Abstract

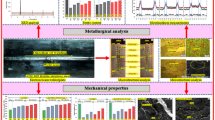

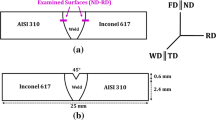

The effect of the postweld heat treatment (550°C for 75 min) on the electron beam welded joints of AISI 409 thick plates was assessed in terms of tensile and impact performance. Through thickness, analysis was carried out by dividing the weld joint into three sections, i.e., top section, middle section, and bottom section. The results showed that the size of the grains got refined at the bottom. The heat treatment also led to reduction in the grain size. X-ray diffraction analysis showed the presence of martensite in the weld joint which reduced after heat treatment. The 532 MPa tensile strength was achieved after the heat treatment for the specimens extracted from the bottom of the welded plate. The impact toughness of the weld joint was 37% less than the base metal; however, impact toughness of 31J was achieved at the top section after postweld heat treatment.

Similar content being viewed by others

References

C. Kose, C. Topal, Laser welding of AISI 410S ferritic stainless steel. Mater. Res. Express. 6(8), 1–14 (2019). https://doi.org/10.1088/2053-1591/ab26c0

S.K. Gupta, A.R. Raja, M. Vashista, M.Z.K. Yusufzai, Effect of heat input on microstructure and mechanical properties in gas metal arc welding of ferritic stainless steel. Mater. Res. Express. 6(3), 1–46 (2019)

A. Doomra, B. Singh, S.S. Sandhu, Influence of welding parameters and post weld heat treatment on the metallurgical and mechanical properties of electron beam welded thick AISI 409 ferritic stainless steel. Metallogr. Microstruct. Anal. 10, 219–235 (2021). https://doi.org/10.1007/s13632-021-00735-9

M.O.H. Amuda, S. Mridha, Grain refinement in ferritic stainless steel welds : the journey so far. Adv. Mater. Res. 86, 1165–1172 (2010). https://doi.org/10.4028/www.scientific.net/AMR.83-86.1165

A.C.T.M. Van Zwieten, J.H. Bulloch, Some considerations on the toughness properties of ferritic stainless steels-a brief review. Int. J. Press. Vessel. Pip. 56(1), 1–31 (1993). https://doi.org/10.1016/0308-0161(93)90114-9

R.D. Campbell, Ferritic stainless steel welding metallurgy. Key Eng. Mater. 69–70, 167–216 (1992). https://doi.org/10.4028/www.scientific.net/kem.69-70.167

M.O.H. Amuda, S. Mridha, An overview of sensitization dynamics in ferritic stainless steel welds. Int. J. Corros. 2011, 1–9 (2011). https://doi.org/10.1155/2011/305793

A.K. Lakshminarayanan, V. Balasubramanian, An Assessment of microstructure, hardness, tensile and impact strength of friction stir welded ferritic stainless steel joints. Mater. Des. 31(10), 4592–4600 (2010). https://doi.org/10.1016/j.matdes.2010.05.049

E. Taban, E. Kaluc, A. Dhooge, Hybrid (plasma + gas tungsten arc) weldability of modified 12%Cr ferritic stainless steel. Mater. Des. 30(10), 4236–4242 (2009). https://doi.org/10.1016/j.matdes.2009.04.031

A. Kumar, G. Sharma, D.K. Dwivedi, TIG spot weld bonding of 409 L ferritic stainless steel. Int. J. Adhes. Adhes. 84, 350–359 (2018). https://doi.org/10.1016/j.ijadhadh.2018.04.012

M. Mukherjee, T.K. Pal, Influence of heat input on martensite formation and impact property of ferritic-austenitic dissimilar weld metals. J. Mater. Sci. Technol. 28(4), 343–352 (2012). https://doi.org/10.1016/S1005-0302(12)60066-8

N. Ghosh, R. Rudrapati, P.K. Pal, G. Nandi, Parametric optimization of gas metal arc welding process by using taguchi method on ferritic stainless steel AISI409. Mater. Today: Proc. 4, 2213–2221 (2017). https://doi.org/10.1016/j.matpr.2017.02.068

S.S. Sandhu, A.S.S. Shahi, Metallurgical, wear and fatigue performance of inconel 625 weld claddings. J. Mater. Process. Technol. 233, 1–8 (2016). https://doi.org/10.1016/j.jmatprotec.2016.02.010

S. S. Sandhu and A. S. Shahi, “Fracture Toughness and Fatigue Behaviour of Variably Precipitated Inconel 625/AISI 304L Welds BT - Proceedings of the 9th International Symposium on Superalloy 718 & Derivatives: Energy, Aerospace, and Industrial Applications,” 2018, pp. 867–879

A. S. Shahi and S. S. Sandhu, “Pitting Behavior of Thermally Aged Inconel 625 Weld Claddings Made Using SMAW and GMAW Process BT - Proceedings of the 9th International Symposium on Superalloy 718 & Derivatives: Energy, Aerospace, and Industrial Applications,” 2018, pp. 881–898

M.A. Khattak et al., Effect of welding phenomenon on the microstructure and mechanical properties of ferritic stainless steel. J. Adv. Res. Mater. Sci. 1(1), 13–31 (2017)

A.K. Lakshminarayanan, K. Shanmugam, V. Balasubramanian, Effect of autogenous arc welding processes on tensile and impact properties of ferritic stainless steel joints. J. Iron Steel Res. Int. 16(1), 62–68 (2009). https://doi.org/10.1016/S1006-706X(09)60012-1

R.S. Vidyarthy, D.K. Dwivedi, M. Vasudevan, Influence of M-TIG and A-TIG welding process on microstructure and mechanical behavior of 409 ferritic stainless steel. J. Mater. Eng. Perform. 26(3), 1391–1403 (2017). https://doi.org/10.1007/s11665-017-2538-5

K.A. Cashell, N.R. Baddoo, Ferritic stainless steels in structural applications. Thin-Walled Struct. 83, 169–181 (2014). https://doi.org/10.1016/j.tws.2014.03.014

H. Schultz, Electron beam welding machines and equipment, in Electron Beam Welding, ed. by H. Schultz (Abington Publishing, 1993), pp. 1–272

C.I.M. Cottrell, Electron beam welding review -a critical. Mater. Des. 6(December), 285–291 (1985)

M.S. Wȩglowski, S. Błacha, A. Phillips, Electron beam welding – techniques and trends - review. Vacuum. 130, 72–92 (2016). https://doi.org/10.1016/j.vacuum.2016.05.004

A.K. Lakshminarayanan, V. Balasubramanian, G.M. Reddy, Microstructure and mechanical properties of electron beam-welded AISI 409M-Grade ferritic stainless steel. Int. J. Adv. Manuf. Technol. 1, 153–162 (2011). https://doi.org/10.1007/s00170-010-3044-1

P. Havlík, P. Šohaj, J. Kouril, R. Foret, I. Dlouhý, EBW of stainless steels and ODS ferritic steel. Methods. 4, 5–6 (2014)

M. Tullmin, F.P.A. Robinson, C.A.O. Henning, A. Strausst, J. Le Grange, Properties of laser welded and electron beam welded ferritic stainless steel. J. S. AIr. Inst. Min. Met. 89(8), 243–249 (1989)

M.O.H. Amuda, E.T. Akinlabi, S. Mridha, Ferritic stainless steels: metallurgy, application and weldability. Ref. Modul. Mater. Sci. Mater. Eng. 1–18 (2016). https://doi.org/10.1016/B978-0-12-803581-8.04010-8

M. Keskitalo, J. Sundqvist, K. Mäntyjärvi, J. Powell, A.F.H. Kaplan, The influence of shielding gas and heat input on the mechanical properties of laser welds in ferritic stainless steel. Phys. Procedia. 78(August), 222–229 (2015). https://doi.org/10.1016/j.phpro.2015.11.032

M.S. Rajadurai, S. Naveen, M. Afnas, T. Arun, N. Kumar, S. Surendhar, Methods to avoid material sensitization during welding for developing corrosion resistant exhaust system. Int. J. Recent Dev. Eng. Technol. 4(7), 23–36 (2015)

S. Anttila, P. Karjalainen, S. Lantto, Mechanical properties of ferritic stainless steel welds in using type 409 and 430 filler metals. Weld. World. 57(3), 335–347 (2013). https://doi.org/10.1007/s40194-013-0033-7

E. Taban, E. Deleu, A. Dhooge, E. Kaluc, Laser welding of modified 12% Cr stainless steel: strength, fatigue, toughness, microstructure and corrosion properties. Mater. Des. 30(4), 1193–1200 (2009). https://doi.org/10.1016/j.matdes.2008.06.030

M. Du Toit, C.J. Van Niekerk, Sensitization behaviour of 11–12% Cr AISI 409 stainless steel during low heat input welding. J. South. African Inst. Min. Metall. 111(4), 243–256 (2011)

Severi Anttila and H. P. Heikkinen, “Structural applications of ferritic stainless steels (SAFSS),” 2014

J.J. Demo, Weldable and corrosion-resistant ferritic stainless steels. Metall. Trans. 5, 2253–2256 (1974)

ASTM Standard E3-11, “Standard practice for preparation of metallographic specimens,” 2016. doi: https://doi.org/10.1520/D0638-14.1

N.H. Pryds, X. Huang, The effect of cooling rate on the microstructures formed during solidification of ferritic steel. Metall. Mater. Trans. A. 31A, 3155–3166 (2000)

ASTM Standard E407-99, “E407-99: Standard practice for microetching metals and alloys,” ASTM Int., pp. 1–21, 2012

A. Kumar, B. Singh, S.S. Sandhu, Influence of thermal aging on metallurgical, mechanical and corrosion performance of electron beam welded 18mm thick AISI 316. Fusion Eng. Des. 161, 112092 (2020). https://doi.org/10.1016/j.fusengdes.2020.112092

A. Kumar, B. Singh, S.S. Sandhu, Effect of thermal aging on impact toughness of electron beam-welded AISI 316 stainless steel. Fusion Eng. Des. 159, 111949 (2020). https://doi.org/10.1016/j.fusengdes.2020.111949

A. Kumar, S. S. Sandhu, and B. Singh, “Effect of thermal aging on impact toughness of electron beam-welded AISI 316 stainless steel,” in minerals, metals and materials series, 2020, pp. 169–180, doi: https://doi.org/10.1007/978-3-030-36628-5_16

ASTM standard E 23-12c, “Standard test methods for notched bar impact testing of metallic materials,” 2013. doi: https://doi.org/10.1520/E0023-12C.2

ASTM Standard E8, “Standard test methods for tension testing of metallic materials,” ASTM Int., pp. 1–27, 2013, doi: https://doi.org/10.1520/E0008_E0008M-13A

A. Sharma, V. Kumar, S.S. Sandhu, Efects of welding speed on the microstructure, mechanical properties and corrosion resistance of the electron beam welded AISI 321 plates. Metallogr. Microstruct. Anal. 10, 184–198 (2021)

A. Sharma, V. Prabhakar, S. Sandhu, Microstructural characterization and mechanical performance along the thickness of electron beam welded stabilized AISI 321 stainless steel. Metall. Mater. Eng. (2021). https://doi.org/10.30544/592

A. Sharma, S. Sandhu, V. Kumar, Assessment of mechanical and metallurgical properties of thermally aged electron beam welded AISI 321 stainless steel. Adv. Mater. Res. 1160, 93–102 (2021). https://doi.org/10.4028/www.scientific.net/AMR.1160.93

D.J. Kotecki, T.A. Siewert, WRC-1992 constitution diagram for stainless steel weld metals : a modification of the WRC-1988 diagram. Weld. Res. Suppl. 71(5), 171–178 (1992)

T. Mohandas, G. Madhusudhan Reddy, M. Naveed, A comparative evaluation of gas tungsten and shielded metal arc welds af a ferritic stainless steel. J Mater Process Technol. 94(2), 133–140 (1999). https://doi.org/10.1016/S0924-0136(99)00092-8

M.O.H. Amuda, S. Mridha, Grain refinement and hardness distribution in cryogenically cooled ferritic stainless steel welds. Mater. Des. 47, 365–371 (2013). https://doi.org/10.1016/j.matdes.2012.12.008

A.K. Lakshminarayanan, V. Balasubramanian, Evaluation of microstructure and mechanical properties of laser beam welded AISI 409M grade ferritic stainless steel. J. Iron Steel Res. Int. 19(1), 72–78 (2012). https://doi.org/10.1016/S1006-706X(12)60050-8

A.K. Lakshminarayanan, V. Balasubramanian, Comparison of electron beam and friction stir weldments of modified 12 wt.% ferritic stainless steel. Mater. Manuf. Process. 26(6), 37–41 (2011). https://doi.org/10.1080/10426914.2010.515643

M.V. Venkatesan, N. Murugan, S. Sam, S.K. Albert, Effect of heat input on macro, micro and tensile properties of flux cored arc welded ferritic stainless steel joints. Trans. Indian Inst. Met. 67(3), 375–383 (2014). https://doi.org/10.1007/s12666-013-0358-3

E. Taban, A. Dhooge, E. Kaluc, Plasma arc welding of modified 12% Cr stainless steel. Mater. Manuf. Process. 24(6), 649–656 (2009). https://doi.org/10.1080/10426910902769152

E. Taban, E. Deleu, A. Dhooge, E. Kaluc, Submerged arc welding of thick ferritic martensitic 12Cr stainless steel with a variety of consumables. Sci. Technol. Weld. Join. 13(4), 327–334 (2008). https://doi.org/10.1179/174329307X213710

S.S.M. Tavares, L.F.G. de Souza, T.C. de Chuvas, C.L.C. da Machado, Influence of heat treatments on the microstructure and degree of sensitization of base metal and weld of AISI 430 stainless steel. Rev. Mater. 22, 2–9 (2017). https://doi.org/10.1590/s1517-707620170005.0275

A. Doomra, S.S. Sandhu, B. Singh, Effect of post weld heat treatment on metallurgical and mechanical properties of electron beam welded AISI 409 ferritic steel. Metall. Mater. Eng. 26(3), 279 (2020). https://doi.org/10.30544/545

A. Doomra, B. Singh, S.S. Sandhu, Weldability studies of AISI 409 ferritic stainless steel thick plates using electron beam welding process. Int. J. Manuf. Mater. Mech. Eng. 11(2), 55–67 (2021). https://doi.org/10.4018/IJMMME.2021040104

A. Doomra, S.S. Sandhu, B. Singh, Weldability studies of 18mm thick AISI409 ferritic stainless steel plate using electron beam welding process. Ann Fac Eng Hunedoara Int J Eng. 18(3), 23–28 (2020)

J. Pekkarinen, V. Kujanpää, The effects of laser welding parameters on the microstructure of ferritic and duplex stainless steels welds. Phys. Procedia. 5, 517–523 (2010). https://doi.org/10.1016/j.phpro.2010.08.175

V.L. Manugula, K.V. Rajulapati, G.M. Reddy, K.B.S. Rao, Role of evolving microstructure on the mechanical properties of electron beam welded ferritic-martensitic steel in the as-welded and post weld heat-treated states. Mater. Sci. Eng. A. 698, 36–45 (2017). https://doi.org/10.1016/j.msea.2017.05.036

A.K. Lakshminarayanan, V. Balasubramanian, Influences of welding processes on microstructure and mechanical properties of modified 12 Wt.% Cr ferritic stainless steel. Int. J. Manuf. Res. 7(4), 331–353 (2012). https://doi.org/10.1504/IJMR.2012.050100

E. Taban, E. Deleu, A. Dhooge, E. Kaluc, Gas metal arc welding of modified X2crnil2 ferritic stainless steel. Kov. Mater. 45(2), 67–74 (2007)

C. Thomas and R. Apps, “Weld Heat-Affected Zone Properties in AISI 409 Ferritic Stainless Steel,” in Toughness of Ferritic Stainless Steels, 2009, pp. 161–183

M. Mukherjee, A. Dutta, P. Kanjilal, T.K. Pal, S. Sisodia, Enhancement of microstructural and mechanical properties by pulse mode of metal transfer in welded modified ferritic stainless steel. ISIJ Int. 55(7), 1439–1447 (2015). https://doi.org/10.2355/isijinternational.55.1439

A.N. Vasileiou, M.C. Smith, J. Balakrishnan, J.A. Francis, C.J. Hamelin, The impact of transformation plasticity on the electron beam welding of thick-section ferritic steel components. Nucl. Eng. Des. 323, 309–316 (2017). https://doi.org/10.1016/j.nucengdes.2017.03.040

I. A. DeArdo, “Mechanical behavior of 409 ferritic stainless steel,” McGili University Montreal, 1998

E. Ranjbarnodeh, S. Hanke, S. Weiss, A. Fischer, Effect of welding parameters on the heat-affected zone of AISI409 ferritic stainless steel. Int. J. Miner. Metall. Mater. 19(10), 923–929 (2012). https://doi.org/10.1007/s12613-012-0648-5

K. Bhanu Sankara Rao, K. Laha, R. Sandhya, B. Raj, Mechanical behaviour of stainless steel, ferritic steel welds and weld joints, in Weld Cracking in Ferrous Alloys (2009), pp. 153–184

C.J.V.J. Van Niekerk et al., Sensitization of AISI 409 ferritic stainless steel during low heat input arc welding. Weld. World. 56(5–6), 54–64 (2012). https://doi.org/10.1007/BF03321350

C. Kose, C. Topal, Effect of post weld heat treatment and heat input on the microstructure and mechanical properties of plasma arc welded AISI 410S ferritic stainless Steel. Mater. Res. Express. 6(6), 1–20 (2019). https://doi.org/10.1088/2053-1591/ab09b6

E. Deleu, A. Dhooge, E. Taban, E. Kaluc, Possibilities and limitations to improve the weldability of low carbon 12Cr ferritic stainless steel for expanded industrial applications. Weld. World. 53(9–10), 198–208 (2009). https://doi.org/10.1007/BF03321131

M.S. Węglowski, S. Błacha, A. Phillips, Electron beam welding-techniques and trends-review. Vacuum. 130, 72–92 (2016). https://doi.org/10.1016/J.VACUUM.2016.05.004

Acknowledgment

The authors wish to acknowledge the support extended by the Department of Mechanical Engineering, IKG Punjab Technical University, Kapurthala, and Sant Longowal Institute of Engineering and Technology, Longowal.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Doomra, A., Sandhu, S.S. Metallurgical and Mechanical Properties Variation Along the Thickness of Electron Beam Welded Ferritic Stainless Steel Joints After Postweld Heat Treatment. Metallogr. Microstruct. Anal. 10, 795–814 (2021). https://doi.org/10.1007/s13632-021-00803-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-021-00803-0