Abstract

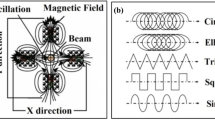

The effect of the circular beam oscillation on the quality of the electron beam welded joint of 18 mm thick SS 316 plates was assessed on tensile and impact performance. These tests were conducted in as-welded condition and after thermal aging treatments viz. 750°C for 24 h (T1) and 750°C for 300 h (T2). The results showed that the use of circular beam oscillation pattern enhanced the cooling rate through step solidification which restricts the transformation of ferrite (%) in the weld bead. The microstructure of the weld zone varied from the coarse lathy ferrite to colonies of fine lathy ferrite while traversing from top to bottom sections of the weld zone. The tensile and impact test results showed that the beam oscillation pattern reduced the UTS, ductility and impact toughness in all the sections. Further, it was observed that the thermal aging treatment for long hours improved the solidification pattern and reduced the effect of beam oscillation. The treatments T1and T2 enhanced the tensile properties as the carbides precipitation at the grain boundaries prevents the sliding of grain boundary against transverse load. Whereas, the impact toughness reduced drastically after the treatments T1 and T2 due to the embrittlement caused by precipitation of the Cr rich carbides.

Similar content being viewed by others

References

ASM International, Introduction to stainless steels, in: Alloy Dig. Sourceb. Stainl. Steels, ASM International, 2000: pp. 1–7. www.asminternational.org

A. Sedriks, O. Zaroog, Corrosion of stainless steels, in: Ref. Modul. Mater. Sci. Mater. Eng., Elsevier Inc., 2017: pp. 1–5. https://doi.org/10.1016/B978-0-12-803581-8.02893-9

ASM International, Austenitic stainless steels, in: Stainl. Steels Des. Eng., ASM International, 2008: pp. 69–78. https://doi.org/10.1016/b978-0-12-803581-8.02509-1

K.H. Lo, C.H. Shek, J.K.L. Lai, Recent developments in stainless steels. Mater. Sci. Eng. R. 65, 39–104 (2009). https://doi.org/10.1016/j.mser.2009.03.001

K. Weman, The Weldability of steel, in: Weld. Process. Handb., Elsevier, 2012: pp. 191–206. https://doi.org/10.1533/9780857095183.191

R. Singh, Welding corrosion-resistant alloys stainless steel. Weld Metall Weld Process. (2016). https://doi.org/10.1016/B978-0-12-804176-5.00018-9

J.C. Lippold, D.J. Kotecki, Welding Metallurgy and Weldability of Stainless Steels, Wiley Interscience, (2005).

K.D. Ramkumar, D. Mishra, M.K. Vignesh, B.G. Raj, N. Arivazhagan, S.V. Naren, S.S. Kumar, Metallurgical and mechanical characterization of electron beam welded super-duplex stainless steel UNS 32750. J. Manuf. Process. 16, 527–534 (2014). https://doi.org/10.1016/j.jmapro.2014.07.011

D.J. Smith, G. Zheng, P.R. Hurrell, C.M. Gill, B.M.E. Pellereau, K. Ayres, D. Goudar, E. Kingston, Measured and predicted residual stresses in thick section electron beam welded steels. Int. J. Press. Vessel. Pip. 120–121, 66–79 (2014). https://doi.org/10.1016/j.ijpvp.2014.05.001

B.S.S. Yilbas, M. Sami, J. Nickel, A. Coban, S. a. M.A.M. Said, Introduction into the electron beam welding of austenitic 321-type stainless steel, J. Mater. Process. Technol. 82 (1998) 13–20. https://doi.org/10.1016/S0924-0136(97)00485-8

H. Schultz, Electron beam welding (Abingtom Publishing, Cambridge England, 2004)

J. Kar, S.K. Roy, G.G. Roy, Effect of beam oscillation on electron beam welding of copper with AISI-304 stainless steel. J. Mater. Process. Technol. 233, 174–185 (2016). https://doi.org/10.1016/j.jmatprotec.2016.03.001

K. Komerla, S. Gach, T. Vossel, A. Schwedt, A. Bührig-Polaczek, U. Reisgen, W. Bleck, The effect of beam oscillations on the microstructure and mechanical properties of electron beam welded steel joints. Int. J. Adv. Manuf. Technol. 102, 2919–2931 (2019). https://doi.org/10.1007/s00170-019-03355-4

X. Xia, J. Wu, Z. Liu, X. Shen, J. Ma, Z. Liu, Study of microstructure di ff erence properties of electron beam welds with beam oscillation of 50 mm 316L in CFETR. Fusion Eng. Des. 138, 339–346 (2019). https://doi.org/10.1016/j.fusengdes.2018.12.011

T.V. Olshanskaya, D.N. Trushnikov, V.Y. Belenkii, G.M. Mladenov, Effect of electron beam oscillations on the formation of the structure and properties of the welded joint. Weld Int. (2013). https://doi.org/10.1080/09507116.2013.796638

S.R. RajaKumar, G.D. Janaki Ram, R. Koteswara, Effect of beam oscillation on borated stainless steel electron beam welds. Mater. Test. (2015). https://doi.org/10.3139/120.110740

ASTM E3-01, Standard guide for preparation of metallographic specimens, ASTM International, West Conshohocken, PA, (2001), www.astm.org, n.d

ASTM standard E8/E8M–13, Standard test methods for tension testing of metallic materials,ASTM International, West Conshohocken, PA, www.astm.org., (2013). www.astm.org

ASTM E23-12c, Standard test methods for notched bar impact testing of metallic materials, i (2013). https://doi.org/10.1520/E0023-12C.2

B. Weiss, R. Stickler, Phase instabilities during high temperature exposure of 316 austenitic stainless steel. Metall. Trans. 3, 851–866 (1972). https://doi.org/10.1007/bf02647659

ASTM E 384, Standard Test Method for Microindentation Hardness of Materials, in: ASM International, n.d

X. Xia, J. Wu, Z.Z. Liu, X. Shen, J. Ma, Z.Z. Liu, Study of microstructure difference properties of electron beam welds with beam oscillation of 50 mm 316l in CFETR. Fusion Eng. Des. 138, 339–346 (2019). https://doi.org/10.1016/j.fusengdes.2018.12.011

P. Zhu, X. Cao, W. Wang, J. Zhao, Y. Lu, T. Shoji, An investigation on microstructure and pitting corrosion behavior of 316L stainless steel weld joint. J. Mater. Res. 32, 3904–3911 (2017). https://doi.org/10.1557/jmr.2017.316

X. Xia, J. Wu, Z. Liu, H. Ji, X. Shen, J. Ma, P. Zhuang, Correlation between microstructure evolution and mechanical properties of 50 mm 316L electron beam welds. Fusion Eng. Des. 147, 111245 (2019). https://doi.org/10.1016/j.fusengdes.2019.111245

G. Casalino, A. Angelastro, P. Perulli, P. Posa, P.R. Spena, Fiber laser-MAG hybrid welding of DP/AISI 316 and TWIP/AISI 316 dissimilar weld. Procedia CIRP. 79, 153–158 (2019). https://doi.org/10.1016/j.procir.2019.02.035

M. Alali, I. Todd, B.P. Wynne, Through-thickness microstructure and mechanical properties of electron beam welded 20 mm thick AISI 316L austenitic stainless steel. Mater. Des. 130, 488–500 (2017). https://doi.org/10.1016/j.matdes.2017.05.080

X. Zhang, G. Mi, L. Chen, P. Jiang, X. Shao, C. Wang, Microstructure and performance of hybrid laser-arc welded 40 mm thick 316 L steel plates. J. Mater. Process. Tech. 259, 312–319 (2018). https://doi.org/10.1016/j.jmatprotec.2018.05.005

R.K. Buddu, N. Chauhan, P.M. Raole, Mechanical properties and microstructural investigations of TIG welded 40 mm and 60 mm thick SS 316L samples for fusion reactor vacuum vessel applications. Fusion Eng. Des. 89, 3149–3158 (2014). https://doi.org/10.1016/j.fusengdes.2014.10.006

A. Kumar, B. Singh, S.S. Sandhu, Effect of thermal aging on metallurgical, tensile and impact toughness performance of electron beam welded AISI 316 SS joints. Fusion Eng. Des. 159, 169–180 (2020)

J. Kar, S.K. Roy, G.G. Roy, Effect of beam oscillation on microstructure and mechanical properties of AISI 316L electron beam welds. Metall. Mater. Trans. A. 48, 1759–1770 (2017). https://doi.org/10.1007/s11661-017-3976-2

S. Goyal, R. Sandhya, M. Valsan, K. Bhanu Sankara Rao, The effect of thermal ageing on low cycle fatigue behaviour of 316 stainless steel welds, Int. J. Fatigue. 31 (2009) 447–454. https://doi.org/10.1016/j.ijfatigue.2008.07.006

H. Shaikh, H.S. Khatak, S.K. Seshadri, J.B. Gnanamoorthy, P. Rodriguez, Effect of ferrite transformation on the tensile and stress corrosion properties of type 316 L stainless steel weld metal thermally aged at 873 K. Metall. Mater. Trans. A. 26, 1859–1868 (1995). https://doi.org/10.1007/BF02670773

V.S. Raghunathan, V. Seetharaman, S. Venkadesan, P. Rodriguez, The influence of post weld heat treatments on the structure, composition and the amount of ferrite in type 316 stainless steel welds. Metall. Trans. A. 10A, 1683–1689 (1979)

J. Chen, C. Jang, B.S. Kong, Q. Xiao, G. Obulan Subramanian, H.S. Kim, J.H. Shin, Effect of thermal ageing on the corrosion behaviour of austenitic stainless steel welds in the simulated PWR primary water, Corros. Sci. 172 (2020). https://doi.org/10.1016/j.corsci.2020.108730

J. Singh, A.S. Shahi, Electrochemical corrosion behavior and microstructural characteristics of electron beam welded UNS S32205 duplex stainless steel, Mater. Corros. (2021) 1–20. https://doi.org/10.1002/maco.202012201

J. Singh, A.S. Shahi, Metallurgical, impact and fatigue performance of electron beam welded duplex stainless steel joints. J. Mater. Process. Technol. 272, 137–148 (2019). https://doi.org/10.1016/j.jmatprotec.2019.05.010

A. Doomra, S.S. Sandhu, B. Singh, Effect of post weld heat treatment on metallurgical and mechanical properties of electron beam welded AISI 409 ferritic steel, Metall. Mater. Eng. (2020).

A. Doomra, S.S. Sandhu, B. Singh, Weldability studies of 18mm thick AISI409 ferritic stainless steel plate using electron beam welding process. Int. J. Manuf. Mater. Mech. Eng. 18, 23–28 (2021). https://doi.org/10.4018/IJMMME.2021040104

P. Gao, K.F. Zhang, B.G.B.W. Zhang, S.S. Jiang, B.G.B.W. Zhang, Microstructures and high temperature mechanical properties of electron beam welded inconel 718 superalloy thick plate. Trans. Nonferrous Met. Soc. China. 21, s315–s322 (2011). https://doi.org/10.1016/S1003-6326(11)61598-7

R. Singh, S. Singh Jolly, Influence of multipass welding procedures and thermal aging conditions on the impact toughness of AISI 316 austenitic stainless steel butt welded joints, Int. J. Appl. Eng. Res. 13 (2018) 9283–9287. http://www.ripublication.com

L.P. Stoter, Thermal ageing effects in AISI type 316 stainless steel. J. Mater. Sci. 16, 1039–1051 (1981). https://doi.org/10.1007/BF00542750

C.R. Das, A.K. Bhaduri, S. Raju, R. Balakrishnan, S. Mahadevan, S.K. Albert, P. Mastanaiah, Influence of electron beam welding parameters on microstructure and charpy impact properties of boron-added modified 9Cr-1Mo steel weld. Weld. World. 60, 1141–1146 (2016). https://doi.org/10.1007/s40194-016-0369-x

B. Shashank Dutt, G. Sasikala, G. Shanthi, S. Venugopal, M. Nani Babu, P.K. Parida, A.K. Bhaduri, Mechanical behaviour of SS 316 (N) weld after long term exposure to service temperatures, Procedia Eng. 10 (2011) 2725–2730. https://doi.org/10.1016/j.proeng.2011.04.454

B.S. Dutt, M.N. Babu, G. Shanthi, A. Moitra, G. Sasikala, Effect of thermal aging and test temperatures on fracture toughness of SS 316(N) welds. J. Mater. Eng. Perform. 27, 1957–1961 (2018). https://doi.org/10.1007/s11665-018-3255-4

Acknowledgement

The authors are thankful to Er. Jaspal Singh Dhesi Deputy, General Manager - Welding Operations at Hendrickson, Pune Maharashtra, India for the help extended during the experimental work. Further, the facilities provided by SLIET, Longowal, IIT, Ropar and PEC Chandigarh are gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that there is no conflict of interest

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, A., Sandhu, S.S. Effect of Beam Oscillation on Metallurgical and Mechanical Properties of the Electron Beam Welded SS 316 Welded Joints. Metallogr. Microstruct. Anal. 10, 776–794 (2021). https://doi.org/10.1007/s13632-021-00804-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-021-00804-z