Abstract

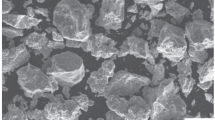

The wettability of two Zn–Al alloy coatings (called “McGill 2” and “McGill 3” with 27 and 10 wt% Al, respectively) on the compacted graphite cast iron substrate was studied using the static sessile drop method. The effects of wetting time and coating composition on the macrostructural and microstructural evolution of the system were investigated. It was found that although the contact angle was obtuse for both coating materials over the time, the interfacial reactions occurred between the drop and the substrate from the first stage of contact. The most significant result was the formation of a uniform and thick reaction layer (interlayer) with the diffusion-controlled property at the interface. The results showed that “McGill 2” coating is superior to “McGill 3” alloy as an intermediate material for the Al–Fe cast joining application. The “McGill 2” interlayer revealed a composite nature as it consisted of different layers of solid, in the form of stable Al x Fe y Si z intermetallic phases from the initial steps of the reactions.

Similar content being viewed by others

References

M. Khaleel, Joining of dissimilar metals for automotive applications: from process to performance, in Automotive Lightweighting Materials. U.S. Department of Energy Annual Progress Report (2004), pp. 255–261

S. Adachi, J. Inami, Method for joining metals and valve seat provided in a cylinder head. Eur. Patent Appl. EP794030 A1 19970910 (1997)

N. Kageyama, A. Itoh, E. Tamura, K. Kanno, T. Aoki, T. Sato, Aluminum alloy member, with insert provided therein, possessing improved damping capacity and process for producing the same. U.S. Patent 5976709 (1999)

J.C. Viala, M. Peronnet, F. Barbeau, F. Bosselet, J. Bouix, Interface chemistry in aluminum alloy castings reinforced with iron base inserts. Compos. A Appl. Sci. Manuf. 33(10), 1417–1420 (2002)

Ph. Vaillant, J.P. Petitet, Interactions under hydrostatic pressure of a mild steel with liquid aluminum alloys. J. Mater. Sci. 30(18), 4659–4668 (1995)

G. Durrant, M. Gallerneault, B. Cantor, Squeeze cast aluminum reinforced with mild steel inserts. J. Mater. Sci. 31(3), 589–602 (1996)

Z.W. Chen, D.T. Fraser, M.Z. Jahedi, Structures of intermetallic phases formed during immersion of H13 tool steel in an Al–11Si–3Cu die casting alloy melt. Mater. Sci. Eng. A 260(1–2), 188–196 (1999)

M. Sundqvist, S. Hogmark, Effects of liquid aluminum on hot-work tool steel. Tribol. Int. 26(2), 129–134 (1993)

J.L. Jorstad, R.A. Morley, W.H. Overbagh, G.W. Steele, Process for creation of metallurgically bonded inserts cast-in-place in a cast aluminum article. U.S. Patent 5333668 (1994)

P.-G. Gennes, F. Brochard-Wyart, D. Quéré, Capillarity and Wetting Phenomena: Drops, Bubbles, Pearls, Waves, 1st edn. (Springer, New York, 2004)

M.G. Nicholas, Joining processes: introduction to brazing and diffusion bonding, 1st edn. (Springer, New York, 1998)

J. Xu, X. Liu, M.A. Bright, J.G. Hemrick, V. Sikka, E. Barbero, Reactive wetting of an iron-base superalloy MSA2020 and 316L stainless steel by molten zinc–aluminum alloy. Metall. Mater. Trans. A 39, 1382–1391 (2008)

N. Ebrill, Y. Durandet, L. Strezov, Dynamic reactive wetting and its role in hot dip coating of steel sheet with an Al–Zn–Si alloy. Metall. Mater. Trans. B 31B(5), 1069–1079 (2000)

A.J. Sunwoo, J.W. Morris, G.K. Lucey, The growth of Cu–Sn intermetallics at a pretinned copper solder interface. Metall. Trans. A 23(4), 1323–1332 (1992)

A.S. Zuruzi, C.-H. Chiu, S.K. Lahiri, K.N. Tu, Roughness evolution of Cu6Sn5 intermetallic during soldering. J. Appl. Phys. 86(9), 4916–4921 (1999)

Z. Xu, J. Yan, C. Wang, S. Yang, Substrate oxide undermining by a Zn–Al alloy during wetting of alumina reinforced 6061 Al matrix composite. Mater. Chem. Phys. 112(3), 831–837 (2008)

T.R. Fletcher, J.A. Cornie, K.C. Russell, Wettability of SiC particulates with Zn and Zn–Al alloys, in Cast Reinforced Metal Composites; Proceedings of the International Symposium Advances Cast Reinforced Metal Composites (Chicago, 1988); (A89-33151 13-24)

A. Urena, L. Gil, E. Escriche, J.M.G. Salazar, M.D. Escalera, High temperature soldering of SiC particulate aluminium matrix composites (series 2000) using Zn–Al filler alloys. Sci. Technol. Weld. Join 6(1), 1–11 (2001)

A. Mathieu, S. Matteï, A. Deschamps, B. Martin, D. Grevey, Temperature control in laser brazing of a steel/aluminium assembly using thermographic measurements. NDT E Int. 39(4), 272–276 (2006)

A. Mathieu, R. Shabadi, A. Deschamps, M. Suery, S. Matteï, D. Grevey, E. Cicala, Dissimilar material joining using laser (aluminum to steel using zinc-based filler wire). Opt. Laser Technol. 39(3), 652–661 (2007)

Y. Hisamatsu, N.T. Kyōkai, in Galvatech’ 89: International Conference Zinc and Zinc Alloy Coated Steel Sheet, Proceedings (Tokyo, 1989)

M.M. Schwartz, Brazing, 2nd ed (ASM International, Materials Park, Ohio, 2003), pp. 11–13

A.R. Marder, The metallurgy of zinc-coated steel. Prog. Mater. Sci. 45(3), 191–271 (2000)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moosavi-Khoonsari, E., Jalilian, F., Paray, F. et al. Wettability Behavior of Zinc-Based Alloys on Cast Iron. Metallogr. Microstruct. Anal. 6, 221–232 (2017). https://doi.org/10.1007/s13632-017-0349-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13632-017-0349-6