Abstract

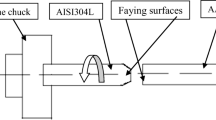

The aim of this study is to investigate the effects of the parameters such as friction pressure, friction time, forging pressure and forging time on mechanical and metallurgical properties of friction welded joints of inconel 713C and AISI 4140 material pair. Tensile tests and hardness tests were carried out to determine the mechanical properties of welded joints. Following tensile tests, the fracture surfaces occurred in the joints were examined by scanning electron microscope (SEM), and the type of fracture and fracture surface characteristics were evaluated. Optical microscope and electron microscope were used to examine the metallurgical properties of welded joints. The tensile, hardness, and microstructure results were associated with the welding process parameters. It was concluded that the highest strength was obtained as 718 N/mm2 and there was a significant increase in hardness values in the thermomechanically affected zone (fully deformed zone) of all samples. In all welding tests, it was determined that the fracture location was on the side of AISI 4140 steel material. As a result of friction welded joints, while γ and γ′-Ni3(Al, Ti) phases were observed in the matrix, the formation of the γ′′-Ni3Nb phase at the grain boundaries was also determined by SEM-EDS analysis. Also it was shown that the carbides deposited at the grain boundaries are generally carbides formed by Nb.

Similar content being viewed by others

References

S. Rusz, I. Schindler, K. Hrbáček, P. Kawulok, R. Kawulok and P. Opěla, Investigation of Deformation Behaviour of The Nickel Alloys in 713 LC and MAR M-247, http://konsys2.tanger.cz/files/proceedings/21/papers/3774.pdf, Accessed from 29 Oct 2021.

J. R. Stephens, Superalloy Resources - Supply and Availability, NASA Technical Memorandum 89866, 1987, https://ntrs.nasa.gov/api/citations/19870011644/downloads/19870011644.pdf, Accessed from 29 Oct 2021.

L. Yang, “Modelling of the Inertia Welding of Inconel 718”, Ph.D. Thesis, Birmingham University, 2010.

N. Boutarek and M. A. Achehe, Fractured Surface of An Inconel 713 Superalloy Turbine Blade, http://konsys-t.tanger.cz/files/proceedings/11/reports/1140.pdf, Accessed from 29 Oct 2021.

S. Zhou, D. Chai, J. Yu, G. Ma and D. Wu, Microstructure Characteristic and Mechanical Property of Pulsed Laser Lap-Welded Nickel-Based Superalloy and Stainless Steel, J. Manuf. Process., 2017, 25, p 220–226.

T.J. Ma, L.F. Tang, W.Y. Li, Y. Zhang, Y. Xiao and A. Vairis, Linear Friction Welding of A Solid-Solution Strengthened Ni-Based Superalloy: Microstructure Evolution and Mechanical Properties Studies, J. Manuf. Process., 2018, 34(2), p 442–450.

M. Kimura, K. Nakashima, M. Kusaka, K. Kaizu, Y. Nakatani and M. Takahashi, Joining Phenomena and Tensile Strength of Joint Between Ni-Based Superalloy and Heat-Resistant Steel By Friction Welding, Int. J. Adv. Manuf. Technol., 2019, 103(1–4), p 1297–1308.

P.K. Krajewski, G. Piwowarski, J. Buras, W.K. Krajewski, P. Rutkowski, D. Szeliga, Thermo-Physical Properties of Selected Inconel Alloys, Arch. Metall. Mater., 2014, 59(3), p 1055–1058.

D. Ananthapadmanaban, “Studies on Friction Weldability of Low Carbon Steel with Stainless Steel and Aluminium with Copper”, Ph.D. Thesis, Sathyabama University, 2012

S. Dev, K.D. Ramkumar, N. Arivazhagan and R. Rajendran, Investigations on the Microstructure and Mechanical Properties of Dissimilar Welds of Inconel 718 and Sulphur Rich Martensitic Stainless Steel, AISI 416, J. Manuf. Process., 2018, 32(4), p 685–698.

M.B. Lachowicz, Microstructural Changes In Padding Welds Made From The 713C Alloy After Heat Treatment, Arch. Foundry Eng., 2010, 10(3), p 11–16.

A. Koren, M. Roman, I. Weisshaus and A. Kaufman, Improving the Weldability of Ni-Base Superalloy 713 C, Weld. J., 1982, 61(11), p 348–351.

S. Kalluri, K.B.S. Rao, G.R. Halford and M. Mcgaw, Deformation and Damage Mechanisms in Inconel 718 Superalloy, J. Miner. Metals Mater. Soc., 1994 https://doi.org/10.7449/1994/Superalloys_1994_593_606

S.H. Mousavi Anijdan, M. Sabzi, M. Ghobeiti-Hasab and A. Roshan-Ghiyas, Optimization of Spot Welding Process Parameters in Dissimilar Joint of Dual Phase Steel DP600 and AISI 304 Stainless Steel to Achieve The Highest Level of Shear-Tensile Strength, Mater. Sci. Eng. A, 2018, 726(2), p 120–125.

M. Sabzi, S.H. Mousavi Anijdan, A.R. Eivani, N. Park and H.R. Jafarian, The Effect of Pulse Current Changes in PCGTAW on Microstructural Evolution, Drastic Improvement in Mechanical Properties, and Fracture Mode of Dissimilar Welded Joint of AISI 316L-AISI 310S Stainless Steels, Mater. Sci. Eng. A, 2021, 823(7), p 1–13.

M. Anuradha, V.C. Das, P. Susila, M. Cheepu and D. Venkateswarlu, Effect of Welding Parameters on TIG Welding of Inconel 718 to AISI 4140 Steel, Trans. Indian Inst. Met., 2020, 73(6), p 1515–1520.

U. Caligulu and M. Yalcinoz, The Weldability of AISI 4340-AISI 2205 Steels Using Friction Welding, Optoelectron. Adv. Mater. Rapid Commun., 2015, 9(7–8), p 1064–1071.

P. Anitha, C.M. Manik, V. Saravanan and S. Rajakumar, Effect of Friction Time on Microstructure and Mechanical Properties of Friction Welded Inconel718 and SS410 Dissimilar Joints, J. Manuf. Eng., 2017, 12(1), p 12–16.

M. Cheepu and W.S. Che, Characterization of Interfacial Microstructure in Friction Welds Between Inconel 718 and SM45C Steel, Trans. Indian Inst. Met., 2020, 73(6), p 1567–1571.

V.T. Gaikwad, M.K. Mishra, V.D. Hiwarkar and R.K.P. Singh, Microstructure and Mechanical Properties of Friction Welded Carbon Steel (EN24) and Nickel-Based Superalloy (IN718), Int. J. Miner. Metall. Mater., 2021, 28(1), p 111–119.

H. Cho and S. Suh, Friction Welding of Inconel 713C and SCM 440, J. KWS, 1997, 15(6), p 78–84.

S.K. Jo, Y.S. Kong and Y.D. Kim, The Effects of pH on the Corrosion Characteristics in Dissimilar Friction Welded Zone of IN713LC-SCM440, J. Ocean Eng. Technol., 2005, 19(2), p 53–59.

J.T. Yeom, J.H. Park, J.W. Lee and N.K. Park, Characterization of Friction Welding for IN713LC and AISI 4140 Steel, Mater. Sci. Forum, 2004, 449(452), p 53–56.

Y.N. Gornostyrev, O.Y. Kontsevoi, K.Y. Khromov, M.I. Katsnelson and A.J. Freeman, The Role of Thermal Expansion and Composition Changes in the Temperature Dependence of the Lattice Misfit in Two-Phase γ/γ′ Superalloys, Scr. Mater., 2007, 56(2), p 81–84.

R.W. Swindeman and M.J. Swindeman, A Comparison of Creep Models for Nickel Base Alloys for Advanced Energy Systems, Int. J. Press. Vessel. Pip., 2008, 85(1–2), p 72–79.

F. Zupanič, T. Bončina, A. Križman and F.D. Tichelaar, Structure of Continuously Cast Ni-Based Superalloy Inconel 713C, J. Alloys Compd., 2001, 329(1–2), p 290–297.

S. Pospisilova, T. Podrabsky and K. Stransky, Heterogeneıty of Inconel 713 LC and Inconel 738 LC, http://citeseerx.ist.psu.edu/viewdoc/download?doi=10.1.1.648.6480&rep=rep1&type=pdf, Accessed from 29 Oct 2021

D. Pieczaba and A. Jach, Evaluation of Superalloy Inconel 713C Dendritic Microstructure of the Turbine Blade Castings, Arch. Metall. Mater., 2010, 55(1), p 25–35.

T. Podrábský, M. Juliš, S. Pospíšilová, K. Němec, K. Hrbáček, A. Rek and Z. Jonšta, Changes in Microstructure of Turbine Wheel Made of Inconel 713LC, Acta Metall. Slovaca, 2005, 11, p 62–67.

F. Binczyk and J. Śleziona, Phase Transformations and Microstructure of IN-713C Nickel Superalloy, Arch. Foundry Eng., 2009, 2009(2), p 109–112.

H. Matysiak, M. Zagorska, A. Balkowiec, B.A. Cieslak, R. Cygan, J. Cwajna, J. Nawrocki and K.J. Kurzydłowski, The Microstructure Degradation of the in 713C Nickel-Based Superalloy After the Stress Rupture Tests, J. Mater. Eng. Perform., 2014, 23(9), p 3305–3313.

L. Kunz, P. Lukáš and R. Konečná, Fatigue Properties of Superalloy IN 713LC and Relation to Microstructure, Medziagotyra, 2008, 14(3), p 221–225.

M. Sabzi and S.M. Dezfuli, Post Weld Heat Treatment of Hypereutectoid Hadfield Steel: Characterization and Control of Microstructure, Phase Equilibrium, Mechanical Properties and Fracture Mode of Welding Joint, J. Manuf. Process., 2018, 34(4), p 313–328.

S.H.M. Anijdan and M. Sabzi, The Effect of Heat Treatment Process Parameters on Mechanical Properties, Precipitation, Fatigue Life, and Fracture Mode of an Austenitic Mn Hadfield Steel, J. Mater. Eng. Perform., 2018, 27(10), p 5246–5253.

P. Anitha, M.C. Majumder, V. Saravanan and S. Rajakumar, “Microstructural Characterization and Mechanical Properties of Friction-Welded IN718 and SS410 Dissimilar Joint, Metallogr. Microstruct. Anal., 2018, 7(3), p 277–287.

N. Salk, Metal Injection Moulding of Inconel 713C for Turbocharger Applications, Powder Inject. Mould Int, 2011, 5(3), p 45–48.

Acknowledgments

This work was supported by the Scientific and Technological Research Council of Turkey (TÜBİTAK) with Grant No: MAG-215M079. I greatly acknowledge the Scientific and Technological Research Council of Turkey for financial support of this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Çavuşoğlu, N. Effect of Friction Welding Parameters on the Mechanical and Microstructural Properties of Dissimilar IN713C-AISI 4140 Joints. J. of Materi Eng and Perform 31, 4035–4048 (2022). https://doi.org/10.1007/s11665-021-06474-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06474-w