Abstract

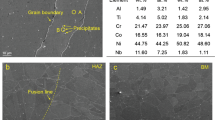

In the present work, effect of post-weld heat treatment (PWHT) on the microstructure, hardness, and corrosion behavior of friction welded IN713LC superalloy and AISI 4140 steel joint was investigated. Microstructural characterization was performed using optical microscopy (OM), scanning electron microscopy (SEM), and electron backscatter diffraction (EBSD) techniques. The microstructure near weld interface (WI)/thermo-mechanically affected (TMAZ) region of IN713LC was changed from coarse dendritic structure to fine equiaxed grains. Due to dynamic recrystallization (DRX), as compared to base materials, increase in fraction of high-angle grain boundary (HAGB) and decrease in fraction of low-angle grain boundary (LAGB) were observed in WI/TMAZ (both as-welded and PWHT samples). Lath martensite was observed at WI/TMAZ of AISI 4140 steel of as-welded specimen; however, after PWHT, it transformed into the tempered martensite. The electrochemical corrosion behavior was evaluated using potentiodynamic polarization tests in 3.5 wt. % NaCl solution. Result showed that corrosion resistance of welded joint was higher than that of AISI 4140 steel and reduced after PWHT.

Similar content being viewed by others

References

W. Li, A. Vairis, M. Preuss, T. Ma, Linear and rotary friction welding review. Int. Mater. Rev. 61, 71–100 (2016)

C.R. Arganis-Juarez, J.A. Aguilar-Torres, J.H. Ramirez-Ramírez, F.A. Perez-Gonzalez, N.F. Garza-Montes-de-Oca, R. Colas, Characterization of dissimilar welds of carbon steels and Ni-filler alloy. Metallogr. Microstruct. Anal. 12, 634–644 (2023)

G. Baxevanis, F. Siokos, A. Kaldellis, D. Ioannidou, V. Stergiou, P. Skarvelis, P.E. Tsakiridis, Effect of post-weld heat treatment on hardness and corrosion resistance of dissimilar electron beam welded joints of Inconel 713LC and AISI 4140 steel. J. Mater. Eng. Perform. 5, 1–13 (2023)

A. Mirak, B. Shams, S. Bakhshi, Dissimilar welding of Inconel 713 superalloy and AISI 4140 steel using Nd:YAG pulse laser: an investigation on the microstructure and mechanical properties. Opt. Laser Technol. 152, 108143 (2022)

R.R. Ye, H.Y. Li, R.G. Ding, T.J.A. Doel, S. Bray, A. Walpole, P. Bowen, Microstructure and microhardness of dissimilar weldment of Ni-based superalloys IN718-IN713LC. Mater. Sci. Eng. A. 774, 138894 (2020)

J. Dupont, J. Lippold, S. Kiser, Welding metallurgy and weldability of nickel-base alloys (Wiley, New York, 2011)

M. Bayrak, F. Ozturk, M. Demirezen, Z. Evis, Analysis of tempering treatment on material properties of DIN 41Cr4 and DIN 42CrMo4 steels. J. Mater. Eng. Perform. 16, 597–600 (2007)

M. Afshari, F. Taher, M.R. Samadi, M. Ayaz, Optimizing the mechanical properties of weld joint in laser welding of GTD-111 superalloy and AISI 4340 steel. Opt. Laser Technol. 156, 108537 (2022)

X.B. Liu, G. Yu, M. Pang, J.W. Fan, H.H. Wang, C.Y. Zheng, Dissimilar autogenous full penetration welding of superalloy K418 and 42CrMo steel by a high power CW Nd:YAG laser. Appl. Surf. Sci. 253, 7281–7289 (2007)

K. Han, H. Wang, B. Zhang, J. Zhao, J. Lei, X. Zhao, Microstructural/mechanical characterizations of electron beam welded IN738LC joint after post-weld heat treatment. J. Mater. Res. Technol. 17, 1030–1042 (2022)

T. Saju, M. Velu, Characterization of welded joints of dissimilar nickel-based superalloys by electron beam and rotary friction welding. J. Mater. Eng. Perform. 31, 9462–9480 (2022)

Y. Ding, G. You, H. Wen, P. Li, X. Tong, Y. Zhou, Microstructure and mechanical properties of inertia friction welded joints between alloy steel 42CrMo and cast Ni-based superalloy K418. J. Alloys Compd. 803, 176–184 (2019)

N. Cavusoglu, Effect of friction welding parameters on the mechanical and microstructural properties of dissimilar IN713C-AISI 4140 joints. J. Mater. Eng. Perform. 31, 4035–4048 (2022)

J. Luo, L. Li, Y. Dong, X. Xu, A new current hybrid inertia friction welding for nickel-based superalloy K418-alloy steel 42CrMo dissimilar metals. Int. J. Adv. Manuf. Technol. 70, 1673–1681 (2014)

V.T. Gaikwad, M.K. Mishra, V.D. Hiwarkar, R.K.P. Singh, Microstructure and mechanical properties of friction welded carbon steel (EN24) and nickel-based superalloy (IN718). Int. J. Miner. Metall. Mater. 28, 111–119 (2021)

P. Anitha, M.C. Majumder, V. Saravanan, S. Rajakumar, Microstructural characterization and mechanical properties of friction-welded IN718 and SS410 dissimilar joint. Metallogr. Microstruct. Anal. 7, 277–287 (2018)

S.V. Lalam, G.M. Reddy, T. Mohandas, M. Kamaraj, B.S. Murty, Continuous drive friction welding of Inconel 718 and EN24 dissimilar metal combination. Mater. Sci. Technol. 25, 851–861 (2009)

M.A. Derakhshi, J. Kangazian, M. Shamanian, Electron beam welding of Inconel 617 to AISI 310: Corrosion behavior of weld metal. Vacuum. 161, 371–374 (2019)

ASTM International G5-14. Standard Reference Test Method for Making Potentiodynamic Anodic Polarization Measurements. ASTM Int. 1- 8 (2018)

R.C. Reed, The superalloys: fundamentals and applications (Cambridge University Press, Cambridge, 2008)

V.T. Gaikwad, M.K. Mishra, V.D. Hiwarkar, R.K.P. Singh, Role of friction time on the joint characteristics of continuous drive friction-welded Inconel 718 and EN24 steel. J. Mater. Eng. Perform. 32, 1660–1670 (2023)

M.K. Mishra, A.G. Rao, I. Balasundar, B.P. Kashyap, N. Prabhu, On the microstructure evolution in friction stir processed 2507 super duplex stainless steel and its effect on tensile behaviour at ambient and elevated temperatures. Mater. Sci. Eng. A. 719, 82 (2018)

E.B. Caldona, A.C.C. de Leon, J.D. Mangadlao, K.J.A. Lim, B.B. Pajarito, R.C. Advincula, On the enhanced corrosion resistance of elastomer-modified polybenzoxazine/graphene oxide nanocomposite coatings. React. Funct. Polym. 123, 10–19 (2018)

Y.B. Guo, C. Li, Y.-C. Liu, L.-M. Yu, Z.-Q. Ma, C.-X. Liu, H.-J. Li, Effect of microstructure variation on the corrosion behavior of high-strength low-alloy steel in 35 wt.% NaCl solution. Int. J. Miner. Metall. Mater. 22, 604–612 (2015)

T. Datta, A.D. Pathak, S. Basak, S. Gollapudi, K.K. Sahu, Fractal behavior of surface oxide crack patterns on AISI 4140 high-strength low-alloy steel exposed to the simulated offshore environment. Appl. Surf. Sci. Adv. 5, 100110 (2021)

Acknowledgements

The authors acknowledge to Kalyani Centre for Technology and Innovation, Bharat Forge Ltd., Pune, for providing laboratory and library facilities. The authors would also like to acknowledge Mr. Yatin Tambe, Director of the Friction Welding Technologies Pvt. Ltd., Pune for providing welding facilities. Authors are also thankful to Dr. Raju Kadam and Dr. Bharat Padekar for their assistance in various aspects of the project.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Gaikwad, V.T., Mishra, M.K. & Singh, R.K.P. Influence of Post-weld Heat Treatment on Microstructure and Corrosion Behavior of Dissimilar Friction Welded Joint of IN713LC Superalloy and AISI 4140 Steel. Metallogr. Microstruct. Anal. (2024). https://doi.org/10.1007/s13632-024-01073-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13632-024-01073-2