Abstract

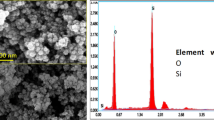

The effects of an ε-caprolactam (CL) modified nanosilica (MNS) component on thermal properties, morphology and rheological behavior of PA6/SiO2 nanocomposites were investigated. Star-shaped PA6/SiO2 nanocomposites were synthesized through a two-step in situ anionic ring-opening polymerization (AROP) of CL monomer by hexamethylene diisocyanate (HDI) linking the nanoparticles and CL in a reactive melt blending. The star-shaped structure was observed by field emission scanning electron microscope (FESEM) and elemental mapping. Moreover, the study on chemical structure of the samples was carried out by Fourier transform infrared (FTIR), energy-dispersive X-ray spectroscopy (EDX) and carbon nuclear magnetic resonance (13C NMR) spectroscopy. Incorporating MNS increased γ-crystal and arm numbers of the star-shaped structure. Thermal degradation increased in the star-shaped samples due to the effects of MNS and molecular weight (MW). However increasing the number of arms was effective in increasing the temperature of degradation. In addition, the crossover of storage modulus (Gʹ) and loss modulus (Gʺ) shifted to higher frequencies in the low- and lower frequencies in the multi-arms star-shaped samples. Shear viscosity and glass transition temperature (Tg) of the multi-arms samples with maximum MNS loading were lower than those of other samples. Furthermore, dispersity, and their MWs were higher than those of other samples. Therefore, the resulting multi-arms star-shaped nanocomposites may be desirable for industrial productions in absence of solvents and lowering cost and energy rather than linear PA6.

Graphic abstract

Similar content being viewed by others

References

Mahfuz H, Hasan M, Dhanak V, Beamson G, Stewart J, Rangari V, Wei X, Khabashesku V, Jeelani S (2008) Reinforcement of nylon 6 with functionalized silica nanoparticles for enhanced tensile strength and modulus. Nanotechnology 19:445702

Murthy NS (2006) Hydrogen bonding, mobility, and structural transitions in aliphatic polyamides. J Polym Sci Part B 44:1763–1782

Ageyeva T, Sibikin I, Karger-Kocsis J (2018) Polymers and related composites via anionic ring-opening polymerization of lactams: recent developments and future trends. Polymer 10:357

Zhu N, Gong H, Han W, Zeng WB, Wang HX, Fang Z, Zhang X, Li K (2015) Synthesis and characterization of star-branched polyamide 6 via anionic ring-opening polymerization with N, N′, N″-trimesoyltricaprolactam as a multifunctional activator. Chin Chem Lett 26:1389–1392

Hu GH, Li H, Feng LF (2006) Follow-up of the course of the anionic ring-opening polymerization of lactams onto an isocyanate bearing polymer backbone in the melt. J Appl Polym Sci 102:4394–4403

Su WF (2013) Principles of polymer design and synthesis. Springer-Verlag, Berlin

Russo S, Maniscalco S, Ricco L (2015) Some new perspectives of anionic polyamide 6 (APA 6) synthesis. Polym Adv Technol 26:851–854

Chemat F, Fabiano-Tixier AS, Vian MA, Allaf T, Vorobiev E (2015) Solvent-free extraction of food and natural products. Trends Anal Chem 71:157–168

Che J, Xiao Y, Wang X, Pan A, Yuan W, Wu X (2007) Grafting polymerization of polyacetal onto nano-silica surface via bridging isocyanate. Surf Coat Technol 201:4578–4584

Kannan K, Radhika D, Nesaraj AS, Sadasivuni KK, Raghava Reddy K, Kasai D, Raghu AV (2020) Photocatalytic, antibacterial and electrochemical properties of novel rare earth metal oxides-based nanohybrids. Mater Sci Energy Technol 3:853–861

Yu Y, Rong MZ, Zhang MQ (2015) Grafting of hyperbranched aromatic polyamide onto silica nanoparticles. Polymer 51:492–499

Shanmugan S, Gorjian S, Elsheikh AH, Essa FA, Omara ZM, Raghu AV (2021) Investigation into the effects of SiO2/TiO2 nanolayer on the thermal performance of solar box type cooker. Energy Sources Part A 43:2724–2737

Yang F, Ou Y, Yu Z (1998) Polyamide 6/silica nanocomposites prepared by in situ polymerization. J Appl Polym Sci 69:355–361

Cai L, Lin Z, Qian H (2010) Dispersion of nano-silica in monomer casting nylon6 and its effecton the structure and properties of composites. Exp Polym Lett 4:397–403

Yang J, Han CR, Duan JF, Xu F, Sun RC (2013) Interaction of silica nanoparticle/polymer nanocomposite cluster network structure: revisiting the reinforcement mechanism. J Phys Chem C 117:8223–8230

Shwetharani R, Chandana HR, Sakara Geetha M, Balakrishna R, Raghava Reddyb K, Raghu AV (2020) Photocatalytic semiconductor thin films for hydrogen production and environmental applications. Int J Hydrog Energy 45:18289–18308

Omidi S, Ahmadi S, Ghorbani P, Moazezi M (2015) In situ polymerization of ε-caprolactam in the presence of polyester polyol and nanosilica toward amorphous polyamide6/SiO2 nanocomposite. Iran Polym J 24:945–952

Li L, Yang G (2011) Synthesis and characterization of nylon 6/mesoporous silica nanocomposites via in situ synchronous hydrolytic polymerization of tetraethylorthosilicate and ε-caprolactam. J Appl Polym Sci 120:1957–1964

Li Y, Liu K, Xiao R (2017) Preparation and characterization of flame-retarded polyamide 66 with melamine cyanurate by in situ polymerization. Macromol Res 25:779–785

Motaung TE, Mochane MJ, Linganiso ZL, Mashigo AP (2017) In situ polymerization of nylon-cellulose nanocomposite. Polym Sci 3:1–8

Ahmadi S, Jahani Y, Naderi G, Asadollahzadeh AH (2015) Supertough (polyamide 6)/(acrylonitrile butadiene rubber) nano alloy through in situ polymerization of caprolactam in the presence of acrylonitrile butadiene rubber nanophase. J Vinyl Addit Technol 21:116–121

Wu ZW, Xu W, Liu YC, Xia JK, Wu QX, Xu WJ (2009) Preparation and characterization of flame-retardant melamine cyanurate/polyamide 6 nanocomposites by in situ polymerization. J Appl Polym Sci 113:2109–2116

Zeng H, Gao C, Wang Y, Watts PCP, Kong H, Cui X, Yan D (2006) In situ polymerization approach to multiwalled carbon nanotubes-reinforced nylon 1010 composites: mechanical properties and crystallization behavior. Polymer 47:113–122

Zhao X, Li Y, Chen W, Li S, Zhao Y, Du S (2019) Improved fracture toughness of epoxy resin reinforced with polyamide 6/graphene oxide nanocomposites prepared via in situ polymerization. Compos Sci Technol 171:180–189

Wang R, Wu L, Zhuo D, Zhang J, Zheng Y (2018) Fabrication of polyamide 6 nanocomposite with improved thermal conductivity and mechanical properties via incorporation of low graphene content. Ind Eng Chem Res 57:10967–10976

Zhang L, Xiong Y, Ou E, Chen Zh, Xiong Y, Xu W (2011) Preparation and properties of nylon 6/carboxylic silica nanocomposites via in situ polymerization. J Appl Polym Sci 122:1316–1324

Kashani Rahimi S, Otaigbe JU (2017) The effects of the interface on microstructure and rheo-mechanical properties of polyamide 6/cellulose nanocrystal nanocomposites prepared by in situ ring-opening polymerization and subsequent melt extrusion. Polymer 127:269–285

Kherroub DE, Belbachir M, Lamouri S, Bouhadjar L, Chikh K (2013) Synthesis of polyamide-6/montmorillonite nanocomposites by direct in situ polymerization catalysed by exchanged clay. Orient J Chem 29:1429–1436

Shen L, Du Q, Wang H, Zhong W, Yang Y (2004) In situ polymerization and characterization of polyamide 6/silica nanocomposites derived from water glass. Polym Int 53:1153–1160

Dixon D, Lemonine P, Hamilton J, Lubarsky G, Archer E (2013) Graphene oxide–polyamide 6 nanocomposites produced via in situ polymerization. J Thermoplast Compos Mater 28:372–389

Thomas H (2004) SEC molecular-weight-sensitive detection. Int J Polym Anal Charact 9:97–135

Warakomski JM (1992) Synthesis and properties of star-branched nylon 6. Chem Mater 4:1000–1004

Gopal Kadam P, Mhaske S (2011) Synthesis of star-shaped polymers. Des Monomer Polym 14:515–540

Fu P, Wang M, Liu M, Jing Q, Cai Y, Wang Y, Zhao Q (2011) Preparation and characterization of star-shaped nylon 6 with high flowability. J Polym Res 18:651–657

Martino L, Basilissi L, Farina H, Aldo Ortenzi M, Zini E, Di Silvestro G, Scandola M (2014) Bio-based polyamide 11: synthesis, rheology and solid-state properties of star structures. Eur Polym J 59:69–77

Reyes-Gallardo E, Lucena R, Cárdenas S (2017) Silica nanoparticles-nylon 6 composites: synthesis, characterization and potential use as sorbent. RSC Adv 7:2308–2314

Konstantopoulos G, Maroulas P, Dragatogiannis DA, Koutsoumpis S, Kyritsis A, Charitidis CA (2021) The effect of interfacial resistance and crystallinity on heat transfer mechanism in carbon nanotube reinforced polyethylene. Mater Design 199:109420

Sakai T, Binti Shamsudim NS, Fukushima R, Kageyama K (2021) Effect of matrix crystallinity of carbon fiber reinforced polyamide 6 on static bending properties. Adv Compos Mater 30:71–84

Ruymbeke EV, Slot JJM, Kapnistos M, Steeman PAM (2013) Structure and rheology of branched polyamide 6 polymers from their reaction recipe. Soft Matter 9:6921

Ehsan KYA, Avramenko V, Ahmadi S (2013) Reducing the flammability of nylon-6 by introducing a fireproofing agent during the anionic polymerization of e-caprolactam. Int Polym Sci Technol 40:19–21

Zhang CL, Feng LF, Hu GH (2006) Anionic polymerization of lactams: a comparative study on various methods of measuring the conversion of ε-caprolactam to polyamide 6. J Appl Polym Sci 101:1972–1981

Li L, Yang G (2009) Synthesis and properties of hydroxyapatite nanorod-reinforced polyamide 6 nanocomposites. Polym Int 58:380–387

Zilberman M, Siecmann A, Narkis M (1996) Structure and properties of 6/6.9 copolyamide series, amorphous phase. J Appl Polym Sci 59:581–587

Xu Q, Chen F, Li X, Zhang Z (2013) The effect of surface functional groups of nanosilica on the properties of polyamide 6/SiO2 nanocomposite. Pol J Chem Technol 15:20–24

Sar P, Ghosh Roy S, Ghosh S, De P, Ghosh S (2020) Synthesis of glutamic acid derived organogels and their applications in dye removal from aqueous medium. Macromol Mater Eng 305:1900809

Raghu AV, Gadaginamath GS, Aminabhavi TM (2005) Synthesis and characterization of novel polyurethanes based on 1,3-bis(hydroxymethyl) benzimidazolin-2-one and 1,3-bis(hydroxymethyl) benzimidazolin-2-thione hard segments. J Appl Polym Sci 98:2236–2244

Raghu AV, Gadaginamath GS, Mallikarjun NN, Aminabhavi TM (2006) Synthesis and characterization of novel polyureas based on benzimidazoline-2-one and benzimidazoline-2-thione hard segments. J Appl Polym Sci 100:576–583

Davis RD, Jarrett WL, Mathias LJ (2001) Solution 13C-NMR spectroscopy of polyamide homopolymer (nylons 6, 11, 12, 66, 69, 610 and 612) and several commercial copolymers. J Polym 42:2621–2626

Zheng Y, Ning R, Zheng Y (2005) Study of SiO2 nanoparticles on the improved performance of epoxy and fiber composites. J Reinf Plast Compos 24:223–233

Ponjavic M, Nikolic MS, Stevanovic S, Nikodinovic-Runic J, Jeremic S, Pavic A, Djonlagic J (2020) Hydrolytic degradation of star-shaped poly(ε-caprolactone)s with different number of arms and their cytotoxic effects. J Bioact Compos Polym 35:517–537

Shin BY, Kim JH (2015) Rheological and mechanical properties of polyamide 6 modified by electron-beam initiated mediation process. Radiat Phys Chem 112:88–96

Kumar N, Mandal A (2018) Surfactant stabilized oil-in-water nanoemulsion: stability, interfacial tension, and rheology study for enhanced oil recovery application. Fossil Fuels 32:6452–6466

Lucas A, Tauleigne A, Da Cruz-Boisson F, Crépet A, Bergeron-Vanhille A, Martin G, Garois N, Cassagnau P, Bounor-Legaré V (2020) Mechanical properties enhancement while decreasing the viscosity of copolyether–ester from in situ formation of star-based structures by reactive extrusion. Ind Eng Chem Res 59:16579–16590

Araujo EM, Paz RA, Medeiros VN (2011) Polyamide 6 nanocomposites with inorganic particles modified with three quaternary ammonium salts. Materials 4:1956–1966

Chow W, Mohd Ishak Z (2007) Mechanical, morphological and rheological properties of polyamide 6/organo-montmorillonite nanocomposites. Express Polym Lett 1:77–78

Li W, Ma J, Wu S, Zhang J, Cheng J (2021) The effect of hydrogen bond on the thermal and mechanical properties of furan epoxy resins: molecular dynamics simulation study. Polym Test 101:107275

Sharafi S, Li G (2016) Multiscale modeling of vibration damping response of shape memory polymer fibers. Compos B 91:306–314

Geethamma VG, Asaletha R, Kumar Kalarikkal N, Thomas S (2014) Vibration and sound damping in polymers. Resonance 19:821–833

Hutchinson JM (2009) Determination of the glass transition temperature. J Therm Anal Calorim 98:579–589

Vasanthan N, Salem D (2001) FTIR spectroscopic characterization of structural changes in polyamide 6 fibers during annealing and drawing. J Polym Sci Part B 39:536–547

Hornsby P, Tung J, Tarverdi K (1994) Characterization of polyamide 6 made by reactive extrusion. I. Synthesis and characterization of properties. J Appl Polym Sci 53:891–897

da Anisio PR, Melissa A, Leite D, Maria AE, da Medeiros VN, de Jeferson MTA, Pessan LA (2016) Polím 26:1

García M, Vliet G, Ten Cate MGJ, Chavez F, Norder B, Kooi B, Zyl WE, Verweij H, Blank DHA (2014) Large-scale extrusion processing and characterization of hybrid nylon 6/SiO2 nanocomposites. Polym Adv Technol 15:164–172

Zhang S, Zhang J, Tang L, Huang J, Fang Y, Ji P, Wang C, Wang H (2019) A novel synthetic strategy for preparing polyamide 6 (pa6)-based polymer with transesterification. Polymers 11:978

Mohammadi M, Ahmadi S, Ghasemi S (2020) Structure architecture and morphology changes study in nylon 6/12 copolymers through anionic copolymerization via response surface methodology modeling. Polymer 188:122093

Beatrice CA (2010) Rheological, mechanical, optical, and transport properties of blown films of polyamide 6/residual monomer/montmorillonite nanocomposites. J Appl Polym Sci 116:3581–3592

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mashayekhi, R., Ehsani, M., Ahmadi, S. et al. Synthesis of star-shaped polyamide-6/SiO2 nanocomposites by in situ anionic polymerization through reactive extrusion. Iran Polym J 31, 317–331 (2022). https://doi.org/10.1007/s13726-021-00994-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-021-00994-x