Abstract

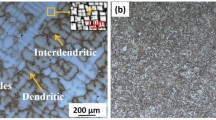

In this present study, the microstructural and damage characterizations of Inconel 740H alloy welded joint during creep process at 750 °C and 210 MPa were investigated via scanning electron microscopy, electron back-scattered diffraction, and transmission electron microscopy. For the base metal (BM), no significant change for austenite grains occurs with increasing creep time from 1000 to 2651 h. Creep cavities mainly distributed along the grain boundaries are formed due to the existence of larger M23C6 carbide. After the creep exposure for 2651 h, creep cracks are formed as a consequence of the coalescence of several creep cavities. In comparison to heat affected zone (HAZ), weld metal (WM) shows fewer creep cavities, which implies that WM exhibits superior creep property. No obvious textural features are present for Inconel 740H welded joint after creep at 750 °C for different regions. There is no significant coarsening for γ′ precipitates in size, which implies that γ′ precipitates show superior high-temperature stability. In comparison to BM and HAZ, WM shows higher dislocation density due to welding thermal cycling. The interaction behavior of dislocations and γ′ precipitates was enhanced, which can significantly strengthen the γ matrix.

Similar content being viewed by others

Data Availability

The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

R. Viswanathan and W. Bakker, Materials for Ultrasupercritical Coal Power Plants: Boiler Materials—Part1, J. Mater. Eng. Perform., 2001, 10, p 81–95.

B.M.B. Grant, E.M. Francis, J.Q.D. Fonseca, M. Preuss and M.R. Daymond, The Effect of γ′ Size and Alloy Chemistry on Dynamic Strain Ageing in Advanced Polycrystalline Nickel Base Superalloys, Mater. Sci. Eng. A, 2013, 573, p 54–61.

D. Liu, L. Yan and S. Hou, The Evaluation of High Temperature Corrosion of the Inconel 740H in Simulated Coal-Fired Environments, Corros. Sci., 2019, 161, p 108150.

S. Zhao, X.S. Xie, G.D. Smith and S.J. Patel, Research and Improvement on Structure Stability and Corrosion Resistance of Nickel-Base Superalloy Inconel Alloy 740, Mater. Des., 2006, 27, p 1120–1127.

S. Zhao, X.S. Xie and G.D. Smith, The Oxidation Behavior of the New Nickel-Based Superalloy Inconel 740 with and Without NaSO4 Deposit, Surf. Coat Tech., 2004, 185, p 178–183.

C.J. Cowen, P.E. Danielson and P.D. Jablonski, The Microstructural Evolution of Inconel 740 During Solution Treatment, Aging, and Exposure at 760 °C, J. Mater. Eng. Perform., 2011, 20, p 1078–1083.

Y.Y. Dang, X.B. Zhao, H.F. Yin, J.T. Lu, Y. Yuan, Z. Yang and Y.F. Gu, Microstructure Stability of Inconel 740H Alloy after Long Term Exposure at 750 °C, J. Mater. Eng., 2016, 44(9), p 58–62.

R. Sitek, Influence of the High-Temperature Aluminizing Process on the Microstructure and Corrosion Resistance of the Inconel 740H Nickel Superalloy, Vacuum, 2019, 167, p 554–563.

J. Wang, J. Dong, M. Zhang and X. Xie, Hot Working Characteristics of Nickel-Base Superalloy 740H during Compression, Mater. Sci. Eng. A, 2013, 566, p 61–70.

C. Yan, Z.D. Liu, A. Godfrey, W. Liu and Y.Q. Weng, Microstructure Evolution and Mechanical Properties of Inconel 740H during Aging at 750 °C, Mater. Sci. Eng. A, 2014, 589, p 153–164.

W. Zhang, J. Lu, J. Wang, L. Sang, J. Ma, Y. Zhang and Z. Zhang, In-situ EBSD Study of Deformation Behavior of Inconel 740H Alloy at High-Temperature Tensile Loading, J. Alloy Compd., 2020, 820, p 153424.

P.S.M. Jena, R.K. Singh, L. Mahanta, S. Paswan and J.K. Sahu, Low Cycle Fatigue Behaviour of Nickel Base Superalloy IN 740H at 760 °C: Influence of Fireside Corrosion Atmosphere, Int. J. Fatigue, 2018, 116, p 623–633.

A.M. Brittan, J. Mahaffey, M. Anderson and K. Sridharan, Effect of Supercritical CO2 on the Performance of 740H Fusion Welds, Mater. Sci. Eng. A, 2019, 742, p 414–422.

H. Jiang, J. Dong and M. Zhang, The Phase Decomposition with Related Element Interaction and Redistribution during Long Term Aging of 740H Superalloy, J. Alloy Compd., 2019, 782, p 323–333.

K. Shin, J. Lee, J. Han, K. Lee, B. Kong and H. Hong, Transition of Creep Damage Region in Dissimilar Welds between Inconel 740H Ni-Based Superalloy and P92 Ferritic/Martensitic Steel, Mater. Chacter., 2018, 139, p 144–152.

R. Radis, M. Schaffer, M. Albu, G. Kothleitner, P. Polt and E. Kozeschnik, Multimodal Size Distributions of γ′ Precipitates during Continuous Cooling of UDIMET 720 Li, Acta Mater., 2009, 57, p 5739–5747.

Y. Chong, Z.D. Liu, A. Godfrey, L. Wang, W. Liu and Y.Q. Weng, Heat Treatment of a Candidate Material for 700 °C A-USC Power Plants, J. Iron Steel Res. Inter., 2015, 22(2), p 150–156.

N.D. Evans, P.J. Maziasz, R.W. Swindeman and G.D. Smith, Microstructure and Phase Stability in Inconel 740 during Creep, Scr. Mater., 2004, 51, p 503–507.

Y. Guo, T. Li, C. Wang, S. Hou and B. Wang, Microstructure and Phase Precipitate Behavior of Inconel 740H during Aging, T. Nonferr. Metal Soc., 2016, 26, p 1598–1606.

J.J. Barbadillo, B.A. Baker, X.S. Xie, Microstructure Stability of Alloy 740H and its Effect on Material Properties, Proceedings of the ASME Symposium on elevated temperature application of materials for fossil, nuclear, and petrochemical industries, (2014)

D.H. Bechetti, J.N. Dupont, J.J. Barbadillo and B.A. Baker, Homogenization and Dissolution Kinetics of Fusion Welds in Inconel Alloy 740H, Metall. Mater. Trans. A, 2014, 45A, p 3051–3063.

K. Wang, H. Jing, L. Xu, Y. Han, L. Zhao, B. Xiao and S. Yang, A Piecewise Constitutive Model, Microstructure and Fracture Mechanism of a Nickel-Based Superalloy 750H during High-Temperature Tensile Deformation, J. Mater. Sci., 2019, 54, p 9775–9796.

G.S. Shin, J.Y. Yun, M. Chul Park and S.J. Kim, Effect of Mo on the Thermal Stability of γ′Precipitate in Inconel 740 Alloy, Mater. Charact., 2014, 95, p 180–186.

R.A. Ricks, A.J. Porter and R.C. Ecob, The Growth of γ′ Precipitates in Nickel-Base Superalloys, Acta Metall., 1983, 31(1), p 43–53.

S. Zhao, X. Xie, G.D. Smith and S.J. Patel, Microstructural Stability and Mechanical Properties of a New Nickel-based Superalloy, Mater. Sci. Eng. A, 2003, 355, p 96–105.

X. Zhao, Y. Dang, H. Yin, Y. Yuan, J. Lu, Z. Yang and Y. Gu, Evolution of the Microstructure and Microhardness of a New Wrought Ni–Fe Based Superalloy during High Temperature Aging, J. Alloy Compd., 2015, 644, p 66–70.

Acknowledgments

This work was financially supported by National Natural Science Foundation of China [52025052, 51975405] and Demonstration Project of National Marine Economic Innovation [BHSF2017-22].

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xiao, D., Jing, H., Xu, L. et al. Microstructure and Damage Evolution of Inconel 740H Welded Joint during Creep Process at 750 °C. J. of Materi Eng and Perform 30, 4562–4571 (2021). https://doi.org/10.1007/s11665-021-05759-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05759-4