Abstract

In a growing world population scenario, greater demand for food and in turn agricultural input is expected in the coming decades. The development of innovative sustainable amendments and fertilizers such as hydrogels (HGs) relies on this context. HGs are defined as 3D polymeric networks with the ability to absorb and retain a large amount of water (i.e., swellability). HGs swellability makes them ideal platforms for water- and nutrient-controlled release. The literature reflects a notable diversity in HGs composition, properties, and impacts on agroecosystems, resulting in the dissemination of information across multiple publications. Within this context, the primary aim of this scientific review is to systematically compile, critically evaluate, and synthesize the latest findings and relevant literature pertaining to the application of HGs in agroecosystems. We found that this class of materials was consistently found on soil bulk density, crop available water, soil electrical conductivity, cation exchange capacity and main cereal or legume crops performances particularly under moderate water deficit conditions, suggesting their effectiveness for arid and semi- arid areas. Encouraging results were also found on pesticide, agrochemicals, and microorganisms delivering. Thus, the delivery of agronomic inputs with loaded-HG may play a key role in forthcoming agriculture that would minimize the agronomic impact on the environment. Nevertheless, some critical issues still remain open, concerning: (i) the decreased of HG effectiveness following wetting and drying cycles, (ii) the impact of Na+ contained in HG on crop cells, (iii) the HG effect on soil saturated hydraulic conductivity and pH, and (iv) HG biodegradability and their fate into the environment. In conclusion, HGs seem a promising technology to reach/maintain food security and soil health, but future research should address the development of well-defined protocols for producing biowaste-derived HG that will ensure their biodegradability and non-toxicity and will disclose new insights into a circular economy approach agronomy. One of the biggest challenges would be the synthesis of “smart” HG able to respond to environmental stimuli triggering molecule(s) release in soil.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Content

-

1. Introduction

-

2. Methodology

-

3.1 Material origin

-

3.2 Cross-linking

-

3.3 Physical state

-

5.1.1 Soil bulk density, porosity and soil erosion prevention

-

5.1.2 Soil water retention and saturated hydraulic conductivity

-

5.1.3 Soil pH, electrical conductivity and cation exchange capacity

-

5.2.1 HG as soil conditioner

-

5.2.2 HG as seed coating

1 Introduction

“Zero Hunger” is one of the Sustainable Development Goals identified by the United Nations in the 2030 Agenda (U.N. 2015). Despite considerable progress since the 1990s, more than 800 million people in the world are still undernourished, and the trend has been on the rise since 2014 (Lal 2020). In a growing world population scenario (up to 9.7 billion by 2050 according to United Nations (United Nations 2019)), greater demand for food is expected in the coming decades (FAO-UNESCO 2009). As a result, an increased amount of both agricultural input (e.g., water and chemicals) and croplands will be required. Globally, agriculture is estimated to exploit 7130 km3 of water every year (de Fraiture and Wichelns 2010) and this amount is expected to increase by 70-to-90% without improvements in water use efficiency and land management (Molden et al. 2007). The annual global pesticide usage is about 1.9 million tons (FAOSTAT 2018) associated with expenditures of around USD 40 billion, and the consumer trend is expected to rise again over the next few years (Popp et al. 2013). Moreover, in order to increase the cropland surface, many issues need to be considered, including threats to the ecosystem, such as water scarcity and soil and water pollution, which unfortunately affect many areas of the world (Rodríguez-Eugenio et al. 2018; Walker et al. 2019; Rosa et al. 2020). Thus, finding sustainable approaches for cropland intensification is a pressing need for the scientific community to meet food security and environmental protection at the same time (FAO 2011; Mancosu et al. 2015). Moreover, healthy soils and healthy land are the basic conditions to be able to achieve the goals described in the SDG framework (Visser et al. 2019). In this context, the development of innovative technologies including amendments and fertilizers that allow a rational use of natural resources might contribute to improving cropland use. Among different options, the design and production of new materials integrating themselves in the environment and acting as an amendment is particularly promising.

Hydrogels (HGs) are conventionally defined as natural or synthetic polymeric 3D networks with the ability to absorb and retain large volumes of liquids, therefore increasing their volume (i.e., swellability) (Thakur and Thakur 2015) (Figure 1) or “gel in which the swelling agent is water. The network component of a hydrogel is usually a polymer network” (IUPAC 1997). The HGs may occur in a solid, semi-solid, or liquid state which influences their swelling characteristics. The HG characteristics can be analyzed by coupling a series of different analytical techniques including spectroscopy for chemical composition determination, diffraction for microstructure investigation, and microscopy for morphology revelation. The materials used for HGs are based on cross-linked polymers (Ullah et al. 2016), where cross-linking can be physical or chemical, as detailed in the following. Irrespective of the different cross-linking types, HGs have high water adsorption capacity due to a stable 3D structure. These materials are also characterized by their ability to change their chemical structure, inducing also relevant volume changes, as a consequence of physical conditions such as pH, temperature, salt concentration, electric field, and solvent quantity. HG can be synthetic or come from natural sources. Synthetic polymers can be derived from different macromolecular chains such as poly(acrylates). Natural polymers are instead typically prepared from cellulose.

Over the decades, HGs have been widely used in different fields such as cosmetics, food additives (Ullah et al. 2016), tissue engineering (Raho et al. 2020), drug delivery (El-Sherbiny et al. 2005), pharmaceuticals (Urban et al. 2018), regenerative medicine (Sannino et al. 2008), and waste management (Fan et al. 2015a). Despite the use of HGs for agronomic purposes, for instance, to improve soil water holding capacity (e.g., in arid environments) and soil physical properties, which have been studied since the 1980s (Bearce and McCollum 1977; Wang and Boogher 1987; Blodgett et al. 1993; Hüttermann et al. 1999), HGs have only more recently started to be commercialized on a larger scale. Indeed, their unique physical properties, including their porosity and swelling capacity, make them ideal platforms for controlled water and nutrient delivery. The successful application of HGs could be an important goal for arid and semi-arid regions where irrigation water is a scarce commodity, short-term drought is a possible cause of crop losses, and the cost of irrigation maintenance must be minimized. Furthermore, HG loaded with nutrients could represent a possible solution for future agronomy that will have to face the challenge related to nutrient scarcity with particular emphasis on phosphorus (George et al. 2016). The literature reflects a notable diversity in HGs composition, properties, and impacts on agroecosystems, resulting in the dissemination of information across multiple publications. Thus, the main objective of this review is to collate, analyze, and synthesize the most current knowledge regarding hydrogels application in agroecosystems by using the framework reported in Figure 2.

2 Methodology

The literature review was conducted through a systematic search across the Scopus, Web of Science, and Google Scholar databases, utilizing the keywords “hydrogel,” “superabsorbent materials,” and “superabsorbent polymer” within the agricultural subject domain. The search yielded 3542, 563, and 208,400 articles, respectively. Following the removal of duplicates, the papers underwent a two-step filtration process: (i) inclusion of articles published between 2006 and 2023, and (ii) selection of original or review peer-reviewed research. Subsequently, the relevance of the articles was assessed through an examination of their abstract, resulting in the identification of 129 articles deemed suitable for inclusion in the present review.

The full text of these 129 articles was thoroughly examined, and their references were scrutinized for additional relevant sources. Due to the limited number of papers available on the specific topic, an expansion of the literature search was deemed necessary, encompassing studies published prior to 2006. Although these earlier publications constituted approximately 19% of the total cited literature, they were considered essential for a comprehensive understanding of the subject matter. In conclusion, a total of 185 papers were ultimately included in this study.

3 Main features of hydrogels and their classification

The variability in the composition of HGs is attributed to the diverse nature of their constituent building blocks and their respective molar ratios. The classification of hydrogels can be systematically conducted using various criteria, including but not limited to the origin of the material and its building blocks, the type of cross-linking employed, the physical state of HG, and the electrical charge within the network. This systematic approach allows for a comprehensive understanding of the factors influencing hydrogel composition, facilitating a more structured analysis of their characteristics and functionalities.

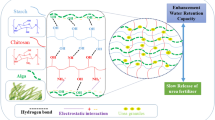

3.1 Materials origin

The classification of HG can be systematically initiated based on the origin of the material, distinguishing between synthetic and natural sources. Synthetic polymers encompass a range of macromolecular chains, including poloxamers (i.e., non-ionic triblock copolymers), poly(acrylates), poly(acrylamide), poly(acrylic acid), poly(hydroxyalkyl methacrylates), poly(methacrylamides), and their derivatives (Hwang and Damodaran 1996). Conversely, natural polymers are typically derived from materials such as alginate, chitosan, gelatin, pectin, carrageenan, guar gum, gellan gum, and cellulose (Tanan et al. 2019; Nuzzo et al. 2020b) (Figure 3). Notably, the cellulose is extensively employed due to its environmentally friendly characteristics.

Synthetic hydrogels are advisable when a specific network structure is crucial; however, due to uncertainties regarding their environmental fate, comprehensive studies are imperative before considering their application in field settings (Tanan et al. 2019). However, for applications with a focus on biodegradability and eco-friendliness, such as in agronomic and environmental contexts, hydrogels of natural origin are often deemed more suitable (Nuzzo et al. 2020b, a). The sustainability of HG production emerges as a critical concern, aligning with the objectives of the U.N. 2030 Agenda Goals. Notably, Salehi and Moghadam (2023) recently delineated methods for the sustainable production of hydrogels, further emphasizing the importance of environmentally responsible practices in hydrogel research and development.

3.2 Cross-linking

Cross-linking plays an important role in the performance of HGs since the ability of a hydrogel to absorb and retain water and water solutions primarily depends on the type and extension (i.e., degree) of the cross-linking of the hydrogel (Maitra and Shukla 2014) as well as external parameters, such as pH and ionic strength of the solution. HGs can be classified according to the nature of the cross-linking, i.e., physical and chemical. In physically cross-linked HGs, characterized by weak interactions, such as Van der Walls or hydrogen bonding (Takigami et al. 2007), the dissolution is prevented by these physical interactions between polymer chains (Slaughter et al. 2009) which might be obtained through several methods, e.g., freezing and thawing cycles (Hassan and Peppas 2000), maturation through heat-induced aggregation process (Aoki et al. 2007), ionic interaction (Zhao et al. 2009), and complex formation (Tsuji 2005). Physically crosslinked HGs are mostly used in food, pharmaceutical, and biomedical applications where cross-linking agents are generally to be avoided to be food-compliant and not toxic (Chung and Park 2009). However, in chemically cross-linked HG, a cross-linking agent, which is typically a molecule with one or more reactive (e.g., polymerizable) moieties, is involved to obtain 3D polymeric networks (Varaprasad et al. 2017). The covalent bonding is responsible for the chemical cross-linking; thus, HG dissolution takes place only when cross-link points are chemically cleaved (Chung and Park 2009). Various methods for obtaining chemically cross-linked HGs are reported in the literature, e.g., chemical cross-linking (Hennink and van Nostrum 2012), chemical or radiation grafting (Athawale and Lele 1998; Said et al. 2004), condensation reaction (De Nooy et al. 2000), enzymatic reaction (Sperinde and Griffith 1997), high-energy radiation (Zhao et al. 2003), and free radical polymerization (Varaprasad et al. 2010).

3.3 Physical state

The HGs may occur in a solid, semi-solid, or liquid state due to different swelling and diffusion characteristics (Varaprasad et al. 2010). Solid HGs are solid at room temperature, characterized by strong covalent or ionic cross-linking, and can swell when immersed in liquid solution (Varaprasad et al. 2010), the swelling being a complex phenomenon resulting from concurrent entropic and enthalpic contributions (Flory and Rehner 1943; Flory 1953). For their peculiar behavior mentioned above, they are mostly used for biomedical, environmental, and ecological applications. Semisolid HGs are characterized instead by a soft microstructure that is bonded through interfacial forces, i.e., Van der Waals, hydrogen bonds, and electrostatic forces, which prevent dissolution. Due to the soft consistency, they are often used in drug delivery (Nep and Conway 2011). Finally, liquid HGs are in a liquid state at room temperature, but, below a certain temperature, they present soft tissue properties that make them ideal materials for biomedical applications (Dou et al. 2014).

3.4 Other classifications

Other classifications found in the literature may respond to specific synthesis and/or application needs (Varaprasad et al. 2010; Ullah et al. 2016), for example, classification based on the size of the HG or the presence/absence of network electrical charge (neutral, ionic, amphoteric, or zwitterionic HG) (Darge et al. 2019) or based on the synthesis route for the polymer matrix (homopolymers, copolymers, or multipolymers) (Ullah et al. 2016).

4 Common methods of HG characterization

HG characterization is a fundamental step in predicting their interaction with other materials and, in turn, optimizing their synthesis for specific applications (Table 1). Typically, hydrogels are complex and multicomponent materials, and their characterization encompasses the determination of compositional, microstructural, morphological, mechanical/viscoelastic, and functional properties (e.g. swelling degree) properties. The picture becomes even more challenging whenever the polymeric network is, such as in the case of hybrid HG, intercalated/interpenetrated with inorganic building blocks (e.g., clays or nanoparticles) (Mirabedini et al. 2015). In the latter case, the mutual arrangement of organic and inorganic building blocks as well as their interactions should be taken into account. The HG microstructure is typically investigated by combining spectroscopy and diffraction techniques. With energy-disperse X-ray spectroscopy (EDS), nuclear magnetic resonance (NMR) spectroscopy, Fourier transform infrared spectroscopy (FTIR), and/or Raman spectroscopy, the chemical composition can be investigated from elemental to molecular and finally to polymer scale (Sarkar and Singh 2017). The morphology of HG can be revealed by microscopy and tomography techniques, while scanning electron microscopy (SEM) and transmission electron microscopy (TEM) allow for external surface and internal structure characterization, respectively (Raghavendra et al. 2015). However, both these latter methodologies are limited to the external surface or inner structure of thin sections; thus, other emerging techniques, e.g., X-ray computed microtomography, might provide valuable insights into the HG 3D structure investigation (Womack et al. 2022). One of the most studied HG properties is the degree of swelling as it quantifies how much water HG can absorb and, in turn, rules the applicability of the HG (Flory 1953; Ullah et al. 2016). The degree of swelling is usually calculated as the ratio between the adsorbed water weight and the dry HG weight (Guilherme et al. 2015):

where the dry hydrogel weight is the weight of the hydrogel before water immersion. Compositions, cross-linking, and formulations can be tuned and optimized to achieve extremely fast and high water absorption (Chen et al. 1999).

Together with swelling, thermal stability, and viscoelastic properties, there are other physical-chemical properties of HG that may be useful to predict and tune their performances, degradation, and environmental fate (Chang et al. 2009). Finally, according to some specific purposes, other properties of HGs can be determined such as the kinetics of molecule release for agronomic and drug delivery issues (Li et al. 2016).

5 HG agronomical application

In the last 10 years, the primary sector has drawn attention to the use of HG for soil structure improvement and water and nutrient use efficiency increase (Bai et al. 2010; Guilherme et al. 2015; Thombare et al. 2018). HGs have been tested in two different applications: as soil conditioners (Agaba et al. 2011; Guilherme et al. 2015; Thombare et al. 2018) or as seed coating (Zohuriaan-Mehr et al. 2010). In the following sections, the existing literature on HGs is collated and synthesized according to potential effects on soil or crop production.

5.1 HG effects on soil physical-chemical properties

5.1.1 Soil bulk density, porosity, and soil erosion prevention

Bulk density, defined as the ratio of dry matter (105 °C-oven dry) to volume, is predominantly affected by HGs during the swollen stage, characterized by high moisture content (Thombare et al. 2018). Therefore, HGs are commonly recognized for their capacity to reduce soil bulk density (BD) by creating increased pore space during the dehydration process from the swollen stage.

Soil particles undergo reorganization around HGs during the swelling stage, resulting in an expansion in soil volume and, consequently, an increase in total porosity (Hussien et al. 2012; Nada and Blumenstein 2015). A recent laboratory experiment by Womack et al. (2022), utilizing a combination of traditional destructive techniques and x-ray tomography, revealed that soils amended with HG exhibited an overall increase in lsevieratio (i.e., pores > 828 μm) exceeding 12% compared to the control treatment.

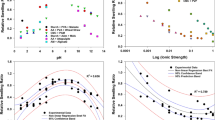

The soil type emerged as a pivotal factor influencing BD, with coarse soils exhibiting greater efficacy than fine soils (Figure 3a). In sandy soils treated with HG, BD demonstrated reductions ranging from 17–29% (Hussien et al. 2012) and 2–19% (Nada and Blumenstein 2015) compared to controls (no HG addition) with initial BD of 1.68 and 1.51 g cm−3, respectively. Comparable reductions in the range of 3–12% were observed in sandy loam soils during field experiments by Abrisham et al. (2018) and in a laboratory experiment by Sarmah & Karak (2019) with a control (i.e., no HG) BD of 1.28–1.56 g cm−3. In sandy loam/sandy clay loam soils, Shahid et al. (2012) (lab experiment) and Thombare et al. (2018) (lab experiment) noted a 7% average reduction in BD, decreasing from 1.46 and 1.34 g cm−3 in controls to a minimum of 1.27 and 1.22 g cm−3 with HG.

Under “soilless” conditions, as exemplified by Verma et al. (2019), where HGs were physically mixed with a cocopeat-perlite-vermiculite mixture, BD remained similar to the control (1.48 vs 1.46 g cm−3). It is worth noting that the influence of HG on BD may be masked by methodological constraints.

The origin of HG appears to be an additional factor influencing BD. Poly(acrylic acid)-derived HG demonstrated a greater effect (Hussien et al. 2012; Sarmah and Karak 2019) compared to polyacrylamide (Shahid et al. 2012; Nada and Blumenstein 2015; Abrisham et al. 2018), guar gum (Thombare et al. 2018) or polyacrylate-based HGs (Verma et al. 2019), with an average decrease of 13, 8, 8 and 1%, respectively (Figure 3b), all studies having a control BD exceeding 1.3 g cm−3.

Lastly, the quantity of HG added to the soil emerged as a significant influencing factor, with BD showing a linear and negative correlation with the HG rate. Irrespective of HG or soil type, a lower HG rate corresponded to a higher BD) (Figure 3c) (Hussien et al. 2012; Nada and Blumenstein 2015; Abrisham et al. 2018; Thombare et al. 2018; Sarmah and Karak 2019). For example, in a laboratory experiment, Shahid et al. (2012) found a BD of 1.46, 1.41, 1.40, 1.35, and 1.27, respectively, for control, 0.1, 0.2, 0.3, and 0.4% HG concentration.

Erosion stands as a significant soil threat, contributing to land degradation with adverse consequences on crop yields and posing a risk to the sustainability of human societies (Mol and Keesstra 2012). HGs have been identified as potential soil stabilizers, defined as materials capable of forming a network that serves as a bridge between the soil surface and soil particles, thereby promoting enhanced soil aggregation (Yang et al. 2008; Erci et al. 2021).

Ilyasov et al. (2021) investigated a loosely cross-linked HG composed of acrylamide, potassium acrylate, starch and bis(acrylamide) and observed its effectiveness in stabilizing soil particles against wind and water erosion. Yang et al. (2008) used HG based on biodegradable poly(aspartic acid)-based HG as a soil stabilizer, noting an increase in soil compressive strength and resistance to wind erosion. Buchmann et al. (2015) verified enhanced rheological stability following the addition of polyacrylic acid-based HG to sandy loam soil. Yang et al. (2021) found HG increased the soil organic carbon content and its labile fraction in the 0–50-cm soil layer and, concurrently, improved the stability of the soil structure in 0–30-cm and 40–60-cm depths.

The erosion ratio in natural soil is typically influenced by its initial water content, but in HG-treated soils, the erosion ratio remained consistently low (i.e., less than 0.2%) irrespective of their initial water content (Chang et al. 2015). The efficacy of HG in soil erosion protection is primarily attributed to its chemical constituents. Previous studies have associated the direct use of polyvinyl acetate or polyacrylamide with a reduction in erosion risk exceeding 80% as assessed by wind tunnel experiments (Yang and Tang 2012; Feizi et al. 2018). This reduction is attributed to the greater cohesive and adhesive forces within polymers that result in improved aggregate stability (He et al. 2008; Feizi et al. 2018). Notably, these positive outcomes can be achieved with very low application rates, e.g., 1–2 kg ha−1 if applied through surface irrigation (Sojka et al. 2007).

While HGs and their precursors have demonstrated effectiveness in preventing soil loss through erosion, Erci et al. (2021) underscored the need to balance their efficacy with the associated cost, especially when compared to other stabilizers (e.g., molasses and cement) with lower performance levels.

Looking beyond soil erosion, future research could explore HG as a novel tool to mitigate other soil threats. For example, Ostrand et al. (2021) concluded that HG may offer insights into soil compaction remediation, even in frigid semiarid soil where particle rearrangement may foster soil aggregation.

5.1.2 Soil water retention and saturated hydraulic conductivity

Soil water retention denotes the capacity of soil to retain water, a crucial parameter in agronomy, and soil science. Beyond mere water retention, a pivotal consideration is the soil available water (SAW), representing the difference between the field capacity (FC) and the wilting point (WP). The positive and consistent augmentation in water at FC subsequent to HG application is well established in the literature, resembling the behavior of clay and soil organic matter, ranging from +13.5% (Thombare et al. 2018) to +300% (Montesano et al. 2015) (Table 2). This increase is attributed to the interaction between matric tension, HG application dose, and soil type (Dorraji et al. 2010; Ullah et al. 2016; Thombare et al. 2018; M’barki et al. 2019) (Figure 4).

Modified from Leciejewski (2009)

Water retention curve in soil added with different doses of HG, from 0.5 to 6 g dm−3.

Notably, Montesano et al. (2015) and Nada and Blumenstein (2015) observed a remarkable increase in sandy soils, more than 50% in FC with respect to the control (soil with no HG), employing cellulose and acrylamide-based HGs, respectively. Soils characterized by sandy clay loam (Shahid et al. 2012; Thombare et al. 2018), sandy loam (Akhter et al. 2004; Shahid et al. 2012), or loamy textures (Akhter et al. 2004) displayed a slightly lower average FC enhancement, around + 40%. Conversely, in finer soil, the efficacy of HG appeared diminished, likely due to their inherently favorable structure and water retention characteristics, as observed in clay loam soil by Narjary et al. (2012).

In addition to soil characteristics, a direct relationship between VWC at FC and HG concentration is evident, as depicted in Figure 5a. This increase is particularly pronounced for HG application dose exceeding 0.4%, resulting in VWC at least doubled with respect to the control treatment (Montesano et al. 2015; Shahid et al. 2012, Nada and Blumenstein 2015).

Average water content variation with respect to the control treatment (soil with no hydrogel addition) at field capacity (FD) (a) and wilting point (WP) (b) based on hydrogel concentration (number inside the graph). The diameter of the balls represents the standard error of the mean. In the case of only one observation used (e.g., 0.5, 1, and 2% application rate at FC), the sphere diameter has been set to 0.01 cm.

Thombare et al. (2018) reported VWC values of 18.5, 21.0, 22.7, and 23.7% for the control, 0.1, 0.2, and 0.3% HG respectively. Similarly, also Montesano et al. (2015) observed a 60, 200, and 300% increase with 0.5, 1, and 2% HG concentration, respectively. Furthermore, the WP exhibited an increase ranging from 6 to 300% of VWC across the reviewed literature, with a more pronounced effect observed for polyacrylamide-based HGs (Akhter et al. 2004) compared to other HG origins (Shahid et al. 2012; Montesano et al. 2015; Nada and Blumenstein 2015; Thombare et al. 2018) (Table 2).

The positive impact of HG application on SAW is evident, with the VWC variation at FC generally exceeding that at WP (Montesano et al. 2015; Nada and Blumenstein 2015; Thombare et al. 2018). Textural classes exhibited a consistent trend, with a more substantial increase in SAW observed in coarser soils (Montesano et al. 2015) compared to finer soils (Akhiar et al. 2017). Koupai et al. (2008) investigated the addition of 0.4% HG and observed an increased SAW from 0.454 to 0.984 g kg−1 in sandy loam soil and from 1.59 to 1.789 g kg−1 in clay soil. With an elevated HG concentration of 0.6%, the same authors demonstrated a further increase in SAW of 0.05 (sandy loam) and 0.15 g kg−1 (clay).

In contrast, Akhter et al. (2004) reported a unique finding, wherein WP exhibited a greater increase compared to FC. The WP increase was 6- to 18-fold that of FC, suggesting a potential negative impact of HG application on SAW. This observation persisted regardless of HG concentration (ranging from 0.1 to 0.3%). Nevertheless, the literature consistently demonstrates a proportional increase in VWC at WP with HG application dose, similar to the observed trend for FC (Figure 5b).

The application of HG to soil is anticipated to support crop growth, particularly horticultural crops, in arid or non-irrigated lands through the release of water derived from HG (Jahan and Mahallati 2020). Notably, the review by Nirmala and Guvvali (2019) reported that plants grew regularly despite a significant reduction (− 50%) of supplied water in HG-amended soil in open-field cultivation simulating conditions. In a HYDRUS 1-D simulation, Smagin et al. (2019) revealed a systematic increase in the water supply to the rhizosphere and prolonged active root water uptake, proportional to HG concentration, resulting in a 1.5–2-fold increase in available water storage and delay in the irrigation water demand up to 10 days.

As a final remark, it should be highlighted that the water retention in the soil may experience a decline during wetting and drying cycles, as well as due to HG degradation. In a laboratory experiment, Akhter et al. (2004) subjected acrylamide-based HG to three re-watering cycles, revealing a modest reduction in water absorption after the second and third cycles compared to the initial one. This trend had a different magnitude depending on the water salinity, with greater reduction among the re-watering cycles with saline water (i.e., EC = 5.09 dS m−1) and lower with distilled water. It is hypothesized that Ca+2, Mg+2, and potentially other ions present in water could have attached permanently to the carboxylic acid groups of the acrylic acid, blocking the active negative sites of the HG and consequently reducing the water absorption (Shahid et al. 2012).

In addition to wetting and drying cycles, microbial degradation may also adversely affect water retention. Although the specifics of biodegradation are discussed later in this study, it is important to anticipate that HG water retention capacity depends on the complex relationship of factors such as half-life, structural integrity, structure and cross-linking, and chemical composition. To the best of our knowledge, no comprehensive study addressing all these aspects is currently available in the literature. Song et al. (2020) demonstrated that synthetic HG (e.g., acrylic or polyacrylamide HG) exhibited limited degradation (< 2%) after 120 days, whereas HG derived from natural polymers exhibited a higher degradation rate (e.g., 20%).

In the existing literature, the impact of HG addition on saturated hydraulic conductivity (Ks) appears inconsistent and dependent on the interaction between soil texture and HG concentration. Specifically, diverse behaviors have been observed in sandy soils based on HG concentration (El-Shafei et al. 1994; Hussien et al. 2012; Nada and Blumenstein 2015). In a lab experiment where low HG concentration (e.g., ≤ 1%) was applied, El-Shafei et al. (1994) found a linear decrease in Ks from the control (25.2 cm h−1) to 1% HG concentration (24.8 cm h−1). Similarly, Song et al. (2020) observed a reduction in lab-derived Ks with increasing HG concentration, ranging from 1.14 cm h−1 in the control (no HG) to 0.12 cm h−1 with 0.975% of alginate-derived HG. This reduction was attributed to factors such as HG fluidity leading to soil pores blockage, and increased friction between soil particles, hydrogel, and water, ultimately impeding water infiltration. In the study reported by Mohawesh and Durner (2019), a 0.5% acrylate-based HG addition caused a 3-fold Ks reduction in a lab experiment due to increased pore tortuosity.

In a contrasting scenario involving higher HG concentration (e.g., > 1%), Hussien et al. (2012) detected an opposite effect, with Ks approximately 8-fold greater than the control (165 vs 21m day−1). The authors proposed that a higher number of swollen HG particles may have created preferential paths for water flow under the hydraulic head gradient. Additionally, Albalasmeh et al. (2021) highlighted the differential impact of low (greater Ks improvement) vs. high molecular weight HGs (lower Ks improvement) on Ks improvement, suggesting that increased infiltration capacity due to HG addition could mitigate adverse effects of ponding water on the soil surface, particularly during heavy rainstorms (Albalasmeh et al. 2021).

Inconsistent results were reported in sandy clay loam soils by Shahid et al. (2012) and Hussien et al. (2012) who observed opposite effects, with a relative variation of − 174% (74.9 vs 27.3 mm h−1) and + 66% (0.9 vs 4.75 m day−1), respectively (Table 3). Shahid et al. (2012) attributed the phenomenon to the HG capacity of absorbing water and tying it inside the gel bonding (El Shafei et al. 1992), while Hussien et al. (2012) hypothesized that swollen HG particles increased in the number of conducting pores promoting water drainage (El-Shafei et al. 1994; Hussien et al. 2012). The contradictory outcomes in finer soils, indicating both Ks decrease and increase, may be linked to factors such as pores tortuosity/continuity (Mohawesh and Durner 2019) and the physical state of water entrapped in the HG (Buchmann et al. 2015). The varying soil-HG mixing could generate diverse porosity paths with different tortuosity grades, and the ratio between “bonded” and “free water” may be a critical factor in water movement in HG-enriched soils, although this concept requires further investigation.

5.1.3 Soil pH, electrical conductivity, and cation exchange capacity

Soil pH, a dynamic parameter, plays a crucial role in influencing nutrient availability and the potential phytotoxicity of nutrients and toxic elements (Rengel 2015). In a study by Bai et al. (2010) investigating polyacrylate- and polyacrylamide-based HG effects on clay loam soil pH under various water regimes, an overall decrease in pH was observed in response to HG application under severe and moderate water deficits, with the largest reduction noted in the polyacrylamide-based HG. Conversely, an opposite trend emerged under extreme water deficit and sufficient soil moisture content. Shahid et al. (2012) noted a progressive pH reduction with increasing HG concentration, ranging from 7.40 in the control to 7.04 for 0.4% HG. Similarly, Parvathy et al. (2014) recorded a pH reduction of 4.5-/4.8% following 0.5% HG addition in a pot experiment, attributing it to the presence of carboxylate ions in HG, which decreased the soil pH. While HG can influence soil pH through its chemical structure, including the presence of exchangeable acids and ions (Bai et al. 2010), its pH-sensitive molecules may also make it an ideal platform for nutrient and water delivery in agroecosystems in response to plant/soil stimuli.

Soil electrical conductivity (EC) is a measure of the amount of salts in the soil and it is correlated with soil properties that directly impact crop productivity. Shahid et al. (2012) observed a proportional increase in EC with HG amount by about 6, 11, 45, and 56% for 0.1, 0.2, 0.3, and 0.4% wt HG concentrations, respectively. Interestingly, Bai et al. (2010) suggested that soil EC might be influenced by the number of wetting and drying cycles, observing an EC 1.7 times greater than the control during the first wetting and drying cycle, even at a low HG concentration (e.g., 0.05%). Conversely, subsequent cycles exhibited EC reduction in the 17–65% range.

Cation exchange capacity (CEC) represents the amount of cations retained on the surface of soil particles and appears positively influenced by HG application in a dose-dependent manner. Abrisham et al. (2018) demonstrated an increase in CEC from 6.4 meq 100 g−1 in the control to 7.2 (0.2% HG) and 8.2 meq 100 g−1 (0.5% HG). This finding was supported by El-Saied et al. (2016), who speculated that HG application may impact pH-dependent exchangeable sites, further contributing to observed enhancement in CEC.

5.2 Crop growth and production

The seed germination and initial seedling development are pivotal stages for the successful establishment of crops, contingent upon various factors, with crop available water being of utmost importance. In environments characterized by poor water content, especially in arid and semi-arid regions, the use of soil conditioners holds significant potential (McGuire et al. 1978). In this regard, HG emerges as a promising tool not only as a soil conditioner but also as a seed coating, contributing substantially to the early phases of crop development. The following paragraphs provide a synthesis of current knowledge on HG application, encompassing both soil conditioning and seed coating, across diverse crops and phenological stages.

5.2.1 HG as soil conditioner

During the germination phase, the literature generally indicates limited or no discernible beneficial effect when HG is incorporated into the soil. Notably, Shahid et al. (2012) observed a 10% increase in wheat (Triticum aestivum L.) germination in a pot experiment when 0.3–0.4% polyacrylamide-based HG was added to sandy loam soil. Similarly, Rehman et al. (2011) reported greater rice (Oryza sativa L.) emergence in plots treated with carbonyl amide-based HG compared to control plots (186 vs 158), regardless of sowing method (e.g., flat, ridge, bed sowing). In contrast, Akhter et al. (2004) found no differences in seed germination among wheat, barley (Hordeum vulgare L.), and chickpea (Cicer arietinum L.) in a pot experiment involving sandy loam or loamy soils.

Moving to seedling development, consistently positive effects were identified for wheat, barley, chickpea, and rice (Akhter et al. 2004; Rehman et al. 2011; Shahid et al. 2012). For instance, Shahid et al. (2012) observed increased wheat shoot length at 0.3% (24.36 cm) and 0.4% (25.80 cm) HG application rate compared to the untreated pot (16.24 cm). At maturity, Rehman et al. (2011) found that the application of HG significantly improved rice height (84 vs 71 cm). In the same way, shoot fresh and dry weights of wheat, barley, and chickpea were greater after the addition of HG, irrespective of soil type (Akhter et al. 2004). Rehman et al. (2011) also found that HG significantly enhanced rice kernel yield (2.39 vs 2.25 t ha−1) due to increased water retention.

At the field scale, Yazdani et al. (2007) observed improved soybean (Glycine max (L.) Merr.) dry matter, crop growth rate and, harvest index with 225 kg ha−1 of HG application. Satriani et al. (2018) demonstrated that HG application under moderate deficit irrigation field conditions allowed achieving the same bean (Phaseolus vulgaris L.) yield as the well-irrigated treatment, indicating HG effectiveness in Mediterranean and arid areas. Notably, beneficial effects extended beyond cereals and legumes, encompassing crops such as coffee (Coffea spp.) (de Jesus Souza et al. 2016; Mote et al. 2018) cucumber (Cucumis sativus L.) (Montesano et al. 2015; Gholamhoseini et al. 2018), sweet basil (Ocimum basilicum L.) (Montesano et al. 2015), spinach (Ipomoea aquatica Forsk) (Fan et al. 2015b), olive trees (Olea europaea L.) (M’barki et al. 2019), Khasi mandarin (Citrus reticulata Blanco) (Pattanaaik et al. 2015), rapeseed (Brassica napus L.) (Tang et al. 2014), and others.

It is important to highlight that the effectiveness of HG as a soil conditioner may diminish following wetting and drying cycles (Akhter et al. 2004). To optimize its efficacy, HG should be applied in close proximity to crop sowing. While many studies are still at the plot scale, a recent meta-analysis by Zheng et al. (2023) indicated a potential ~ 13% improvement in Asian crop yield with field-scale HG application, irrespective of crop type and dosage. Diverse application doses are reported in literature, with Yazdani et al. (2007) advocating for a 225 kg ha−1 application dose, Jahan and Mahallati (2020) suggesting 100 kg ha−1 as optimal for both yield and economic aspects, and Bana et al. (2023) noting significant crop response only up to 2.5 kg ha−1, with higher doses (e.g., 5, 7.5 kg ha−1) proving less beneficial for pearl millet yield increment.

5.2.2 HG as seed coating

Both synthetic and natural-derived HGs have been explored as seed coating as documented in the studies of Mazen et al. (2015), Chen et al. (2016, 2017), and Hotta et al. (2016). Hotta et al. (2016) investigated the impact of polyacrylamide (a synthetic polymer) and agar/ι- carrageenan blend (a natural polymer) as coatings on wheat seed germination, observing contrasting results based on the water regime. Under optimal moisture conditions, polyacrylamide HG enhanced radicle emergence, germination speed, and seed vigor in proportion to the coating thickness. Conversely, at the same moisture level, the agar/ι- carrageenan blend HG led to a slight reduction in germination percentage (90 vs 93%), likely attributed to the thicker coating volume (16 mL), potentially limiting seed aeration (Hotta et al. 2016). Interestingly, under drought conditions the natural polymer (agar/ι- carrageenan blend) showed an opposite trend, speculating that it may foster root/shoot development due to trace elements present in its impure chemical composition, including Mg, K, Ca, Na, and S.

In another study, Mazen et al. (2015) explored various HGs, including polyacrylic acid/polyacrylate-, starch-, vinyl alcohol-, polyacrylate-, and cellulose-based HG, as a seed coating for maize. While maize germination was not significantly affected by HG, plant height increased with different HG types. For instance, plant height increased by 39.3, 50.4, 26.6, 53.5, and 43.6%, respectively. Furthermore, root length increased by more than 50% when HG was applied at a rate exceeding 0.4%, changing from 37.7 cm plant−1 in the control to 45.8 (starch-based HG), 39.7 (vinyl alcohol-based HG), 42.5 (polyacrylate-based HG), and 38.4 cm plant−1 (cellulose-based HG) (Mazen et al. 2015).

However, Chen et al. (2016) presented contrasting findings, reporting that polyacrylate-based HG coatings had a negative impact on maize rooting. Scanning electron microscope images revealed damaged root tip cross sections characterized by irregular and distorted cells. Chen et al. (2017) further confirmed that sodium polyacrylate and potassium polyacrylate HG negatively affected maize growth. The authors attributed this negative impact to the excessive accumulation of Na in roots resulting from the HG manufacturing process. The neutralization of acrylic acid, used in HG production, involves either sodium hydroxide (NaOH) or potassium hydroxide (KOH), leading to a high concentration of Na and K inside the gel (Chen et al. 2017).

These results highlight the complexity of the effects of HG seed coatings, emphasizing the importance of considering both the specific type of HG and the environmental conditions under which they are applied.

5.3 Controlled release of agrochemicals

Pesticides and fertilizers stand as indispensable agrochemicals in modern agriculture, significantly contributing to enhanced crop productivity. The global attention towards the utilization of HG for agrochemical delivery has escalated due to their numerous benefits, including continuous, time-controlled and gradual nutrient supply, proximity to absorption zone (i.e., roots), lower applications number and reduced loss through leaching, volatilization, and immobilization (Campos et al. 2014; Milani et al. 2017). Notably, considerable N recovery from non-losses might be substantial, e.g., Zhou et al. (2018) reported a 52 to 20% reduction in N loss from urea-loaded HG compared to direct urea application.

Two primary mechanisms are enabling HG loading: (i) physical combination, or encapsulation, and (ii) mediated by the formation of covalent chemical bonds. The former governs the release rate (Akelah 1990), while the latter involves water diffusion, convective flow, and concentration gradient processes (Shavit et al. 1997; Zeng and Shi 2009; Wang et al. 2011). The amount of loaded molecules is directly proportional to the hydrophilicity and swelling degree of the HG (Bortolin et al. 2012).

The controlled release of agrochemicals is widely acknowledged to be contingent upon coating thickness and diffusion coefficient, as defined by Fick’s First Law (Milani et al. 2017). The release pattern of molecules from HG follows a sigmoidal behavior characterized by an initial negligible release (“lag phase”), followed by a phase of constant release (“linear phase”), and a transition into a gradual decay (“decay phase”) (Shaviv 2001). These release dynamics are intricately linked to the structure of the HG and its 3D network weakening or relaxation, where a higher degree of structure degradation correlates with faster release dynamics (Xiao et al. 2017; Sarmah and Karak 2019).

In the early stage, lasting a few days, the polymeric network remains robust (i.e., the network structure is intact), resulting in a minimal release of nutrients. Subsequently, during the second phase, spanning dozens of days, as network degradation initiates, a significant portion of the agrochemical is released. Finally, over a few weeks, almost the entirety (> 90–99%) of the agrochemical is released. For an in-depth exploration of release mechanisms, Guilherme et al. (2015) provide a comprehensive review.

In an optimal scenario, the controlled release of nutrients from HG is designed to fulfil the entirety of crop nutrient requirement over the entire growing season, achieved via a singular application (Calabi-Floody et al. 2018; Chen et al. 2018). This strategic approach is grounded in the recognition that crops typically exhibit high nutrient demand during the active growth period, while nutrient requirements are minimal or non-existent during earlier growth stages and at maturity.

Numerous studies in the literature have investigated a diverse range of HG formulations loaded with fertilizers, spanning from single nutrient formulation such as urea (CO(NH2)2) (Cheng et al. 2018; León et al. 2019) or ammonium sulfate (NH4)2SO4 (Bortolin et al. 2012; León et al. 2019), to multi-nutrient formulation like potassium dihydrogen phosphate KH2PO4 (Bortolin et al. 2012), potassium nitrate KNO3 (León et al. 2019), and NPK fertilizers with different ratings (Jamnongkan and Kaewpirom 2010; Essawy et al. 2016). The majority of these studies has primarily conducted report laboratory experiments, investigating diverse release times.

Wen et al. (2016) observed a 30-day urea released from cotton stalk-derived HG, noting a higher rate during the initial 5 days. A similar trend was observed by Zhan et al. (2004) for phosphate release from polyvinylalcohol-derived HG. Cheng et al. (2018) reported that, after 40 days, only less than 4% of urea was released, suggesting that acrylic acid-loaded HG might effectively meet crop needs for an entire season if precisely designed. These findings were corroborated by Skarpa et al. (2023), who, in laboratory experiment involving a mixture of HG, NPK fertilizer, and zeolite, observed the maximum N release after 90 days from amendment application.

It is important to note that the release dynamics may vary among nutrients when using multi-nutrient-loaded HG. Noppakundilograt et al. (2015) reported, that after 30 days of NPK-HG immersion in water, the highest release rates for N (84%), intermediate rates for P (62%), and the lowest rate for K (36%). The authors hypothesized that the smaller ionic radius of K+ compared to that of N in ammonium form (NH4+) resulted in greater interactions with HG structure, lower repulsion forces, reduced water absorption, and consequently, slower K+ release.

Several other factors influence release dynamics, including HG synthesis conditions. Bortolin et al. (2012) highlighted the significance of the acrylamide-to-methylcellulose ratio in controlling (NH4)2SO4 and KH2PO4 release due to their impact on hydrophilicity and the HG network structure. Li et al. (2016) suggested that the type of solution used for HG synthesis may also play a crucial role, as cations with higher charge might compete for adsorption sites, potentially increasing fertilizer diffusion coefficient and accelerating fertilizer release. Temperature was found to strongly impact nutrient release. Liang et al. (2007) demonstrated that urea release curves at different temperatures were similar, except for the initial release amount (after 2 days) which varied significantly: 9, 27, and 46% of N release from P(acrylic acid-co-acrylamide)/kaolin HG exposed at 5, 20, and 35 °C, respectively). Moreover, polymers are influenced by pH, affecting the swelling degree of HG. At acid pH, protonation of unreacted groups (e.g., NH2 of chitosan) facilitates hydrogen bond dissociation of amino groups, increasing the release rate. Conversely, high pH weakens the protonation of unreacted groups, resulting in reduced swelling and a lower release rate (Shu et al. 2001; El-Sherbiny et al. 2005).

Finally, the addition of inorganic particles, such as clay minerals, to the HG can modify release kinetics by acting as a “retardant factor” through various mechanisms, including physical barrier and electrostatic interactions. When sufficiently dispersed, these particles create longer tortuous paths, slowing nutrient release (Guilherme et al. 2010, 2015).

Likewise of nutrient delivery, HG can play a pivotal role in the development of controlled release pesticides (Flores Céspedes et al. 2007). Such formulations offer numerous advantages, including a reduction in application dose, environmental degradation of active molecules, toxicity, volatilization, and leaching (Akelah 1996; Rudzinski et al. 2002). Consequently, this leads to a decrease in environmental pollution and drift, an extension of application intervals, and an increase in the number of target organisms (Akelah 1996; Rudzinski et al. 2002).

A substantial body of research has explored the use of alginate as a base for HG synthesis due to its biodegradability, nontoxicity, and swelling capacity (Işıklan 2007; Hendrawan et al. 2016). However, pure alginate-derived HG typically exhibits poor slow-release properties. As previously discussed for fertilizer delivery, the structure of alginate-based HG can be enhanced by incorporating retardant factors such as clay, bentonite, natural-derived colloids, anthracite, or activated carbon (Flores Céspedes et al. 2007; Bortolin et al. 2012; Zhang et al. 2020).

Flores Céspedes et al. (2007) conducted experiments with alginate-based HG for the slow release of chloridazon (C10H8ClN3O) and metribuzin (C8H14N4OS). They observed that 90% of the molecules dissolved in water after 48 and 13 h for chloridazon and metribuzin, respectively, compared to 2 and 0.5 h required for herbicides alone (without HG) dissolution (Figure 6).

Cumulative release of chloridazon (a) and metribuzin (b) from granules in water (error bars represent the standard deviation of three replicates). Different data series represent different treatments: ClA, chloridazon-alginate; ClAB, chloridazon-alginate-bentonite; ClAAn, chloridazon-alginate-anthracite; ClAC, chloridazon-alginate-activated carbon; ClABC20, chloridazon-alginate-bentonite-20% of activated carbon in dry formulation; MA, metribuzin-alginate; MAB, metribuzin-alginatebentonite; MAAn, metribuzin-alginate-anthracite; MAC, metribuzin-alginate-activated carbon, MABC20, Metribuzin-alginate-bentonite-20% of activated carbon in dry formulation (modified from Flores Céspedes et al. (2007)).

In a recent review, Mujtaba et al. (2020) explored the use of chitosan-derived HG for herbicide delivery. They reported that this approach can facilitate a slow release of compounds while maintaining herbicidal activity at commercial formulation levels, thereby reducing soil leaching losses by 15–40%. Despite these benefits, the authors emphasized the need for additional studies to ascertain any potential toxic effect of chitosan on plants. Moreover, challenges arise in applying chitosan-based HG as commercial products in agriculture when formulations without the incorporation of monomers based on acrylates or acrylamides exhibit moderate water absorbency (e.g., < 70 g g−1) (Michalik and Wandzik 2020).

Despite extensive efforts in the encapsulation of pesticides within HGs, future challenges lie in formulating pesticide-loaded HG capable of responding to environmental stimuli, such as the presence of the target pest. Singh et al. (2020) recently classified stimuli-responsive polymers based on the nature of the stimulus, including pH, redox, temperature, and presence of enzymes. Further insights into agrochemical release can be found in the comprehensive review by Campos et al. (2014).

5.4 Controlled release of microorganisms

The rhizosphere is colonized by high abundances of plant-associated microorganisms (Mos) (Berg et al. 2005; Schlaeppi and Bulgarelli 2015) that fulfil important ecosystem functions for both crop and soil health (Smith et al. 1999; Abd El-Rehim et al. 2004). These Mos can promote plant growth through direct and indirect interaction, with the latter involving competition with plant pathogens (Berg 2009). Therefore, there is a pressing need for the development of low-cost and reliable carriers capable of delivering Mos under field conditions (Sivaram et al. 2023).

The application of MO inoculants has gained recent recognition for enhancing stress tolerance, providing disease resistance, promoting nutrient availability, and uptake, and increasing biodiversity (Lugtenberg et al. 2002; Morrissey et al. 2004). In comparison to synthesized chemicals, such as pesticides and fertilizers, MO inoculants have the potential to increase input efficiency, thereby reducing risk to human health and the environment (Berg 2009; Berg and Smalla 2009). The use of hydrogels as seed coating in agriculture is a rapidly evolving practice, and these HGs can also serve as carriers for beneficial microbial inoculants (Abobatta 2018).

In the context of Mos delivery, encapsulating these Mos within HGs offers several advantages with respect to free cells. These include a reduced likelihood of inoculum contamination during storage, transport, and application; increased metabolic activity of encapsulated cells; and a decreased risk of off-site drift during application (Cassidy et al. 1996). The loading of Mos is typically achieved by immersing the HG in a liquid solution before forming solid granules (Bai et al. 2010). The cells immobilization may be achieved through various methods: flocculation, adsorption on surfaces, covalent bonding to carriers, cross-linking of cells, encapsulation in a polymer-gel, and entrapment in a matrix (Cassidy et al. 1996). The incorporation of life-compatible ingredients, such as glycerol, has been demonstrated to enhance the tensile properties and crushing strength of microbially loaded HGs without affecting cell physiology or process efficiency (Zhang et al. 2015). Mos release is typically induced by water flow transport (Cassidy et al. 1996). Alternative methods for HG formation, when encapsulating microbial cells, have been successfully tested, including radiopolymerization (Petre et al. 1999). The encapsulation of cells has been obtained also by exploiting the self-assembly of hydrogel on superhydrophobic substrates (Song et al. 2010).

The critical consideration in utilizing HG as Mos carrier lies in ensuring the shelf survivability and viability of bacteria, influenced by various factors, including Mos species. Different Mos exhibit diverse adaptive reactions to environmental stresses. In certain agricultural applications, hydrogel coatings are employed not to carry beneficial strains but rather to serve the opposite function. For example, they are employed to defend plants against soilborne bacterial or fungal pathogens. This approach is facilitated by the ease of formulating HGs that release antimicrobial compounds or possess intrinsic toxicity to microbes due to their chemical structure (Mohamed and Fahmy 2012). Consequently, when the objective shifts towards the secure delivery of HG-borne plant-growth-promoting microorganisms, several considerations need to be carefully addressed.

Perez et al. (2018) conducted a study where HG loaded with Azospirillum brasilense AZ39 and Pseudomonas fluorescens ZME4 were prepared using chitosan/starch-based hydrogels. This loaded HG was stored for up to one year, and its survivability and viability were evaluated. The results indicated a reduction in bacteria concentration for both species, decreasing from 1010 CFU/g of swollen HG immediately before drying to 109 CFU/g 15 days after drying. After 1 year, Azospirillum bacteria maintained unchanged viability (109 CFU/g), while Pseudomonas viability decreased to 107 CFU/g.

Another critical consideration is the “type of carrier.” Suman et al. (2016) discovered that Mos associated with plant stimulation, such as Azotobacter chroococcum (nitrogen fixer), Pseudomonas fluorescens (phosphate solubilizer), and Trichoderma viride (phyto-stimulator), experienced enhanced benefits when carried on HG compared to other materials like lignite and liquid shelf. In a separate experiment, the germination and seedling growth of Sorghum bicolor seeds were improved when coated with HGs containing plant-growth-promoting rhizobacteria (Widawati and Suliasih 2018).

The utilization of non-synthetic polymers as HG matrixes has also been explored for agricultural and food applications (Ghobashy 2020; Klein and Poverenov 2020). This approach could mitigate the risk of toxicity when uploading microbial cells. However, it is essential to note that the toxicity of natural HGs should be further investigated.

The cross-linking agent plays a crucial role in the survival of hydrogel-immobilized microorganisms. Substituting boric acid with sodium sulfate has been proven effective in enhancing the survival rate of polyvinyl alcohol hydrogel beads (Takei et al. 2011). This substitution provides a significant improvement in the hydrogel’s ability to support the viability of immobilized microorganisms.

Additionally, the viability of fungal inoculants has been found independent of the size of mycelial fragments. Leštan et al. (1998) demonstrated that small single-hyphae of Irpex lacteus (Mad-517, ATCC 11245) and Trametes versicolor (MD-277) exhibited viability comparable to larger fragments. It is worth noting that the inoculum can impact the HG physical properties. For instance, Liffourrena and Lucchesi (2018) observed a reduction in hydrophilicity in alginate-derived HG due to microbial inoculants.

6 Biodegradability and toxicity of HGs

The biodegradability of soil conditioners is a desired key property for soil and groundwater protection (European Commission 2020). Thus, HG environmental fate is a key aspect to be considered before field application (Li and Chen 2020). It would be desirable that exhausted HGs would biodegrade through microorganisms’ action and/or atmospheric agents. Reasonably, the microbial community should already have enzymes able to degrade natural-derived HG, while the environmental fate of synthetic polymers is mostly unknown and specific studies might be requested prior to their usage. For example, Nyyssölä and Ahlgren (2019) investigated polyacrylamide biodegradation and they found that the degradation starts with deamination through amidase to form ammonia and polyacrylate. The former can be utilized as a N source by Mos while the latter, i.e., polyacrylate, seems more recalcitrant to biodegradation and thus may potentially accumulate in the soil profile. Turioni et al. (2021) recently found out in a lab experiment how the complex interaction between soil characteristics (e.g., C/N ratio, soil organic matter content and pH) and land use type (agricultural vs natural soils) could significantly affect the HG biodegradability. Indeed, the same author found high biodegradation of cellulose-based HG in agricultural soils with low soil organic matter content due to microbial utilization of HG as a C source. On the contrary, in natural-like soils or in saline soils the acidic pH and the high salt concentration may respectively slow down HG biodegradation (Turioni et al. 2021).

The capacity of soil microorganisms to degrade HG is also related to HG half-life. Smagin et al. (2018) studied HGs biodegradation and found the half-time period of microbial decay of HGs ranged from 0.5 to 2.6 years and only in one sample having amphiphilic fillers in the form of dispersed peat was > 5 years. Numerical simulation of HG biodegradation estimated a HG half-life of 1.2 years in humid conditions while it decreased down to 0.4 years in arid conditions (Smagin et al. 2014). Indeed, beyond Mos substrate utilization, also abiotic factors influence HG biodegradation, first the temperature. Smagin et al. (2014) incubated HG mixed with soil at 20, 30, and 37 °C and showed that the degree of biodegradation increased with temperature. Second, fertilizer, especially fertilizer containing N, application may also accelerate the HG biodegradability since C and N may be limiting elements in soil (Pointing 2001). Also, ultraviolet (UV) radiation breaks polymers into oligomers. Neethu et al. (2018) found polyacrylate to be more sensitive to aerobic and anaerobic microbiological degradation after UV exposure. The same authors pointed out that oligomers are too voluminous to be absorbed by crop roots; thus, they have no bioaccumulation potential (Neethu et al. 2018). Indeed, considering the possibility of toxic degradation, by-product formation is another aspect to consider before field HG application. For example, acrylamide, the monomer of polyacrylamide, is neurotoxic. Contrarily to what Nyyssölä and Ahlgren (2019) reported, Kalhapure et al. (2016) observed that polyacrylamide can never degrade into monomers and that no acrylamide was found in soil or plant tissue after HG degradation (Kalhapure et al. 2016). Nevertheless, synthetic hydrogels, produced by polymerization of highly toxic monomers (e.g., acrylamide), might contain unreacted residues that should be removed before their usage (for further details, please see the related literature (e.g., Friedman, 2003)).

Finally, HG degradation should not affect soil fertility and health. Saruchi et al. (2019) found that HG degradation did not affect soil organic carbon, phosphorus, and potassium content.

7 Concluding remarks and future perspectives

In this scientific review, we systematically compile, critically evaluate, and synthesize the latest findings and relevant literature pertaining to the application of HGs in agroecosystems ranging from the effects on soil properties to the influence on crop traits and yield.

Many different types of polymers can be synthetized from both natural- and synthetic-derived polymers, and the availability of different building blocks (either organic or inorganic, i.e., clays), the variation of their molar ratios, and the optimization of synthesis conditions allow virtually indefinite widening of the microstructure, swellability, and properties of candidate HGs. Synthetic-derived HGs are characterized by well-defined and reproducible compositions, but natural-derived HGs, though less homogeneous from the compositional point of view, may provide benefits related to the presence of trace elements that may play a nutritional role. Moreover, HGs derived from natural feedstocks are easily bio-degraded and are better suited to comply with the principles of the circular economy.

Hydrogel application seemed to be a promising technology to reach/maintain food security and soil health. Indeed, we have observed a consistent positive impact of this category of materials on various soil properties, mimic the effect of clay and soil organic matter, including bulk density, crop-available water, soil electrical conductivity, cation exchange capacity, and the performance of major cereal and legume crops, particularly in regions experiencing moderate water deficits. These findings suggest the potential effectiveness of these materials in arid and semi-arid environments. Additionally, promising outcomes have been noted in the delivery of pesticides, agrochemicals, and microorganisms. Therefore, incorporating loaded hydrogels for agronomic inputs could play a pivotal role in future agriculture, mitigating environmental impacts associated with traditional agronomic practices. However, some contrasting or contradicting results regarded HG effects on crop available water following subsequent wetting and drying cycles, saturated hydraulic conductivity, soil pH, cationic exchange capacity, and electrical conductivity.

The conflicting results highlighted by screening the extensive literature suggests also that the HGs synthesis can be adapted for opposite purposes, e.g., germination delay or speed up, and/or rooting inhibition or promotion.

Future research should address (i) the development of optimized protocols for producing, in a reproducible and up-scalable fashion, biowaste-derived HGs that would ensure their biodegradability and nontoxicity, (ii) the potential impact of sodium ions contained within HGs on crop cells, (iii) the influence of HGs on soil saturated hydraulic conductivity and pH, (iv) the decline in HG effectiveness following wetting and drying cycles, and (iv) the biodegradability of hydrogels and their environmental fate. Another aspect on which future research should focus is the definition of an optimal dose when HG is applied as soil conditioners (i.e., mixed in the soil) according to HGs type. In general, the literature has shown that the effect is greater as the application dose increases, but the research community should find a balance based on a cost-benefit analysis. More effort should be given to HGs seed coating combined with molecule release to improve fertilizer and pesticide use efficiency, at the same time improving the mechanical stability, the microstructure, the release capability, and the processability of the coatings. Finally, one of the biggest challenges will be the design and the synthesis of “smart” and responsive HGs able to respond to selective environmental stimuli (e.g., pH, temperature, light, or specific molecules, and the combination thereof) resulting in structural changes that allow, in turn, controlled molecule (nutrients or pesticides) release.

Data availability

Not applicable

Code availability

Not applicable

References

Abd El-Rehim HA (2006) Characterization and possible agricultural application ofpolyacrylamide/sodium alginate crosslinked hydrogels prepared by ionizing radiation. J Appl Polym Sci 101:3572–3580. https://doi.org/10.1002/app.22487

Abd El-Rehim HA, Hegazy ESA, Abd El-Mohdy HL (2004) Radiation synthesis of hydrogels to enhance sandy soils water retention and increase plant performance. J Appl Polym Sci 93:1360–1371. https://doi.org/10.1002/app.20571

Abobatta W (2018) Impact of hydrogel polymer in agricultural sector. Adv Agric Environ Sci 1:59–64. https://doi.org/10.30881/aaeoa.00011

Abrisham ES, Jafari M, Tavili A et al (2018) Effects of a super absorbent polymer on soil properties and plant growth for use in land reclamation. Arid L Res Manag 32:407–420. https://doi.org/10.1080/15324982.2018.1506526

Adel AM, Abou-Youssef H, El-Gendy AA, Nada AM (2010) Carboxymethylated cellulose hydrogel; sorption behavior and characterization. Nat Sci 8(8):244–256

Agaba H, Orikiriza LJB, Obua J et al (2011) Hydrogel amendment to sandy soil reduces irrigation frequency and improves the biomass of Agrostis stolonifera. Agric Sci 2:544–550. https://doi.org/10.4236/as.2011.24071

Akelah A (1996) Novel utilizations of conventional agrochemicals by controlled release formulations. Mater Sci Eng C 4:83–98. https://doi.org/10.1016/0928-4931(96)00133-6

Akelah A (1990) Applications of functionalized polymers in agriculture. J Islam Acad Sci 3:49–61. https://jag.journalagent.com/ias/pdfs/IAS_3_1_49_61.pdf (accessed 14/02/2024)

Akhiar A, Battimelli A, Torrijos M, Carrere H (2017) Comprehensive characterization of the liquid fraction of digestates from full-scale anaerobic co-digestion. Waste Manag 59:118–128. https://doi.org/10.1016/j.wasman.2016.11.005

Akhter J, Mahmood K, Malik KA et al (2004) Effects of hydrogel amendment on water storage of sandy loam and loam soils and seedling growth of barley, wheat and chickpea. Plant, Soil Environ 50:463–469. https://doi.org/10.17221/4059-pse

Albalasmeh AA, Hamdan EH, Gharaibeh MA, El HA (2021) Improving aggregate stability and hydraulic properties of sandy loam soil by applying polyacrylamide polymer. Soil Tillage Res 206:104821. https://doi.org/10.1016/J.STILL.2020.104821

Aoki H, Al-Assaf S, Katayama T, Phillips GO (2007) Characterization and properties of Acacia lsevie (L.) Willd. Var. lsevie with enhanced properties (Acacia (sen) SUPER GUMTM): Part 2-Mechanism of the maturation process. Food Hydrocoll 21:353–358. https://doi.org/10.1016/j.foodhyd.2006.04.002

Athawale VD, Lele V (1998) Graft copolymerization onto starch. II. Grafting of acrylic acid and preparation of it’s hydrogels. Carbohydr Polym 35:21–27. https://doi.org/10.1016/S0144-8617(97)00138-0

Bai W, Zhang H, Liu B et al (2010) Effects of super-absorbent polymers on the physical and chemical properties of soil following different wetting and drying cycles. Soil Use Manag 26:253–260. https://doi.org/10.1111/j.1475-2743.2010.00271.x

Bana RS, Grover M, Singh D et al (2023) Enhanced pearl millet yield stability, water use efficiency and soil microbial activity using superabsorbent polymers and crop residue recycling across diverse ecologies. Eur J Agron 148:126876. https://doi.org/10.1016/j.eja.2023.126876

Bao Y, Ma J, Lib N (2011) Synthesis and swelling behaviors of sodium carboxymethylcellulose-g-poly(AA-co-AM-co-AMPS)/MMT superabsorbent hydrogel. Carbohydr Polym 84:76–82. https://doi.org/10.1016/j.carbpol.2010.10.061

Bearce B, McCollum R (1977) A comparison of peat-lite and non-composted hardwood-bark mixes for use in pot and bedding-plant production and the effects of a new hydrogel soil amendment on their performance. Flor Rev 10:21–24. https://hortscans.ces.ncsu.edu/library/all/doc_id/289/ (accessed 14/02/2024)

Berg G (2009) Plant-microbe interactions promoting plant growth and health: perspectives for controlled use of microorganisms in agriculture. Appl Microbiol Biotechnol 84:11–18. https://doi.org/10.1007/s00253-009-2092-7

Berg G, Smalla K (2009) Plant species and soil type cooperatively shape the structure and function of microbial communities in the rhizosphere. FEMS Microbiol Ecol 68:1–13. https://doi.org/10.1111/j.1574-6941.2009.00654.x

Berg G, Krechel A, Ditz M et al (2005) Endophytic and ectophytic potato-associated bacterial communities differ in structure and antagonistic function against plant pathogenic fungi. FEMS Microbiol Ecol 51:215–229. https://doi.org/10.1016/j.femsec.2004.08.006

Blodgett AM, Beattie DJ, White JW, Elliott GC (1993) Hydrophilic polymers and wetting agents affect absorption and evaporative water loss. HortScience 28:633–635. https://doi.org/10.21273/HORTSCI.28.6.633

Bortolin A, Aouada FA, de Moura MR et al (2012) Application of polysaccharide hydrogels in adsorption and controlled-extended release of fertilizers processes. J Appl Polym Sci 123:2291–2298. https://doi.org/10.1002/app

Buchmann C, Bentz J, Schaumann GE (2015) Intrinsic and model polymer hydrogel-induced soil structural stability of a silty sand soil as affected by soil moisture dynamics. Soil Tillage Res 154:22–33. https://doi.org/10.1016/j.still.2015.06.014

Calabi-Floody M, Medina J, Rumpel C et al (2018) Smart fertilizers as a strategy for sustainable agriculture. Adv Agron 147:119–157. https://doi.org/10.1016/bs.agron.2017.10.003

Campos EVR, de Oliveira JL, Fraceto LF, Singh B (2014) Polysaccharides as safer release systems for agrochemicals. Agron Sustain Dev 35:47–66. https://doi.org/10.1007/s13593-014-0263-0

Cassidy MB, Lee H, Trevors JT (1996) Environmental applications of immobilized microbial cells: a review. J Ind Microbiol 16:79–101. https://doi.org/10.1007/BF01570068

Chang C, Duan B, Zhang L (2009) Fabrication and characterization of novel lsevierat cellulose-alginate hydrogels. Polymer (guildf) 50:5467–5473. https://doi.org/10.1016/j.polymer.2009.06.001

Chang I, Prasidhi AK, Im J et al (2015) Soil treatment using microbial biopolymers for anti-desertification purposes. Geoderma 253–254:39–47. https://doi.org/10.1016/J.GEODERMA.2015.04.006

Chen J, Park H, Park K (1999) Synthesis of superporous hydrogels: hydrogels with fast swelling and superabsorbent properties. J Biomed Mater Res 44:53–62. https://doi.org/10.1002/(SICI)1097-4636(199901)44:1%3c53::AID-JBM6%3e3.0.CO;2-W

Chen X, Mao X, Lu Q et al (2016) Characteristics and mechanisms of acrylate polymer damage to maize seedlings. Ecotoxicol Environ Saf 129:228–234. https://doi.org/10.1016/j.ecoenv.2016.03.018

Chen X, Huang L, Mao X et al (2017) A comparative study of the cellular microscopic characteristics and mechanisms of maize seedling damage from superabsorbent polymers. Pedosphere 27:274–282. https://doi.org/10.1016/S1002-0160(17)60305-9

Chen J, Lü S, Zhang Z et al (2018) Environmentally friendly fertilizers: a review of materials used and their effects on the environment. Sci Total Environ 613–614:829–839. https://doi.org/10.1016/j.scitotenv.2017.09.186

Cheng D, Liu Y, Yang G, Zhang A (2018) Water- and fertilizer-integrated hydrogel derived from the polymerization of acrylic acid and urea as a slow-release N fertilizer and water retention in agriculture. J Agric Food Chem 66:5762–5769. https://doi.org/10.1021/acs.jafc.8b00872

Chung HJ, Park TG (2009) Self-assembled and nanostructured hydrogels for drug delivery and tissue engineering. Nano Today 4:429–437. https://doi.org/10.1016/j.nantod.2009.08.008

Dal Ferro N, Delmas P, Duwig C, Simonetti G, Morari F (2012) Coupling X-ray microtomography and mercury intrusion porosimetry to quantify aggregate structures of a cambisol under different fertilisation treatments. Soil Till Res 119:13–21. https://doi.org/10.1016/j.still.2011.12.001

Darge FH, Andrgie TA, Tsai H-C, Lai J-Y (2019) Polysaccharide and polypeptide based injectable lsevie-sensitive hydrogels for local biomedical applications. Int J Biol Macromol 133:545–563. https://doi.org/10.1016/j.ijbiomac.2019.04.131

de Fraiture C, Wichelns D (2010) Satisfying future water demands for agriculture. Agric Water Manag 97:502–511. https://doi.org/10.1016/j.agwat.2009.08.008

de Jesus Souza AJ, Guimarães RJ, Colombo A et al (2016) Quantitative analysis of growth in coffee plants cultivated with a water-retaining polymer in an irrigated system. Rev Cienc Agron 47:162–171. https://doi.org/10.5935/1806-6690.20160019

De Nooy AEJ, Capitani D, Masci G, Crescenzi V (2000) Ionic polysaccharide hydrogels via the Passerini and Ugi multicomponent condensations: Synthesis, behavior and solid-state NMR characterization. Biomacromol 1:259–267. https://doi.org/10.1021/bm005517h

Dorraji SS, Golchin A, Ahmadi S (2010) The effects of hydrophilic polymer and soil salinity on corn growth in sandy and loamy soils. Clean – Soil. Air, Water 38:584–591. https://doi.org/10.1002/clen.201000017

Dou QQ, Liow SS, Ye E et al (2014) Biodegradable thermogelling polymers: working towards clinical applications. Adv Healthc Mater 3:977–988. https://doi.org/10.1002/adhm.201300627

El Shafei YZ, Al Omran AM, Al-Darby AM, Al Omran AM (1992) Influence of upper layer treatment of gel-forming conditioner on water movement in sandy soils under sprinkler infiltration. Arid Soil Res Rehabil 6:217–213. https://doi.org/10.1080/15324989209381316

El-Saied H, El-Hady OA, Basta AH et al (2016) Bio-chemical properties of sandy calcareous soil treated with rice straw-based hydrogels. J Saudi Soc Agric Sci 15:188–194. https://doi.org/10.1016/j.jssas.2014.11.004

El-Shafei YZ, Al-Darby AM, Shalaby AM, Al-Omran AM (1994) Impact of a highly swelling gel-forming conditioner (acryhope) upon water movement in uniform sandy soils. Arid Soil Res Rehabil 8:33–50. https://doi.org/10.1080/15324989309381376

El-Sherbiny IM, Lins RJ, Abdel-Bary EM, Harding DRK (2005) Preparation, characterization, swelling and in vitro drug release behaviour of poly[N-acryloylglycine-chitosan] interpolymeric pH and thermally-responsive hydrogels. Eur Polym J 41:2584–2591. https://doi.org/10.1016/j.eurpolymj.2005.05.035

Erci V, Seker C, Basaran M, Erpul G (2021) Determining the effectiveness of some soil stabilizers in wind erosion prevention using wind tunnel experiments. L Degrad Dev 32:2962–2977. https://doi.org/10.1002/LDR.3937

Essawy HA, Ghazy MBM, El-Hai FA, Mohamed MF (2016) Superabsorbent hydrogels via graft polymerization of acrylic acid from chitosan-cellulose hybrid and their potential in controlled release of soil nutrients. Int J Biol Macromol 89:144–151. https://doi.org/10.1016/j.ijbiomac.2016.04.071

European Commission (2020) Biodegradable plastics in the open environment. https://op.europa.eu/en/publication-detail/-/publication/0c0d6267-433a-11eb-b27b-01aa75ed71a1 (accessed 14/02/2024)

Fan JB, Song Y, Wang S et al (2015a) Directly coating hydrogel on filter paper for effective oil-water separation in highly acidic, alkaline, and salty environment. Adv Funct Mater 25:5368–5375. https://doi.org/10.1002/adfm.201501066

Fan R, Luo J, Yan S et al (2015b) Effects of biochar and super absorbent polymer on substrate properties and water spinach growth. Pedosphere 25:737–748. https://doi.org/10.1016/S1002-0160(15)30055-2

FAO (2011) The state of the world’s land and water resources for food and agriculture (SOLAW) – Managing systems at risk. London. https://www.fao.org/documents/card/en?details=cb7654en (accessed 14/02/2024)

FAOSTAT (2018) Pesticides Use. In: FAO. https://www.fao.org/documents/card/en?details=cb3411en (accessed 14/02/2024)

FAO-UNESCO (2009) Global agriculture towards 2050. Rome. https://www.fao.org/fileadmin/templates/wsfs/docs/Issues_papers/HLEF2050_Global_Agriculture.pdf (accessed 14/02/2024)

Feizi Z, Ayoubi S, Mosaddeghi MR et al (2018) A wind tunnel experiment to investigate the effect of polyvinyl acetate, biochar, and bentonite on wind erosion control. Arch Agron Soil Sci 65:1049–1062. https://doi.org/10.1080/03650340.2018.1548765

Flores Céspedes F, Villafranca Sánchez M, Pérez García S, Fernández Pérez M (2007) Modifying sorbents in controlled release formulations to prevent herbicides pollution. Chemosphere 69:785–794. https://doi.org/10.1016/j.chemosphere.2007.05.005