Abstract

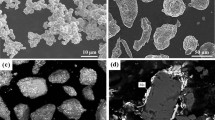

A metal matrix composite material was obtained by self-propagating high temperature synthesis (SHS) from powder mixtures of titanium, carbon (carbon black), and high chromium cast iron of PG-S27 trademark. Synthesized products were crushed and sieved to get a composite powder for plasma spraying of wear resistant coatings. The coatings were tested for hardness and abrasive wear resistance. According to X‑ray diffraction and scanning electron microscopy investigation, the structure of coatings involved fine TiC particles uniformly distributed over the cast iron matrix. It was ascertained that the coatings plasma sprayed with the SHS composite powder had a hardness 2 times greater and abrasive wear resistance 3.5 times greater than that of plasma sprayed with the cast iron powder.

Similar content being viewed by others

REFERENCES

Tsypin, I.I., Belye vysokokhromistye chuguny. Struktura i svoistva (White High-Chromium Cast-Iron: Structure and Properties), Moscow: Mashinostroenie, 1983.

Gnyusov, S.F. and Degtyarev, A.S., Influence of plasma surfacing regimes on the microstructure of vanadium carbide in coatings based on powder PR-H18FNM, Izv. Tomsk.Politekh. Univ., 2014, vol. 32, no. 2, pp. 63–71.

Dampilon, D.V. and Durakov, V.G., Specific structuring of coatings from chromium-vanadium cast iron obtained by electron beam surfacing, Perspekt. Mater., 2012, no. 1, pp. 87–91.

Kalita, V.I., Yarkin, V.V., Kasimtsev, A.V., and Lubman, G.U., Formation of nanosize hardening phases in plasma coatings sprayed with steels, iron and iron-based alloys, Fiz. Khim. Obrab. Mater., 2006, no. 5, pp. 29–40.

Pribytkov, G.A., Polev, I.V., and Durakov, V.G., Cermets and electron beam coatings of the titanium carbide–high-chromium cast iron binder, Perspekt. Mater., 2002, no. 1, pp. 70–75.

Pribytkov, G.A., Krinitcyn, M.G., and Korzhova, V.V., The SHS products in the mixtures of titanium and carbon with abundant Ti, Perspekt. Mater., 2016, no. 5, pp. 59–68.

Pribytkov, G.A., Korzhova, V.V., Baranovskiy, A.V., and Krinitcyn, M.G., Phase composition and structure of composite powders of titanium carbide–P6M5 steel binder produced by SHS method, Izv. VUZov, Poroshk. Metall. Funkts. Pokrytiya, 2017, no. 2, pp. 64–71.

Pribytkov, G.A., Firsina, I.A., Korzhova, V.V., Krinitcyn, M.G., and Polyanskaya, A., Synthesis of composite powders TiC–NiCrBSi alloy binder for surfacing and spraying of wear-resistant coatings, Izv. VUZov, Poroshk. Metall. Funkts. Pokrytiya, 2018, no. 2, pp. 43–53.

Pribytkov, G.A., Baranovskiy, A.V., Firsina, I.A., Durakov, V.G., and Krinicyn, M.G., Hardness and abrasive wear resistance of electron beam coatings deposited by SHS composite powders TiC + P6M5 steel, Uprochnyayushchie Tekhnol. Pokrytiya, 2017, no. 10, pp. 446–452.

Pribytkov, G.A., Krinitcyn, M.G., Firsina, I.A., and Durakov, V.G., Hardness and abrasive wear resistance of electron-beam coatings titanium carbide–titanium binder melted with synthesized composite powders, Vopr. Materialoved., 2017, no. 4, pp. 52–61.

Pribytkov, G.A., Kalita, V.I., Komlev, D.I., Korzhova, V.V., Radyuk, A.A., Baranovskiy, A.V., Ivannikov, A.Yu., Krinitcyn, M.G., and Mikhaylova, A.B., Structure and wear resistance of plasma coatings sprayed with composite powder TiC + P6M5, Fiz. Khim. Obrab. Mater., 2017, no. 3, pp. 45–55.

Kalita, V.I., Komlev, D.I., Pribytkov, G.A., Korzhova, V.V., Radyuk, A.A., Baranovsky, A.V., Ivannikov, A.Yu., Alpatov, A.V., Krinitsyn, M.B., and Mikhaylova, A.B., Variation of contents of carbon, nitrogen, and oxygen upon formation of plasma cermet coatings with steel matrix reinforced with titanium carbide, Inorg. Mater.: Appl. Res., 2018, vol. 9, no. 2, pp. 264–269.

Korosteleva, E.N., Pribytkov, G.A., Kalambaeva, S.S., Korzhova, V.V., and Strel’nitskii, V.E., SHS composite powders TiC–cast-iron binder for surfacing and spraying synthesized in air, Izv. Vyssh. Uchebn. Zaved., Fiz., 2015, vol. 58, no. 6-2, pp. 152–157.

Funding

This work was supported by the Program of Fundamental Research of State Academies of Sciences for 2013–2020, direction III.23, and the Russian Foundation for Basic Research (project nos. 16-08-00493a, 18-32-00330, 17-08-00059a, and 18-08-00842). The experiments on plasma spraying at the Baikov Institute of Metallurgy and Materials Science of the Russian Academy of Sciences were carried out according to the state assignment no. 007-00129-18-00.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by A. Muravev

Rights and permissions

About this article

Cite this article

Pribytkov, G.A., Kalita, V.I., Komlev, D.I. et al. Structure and Wear Resistance of the Coatings Plasma Sprayed with “TiC + High Chromium Cast Iron Binder” Composite Powder. Inorg. Mater. Appl. Res. 11, 558–562 (2020). https://doi.org/10.1134/S2075113320030375

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S2075113320030375