the landslide on the pipeline. According to different simulation results, different emergency solutions can be formulated to avoid excessive measures for low-risk disaster sites.

To consider the influence of parameter values on landslide simulation, we simulated the motion of landslides in multiple groups of different parameters, and finally selected six groups with a degree of discrimination to illustrate the effect of different rock and soil properties. The field investigation showed that small-scale landslides have occurred in the study area, which supported the credibility of the numerical simulation results. Also, the results of small landslides and the predicted most dangerous landslides demonstrate that hazard occurrence does not necessarily lead to pipeline damage. Therefore, it is necessary to distinguish the hazard parameters and quantitatively analyze their impact on the pipeline.

The study showed different landslide impacts on the pipeline in different danger situations. This implies that different emergency measures should be considered depending on pipeline location relative to danger areas. Parameters such as landside slope and width, soil properties in the landslide area, pipeline burial depth, and pipeline laying position are also very important to determining the impact of pipeline disasters.

The pipeline slope disaster risk prediction system proposed in this study allows rapid assessment of whether a disaster is likely to occur and quantifies the impact of disaster occurrence on the pipeline. This is essential for quick and accurate disaster identification and implementation of reasonable emergency measures in advance to avoid pipeline damage by disasters. However, there are still some key gaps between the model used in this study and the field situation. For example, the presence of a pipeline on a slope will hinder sliding to some extent, but it is not considered in the landslide simulation. Also, the model simplifies the pipeline laying position as linear, so does not consider complexity in pipeline laying due to terrain changes. In the next research stage, we will optimize these two elements to create a model that is closer to the field situation to improve the pipeline slope hazard prediction system.

7 Conclusion

The prevention and control of geological disasters, mainly landslides, is currently one of the most important tasks of pipeline safety management in China. In this study, the discrete element software MatDEM was used to simulate landslide movement under different scenarios to predict the possible range of disasters. Classification of pipeline risk level in disaster-prone areas was carried out under different scenarios, and the finite element software ABAQUS was used to quantitatively analyze the impact of landslides on pipelines in medium- and high-risk areas. The study came to four main conclusions:

-

(1)

Considering the influence of rainfall and weathering on rock and soil mass, in the most dangerous situation average landslide speed is about 10 m/s, average displacement about 160 m, maximum kinetic energy density in the entire disaster range is 1.13 × 107 J/m2, and the depth of the slope body near the pipeline is about 2 m. The maximum kinetic energy density during movement is about 3 × 106 J/m2. The risk classification standard shows that a long section of pipeline is located in the high-risk area of landslide in the disaster area, and pipeline damage is likely.

-

(2)

The stress condition of the pipeline under the most dangerous landslide was determined by the strength reduction method, giving a pipeline displacement of 233 cm with a pipeline stress of 598.2 MPa. This exceeds the allowable stress of the pipeline under the action of the landslide, and the pipeline is damaged. Maximum displacement is at the central axis of the landslide, and maximum stress is at the pipeline support area.

-

(3)

The calculation and simulation results indicate that the pipeline at Xinzhan was in a safe state under the influence of small-scale landslides that occurred around April 2015, which is consistent with the actual field situation. However, under the most dangerous slope conditions, landslide occurrence can lead to pipeline damage. Therefore, to avoid heavy losses caused by future disaster occurrences at this section of the pipeline, monitoring needs to be strengthened, and further prevention and control measures should be implemented.

-

(4)

The calculation results show that for both small-scale and the most dangerous landslides, pipeline deformation is focused on the central axis of the landslide area, while stress is concentrated in both the central axis area and the pipeline support areas to each side. Therefore, these areas should be the focus of prevention and control measures in the treatment of pipeline landslides.

References

Almahakeri, M., I.D. Moore, and A. Fam. 2019. Numerical techniques for design calculations of longitudinal bending in buried steel pipes subjected to lateral earth movements. Royal Society Open Science 6(7): Article 181550.

Alvarado-Franco, J.P., D. Castro, N. Estrada, B. Caicedo, M. Sánchez-Silva, L.A. Camacho, and F. Muñoz. 2017. Quantitative-mechanistic model for assessing landslide probability and pipeline failure probability due to landslides. Engineering Geology 222(16): 212–224.

An, H., C. Ouyang, C. Zhao, and W. Zhao. 2020. Landslide dynamic process and parameter sensitivity analysis by discrete element method: The case of Turnoff Creek rock avalanche. Journal of Mountain Science 17(1): 1581–1595.

Bar, N., M. Kostadinovski, M. Tucker, G. Byng, R. Rachmatullah, A. Maldonado, and T. Yacoub. 2020. Rapid and robust slope failure appraisal using aerial photogrammetry and 3D slope stability models. International Journal of Mining Science and Technology 30(5): 651–658.

Calvetti, F., C. Di Prisco, and R. Nova. 2004. Experimental and numerical analysis of soil–pipe interaction. Journal of Geotechnical and Geoenvironmental Engineering 130(12): 1292–1299.

Chen, C., H. Chen, and W. Wu. 2021. Numerical modeling of interactions of rainfall and earthquakes on slope stability analysis. Environmental Earth Sciences 80(16): 1–11.

Cocchetti, G., C. Di Prisco, A. Galli, and R. Nova. 2009. Soil–pipeline interaction along unstable slopes: A coupled three-dimensional approach. Part 1: Theoretical formulation. Canadian Geotechnical Journal 46(11): 1289–1304.

Feng, W., R. Huang, J. Liu, X. Xu, and M. Luo. 2015. Large-scale field trial to explore landslide and pipeline interaction. Soils and Foundations 55(6): 1466–1473.

Gao, P. 2022. New progress in China’s oil and gas pipeline construction in 2021. International Petroleum Economics 30(3): 12–19 (in Chinese).

Gao, J., Y. Yan, and C. Wang. 2011. Research on the application of UAV remote sensing in geologic hazards investigation for oil and gas pipelines. In ICPTT 2011: Sustainable solutions for water, sewer, gas, and oil pipelines, ed. B. Ma, M. Najafi, G. Jiang, and L. Slavin, 381–390. Reston, VA: American Society of Civil Engineers.

Han, B., and Q. Fu. 2019. Numerical calculation of pipe-soil interaction subjected to unstable slope. IOP Conference Series: Earth and Environmental Science 384(1): Article 012101.

Han, B., and Q. Fu. 2020. Study on the pipeline fragility appraisal indicators affected by landslide based on numerical simulation. Journal of Physics: Conference Series 1549(4): Article 042123.

He, B., M. Bai, H. Shi, X. Li, Y. Qi, and Y. Li. 2021. Risk assessment of pipeline engineering geological disaster based on GIS and WOE-GA-BP Models. Applied Sciences 11(21): Article 9919.

Jamshidi, A., A. Yazdani-Chamzini, S.H. Yakhchali, and S. Khaleghi. 2013. Developing a new fuzzy inference system for pipeline risk assessment. Journal of Loss Prevention in the Process Industries 26(1): 197–208.

Jia, N., Z. Yang, M. Xie, Y. Mitani, and J. Tong. 2014. GIS-based three-dimensional slope stability analysis considering rainfall infiltration. Bulletin of Engineering Geology and the Environment 74(3): 919–931.

Karrech, A., X. Dong, M. Elchalakani, H. Basarir, M.A. Shahin, and K. Regenauer-Lieb. 2021. Limit analysis for the seismic stability of three-dimensional rock slopes using the generalized Hoek-Brown criterion. International Journal of Mining Science and Technology 32(2): 237–245.

Kunert, H.G., J.L. Otegui, and A. Marquez. 2012. Nonlinear FEM strategies for modeling pipe–soil interaction. Engineering Failure Analysis 24: 46–56.

Lee, E.M., J.M.E. Audibert, J.V. Hengesh, and D.J. Nyman. 2009. Landslide-related ruptures of the Camisea pipeline system, Peru. Quarterly Journal of Engineering Geology and Hydrogeology 42(2): 251–259.

Leynes, R.D., W.P.C. Pioquinto, and J.A. Caranto. 2005. Landslide hazard assessment and mitigation measures in Philippine geothermal fields. Geothermics 34(2): 205–217.

Li, G., P. Zhang, Z. Li, Z. Ke, and G. Wu. 2016. Safety length simulation of natural gas pipeline subjected to transverse landslide. Electronic Journal of Geotechnical Engineering 21: 4387–4399.

Liang, Z., Q. Yang, J. Zhang, and B. Zhu. 2019. Mechanical Analysis of buried polyethylene pipelines under ground overload. Journal of Failure Analysis and Prevention 19(1): 193–203.

Liang, G., X. Zhang, X. Ling, H. Zhou, and W. Lin. 2021. Analysis of temporal-spatial characteristics of geological disasters in China from 2009 to 2019. Journal of Disaster Prevention and Reduction 37(3): 1674–8565.

Liu, C., D.D. Pollard, and B. Shi. 2013. Analytical solutions and numerical tests of elastic and failure behaviors of close-packed lattice for brittle rocks and crystals. Journal of Geophysical Research: Solid Earth 118(1): 71–82.

Liu, C., D.D. Pollard, S. Deng, and A. Aydin. 2015. Mechanism of formation of wiggly compaction bands in porous sandstone: 1. Observations and conceptual model. Journal of Geophysical Research: Solid Earth 120(12): 8138–8152.

Liu, C., Q. Xu, B. Shi, S. Deng, and H. Zhu. 2017. Mechanical properties and energy conversion of 3D close-packed lattice model for brittle rocks. Computers & Geosciences 103: 12–20.

Liu, P., J. Zheng, B. Zhang, and P. Shi. 2010. Failure analysis of natural gas buried X65 steel pipeline under deflection load using finite element method. Materials & Design 31(3): 1384–1391.

Lombardi, L., M. Nocentini, W. Frodella, T. Nolesini, F. Bardi, E. Intrieri, and N. Casagli. 2016. The Calatabiano landslide (southern Italy): Preliminary GB-InSAR monitoring data and remote 3D mapping. Landslides 14(2): 685–696.

Marinos, V., G. Stoumpos, and C. Papazachos. 2019. Landslide hazard and risk assessment for a natural gas pipeline project: The case of the trans Adriatic pipeline, Albania section. Geosciences 9(2): Article 61.

McQuillan, A., I. Canbulat, and J. Oh. 2020. Methods applied in Australian industry to evaluate coal mine slope stability. International Journal of Mining Science and Technology 30(2): 151–155.

Rajani, B.B., P.K. Robertson, and N.R. Morgenstern. 1995. Simplified design methods for pipelines subject to transverse and longitudinal soil movements. Canadian Geotechnical Journal 32(2): 309–323.

Rojhani, M., M. Moradi, A. Galandarzadeh, and S. Takada. 2012. Centrifuge modeling of buried continuous pipelines subjected to reverse faulting. Canadian Geotechnical Journal 49(6): 659–670.

Sun, W., G. Wang, and L. Zhang. 2021. Slope stability analysis by strength reduction method based on average residual displacement increment criterion. Bulletin of Engineering Geology and the Environment 80(6): 4367–4378.

Tang, Z. 2020. Rupture and explosion of natural gas pipeline caused by road collapse in Suide, Shaanxi Province. https://m.baidu.com/sf_baijiahao/s?id=1674167473749322696&wfr=spider&for=pc&sa=vs_ob_realtime. Accessed 5 Jun 2022 (in Chinese).

Topal, T., and M. Akin. 2009. Geotechnical assessment of a landslide along a natural gas pipeline for possible remediations (Karacabey-Turkey). Environmental Geology 57(3): 611–620.

Vasconez, F., M. Estrella, A. Velastegui, J. Nunez, H. Ponce, and P. Riofrio. 2010. Landslide hazard assessment, monitoring, and stabilization: Villano oil pipeline system, Ecuador. Paper presented at the SPE Annual Technical Conference and Exhibition, 19–22 September 2010, Florence, Italy.

Vasseghi, A., E. Haghshenas, A. Soroushian, and M. Rakhshandeh. 2021. Failure analysis of a natural gas pipeline subjected to landslide. Engineering Failure Analysis 119: Article 105009.

Wang, F., and J. Pan. 2017. Explosion of natural gas pipeline in Southwest Guizhou: 8 dead and 35 injured. http://www.bjnews.com.cn/news/2017/07/02/448871.html?from=timeline&isappinstalled=0. Accessed 3 Jul 2017 (in Chinese).

Xia, G., C. Liu, C. Xu, T. Le, and L. Foong. 2021. Dynamic analysis of the high-speed and long-runout landslide movement process based on the discrete element method: A case study of the Shuicheng landslide in Guizhou. China. Advances in Civil Engineering S1: 1–16.

Xie, F., C. Liu, T. Zhao, and G. Xia. 2021. Slope stability analysis via Discrete Element Method and Monte Carlo Simulations. Earth and Environmental Science 861(3): Article 032023.

Xiong, J., Y. Cao, M. Sun, Y. Wang, and Z. Yong. 2020. Vulnerability evaluation of long-distance oil and gas pipeline under landslide actions based on GIS and Entropy Weight Method. Mountain Research 38(5): 717–725 (in Chinese).

Xu, L., and X. P, and G. Lu. 2022. Dynamic response analysis of gas pipeline under landslide based on DEM⁃FEM coupling. Science Technology and Engineering 22(9): 3518–3524.

Yan, Y., Y. Cui, X. Huang, J. Zhou, W. Zhang, S. Yin, J. Guo, and S. Hu. 2022. Combining seismic signal dynamic inversion and numerical modeling improves landslide process reconstruction. Earth Surface Dynamics 10: 1233–1252.

Yan, Y., S. Ma, S. Yin, S. Hu, Y. Long, C. Xie, and H. Jiang. 2021. Detection and numerical simulation of potential hazard in oil pipeline areas based on UAV surveys. Frontiers in Earth Science 9: Article 665478.

Yan, Y., G. Xiong, J. Zhou, R. Wang, W. Huang, M. Yang, and D. Geng. 2022. A whole process risk management system for the monitoring and early warning of slope hazards affecting gas and oil pipelines. Frontiers in Earth Science 9: Article 1336.

Yan, Y., D. Yang, D. Geng, S. Hu, Z. Wang, W. Hu, and S. Yin. 2019. Disaster reduction stick equipment: A method for monitoring and early warning of pipeline-landslide hazards. Journal of Mountain Science 16(12): 2687–2700.

Yuan, F., L. Li, Z. Guo, and L. Wang. 2015. Landslide impact on submarine pipelines: Analytical and numerical analysis. Journal of Engineering Mechanics 141(2): Article 04014109.

Zahid, U., A. Godio, and S. Mauro. 2020. An analytical procedure for modelling pipeline-landslide interaction in gas pipelines. Journal of Natural Gas Science and Engineering 81: Article 103474.

Zhang, L., M. Fang, X. Pang, X. Yan, and Y. Cao. 2018. Mechanical behavior of pipelines subjecting to horizontal landslides using a new finite element model with equivalent boundary springs. Thin-Walled Structures 124: 501–513.

Zhang, S., S. Li, S. Chen, Z. Wu, R. Wang, and Y. Duo. 2017. Stress analysis on large-diameter buried gas pipelines under catastrophic landslides. Petroleum Science 14(3): 579–585.

Zhang, J., Z. Liang, and C. Han. 2016. Mechanical behavior analysis of the buried steel pipeline crossing landslide area. Journal of Pressure Vessel Technology 138(5): Article 051702.

Zhang, Y., X.M. Meng, T.A. Dijkstra, C.J. Jordan, G. Chen, R.Q. Zeng, and A. Novellino. 2020. Forecasting the magnitude of potential landslides based on InSAR techniques. Remote Sensing of Environment 241: Article 111738.

Zhang, Y., J. Shuai, H. Zhang, D. Yang, H. Jiang, and K. Shan. 2020. A remote real⁃time monitoring system for landslide pipeline state based on cloud service platform. Journal of Safety Science and Technology 16(2): 124–129.

Zhang, Y., J. Tang, Y. Cheng, L. Huang, F. Guo, X. Yin, and N. Li. 2022. Prediction of landslide displacement with dynamic features using intelligent approaches. International Journal of Mining Science and Technology 32(3): 539–549.

Zheng, J., B. Zhang, P. Liu, and L. Wu. 2012. Failure analysis and safety evaluation of buried pipeline due to deflection of landslide process. Engineering Failure Analysis 25: 156–168.

Zhou, X. 2018. Analysis of 10 third party damage accidents of high pressure and above gas pipeline from 2009 to 2017. Technology and Market 25(59–61): 64 (in Chinese).

Zhu, Y., T. Ishikawa, Y. Zhang, B.T. Nguyen, and S.S. Subramanian. 2022. A FEM-MPM hybrid coupled framework based on local shear strength method for simulating rainfall/runoff-induced landslide runout. Landslides 19(8): 2021–2032.

Zhu, H., and M.F. Randolph. 2010. Large deformation finite-element analysis of submarine landslide interaction with embedded pipelines. International Journal of Geomechanics 10(4): 145–152.

Acknowledgments

This study was financially supported by the National Natural Science Foundation of China (Grant Nos. 42120104002, 42271075, and U21A2008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Yan, Y., Zhou, J., Xie, C. et al. Quantitative Estimation of Pipeline Slope Disaster Risk in China. Int J Disaster Risk Sci 14, 298–312 (2023). https://doi.org/10.1007/s13753-023-00462-5

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13753-023-00462-5