Abstract

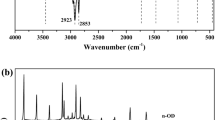

Amorphous polyamide6/fumed silica nanocomposites are a new class of polyamides with improved barrier properties. Recently, polymer/fumed silica nanocomposites have received much attention due to the benefits of strongly improved physical, mechanical and chemical properties compared to the pure polymer. In this study, an amorphous nanocomposite of polyamide6 was prepared via in situ polymerization of ε-caprolactam as a monomer, sodium caprolactam as a catalyst, polyester polyol as a comonomer, toluene diisocyanate as an activator and fumed silica as nanoparticles. Effects of different concentrations of polyester polyol and fumed silica on the formation of nanocomposites and their crystallization, gas permeability and dynamic mechanical properties were investigated in comparison with those of the pure nylon6. Physical and mechanical properties of different formulations which prepared via reactive melt blending were determined using dynamic mechanical thermal analysis, differential scanning calorimetry, X-ray diffraction, scanning electron microscopy and atomic force microscopy techniques. Barrier properties against oxygen and water absorption were examined, as well. Results showed that addition of 4.96 wt% catalyst, 7 wt% activator, 1 wt% polyester polyol and 3 wt% fumed silica led to the best permeability properties.

Similar content being viewed by others

References

Liu Y, Donovan JA (1995) Miscibility and crystallization of semi crystalline nylon6 and amorphous nylon6IcoT blends. Polymer 36:4797–4803

Park YW, Mark JE (2000) Toughening of polyamides by the in situ generation of elastomeric phases. Colloid Polym Sci 278:665–670

Koriyama H, Oyama HT, Ougizawa T, Inoue T, Weber M, Koch E (1999) Studies on the reactive polysulfone–polyamide interface: interfacial thickness and adhesion. Polymer 40:6381–6393

Turner SR, Connell GW, Stafford SL, Hewa JD (2002) Containers, packages for food, drug, cosmetics. US Patent 6444283 B1

Cai LF, Lin ZY, Qian H (2010) Dispersion of nano-silica in monomer casting nylon6 and its effect on the structure and properties of composites. eXPRESS Polym Lett 4:397–403

Yang M, Gao Y, He JP, Li HM (2007) Preparation of polyamide6/silica nanocomposites from silica surface initiated ring-opening anionic polymerization. eXPRESS Polym Lett 1:433–442

Fornes TD, Paul DR (2003) Modeling properties of nylon6/clay nanocomposites using composite theories. Polymer 44:4993–5013

Granado A, Eguiazábal JI, Nazábal J (2004) Solid-state structure and mechanical properties of blends of an amorphous polyamide and a poly (amino-ether) resin. Macromol Mater Eng 289:281–287

Rusu G, Rusu E (2006) Nylon6/SiO2 nanocomposites synthesized by in situ anionic polymerization. High Perform Polym 18:355–375

Li Y, Yu J, Guo ZX (2003) the influence of interphase on nylon-6/nano-SiO2 composite materials obtained from in situ polymerization. Polym Int 52:981–986

Yang F, Ou Y, Jin C (1997) Interfacial interaction and mechanical properties of nylon6-potassium titanate composites prepared by in situ polymerization. J Appl Polym Sci 64:2317–2322

Goettler LA, Neff WJ (1986) Mechanical performance of various nylon6 composites formed by in situ polymerization of caprolactam. Polym Compos 7:383–394

Aso O, Eguiazábal JI, Nazábal J (2007) The influence of surface modification on the structure and properties of a nanosilica filled thermoplastic elastomer. Compos Sci Technol 67:2854–2863

Yang F, Ou Y, Yu Z (1998) Polyamide6/silica nanocomposites prepared by in situ polymerization. J Appl Polym Sci 69:355–361

Yang F, Ou Y, Yu Z (1998) A new conception on the toughness of nylon6/silica nanocomposite prepared via in situ polymerization. J Polym Sci Polym Phys 36:789–795

Barthel H (1995) Surface interactions of dimethylsiloxy group-modified fumed silica. Colloids Surf A 101:217–226

Sinha Ray S, Yamada K, Okamoto M, Ogami A, Ueda K (2003) New polylactide/layered silicate nanocomposites. 3. High-performance biodegradable materials. Chem Mater 15:1456–1465

Jankong S, Srikulkit K (2008) Preparation of polypropylene/hydrophobic silica nanocomposites. J Met Mat Min 18:143–146

Choudalakis G, Gotsis AD (2012) Free volume and mass transport in polymer nanocomposites. Curr Opin Colloid Interface Sci 17:132–140

Van Amerongen GJ (1964) Diffusion in elastomers. Rubber Chem Technol 37:1065–1152

Pinnau I, He Z (2001) Filled superglassy membrane. US Patent 6316684 B1

Santamaría P, González I, Eguiazábal JI (2015) Mechanical and barrier properties of ternary nanocomposite films based on polycarbonate/amorphous polyamide blends modified with a nanoclay. Polym Adv Technol 26:665–673

Merkel TC, Freeman BD, Spontak RJ, He Z, Pinnau I, Meakin P, Hill AJ (2003) Sorption, transport, and structural evidence for enhanced free volume in poly (4-methyl-2-pentyne)/fumed silica nanocomposite membranes. Chem Mater 15:109–123

Ahmadi SH, Morshedian J, Hashemi SA, Carreau PJ (2010) Novel anionic polymerization of ε-caprolactam towards polyamide6 containing nanofibrils. Iran Polym J 19:229–240

Karger-Kocsis J, Friedrich K (1989) Effect of skin-core morphology on fatigue crack propagation in injection moulded polypropylene homopolymer. Int J Fatigue 11:161–168

Liu X, Wu Q (2002) Phase transition in nylon6/clay nanocomposites on annealing. Polymer 43:1933–1936

Campoy I, Gómez MA, Marco C (1998) Structure and thermal properties of blends of nylon6 and a liquid crystal co-polyester. Polymer 39:6279–6288

Mohammadian-Gezaz S, Ghasemi I, Oromiehie AR (2010) Crystallization behavior of PA6 in ABS/PA6 blends prepared by in situ polymerization and compatibilization method. Iran Polym J 22:469–482

Paramoda KP, Liu T (2004) Effect of moisture on the dynamic mechanical relaxation of polyamide-6/clay nanocomposites. J Polym Sci Polym Phys 42:1823–1830

Wu Q, Liu X, Berglund LA (2002) FTIR spectroscopic study of hydrogen bonding in PA6/clay nanocomposites. Polymer 43:2445–2449

Gupta A, Mohan A, Afshari M (2007) High modulus aliphatic nylon fibers via lewis-acid complexation, National Textile Center Annual Report, 1–10

Picard E, Vermogen A, Gérard JF, Espuche E (2007) Barrier properties of nylon-6 montmorillonite nanocomposite membranes prepared by melt blending: influence of the clay content and dispersion state: consequences of modeling. J Membrane Sci 292:133–144

García M, Barsema J, Galindo RE, Cangialosi D, Garcia-Turiel J, van Zyl WE, Verweij H, Blank DHA (2004) Hybrid organic inorganic nylon-6/SiO2: transport properties. Polym Eng Sci 44:1240–1246

Hernandez RJ, Giacin JR, Grulke EA (1992) The sorption of water vapor by an amorphous polyamide. J Membrane Sci 65:187–199

Vassiliou A, Bikiaris D, Pavlidou E (2007) Optimizing melt-processing conditions for the preparation of iPP/fumed silica nanocomposites: morphology, mechanical and gas permeability properties. Macromol React Eng 1:488–501

Acknowledgments

The research for this paper was financially supported by the Iranian national science foundation (INSF). Grant no. 90000236. In developing the ideas presented here.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Omidi, S., Ahmadi, S., Ghorbani, P. et al. In situ polymerization of ε-caprolactam in the presence of polyester polyol and nanosilica toward amorphous polyamide6/SiO2 nanocomposite. Iran Polym J 24, 945–952 (2015). https://doi.org/10.1007/s13726-015-0377-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-015-0377-5