Abstract

Poly(styrene-glycidyl methacrylate) (PSGMA) latex was synthesized by emulsion polymerization method. PSGMA latex was modified with N-methyl-d-glucamine (NMDG), 1,2-bis(3-aminopropylamino)ethane (BAPE), N-(2-hydroxyethyl)ethylenediamine (HEA), and N,N'-dimethylethylenediamine (NMEA). The presence of N amount varying between 2.1 and 4.4% in the results of elemental analysis showed that the modification was successful. Boron adsorption studies were carried out using these modified latexes. The study was carried out using the curcumin method by UV–vis spectrophotometry. For the most effective adsorption process, at pH value of 9, the boron concentration was 10 ppm and the contact time was 60 min. It was found that latex modified with NMDG had a higher adsorption capacity (0.195 mmol/g) than other modified latexes. Particle sizes were determined by dynamic light scattering spectrometry and scanning electron microscopy (SEM) analyses. The particle diameter of PSGMA latex was found to be approximately 140 nm in SEM analysis and the particles were almost monodisperse. After PSGMA latex was modified with NMDG, BAPE, HEA, and NMEA agents and boron adsorption was performed, it was observed that the particle diameters increased to approximately 170, 270, 220, and 260 nm, respectively. An elemental analyzer was used to determine the %N of the structures. The %B2O3 of the structures was determined with a thermogravimetric analyzer. While thermal analysis studies showed that organic components were completely removed from the structure at 700 °C, residues ranging from 4.8 to 10.4% (%B2O3) were found in boron adsorption polymers. The %B amounts were determined with an inductively coupled plasma mass spectroscopy device. It was observed that the amount of adsorbed boron varied between 0.42 and 0.95%, and the highest amount of %B belonged to latex modified with NMDG due to its very simple structure and the location of the –OH groups.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Emulsion polymerization is an important method used in the synthesis of polymer particles, scientifically, commercially, and technologically [1, 2]. Polymeric particles prepared by emulsion polymerization have been extensively researched in recent years and used in many fields such as paints, cosmetic, adhesives, drug delivery systems, automotive industry, textile, and paper coating [3,4,5]. Water is generally used as a solvent in emulsion polymerization, which proceeds through the radical polymerization reaction [6, 7]. An emulsion of the hydrophobic monomer with a surfactant is formed and the reaction is initiated with an initiator capable to form radicals. At the end of the reaction, a milky liquid called “latex” is obtained. The latex is a dispersion of inorganic or organic polymer particles with a colloidal structure dispersed in water. The sizes of the resulting spherical latex particles can vary between 0.1 and 1 µm [8, 9].

Boron (B) element is a natural mineral which is found in the form of borate salts, boric acid, and borosilicate minerals [10], with atomic number five, found in the earth's crust and constituting approximately 0.001 of the earth's crust by weight. Considering the world rankings, Turkey is the country with the most boron reserves and the country that produces the most boron minerals [11]. Boron and boron compounds are widely used in many industries such as ceramics, fuels, porcelain, cosmetics, insecticides, glass, semiconductors, leather, cleaning products pharmaceuticals, electronics, and catalysts. Additionally, the isotope boron-10 plays a crucial role in the nuclear industry, being able to control the rate of nuclear reaction to prevent a nuclear explosion [12]. Boron, which is used in many areas and is very useful, can cause toxic effects in humans, animals and plants if the exposure limit is exceeded [13]. Since there are a number of environmental and health problems caused by boron, the World Health Organization (WHO) has created guidelines for boron limits in drinking water. In 2011, there was a revised the guideline value of boron to 2.4 mg/L [14]. Many methods such as adsorption, membrane filtration, electrodialysis, solvent extraction, and precipitation are used in the literature to remove boron from water. The most economical technique among these methods is adsorption, because this technique can be used easily even if boron is in low concentration [15, 16]. When the literature is examined, many natural and synthetic materials such as minerals and clay, polymeric particles, resins, MOFs, metal oxides and activated carbon have been used to remove boron from aqueous solutions [17]. In recent years, there are many polymers used as boron-selective sorbents in the literature. Some of these are those: poly(glycidyl methacrylate-co-trimethylolpropane trimethacrylate) [18], iminobis-(propylene glycol)-modified chitosan beads [19], the silica–polyallylamine composites [20], glycidyl methacrylate grafted on p(VBC) beads [21], the monodisperse poly(vinylbenzylchloride-co-divinylbenzene) [22], poly(styrene-co-divinylbenzene) [23], and glycidyl methacrylate–methyl methacrylate–divinyl benzene terpolymer [24].

In the study carried out by Xin Li et al., the efficiency of hydrophilic silica–polyallylamine composite (SPC)-based polymer in the water treatment industry was investigated. In the study, first, a new boron adsorbent based on hydrophilic SPC matrix was prepared and N-methyl-d-glucamine (NMDG) modification was carried out. The adsorbent maintained its integrity and high boron removal efficiency after multiple adsorption and desorption cycles [20]. Highly porous polymers have shown promise in adsorption retention of boric acid, a neutral pollutant that is difficult to separate from seawater using conventional reverse osmosis membranes [25]. The incorporation of NMDG into the porous walls of high surface area porous aromatic frameworks (PAF) is accomplished through a straightforward two-step synthesis, resulting in the creation of adsorbents known as PAF-NMDG. PAF-NMDG demonstrates the remarkable ability to reduce boron concentrations in synthetic seawater from 2.91 to less than 0.5 ppm in under 3 min, using only 0.3 mg/mL of adsorbent. Furthermore, it exhibits a high degree of regenerability through acid and base treatment, maintaining stable boron adsorption capacities over at least 10 regeneration cycles. These findings underscore the manifold advantages of employing PAFs over conventional porous polymers in water treatment applications. The spherical NMDG-based hybrid adsorbent is a commonly utilized solution for the highly efficient adsorption of boric acid from water. A novel spherical boron-selective hybrid adsorbent was prepared through a reverse suspension polymerization process, utilizing a sol–gel reaction involving an organosiloxane precursor derived from NMDG and tetramethoxysilane [26]. Notably, this synthesized hybrid adsorbent exhibited an exceptionally high boron adsorption capacity in aqueous solutions, surpassing the performance of the majority of commercial polymer resins and grafting-type adsorbents. Mass spectrometry analysis of the NMDG complex with boric acid confirmed that the predominant interaction during adsorption in the hybrid adsorbent was a 1:1 complexation between NMDG and boron. This research underscores the significant potential of the studied adsorbent for the removal of boron from aqueous solutions. A new multi-hydroxyl functional group based on methacrylate-containing polymeric sorbent was prepared starting from cross-linked glycidyl methacrylate-containing spherical beads [27]. Epoxy-functional spheres can easily undergo a reaction with excess tris(2-aminoethyl)amine to produce an amine sorbent. This resin is subsequently modified with glycidol to introduce multiple hydroxyl groups. The obtained polymeric sorbent was shown to be effective in chelating with H3BO3 and the maximum boron retention capacity of the resin was found to be 4.20 mmol/g resin. The kinetic results of boron retention indicated that the resin is suitable for removing boron, even at ppm concentrations. Furthermore, after undergoing four consecutive adsorption–desorption cycles, the resin exhibited reliable performance for reuse. The adsorbents employed during the adsorption process must possess two primary characteristics: a porous structure and specific functional groups that exhibit preference for adsorbates. The research encompassed the creation of a porous polymer with selective functional groups for boron, achieved by initiating suspension polymerization using readily available GMA and ethylene glycol dimethacrylate (EGDMA) monomers.

In here, poly(styrene-glycidyl methacrylate) (PSGMA) latex was synthesized by emulsion polymer and modified with NMDG, 1,2-bis(3-aminopropylamino)ethane (BAPE), N-(2-hydroxyethyl)ethylenediamine (HEA) and N,N'-dimethylethylenediamine (NMEA). Particle size and polydispersity index (PDI) values of the synthesized PSGMA latex were determined by examining the dynamic light scattering spectrometry (DLS) results. In addition, the obtained results were supported by scanning electron microscope (SEM) images. The modified structures were used in boron adsorption studies. As a result of this adsorption process, the amount of boron oxide (%B2O3) in their structure was determined from the thermogravimetric analyzes of the particles. When the results of the four modified latexes were compared, it was observed that the percentage B2O3 value of the NMDG modified latex was higher than the others. Also, the boron adsorption study was carried out using the curcumin method by UV–vis spectrophotometry. It was found that latex modified with NMDG had a higher adsorption than other latexes. There is no study in the literature where PSGMA latex was modified with four different agents such as NMDG, BAPE, HEA, and NMEA in the same study and used in boron adsorption studies. In this respect, it will add innovation to the literature in terms of using four different modification agents in a single study and revealing the differences of the new materials in boron adsorption studies.

Experimental

Materials

Glycidyl methacrylate (GMA, 97%, Aldrich) and styrene (S, 99%, Aldrich) monomers were used in the synthesis of PSGMA. Monomers were passed through basic alumina column before use to remove inhibitors. Sodium dodecyl sulfate (SDS, ≥99%, Merck) was used as a stabilizer and ammonium persulfate (APS, ≥98%, Merck) was used as an initiator. BAPE (95%, Aldrich), NMEA (95%, Aldrich), HEA (99%, Sigma), NDMG (99%, Fluka), N,N-dimethylformamide (DMF, 99%, Sigma-Aldrich), glycidol (96%, Aldrich), and boric acid (H3BO3, 99%, Alpha-Aesar) were used in PSGMA latex modification. Curcumin (Naturel, TCI) was used for boron adsorption studies. Double-distilled water was used throughout the synthesis.

Methods

The diameters and PDI of the synthesized latexes were measured using a 90° angle with the Malvern ALV/CGS-3 DLS device at room conditions with 3 repetitions after degassing in an ultrasonic bath. Seiko SII EXSTAR600 model thermogravimetric analyzer (TGA) device was used in thermal analysis studies. The analysis was carried out using N2 at a flow rate of 200 mL/min in the range of 30–700 °C with a temperature increase rate of 15 °C/min. The surface morphology of the synthesized, modified particles was examined with a Jeol JSM 5600 brand SEM. ThermoiCAP RQ inductively coupled plasma mass spectroscopy (ICP-MS) device was used to determine the elements in the particles qualitatively and quantitatively as a result of the modifications. Perkin Elmer 2400 Series II organic elemental analyzer (CHNS/O) device was used to determine %C, %H, and %N amounts as a result of modifications. Boron adsorption studies using the curcumin method were carried out using a Perkin Elmer Lambda 35 UV–vis spectrophotometer (UV–vis) at 200–700 nm at 25 °C.

Poly(styrene-glycidyl methacrylate) latex synthesis

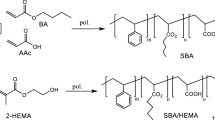

PSGMA latex was synthesized by emulsion polymerization. An amount of 0.06 g of surfactant SDS was dissolved in 68 mL of water. It was mixed in nitrogen environment at 400 rpm for 10 min. A volume of 5 mL styrene (S) was transferred to the medium. 0.1 g of APS was added to the medium with 2 mL of water to start the reaction, and the reaction flask was placed in an oil bath at 60 °C. GMA monomer of 5 mL was added to the flask after 300 min. The reaction was continued for 24 h at 400 rpm. The polymerization reaction is given in Fig. 1. Purification of PSGMA latex was done by centrifugation with distilled water three times at 15,000 rpm for 10 min. The synthesized PSGMA latex particles were in nanometer size and had a milky appearance. The particle was freeze-dried and the latex was preserved in a solid state after purification. DLS and SEM analyzes were performed to determine the particle size of the latex obtained at the end of the synthesis. Then the modification processes were started.

Modifications of PSGMA latex

It is aimed to increase the hydroxyl ends in the structure by opening the epoxy ring on the surface of PSGMA latex. For this purpose, four different amine structures containing hydroxyl groups were selected such as NMDG, BAPE, HEA, and NMEA. After the modification, boron adsorption studies were carried out and the effect of amine groups on adsorption was examined.

Modification of PSGMA latex with NMDG (PSGMA1)

0.5 g of PSGMA latex, 2.5 g of NMDG, 40 mL of DMF were added into a reaction bottle, and it was mixed kept on an oil bath at 500 rpm for 48 h at 80 °C. The modified latex was washed three times with distilled water, centrifuged at 25,000 rpm, and freeze-dried. As seen in Fig. 2, the modification reaction occurs when the amine group opens the epoxy ring of GMA.

Modification of PSGMA latex with amine structures (BAPE, HEA, and NMEA)

On 0.45 g of PSGMA latex in a bottle 35 mL of amine structures (BAPE, HEA, and NMEA) were added. It was stirred at room temperature for 24 h and then at 90 °C on an oil bath at 500 rpm for 2 h. The modified latexes were washed three times with distilled water, centrifuged at 25,000 rpm, and freeze-dried. Next, 0.45 g of the latexes was taken into the bottle, 6 mL of DMF and 2 mL of glycidol were added and mixed at room temperature for 24 h and then 60 °C on oil bath at 500 rpm. The modified latexes were washed 3 times for 20 min at 25,000 rpm and freeze-dried. Latexes modified with BAPE, HEA, and NMEA are named PSGMA2, PSGMA3, and PSGMA4, respectively. As seen in Fig. 3, the modification reactions occur when the amine group opens the epoxy ring of GMA.

The success of the modifications of PSGMA latexes with structures containing amine groups was confirmed by looking at %N data from the elemental analysis results in Table 1.

Boron adsorption studies

–OH group is a highly specific group in boron adsorption. The aim of the study was to modify the PSGMA latex surface with chemicals containing different amounts of –OH groups, determine boron adsorption capacities, compare the values, and determine the latex with the highest boron adsorption capacity.

In boron adsorption studies, modified PSGMA latexes were weighed separately as 500 mg and placed in capped bottles. 20 mL of boric acid solution (pH 9) of different concentrations (1, 3, 5, 10, 15, 20, 50 and 100 mg/L) was placed on them and mixed at 400 rpm for 24 h. Boric acid concentration was measured before and after the process using the spectrophotometry method with curcumin as the color-developing reagent in accordance with the literature. Following each experiment, the remaining concentration of the boric acid solution post-adsorption was determined using a UV–vis spectrophotometer at wavelength of 540 nm, in accordance with the curcumin method [28, 29]. 0.5 M HCl solution and 0.5 M NaOH solution were used to adjust the pH values of boron solutions. As a result, boron adsorption capacities were calculated.

In the experiment, the adsorption capacity of boric acid, denoted as q (mmol/g), was determined using the following equation:

where Co represents the initial concentration of the boric acid solution before adsorption (mmol/L), Ce signifies the residual concentration of the boric acid solution after adsorption (mmol/L), V denotes the volume of the boric acid solution (L), and m stands for the dry weight of PSGMA latexes (g).

To investigate the pH impact on the adsorption capabilities of PSGMA latexes, experiments were conducted using boric acid solutions at temperature of 25 °C, a concentration of 10 ppm (20 mL), and pH values ranging from 3 to 12.

Boron-adsorbed modified latexes were dried in an oven at 50 °C. At the same time, SEM images of these latexes, TGA results, and ICP-MS were examined after boron adsorption.

Results and discussion

Characterizations of PSGMA latex

Particle sizes and PDI values of PSGMA latex were examined by DLS and SEM. The DLS results and SEM image are given in Fig. 4. When the SEM image of PSGMA latex was examined, it was determined that the particle diameters were approximately 140 nm and the particles had a highly monodisperse distribution. In the DLS results, the radius of the latex was 74 nm (diameter 148 nm) and the PDI value was 0.04. SEM and DLS analysis results support each other.

Elemental analysis results of modified PSGMA latexes

First, modification process with amine groups and then boron adsorption were applied to PSGMA latex. %C, %H, and %N amounts of modified latexes were determined by elemental analysis. The elemental analysis results are given in Table 1.

In the elemental analysis results, it is seen that the modification processes with amine groups are successful. As a result of elemental analysis, it was concluded that the unmodified latex (PSGMA) does not contain nitrogen. The %N content of modified latexes varies between 2.1 and 4.4%. Due to different number of amine groups in the modification agents, %N amounts showed different results in each of them.

Evaluation of boron-adsorbed PSGMA latexes

SEM images and DLS chromatograms of PSGMA1 latex after boron adsorption process (PSGMA1b) were examined and the change in latex size after adsorption was examined. Looking at the SEM images, the particle diameter of PSGMA latex was approximately 140 nm (Fig. 4) before the modification process and boron adsorption, but it increased to 170 nm after the modification and boron adsorption (Fig. 5). This increase in particle size confirms that modification and boron adsorption have occurred. Likewise, DLS results confirm this situation. It was observed that the particle radius increased from 74 to 82 nm. At the same time, the particles are highly monodisperse. The SEM image and DLS chromatogram of PSGMA1b are given in Fig. 5.

SEM images of boron-adsorbed latexes (PSGMA1b, PSGMA2b, PSGMA3b, and PSGMA4b) were taken and TGA analyzes were performed. SEM images are given in Fig. 6 and TGA results are given in Fig. 7.

When we look at the SEM images, the monodisperse structure is not disappeared and the particle diameters increase after the modifications of PSGMA and the adsorption of boric acid. After PSGMA latex was modified with NMDG, BAPE, HEA, and NMEA agents and boron adsorption was performed, it was observed that the particle diameters increased to approximately 170, 270, 220, and 260 nm, respectively. Thermogravimetric analysis was used to compare the amount of %B2O3 adsorbed by the modified latexes. Thermogravimetric analyzes of the synthesized particles were performed using nitrogen gas at a temperature increase rate of 15 °C/min in the range of 30–700 °C and a flow rate of 200 mL/min (Fig. 7). When TGA data are analyzed, the most obvious difference is that the decomposition graph gives a single weight loss up to 400 °C since PSGMA is in the raw state, while the weight loss occurs gradually in PSGMA, which has been subjected to the other modified and boron adsorption application, due to the presence of the amine group in its structure. Apart from this, it is observed that first the solvent and then the carbon, oxygen, hydrogen, and amine groups that make up the polymer are removed from structure. We see that there is a structure that does not move away from the polymer when the temperature reaches 700 °C in PSGMA with boric acid adsorption process. It has been confirmed by the examples in the literature that this structure is B2O3, which is known to start at 1400 °C [30, 31]. The remaining %B2O3 amounts are given in Table 2.

As a result of the thermogravimetric analysis, it was observed that the boron adsorption rates were different due to the different positions of the –OH groups in the structures selected as the modification agent. While the sample that adsorbs the most boron is PSGMA1 modified with NMDG, the least adsorption is observed in PSGMA4 latex modified with NMEA. Looking at the differences in %B2O3 amounts in Table 2, it is quite clear that these amounts arise from steric hindrances, the number and positions of –OH groups in the molecules.

The amount of %B adsorbed by boron-adsorbed latexes was determined by the ICP-MS analysis method. The presence of –OH groups in different positions and in different numbers in the structures gave results varying between 0.42 and 0.95% of the adsorbed boron amounts (Table 3). It is seen that the highest amount of %B is in PSGMA1 latex due to its rather simple structure and the positions of –OH groups.

Boron adsorption studies with curcumin method

The boron adsorption studies were carried out using the curcumin method by UV–vis spectrophotometry. The study focused on evaluating the boron adsorption performance of PSGMA latexes, taking into account the variables of pH value, boron concentration, and contact time. The results of these investigations are presented in Fig. 8.

Effect of pH on boron adsorption

Solution pH values were adjusted between 3 and 12 and 20 mL of boric acid solution with a concentration of 10 ppm was used. These solutions were mixed with 0.5 g of modified PSGMA latexes for 24 h. At the end of this period, boron adsorption capacities were calculated and the effect of solution pH on adsorption was examined. The q-pH graph is given in Fig. 8a. As can be seen from the graph, the highest adsorption capacity was reached in PSGMA1 latex at pH 9. This value for PSGMA1 latex was determined to be 0.195 mmol/g. All subsequent studies were carried out at pH 9, where the highest adsorption capacity was reached. The highest boron adsorption capacity value was reached in NMDG modified PSGMA latex (PSGMA1). The pH-dependent nature of boron adsorption can be elucidated by considering the formation of a tetradentate complex between borate and NMDG, alongside the dissociation process of H3BO3. The adsorption of boron, particularly its selective adsorption, is primarily governed by the creation of the tetradentate complex. An increase in pH levels proves to be advantageous in facilitating the formation of the tetradentate complex, thereby leading to an elevated boron adsorption capacity. This mechanistic insight underscores the importance of pH control in optimizing boron adsorption processes. Nevertheless, it is important to note that an escalation in pH levels also promotes a competitive reaction, namely, the dissociation process of H3BO3 into tetrahydroxyborate anions. This phenomenon exerts an unfavorable impact on the overall boron adsorption capacity. At pH values approximately around 9, H3BO3 attains a state of dissociation equilibrium (with a pKa value of 9.2). In this context, an increase in pH becomes more conducive to the formation of tetrahydroxyborate anions rather than the tetradentate complex, ultimately leading to a reduction in boron adsorption capacity. Conversely, within the pH range of 4.0–9.0, the quantity of adsorbed boron, as well as the prevalence of tetrahydroxyborate anions, both exhibits an upward trend in correlation with rising pH levels [20].

As a result of modifications, latexes have different numbers of –OH groups, and the –OH groups found in the structures are specific groups that are very important in boron adsorption. The numbers of –OH groups in PSGMA1, PSGMA2, PSGMA3, and PSGMA4 latexes are 5, 11, 6, and 3, respectively. While the highest adsorption is expected to be in PSGMA2 latex, which contains 11 –OH groups, the amount of boron binding decreases due to the steric hindrance in the structure and the boron adsorption capacity decreases. PSGMA1 latex is a simple molecule with less steric hindrance and its conformation is more suitable for binding boron to the structure. For these reasons, the highest adsorption capacity belongs to PSGMA1 latex. Although PSGMA3 latex has one more –OH group in its structure than PSGMA1 latex, it adsorbs less boron than PSGMA1 latex due to the more complex structure in PSGMA3 latex and the location of the –OH groups creating steric hindrance and reducing the binding of boron to the structure. Although PSGMA4 latex has the simplest structure, it has the lowest boron adsorption capacity due to the presence of 3 –OH groups.

The influence of boric acid concentration

To elucidate the connection between the adsorption capacity of PSGMA and the initial concentration of boric acid, a comprehensive examination was conducted. The study involved evaluating the adsorption capacity of modified PSGMA latexes at a range of boric acid concentrations ranging from 1 to 100 ppm, while maintaining a constant temperature of 25 °C and an initial pH of 9. The graphic showing the effect of boric acid concentration on adsorption capacity is given in Fig. 8b.

In the case where the boric acid concentration varied from 1 to 9 ppm, the predominant form of boron in solution was the single-molecule H3BO3/B(OH)4− [29]. During this range, the adsorption capacity of modified PSGMA latexes exhibited a direct correlation with the boron concentration, showing an increase in adsorption as the concentration of boron increased. In this range, the adsorption capacity increases rapidly. However, within the concentration range of 10–100 ppm, as the boric acid concentration continued to rise, the adsorption capacity of modified PSGMA latexes reached a plateau and that is, the adsorption capacity remained unchanged after 10 ppm. When the graph is examined (Fig. 8b), the latex with the highest adsorption capacity under the same conditions is PSGMA1 latex.

The impact of contact time

To ascertain the optimal contact time and investigate the correlation between the boron adsorption capacity and contact time of the modified PSGMA latexes, an adsorption equilibrium experiment was conducted. The latex of 0.5 g was used and the experiment was performed with an initial concentration of 10 ppm of 20 mL of boric acid, a temperature of 25 °C, and an initial pH of 9. The findings of this experiment are depicted in Fig. 8c.

The results indicated that modified PSGMA latexes exhibited a rapid initial rate of boron adsorption. However, as the contact time increased, the rate of boron adsorption gradually declined until it reached a plateau. After approximately 60 min of contact time, the adsorption capacity of modified PSGMA latexes remained relatively constant, signifying the attainment of adsorption equilibrium. By examining the graph in Fig. 8c, the highest adsorption capacity under the same conditions is shown by PSGMA1 latex. Additionally, a comparison of the boron adsorption capacities of the various adsorbents in the literature is given in Table 4. Although the value obtained in this study seems low, PSGMA latex among others is considered the promising materials in boron adsorption studies when appropriate modification processes are applied.

Conclusion

A poly(styrene-glycidyl methacrylate) latex was synthesized by emulsion polymerization method. The size of the latex was analyzed by DLS and it was observed that the PDI values were 0.04 and the particle radius was nearly 70 nm. In addition, it has been proven that the spherical particles in SEM image have a highly monodisperse size distribution and their diameter was determined to be about 140 nm, showing consistent results with the DLS device data. The PSGMA latex was modified with NMDG, BAPE, HEA, and NMEA. Epoxy ring of glycidyl methacrylate was opened by amine modification agents containing –OH group and boron adsorption was investigated. The success of the amine groups' attempt to open the epoxy ring has been proven by the elemental analysis results showing values varying between 2.1 and 4.4%N amount. After modifications, boron adsorption study was studied. The effects of solution pH, boron concentration, and contact time on boron adsorption were examined with curcumin method using UV–vis spectrophotometry. The pH value was determined as 9, the boron concentration was 10 ppm, and the contact time was 60 min for the most effective adsorption. Interestingly, it was observed that latex modified with NMDG exhibited a superior adsorption capacity of 0.195 mmol/g compared to other latex variations. Thermal analysis studies were carried out between 30 and 700 °C. It was observed that the organic components were completely removed from the structure reaching 700 °C. However, residues (%B2O3) varying between 4.8 and 10.4% were found in the polymers with boron adsorption. According to the results of ICP-MS analysis, it was observed that the boron content percentage of the NMEA agent with the least –OH group was 0.42% and the boron content percentage of the BAPE agent with the most –OH group was 0.82%. However, since there are five –OH groups on a single amine in the NMDG agent and there is no steric hindrance problem like other agents, it is seen that the boron content is 0.95% higher than the others. As a result, the four modifying agents used in the study were compared and it was decided that NMDG was the best modification agent that could be used in boron adsorption. When appropriate modification processes are applied to PSGMA latex, it will be among the promising materials in boron adsorption studies.

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Yamak HB (2013). In: Yilmaz F (ed) Polymer science. In Tech, Rejika. https://doi.org/10.5772/51498

Mahdavian AR, Ashjari M, Makoo AB (2007) Preparation of poly (styrene-methyl methacrylate)/SiO2 composite nanoparticles via emulsion polymerization. An investigation into the compatiblization. Eur Polym J 43:336–344. https://doi.org/10.1016/j.eurpolymj.2006.10.004

Jensen AT, Neto WS, Ferreira GR, Glenn AF, Gambetta R, Gonçalves SB, Valadares LF, Machado F (2017) Synthesis of polymer/inorganic hybrids through heterophase polymerizations. Recent Dev Polym Macro Micro Nano Blends 2017:207–235. https://doi.org/10.1016/B978-0-08-100408-1.00008-X

Rieger E, Blankenburg J, Grune E, Wagner M, Landfester K, Wurm FR (2018) Controlling the polymer microstructure in anionic polymerization by compartmentalization. Angew Chem Int Ed 57:2483–2487. https://doi.org/10.1002/anie.201710417

Gharieh A, Mahdavian AR, Salehi-Mobarakeh H (2014) Preparation of core-shell impact modifier particles for PVC with nanometric shell thickness through seeded emulsion polymerization. Iran Polym J23:27–35. https://doi.org/10.1007/s13726-013-0196-5

Zhang Q, Galvan-Miyoshi JM, Pezzotti F, Ming W (2013) Synthesis and surface properties of PDMS-containing latexes by emulsion polymerization using AIBN as the initiator. Eur Polym J 49:2327–2333. https://doi.org/10.1016/j.eurpolymj.2013.05.018

Gharieh A, Khoee S, Mahdavian AR (2019) Emulsion and miniemulsion techniques in preparation of polymer nanoparticles with versatile characteristics. Adv Colloid Interface Sci 269:152–156. https://doi.org/10.1016/j.cis.2019.04.010

Eliseeva VI, Ivanchev SS, Kuchanov SI, Lebedev AV (1981) Emulsion polymerization and its applications in industry. Springer Science & Business Media, Berlin. https://doi.org/10.1007/978-1-4684-1641-1

Schneider P (1956) Emulsion polymerization, von F. A. Bovey, I. M. Kolthoff, A. I. Medalia und E. J. Meehan. Interscience Pub Inc., New York. 1955. 1.Aufl. XII, 445 S. Angew Chem 68:597–598. https://doi.org/10.1002/ange.19560681741

Dolati M, Aghapour AA, Khorsandi H, Karimzade S (2017) Boron removal from aqueous solutions by electrocoagulation at low concentrations. J Environ Chem Eng 5:5150–5156. https://doi.org/10.1016/j.jece.2017.09.055

Sokmen N, Buyukakinci BY (2018) The usage of boron/ boron compounds in the textile industry and its situation in Turkey. CBU Int Conf Proc 6:1158–1165. https://doi.org/10.12955/cbup.v6.1309

Guan Z, Lv J, Bai P, Guo X (2016) Boron removal from aqueous solutions by adsorption—a review. Desalination 383:29–37. https://doi.org/10.1016/j.desal.2015.12.026

Zhang X, Wei M, Zhang Z, Shi X, Wang Y (2022) Boron removal by water molecules inside covalent organic framework (COF) multilayers. Desalination 526:115548. https://doi.org/10.1016/j.desal.2022.115548

Edition F (2011) Guidelines for drinking-water quality. WHO chron 38:104–108

Öztürk N, Kavak D (2004) Boron removal from aqueous solutions by adsorption on waste sepiolite and activated waste sepiolite using full factorial design. Adsorption 10:245–257. https://doi.org/10.1023/B:ADSO.0000046361.62180.c6

Majidi A, Rahnemaie R, Hassani A, Malakouti MJ (2010) Adsorption and desorption processes of boron in calcareous soils. Chemosphere 80:733–739. https://doi.org/10.1016/j.chemosphere.2010.05.025

Lin JY, Mahasti NNN, Huang YH (2021) Recent advances in adsorption and coagulation for boron removal from wastewater: a comprehensive review. J Hazard Mater 407:124401. https://doi.org/10.1016/j.jhazmat.2020.124401

Wang L, Qi T, Gao Z, Zhang Y, Chu J (2007) Synthesis of N-methylglucamine modified macroporous poly(GMA-co-TRIM) and its performance as a boron sorbent. React Funct Polym 67:202–209. https://doi.org/10.1016/j.reactfunctpolym.2006.11.001

Gazi M, Shahmohammadi S (2012) Removal of trace boron from aqueous solution using iminobis-(propylene glycol) modified chitosan beads. React Funct Polym 72:680–686. https://doi.org/10.1016/j.reactfunctpolym.2012.06.016

Li X, Liu R, Wu S (2011) Efficient removal of boron acid by N-methyl-d-glucamine functionalized silica-poly(allylamine) composites and its adsorption mechanism. J Colloid Interface Sci 361:232–237. https://doi.org/10.1016/j.jcis.2011.05.036

Bayramoglu G, Yavuz E, Senkal BF, Arica MY (2009) Glycidyl methacrylate grafted on p(VBC) beads by SI-ATRP technique: modified with hydrazine as a salt resistance ligand for adsorption of invertase. Colloids Surf A Physicochem Eng Asp 345:127–134. https://doi.org/10.1016/j.colsurfa.2009.04.044

Samatya S, Tuncel SA, Kabay N (2015) Boron removal from RO permeate of geothermal water by monodisperse poly(vinylbenzyl chloride-co-divinylbenzene) beads containing N-methyl-d-glucamine. Desalination 364:75–81. https://doi.org/10.1016/j.desal.2014.01.029

Santander P, Rivas BL, Urbano BF, İpek İY, Özkula G, Arda M, Yüksel M, Bryjak M, Kozlecki T, Kabay N (2013) Removal of boron from geothermal water by a novel boron selective resin. Desalination 310:102–108. https://doi.org/10.1016/j.desal.2012.08.026

Xu Y, Jiang JQ (2008) Technologies for boron removal. Ind Eng Chem Res 47:16–24. https://doi.org/10.1021/ie0708982

Kamcev J, Taylor MK, Shin DM, Jarenwattananon NN, Colwell KA, Long JR (2019) Functionalized porous aromatic frameworks as high-performance adsorbents for the rapid removal of boric acid from water. Adv Mater 31:1808027. https://doi.org/10.1002/adma.201808027

Zhang X, Wang J, Chen S, Bao Z, Xing H, Zhang Z, Su B, Yang Q, Yang Y, Ren Q (2017) A spherical N-methyl-d-glucamine-based hybrid adsorbent for highly efficient adsorption of boric acid from water. Sep Purif Technol 172:43–50. https://doi.org/10.1016/j.seppur.2016.08.002

Torunoglu TG, Burak K, Erdem Y, BahireFiliz S (2022) A new multi-hydroxyl methacrylate based adsorbent for boron removal from aqueous solutions. Sep Sci Technol 57:1702–1713. https://doi.org/10.1080/01496395.2021.2006229

Spicer GS, Strickland JDH (1958) The determination of microgram and sub-microgram amounts of boron:absorptiometric determination using curcumin. Anal Chim Acta 18:231–239. https://doi.org/10.1016/S0003-2670(00)87133-0

Zhang Y, Liang X, Jiang T, Chen Z, Ji X (2022) Removal of boron from aqueous solutions by N-methyl-d-glucamine@γ-glycidoxypropyl-trimethoxysilane with nonwoven basalt fibers support. Mater Today Commun 31:103611. https://doi.org/10.1016/j.mtcomm.2022.103611

Pivkina AN, Meerov DB, Monogarov KA, Frolov YV, Muravyev NV (2020) Prospects of using boron powders as fuel. II. Influence of aluminum and magnesium additives and their compounds on the thermal behavior of boron oxide. Combust Explos Shock Waves 56:148–155. https://doi.org/10.1134/S0010508220020057

Aref’ev KY, Voronetskii AV, Prokhorov AN, Yanovskii LS (2017) Experimental study of the combustion efficiency of two-phase gasification products of energetic boron-containing condensed compositions in a high-enthalpy airflow. Combust Explos Shock Waves 53:283–292. https://doi.org/10.1134/S0010508217030054

SamatyaS KN, Tuncel A (2010) A hydrophilic matrix for boron isolation: Monodisperse-porous poly (glycidyl methacrylate-co-ethylene dimethacrylate) particles carrying diol functionality. React Funct Polym 70:555–562. https://doi.org/10.1016/j.reactfunctpolym.2010.05.004

Samatya S, Kabay N, Tuncel A (2012) Monodisperse-porous N-methyl-d-glucamine functionalized poly (vinylbenzyl chloride-co-divinylbenzene) beads as boron selective sorbent. J Appl Polym Sci 12:1475–1483. https://doi.org/10.1002/app.36912

Jyo A, Aoki S, Uchimura M, Yamabe K, Sugo T (2002) Behavior of chelating fibers having polyol groups in column mode adsorption of boric acid. Anal Sci Suppl 17:i1211–i1214. https://doi.org/10.14891/analscisp.17icas.0.i1211.0

Ying-Kai X, Bu-Yong L, Wei-Guo L, Yun X, George HS (2003) Ion exchange extraction of boron from aqueous fluids by amber-lite IRA 743 resin. Chin J Chem 21:1073–1079. https://doi.org/10.1002/cjoc.20030210819

Busch M, Mickols WE, Jons S, Redondo J, De Witte J (2004) Boron removal in sea water desalination. Int Desalin Water Reuse Q 13:25

Yilmaz AE, Boncukcuoğlu R, Kocakerim MM (2007) A quantitative comparison between electrocoagulation and chemical coagulation for boron removal from boron-containing solution. J Hazard Mater 149:475–481. https://doi.org/10.1016/j.jhazmat.2007.04.018

Funding

Open access funding provided by the Scientific and Technological Research Council of Türkiye (TÜBİTAK).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tuncer, C., Işık, M. Boron adsorption studies of poly(styrene-glycidyl methacrylate) latex: effect of modification agents. Iran Polym J (2024). https://doi.org/10.1007/s13726-024-01342-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13726-024-01342-5