Abstract

The study investigated the potential of the organic fraction of municipal solid waste (OFMSW) for microbial biomass production. The compositional analysis of OFMSW showed richness in sugars, proteins, lipids, organic acids, and ethanol, suggesting promising cheap cultivation feedstock if inhibitory compounds are sustainably detoxified. The enzymatic hydrolysis with Cellic® CTec3 and AMG® 300 L BrewQ (Novozymes A/S) demonstrated excellent saccharification of sugar polymer, reaching 92% glucan hydrolysis and 70% xylan hydrolysis. However, higher enzymatic dosages led to a rise in the total organic acids content, potentially causing increased microbial inhibition. Full hydrolysate and hydrolysate after solids removal were cultivated with seven robust microbial strains. Cultivation on hydrolysate with solids showed consumption of sugars and organic acids solely by commercial backer yeast Saccharomyces cerevisiae. Removal of solids from hydrolysate resulted in increased performance of tested strains, showing consumption of measured organic acids and ethanol by S. cerevisiae, Yarrowia lipolytica DSM 8218, and Cutaneotrichosporon oleaginosus ATCC 20509. Remarkably, the investigation of biomass production revealed superior cell mass formation and detoxification by S. cerevisiae, resulting in 18.9 g of biomass/L hydrolysate with 50% of crude protein (w/w) in shake flasks and 13.2 g/L of hydrolase with 46% of crude protein (w/w) in a 5-L bioreactor. Furthermore, bioreactor cultivation confirmed organic acids and ethanol conversion into biomass, highlighting S. cerevisiae’s suitability for utilizing OFMSW for microbial biomass production. These findings contribute to advancements in biowaste-to-fodder conversion, promoting the development of a more sustainable circular economy.

Graphical abstract

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

OFMSW is a renewable and widely spread biomass source that is largely underutilized. Its richness in nutrients and abundance make it an excellent feedstock for microbial conversions. It was demonstrated that the sugar content was 55.5 ± 10.1% (w/w), the protein content ranged from 17.7 ± 5.5% (w/w), and the lipid content varied between 17.5 ± 6.6% (w/w) on a dry matter basis [1].

However, in regard to microbial cultivation, OFMSW has a relatively high concentration of inhibitors, which originate from the high content of phenolic compounds in fruit, vegetable, tea, and coffee waste residuals [2] that showed the inactivation of both microorganisms [3] and hydrolytic enzymes [4]. In addition to that, metals in OFMSW can inhibit fermentative microorganisms if present in high concentrations [5]. Furthermore, inhibitors could be formed during storage due to ongoing microbial activity [6]. Large groups of microbial metabolites, such as organic acids, alcohols, and aldehydes, have been shown to reduce the activity of enzymes [7, 8] and inhibit microbes [9,10,11,12]. Additionally, during thermal pretreatment, inhibitor formation is common due to the degradation of monomeric sugars and lignin [13, 14]. These factors can disrupt the growth of specific microorganisms. However, it is important to note that microbial consortia, or communities of diverse microorganisms, can naturally grow on and degrade OFMSW, either spontaneously or in semi-controlled environments such as composting processes [15]. This study focuses on the challenges associated with cultivating specific microorganisms on OFMSW and does not include the broader scope of microbial consortia and their potential for spontaneous or controlled degradation of this substrate.

Multiple detoxification techniques for inhibitor removal were designed to combat the inhibitory environment of waste biomasses. These methods include ion-exchange resins, membrane separation, activated carbon, liquid–liquid extraction, alkali neutralization [13], evaporation, and enzymatic and microbial treatment [16]. However, incorporating detoxification steps can negatively impact the cost-effectiveness and sustainability of the production process, making it less desirable [2, 17]. Therefore, the preference lies in using robust fermentative microorganisms that are able to tolerate and/or utilize the inhibitors without the need for additional pretreatments, ensuring a more sustainable and economically viable biorefinery process. Moreover, the presence of antimicrobial compounds and microbial metabolites in OFMSW offers benefits in terms of controlling microbial contamination in non-sterile biological conversions.

The OFMSW requires mechanical, thermal, and biological pretreatment to secure the availability of nutrients for microbial conversion. Mechanical pretreatments are commonly used as the first step for size reduction of present particles, making biomass less resilient for following pretreatments [18]. Next, heat treatment should be considered as it enhances the solubility of organic compounds such as proteins and sugars [19], gelatinizes the starch in OFMSW [20], and breaks down the integrity of the biomass cell wall [21]. Moreover, heat treatment can reduce microbial contamination that could possibly interfere with subsequent fermentation processes [22].

Enzymatic hydrolysis (EH) stands out as the preferred biological pretreatment method for OFMSW due to its sustainable approach. However, the complexity, recalcitrance, and heterogeneous nature of OFMSW necessitate the use of industrial enzyme mixtures. These mixtures typically include cellulases, hemicellulases, amylases, proteases, and other enzymes to break down fibers into fermentable compounds efficiently [23]. Ebrahimian et al. [24] obtained 82% saccharification with 41 g glucose/L from OFMSW by applying Cellic® CTec2 (Novozymes A/S) with the loading of 20 FPU/g OFMSW dry matter and amylases (Novozymes A/S) with the loading of 0.1 g per g of starch in OFMSW. Another EH of OFMSW with Cellic® CTec2 (Novozymes A/S), Cellic® Htec2 (Novozymes A/S) with the loading of 20 FPU/g OFMSW dry matter and α-amylase Liquezyme (Novozymes A/S), and glucoamylase Dextrozyme GA (Novozymes A/S) with the loading of 2 g per kg of starch in OFMSW resulted into 70 g of glucose/L by Mahmoodi et al. [25]. Nwobi and colleagues [23] demonstrated successful saccharification of OFMSW with cellulase complex, amylase, hemicellulase, pectate lyase, lipase, and protease (Novozymes A/S), resulting in a final concentration of 140 g of glucose/L in the hydrolysate. López-Gómez et al. [26] presented enzymatic conversion of OFMSW with cellulases and amylases (Novozymes A/S), achieving a final glucose concentration of 70 g/L.

Biomass saccharification is usually followed by microbial cultivation. The selection of microorganisms for cell biomass production on OFMSW hydrolysate should be based on the following criteria: (1) generally recognized as safe (GRAS); (2) ability to tolerate/metabolize organic acids and other inhibitors; (3) tolerance to low pH; (4) ability to utilize a wide range of carbon sources present in the hydrolysate; (5) high specific growth rate; (6) minimal byproduct formation.

Yarrowia lipolytica, a well-studied robust GRAS yeast, has been demonstrated to effectively metabolize organic acids such as acetic, propionic, and butyric acids into biomass [27,28,29]. Gao et al. [30] achieved biomass production of 14.7 g/L by cultivating Y. lipolytica on pre-fermented OFMSW hydrolysate, showing volatile fatty acid (VFA) conversion into cell mass. They also demonstrated that Y. lipolytica can tolerate a low pH of up to 4. Furthermore, Yang and colleagues [31] presented the utilization of VFA and lactic acid derived from OFMSW by Y. lipolytica, reaching a biomass concentration of 9.2 g/L at a pH of 4.5. Similarly, Pereira et al. [32] and Johnravindar [33] demonstrated consumption of VFA from anaerobically pre-fermented OFMSW, resulting in an overall 10 g and 21 g of biomass/L of hydrolysate slurry.

Rhodosporidium toruloides is another robust GRAS oleaginous yeast that has been shown to utilize organic acids like acetic acid [34], lactic acid [35], propionic acid, and butyric acid [36], degrade toxins such as furfural and its derivates [37], grow at low pH [38], and deacidify OFMSW hydrolysate [39]. Moreover, Ma et al. [35] demonstrated the conversion of enzymatically saccharified OFMSW with R. toruloides, achieving 12.1 g of biomass/L at a pH of 4. In another study, Ma and colleagues [40] obtained over 22 g of biomass/L after cultivating R. toruloides on OFMSW hydrolysate at a pH of 4. Furthermore, their findings suggest that lactic acid in OFMSW promotes yeast proliferation. Additionally, Gao et al. [38] reported that the most optimal pH was 4 for R. toruloides cultivation on OFMSW enzymatic hydrolysate, achieving 15.6 g of biomass/L of hydrolysate.

Cutaneotrichosporon oleaginosus, also known as Trichosporon oleaginosus and Cryptococcus curvatus, is the next promising safe oleaginous yeast that presents to be suitable for cultivation on OFMSW hydrolysate. It has been demonstrated to grow on acetic acid, propionic acid, butyric acid [36], valeric acid, hexanoic acid [41], and other VFAs [42] and detoxify formic acid, furfural, and other common toxins in lignocellulosic hydrolysates [43]. Liu et al. [44] demonstrated C. oleaginosus biomass production on VFA derived from active sludge, reaching 4.5 g of biomass/L of media. Furthermore, Johnravindar [33] reported 14 g of C. oleaginosus cell mass/L cultivated on VFA from anaerobically pre-fermented OFMSW.

Saccharomyces cerevisiae is a well-known, vastly industrially applied yeast that is resilient to a wide variety of inhibitors and excellent for biomass production. It can consume acetic acid, lactic acid, butyric acid, propionic acid [45], malic acid [46], formic acid [47], and ethanol in aerobic cultivation [48]. Moreover, backer’s yeast has excellent pH tolerance and has been shown to thrive in a pH of 4–5 [49], which is the typical pH of OFMSW. Zeng and colleagues [45] demonstrated yeast biomass production from VFA derived from organic waste, achieving 1.5 g of biomass/L. Dornau et al. [5] reported the efficient conversion of enzymatically saccharified OFMSW into S. cerevisiae biomass, showing complete consumption of glucose in the first 12 h into the cultivation.

Another GRAS and commercially applied microorganism, Lipomyces starkeyi, was demonstrated to utilize acetic acid [50], phenolics [51], furfural, and hydroxymethylfurfural in hydrolysates [52] and to tolerate pH up to 2.6 [53]. However, the cultivation of L. starkeyi on OFMSW hydrolysates has not been observed and has yet to be reported. The last selected GRAS organism in the presented work, Mucor indicus, is a filamentous fungus with the ability to grow yeast-like. This fungus was demonstrated to metabolize lignocellulose hydrolysates into cell mass effectively [54] and to tolerate commonly present growth inhibitors [55]. However, published studies predominantly concentrate on bioethanol production from lignocellulose hydrolysates using M. indicus, and the number of studies investigating OFMSW hydrolysates is limited. Previously, Mahmoodi et al. [25] reported the successful application of M. indicus for ethanol production from OFMSW hydrolysate. Furthermore, Borujeni and colleagues [56] achieved 96 g of M. indicus biomass/kg of apple pomace after organosolv pretreatment. Other promising microorganisms worthy of consideration for biomass production from OFMSW hydrolysate, but not covered in this study, include Candida utilis [57], Kluyveromyces marxianus [58], Rhodococcus [59], R. glutinis [33, 42], R. mucilaginosa [60], and Schizosaccharomyces pombe [5].

The present study investigated the impact of enzymatic saccharification of OFMSW on the sugar and organic acid composition of hydrolysates. Robust seven strains were then screened for their ability to consume and detoxify the resulting OFMSW hydrolysates. Two types of OFMSW hydrolysates were used: full OFMSW hydrolysate containing unhydrolyzed solids and OFMSW hydrolysate slurry after removal of solids via centrifugation. After selecting the most suitable form of OFMSW hydrolysate for nutrient utilization, each strain’s cell mass production was examined. The microorganism demonstrating the highest consumption of sugars and organic acids, along with the greatest biomass concentration, underwent cultivation in a 5-L batch bioreactor to fully evaluate its growth and detoxification capabilities.

2 Materials and methods

2.1 Materials

The OFMSW was supplied on the 19th of October 2022 by Ragn-Sells Denmark A/S facility located in Holsted municipality (55°30′41″ N, 8°54′59″ E), Denmark. The OFMSW was stored at − 80 °C until use. The composing elements of the OFMSW applied in this study are tabulated in Table 1. The DM for the OFMSW batch was 14.4% (w/w), and the pH was 4.02. Based on the content of organic acids and ethanol, it can be assumed that OFMSW was pre-fermented during storage and handling, making it inhibitory for selected microorganisms. Furthermore, it is anticipated that other VFAs, including propionic, butyric, and oxalic acids, are also present, although they were not specifically measured in this study. However, the amount of sugar, lipids, and proteins is considerable, accounting for 76.5% of the total organic waste mass, making it a nutritious feedstock.

For enzymatic hydrolysis, Cellic® CTec3 (Novozymes A/S) as a source of cellulases and hemicellulases with specific enzymatic activity 214 FPU/mL and AMG® 300 L BrewQ (Novozymes A/S) as a source of glucoamylase with specific enzymatic activity 300 AGU/mL were used. In this work, Cellic® CTec3 and AMG® 300 L BrewQ are named Ctec3 and AMG, respectively. Sugars, organic acids, and ethanol were investigated through high-performance liquid chromatography (HPLC) (1260 Infinity II, Agilent Technologies). Cutaneotrichosporon oleaginosus ATCC 20509, Yarrowia lipolytica DSM 8218, Lipomyces starkeyi DSM 70296, Rhodosporidium toruloides DSM 70398, Rhodosporidium toruloides DSM 4444, Saccharomyces cerevisiae (commercial dry yeast, Malteserkors tørgær, De Danske Spritfabrikker A/S, Denmark), and Mucor indicus DSM 2185 were applied as fermentative microorganisms.

2.2 Enzymatic hydrolysis

Prior to enzymatic hydrolysis, approximately 2 kg of OFMSW were defrosted at room temperature overnight and gelatinized with autoclavation at 100 °C for 4 h [20]. The experimental procedure involved creating the solution by carefully measuring 70 g of gelatinized OFMSW in an analytical weight fashion within a 250 mL flask. Subsequently, Mili-Q water was added, followed by the addition of enzymes by direct pipetting as the final step. To achieve a final weight of 100 g, required quantities of OFMSW, enzymatic solution, and Mili-Q water were added to each 250-mL shaking flask. Each flask was then placed in an incubator and maintained at 50 °C and 150 RPM for a duration of 24 h. The hydrolysis temperature was selected based on the recommendations from the Novozymes A/S datasheet. The hydrolysis duration of 24 h was chosen based on prior experimental work, which showed no significant difference in sugar yield between 24 and 48 h of incubation. Incubated samples were removed, and each 100 g hydrolysate was divided into two 50-mL Falcon tubes, one of which was kept at − 20 °C. The samples were centrifuged (SL 16 Centrifuge, Thermo Fisher Scientific) at 4500 RPM for 15 min. Five milliliters of supernatant was carefully piped out into new 50-mL Falcon tubes and diluted with 20 mL of Mili-Q water. Each diluted hydrolysate was filtered with 0.22-μm syringe filters and transferred into HPLC vials for subsequent analysis of sugar, organic acids, and ethanol content. For storage, the HPLC vials were frozen at − 20 °C. A final concentration of 10% dry matter (DM) was maintained throughout the experiments, with necessary dilution using Mili-Q water. Equation 1 was used to calculate the addition of Mili-Q water:

where mwater is the mass of Mili-Q water that needs to be added to reach 100 g of total solution mass, mOFMSW is the mass of OFMSW in the reaction mixture, VCtec3 is the volume of added Ctec3 solution, VAMG is the volume of added AMG solution, ρCtec3 is the density of Ctec3 solution, 1.2 g/mL, and ρAMG is the density of AMG solution, 1.16 g/mL.

2.3 Microbial cultivation on hydrolysate

The sugar-rich hydrolysates, prepared with 15 FPU of Ctec3/g dried biomass and 7.5 AMG/g dried biomass, were directly used as fermentation media or underwent centrifugation (SL 16 Centrifuge, Thermo Fisher Scientific) at 4500 RPM for 15 min, and produced slurry was used as fermentation media.

For pre-culture, C. oleaginosus ATCC 20509, Y. lipolytica DSM 8218, L. starkeyi DSM 70296, R. toruloides DSM 70398, and R. toruloides DSM 4444 were transferred from pre-grown YPD (Yeast Extract–Peptone–Dextrose) agar plates into 30 mL YPD liquid media in 50-mL Falcon tubes using an inoculation loop. The tubes were then placed in a shaking incubator (LS-Z shaker with Kelvin + , Kuhner) and incubated for 24 h at 30 °C with 130 RPM agitation. Grown yeast cells were centrifuged at 3000 RPM for 10 min. After centrifugation, the supernatants were discarded, and the pellets containing yeast cells were resuspended in 30 mL of OFMSW hydrolysate. Subsequently, the resuspended yeast cells were directly transferred into 250-mL shaking flasks and supplemented with 70 mL of hydrolysate.

In the case of M. indicus DSM 2185, the strain was streaked onto a YPD agar plate from a glycerol stock using an inoculation loop and then incubated at 30 °C for 6 days. Mature M. indicus spores were rinsed with 40 mL of hydrolysate slurry and gathered in a sterile 50-mL Falcon tube. For inoculation, 10 mL of the spore solution per sample was directly pipetted into the 250-mL flask with 90 mL of hydrolysate. For inoculation of S. cerevisiae, 0.20 g of freeze-dried cells were directly added to each 250-mL shaking flask with 100 mL hydrolysate.

The samples with the final volume of 100 mL in a 250-mL flask were sealed using caps equipped with PTFE membranes. The incubation was performed under aerobic conditions at 30 °C with 130 RPM for 96 h in a shaking incubator (LS-Z shaker with Kelvin+, Kuhner). In the case of M. indicus and S. cerevisiae, the cultivation time was 48 h. After cultivation, each fermentation broth produced from hydrolysate slurry was centrifuged at 3000 RPM for 10 min. Supernatants were discarded, and pellets with cells were washed with 100 mL of Mili-Q water and centrifuged again. The washed cells were used to identify dry cell weight (DCW) by drying at 60 °C and weighing on analytical balance.

2.4 Bioreactor batch cultivation

For bioreactor cultivation, 2.5 L of hydrolysate slurry was prepared by hydrolyzing 3 kg of gelatinized OFMSW with 10% w/w DM equally dived into six 1-L shaking flasks and incubated at 50 °C and 150 RPM for a duration of 24 h. Solids were separated by centrifugation at 4500 RPM for 15 min, and the slurry was collected and transferred to a 5-L bioreactor (Biostream International B.V) with a final volume of hydrolysate media of 2.5 L. The bioreactor was operated with BioBench (Biostream International B.V). Prior to cultivation, the pH sensor (EasyFerm Bio HB Arc 225, Hamilton Bonaduz AG) and the O2-dissolved sensor (VisiFerm DO Arc 225, Hamilton Bonaduz AG) were calibrated and set. Subsequently, the prepared bioreactor was supplemented with 5 g of freeze-dried S. cerevisiae. The cultivation conditions were 30 °C, 100 RPM, and with the original pH of OFMSW. The three 50-mL samples were taken by 100-mL syringe into 50-mL Falcone tubes at 0, 2, 4, 8, 12, 22, 32, and 48 h into the cultivation. Followingly, the samples were centrifuged at 3000 RPM for 10 min. Supernatants were used for analysis of sugar, ethanol, and organic acids, while pellets were washed with 30 mL of Milli-Q water and centrifuged again. The washed cells were then used to determine DCW by drying them at 60 °C and weighing them on an analytical balance.

2.5 Dry matter determination, CHNS elemental analysis, protein content approximation, and lipid content determination

The dry matter (DM), also often referred to as total solid or dry weight, was analyzed in OFMSW and fermented samples based on the following analytical protocol by the National Renewable Energy Laboratory (NREL) [61].

A CHNS elemental analyzer (PerkinElmer 2400 series CHNS/O, USA) was used to analyze the carbon, hydrogen, nitrogen, and sulfur content of the OFMSW. The samples were analyzed as a dried sample, where a 2–10 mg sample was weighed on small tin capsules and analyzed on the elemental analyzer.

The protein content was approximated based on the nitrogen content in dried samples of OFMSW. A nitrogen-to-protein conversion factor (NPCF) of 6.25 was used, as all proteins are assumed to have a 16% (w/w) nitrogen content [62]. The number, taken from the literature, is not an exact figure but represents a well-accepted, widely used approximation. Equation 2, used for the nitrogen-to-protein conversion, is as follows:

where N is nitrogen content % (w/w) in the dried sample, NPCF is the mass ratio of nitrogen to protein, 6.25, and P is the protein content % (w/w) in the dried sample.

The lipids were extracted on SOXTHERM No. 13–0007 (C. Gerhardt Analytical Systems, Germany). For the extraction, 1 to 2 g of the dried and grounded sample was carefully placed in a previously dried extraction thimble, which was stored in a desiccator until use. The extraction beaker glasses (C. Gerhardt Analytical Systems, Germany) were also pre-weighed. Following this, 150 mL of n-hexane was added to each glass beaker, and the extraction process was conducted for approximately 2 h. After extraction, the glass beakers were left in a fume hood overnight to evaporate any residual hexane in lipid fraction. All weight measurements were performed using analytical weights. The calculations were based on the analytical protocol from NREL [63].

2.6 Sugars, organic acids, and ethanol analysis

For the total sugar determination, OFMSW was dried in an oven at 60 °C overnight and was powdered with a knife mill (GRINDOMIX GM 200, Retsch). The total sugar content in OFMSW was identified using the analytical protocol developed by NREL [64]. The characterization of the sugars, ethanol, and organic acids in hydrolyzed and fermented samples was based on the analytical protocol by NREL [65]. Prepared samples were filtered by 0.22-µm syringe filters into HPLC vials and underwent HPLC analysis (Bio-Rad Aminex HPX-87H Column, Bio-Rad Laboratories Inc.), using H2SO4 mobile phase (0.005 M) and RID (refractive index detector) for sugar (glucose, cellobiose, xylose, and arabinose), ethanol, and acetic acid. The organic acids (malic, formic, succinic, glycolic, and lactic acids) were analyzed, using H3PO4 mobile phase (0.2 v/v%) and DAD (diode array detection). The calculation of HPLC results (g/L) into (g/100 g OFMSW DM) was conducted as described in [23, 66]. A conversion factor 0.9 was used to estimate glucan content from glucose concentration, while a conversion factor 0.88 was applied to estimate xylan and arabinan from pentoses.

For starch analysis, dried OFMSW samples were powdered with a porcelain mortar and sieved with a 0.5-mm metal screen. The prepared samples were analyzed for starch content by Megazymes Total Starch HK Assay Kit (Megazyme Ltd.).

2.7 Statistical methods

All trials were performed at least as triplicates, and results are given as mean values with standard deviation. The one-way and two-way analysis of variance (ANOVA) was carried out on all results with one or more independent variables. Additionally, Tukey’s honest significant difference (HSD) tests were performed as an extension of ANOVA, if necessary. R version 4.3.1 [67] and RStudio version 2023.06.2 Build 561 (Posit Software, PBC) were used for all statistical analyses.

3 Results

3.1 Enzymatic hydrolysis

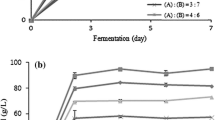

The results illustrated in Fig. 1A demonstrate that with increasing Ctec3 and AMG dosage, the amount of hydrolyzed glucan increases up to 20 FPU Ctec3 and 10 U AMG per g of OFMSW DM, achieving 92% saccharification with 42 g of glucose/L of hydrolysate. However, upon further dosage increase, a plateau in glucan saccharification can be observed. Similarly, for xylan, higher enzymatic dosages result in increased levels of free xylose, except for the dosage of 20 FPU Ctec3 and 10 U AMG per g of OFMSW DM, which exhibited lower xylan saccharification compared to 15 FPU Ctec3 and 7.5 U AMG per gram of OFMSW DM. The ANOVA test confirmed that enzymatic dosage is statistically significant for glucan and xylan conversion with an F-value of 301 and a P-value of 1.46 × 10−8 for glucan hydrolysis and an F-value of 537 and a P-value of 1.47 × 10−9 for xylan hydrolysis. Moreover, Tukey’s HSD test confirmed that there is no significant difference in glucan conversion between the two highest enzymatic dosages.

In addition, produced hydrolysates were investigated on organic acids as they are primary microbial metabolites and compared to untreated OFMSW. The results depicted in Fig. 1B show that overall, with increasing saccharification of OFMSW, the total amount of organic acids rises, reaching up to 42 g of organic acids/L of hydrolysate, which is considerably higher than untreated OFMSW with 26 g of organic acids/L of hydrolysate. The rising pattern is mainly observed for lactic acid, succinic acid, and formic acid. For instance, the content of acetic and glycolic acids fluctuates between the rising enzymatic dosage. The ANOVA test revealed that enzymatic dosage has a significant impact on total acid content, with an F-value of 9.14 and a P-value of 0.0081. However, Tukey’s HSD test showed that there is no statistically significant difference in organic acids between the two highest enzymatic dosages, as well as between the two lowest enzymatic dosages.

3.2 Microbial screening via shake flask cultures

The chosen strains were cultured using both full OFMSW hydrolysate and hydrolysate slurry, the latter obtained after separating unhydrolyzed solids by centrifugation. These hydrolysates were generated with an enzymatic dosage of 15 FPU Ctec3 and 7.5 U AMG per gram of OFMSW dry matter. This specific enzymatic dosage was selected due to its lower organic acid content compared to higher dosages while still achieving sufficient saccharification of the OFMSW.

Based on the results illustrated in Fig. 2A, there are minimal differences in sugar and organic acid contents between OFMSW hydrolysate and cultivated samples among all strains except for S. cerevisiae. It can be observed that S. cerevisiae managed to metabolize all glucose and detoxify the hydrolysate by reducing the amount of organic acids in OFMSW hydrolysate. However, ethanol production was observed for S. cerevisiae despite aerobic cultivation conditions, suggesting that unhydrolyzed solids and/or other factors may cause gas transfer limitations.

The results for hydrolysate slurry, Fig. 2B, show more promising results. All strains seem to reduce the content of organic acids and ethanol compared to the original hydrolysate, except for M. indicus. From all strains, S. cerevisiae, Y. lipolytica, and C. oleaginosus demonstrated the most significant metabolic activity. Mainly, S. cerevisiae and Y. lipolytica fully metabolized acetic and formic acid, while S. cerevisiae and C. oleaginosus substantially utilized lactic acid from the hydrolysate. However, only S. cerevisiae effectively consumed glucose based on sugar concentrations. The absence of xylose in S. cerevisiae fermented broths suggests the presence of other organisms that consumed xylose.

The ANOVA supplemented with Tukey’s HSD test confirmed that only hydrolysate slurries cultivated with S. cerevisiae, Y. lipolytica, and C. oleaginosus have a statistically significant reduction in total organic acids compared to original OFMSW hydrolysate. Moreover, Tukey’s HSD test confirmed that only S. cerevisiae was able to consume glucose, as samples fermented with other stains had no difference in glucose content compared to the original hydrolysate. Furthermore, statistical tests aligned with the observation that significant reductions in lactic acid were observed only in samples cultivated with S. cerevisiae and C. oleaginosus, while S. cerevisiae and Y. lipolytica exhibited significant reductions in acetic and formic acids compared to other samples. In the case of ethanol concentration, there was no statistically significant difference between all fermented samples. Based on the results, it can be concluded that S. cerevisiae, Y. lipolytica, and C. oleaginosus showed the ability to detoxify OFMSW hydrolysate.

3.3 Cell biomass production on OFMSW hydrolysate slurry

Biomass production by selected strains was investigated on OFMSW hydrolysate slurry, as shown in Fig. 3. The results show that all strains produced cell biomass. However, only S. cerevisiae and Y. lipolytica showed substantial biomass formation, achieving DCW of 18.9 g/L with 50.4% (w/w) proximate protein content and 11.9 g/L with 43.8% (w/w) proximate protein content, respectively. These results aligned with those in Fig. 2B, suggesting that metabolized organic acids were used as carbon sources for cell formation. Moreover, upon comparing the outcomes depicted in Figs. 2B and 3, it becomes apparent that L. starkeyi, M. indicus, and two strains of R. toruloides did not grow on the analyzed compounds. However, biomass production was observed, indicating the potential consumption of alternative nutrients present in the OFMSW hydrolysate medium.

The most prominent strain, S. cerevisiae, was cultivated on YPD media to compare cell production with DCW obtained after cultivation on OFMSW hydrolysate slurry as growth media. The results showed that cultivation on YPD yielded a DCW of 11.4 g/L, which was considerably lower than achieved on hydrolysate slurry with 18.9 g of cell biomass/L. This brings new perspectives on OFMSW utilization into single-cell yeast protein.

3.4 S. cerevisiae batch cultivation in 5-L bioreactor

The cultivation was scaled up to a 5-L bioreactor to evaluate the ability of S. cerevisiae to detoxify and thrive in OFMSW hydrolyze slurry. Based on the results depicted in Fig. 4A, it can be observed that all glucose was consumed within the first 8 h of cultivation. However, glucose consumption peaked with ethanol production, resulting in an increase of 10 g of ethanol/L, which corresponds to consumption of 19.6 g of glucose/L. Interestingly, despite the media being saturated with oxygen throughout the cultivation period, anaerobic respiration occurred. Ethanol production correlated with a decrease in pO2 levels between 4 and 6 h into the cultivation, as depicted in Fig. S1, Supplementary Material. This observation suggests that saturated oxygen levels were swiftly depleted due to the heightened metabolic activity of the yeast, leading to oxygen limitation at the beginning of cultivation.

Moreover, ethanol was metabolized entirely after 48 h of cultivation, possibly due to continuous media detoxification by yeast in the presence of oxygen. The biomass was formed over the whole cultivation period, with the highest increase in the initial 12 h into the cultivation, yielding 13.2 g of DCW/L of hydrolysate slurry. The proximate protein content followed the same pattern as DCW, with a final protein concentration of 6.03 g/L of hydrolysate. Overall, the crude protein content fluctuated in biomass from 42.1 to 49.5% (w/w). This range of crude protein content is typically found in S. cerevisiae [68]. Furthermore, the consumption of xylose suggests the presence of other microorganisms, as the applied S. cerevisiae strain can only utilize C6 sugars.

The findings presented in Fig. 4B indicate that the detoxification/deacidification rate was most active in the first 8 h of cultivation, resulting in a drop of measured organic acids from 16.4 to 11.4 g/L. Furthermore, a steady utilization of organic acids was observed throughout the entire cultivation period, except for formic acid, which exhibited minor changes in concentration up to 22 h of cultivation. The pH monitoring displayed a continuous trend of deacidification, with the pH value rising from 4.02 to 4.35 during cultivation. Moreover, the absence of glucose after 8 h of cultivation, coupled with continuous yeast biomass formation, suggests that yeast likely utilized organic acids as a carbon source.

4 Discussion

The analysis of OFMSW composition revealed high levels of sugars, proteins, and lipids, making it a nutrient-rich feedstock ideal for microbial biomass production. However, significant amounts of organic acids, particularly lactic acid, along with ethanol content, were also detected, posing inhibitory challenges for selected microbial cultivations using OFMSW-based media. The organic acids are a natural product of OFMSW anaerobic degradation by microbial hydrolysis and acidogenesis, primarily attributed to Enterococcus, Lactobacillus, Bifidobacterium, and Clostridium [69]. Overall, the quantity and quality of VLAs are determined by OFMSW composition [70], storage temperature [71], moisture content, and the presence of oxygen and microbial inhibitors (heavy metals, polyphenols, ammonia, etc.) [72]. In complex media such as OFMSW, the content of VFA will likely change seasonally and geographically.

Enzymatic saccharification demonstrated the effective conversion of OFMSW glucan and xylan into free sugars. However, it was observed that higher enzymatic dosages led to increased content of organic acids, notably lactic, formic, and succinic acids, potentially intensifying the inhibitory effects of OFMSW hydrolysates. Likewise, Mlaik et al. [73] reported that soluble chemical oxygen demand (SCOD), which is strongly correlated with VFA [74], increased with the rising enzymatic loading during OFMSW saccharification. Therefore, it was decided to proceed with experiments using an enzymatic dosage of 15 FPU Ctec3 and 7.5 U AMG/g of OFMSW DM that achieves significant saccharification while minimizing organic acid formation. During experimental trials, varying saccharification of OFMSW occurred with the same enzymatic loading, fluctuating from 29.2 to 36.4 g of free sugars/L hydrolysate. This variation can be attributed to the continuous microbial activity as long as OFMSW is not frozen. Furthermore, this conclusion is supported by fluctuation in total organic acid content, ranging from 17.4 to 18.6 g/L of hydrolysate, and ethanol, ranging from 8.2 to 9.2 g/L hydrolysate.

OFMSW hydrolysate with unhydrolyzed solids and hydrolysate after removing solids were cultivated with selected microbial strains. The investigation showed that only S. cerevisiae can utilize sugars and organic acids in full OFMSW hydrolysate. The production of ethanol was observed, indicating that high solid content may negatively hinder oxygen transfer during cultivation [75]. Moreover, Dornau et al. [5] suggested that unhydrolyzed solids in OFMSW hydrolysate are rich in metals, which may cause additional microbial inhibition. The separation of solids from the hydrolysate resulted in other strains to consume organic acids and ethanol, particularly Y. lipolytica and C. oleaginosus. Moreover, the removal of solids improved the performance of S. cerevisiae when compared to the full hydrolysate. However, the remaining strains did not utilize the measured compounds.

The investigation of cell mass production from hydrolysate slurry demonstrated that Y. lipolytica and S. cerevisiae thrived in hydrolysates, achieving biomass concentrations of 11.9 g/L and 18.9 g/L of hydrolysate slurry, respectively. Interestingly, other strains produced biomass, yet the exact carbon source is unknown. However, due to the complexity and heterogeneity of OFMSW, it is very likely that other sugars such as fructose, galactose, mannose, and other energy-rich compounds were present in the culture media that the microorganisms may have utilized. Moreover, oleaginous strains, L. starkeyi, M. indicus, and R. toruloides, are well designed to metabolize lipids, which correspond to approximately 18 g of lipids/L in the used hydrolysate.

S. cerevisiae was selected as the superior strain among those tested, primarily because of its highest biomass formation and crude protein content coupled with effective detoxification of OFMSW. Moreover, the growth period for S. cerevisiae was only 2 days, significantly shorter than that of the other tested yeasts, which required 4 days for cultivation. Additionally, when S. cerevisiae was cultivated on YPD media, it achieved only 60% of the biomass concentration compared to that obtained with OFMSW hydrolysate slurry, highlighting its potential as a sustainable alternative for microbial protein production compared to conventional media. Scaled-up cultivation in the 5-L bioreactor showed that S. cerevisiae utilizes sugars and organic acids for cell mass formation. However, ethanol fermentation was observed within the first 8 h of cultivation, likely due to oxygen limitation at the beginning of cultivation. Moreover, ethanol production could possibly be due to the Crabtree effect [76], which occurs when glucose levels are high, resulting in yeast cells favoring ethanol fermentation over aerobic respiration to rapidly metabolize glucose, even in the presence of oxygen. Additionally, this metabolic shift is often observed when yeast cells experience (oxidative) stress or encounter inhibitory environmental conditions. Similar results were reported by Dornau et al. [5], presenting ethanol production during the initial 12 h of aerobic cultivation on OFMSW hydrolysate slurry. Nonetheless, the produced ethanol was eventually consumed by the yeast, possibly due to continuous media detoxification by yeast, allowing it to process ethanol in the presence of oxygen [48]. This resulted in the highest DCW of 13.2 g/L with 46% (w/w) of protein content. To provide context for the achieved results, the biomass concentrations obtained on OFMSW hydrolysate were compared to previously reported concentrations in Table 2.

By comparing the present work with the literature, S. cerevisiae achieved one of the highest reported biomass productivities on OFMSW hydrolysates, only surpassed by R. toruloides [78]. The performance of Y. lipolytica in this study aligns well with other reported biomass concentrations. Conversely, the strains of R. toruloides investigated in this work displayed considerably lower biomass formation from OFMSW hydrolysate compared to other studies, where they achieved the overall highest biomass concentrations and productivity among various microorganisms.

5 Conclusion

In summary, excellent enzymatic conversion of OFMSW sugar polymers using Cellic® CTec3 and AMG® 300 L BrewQ was achieved. However, higher enzymatic dosages led to increased production of VFAs, potentially causing more severe inhibition of microorganisms. To mitigate this, hydrolysates were prepared with dosages that ensured sufficient saccharification while minimizing organic acid formation. Among the seven tested microbial strains, S. cerevisiae, Y. lipolytica, and C. oleaginosus demonstrated the consumption of measured organic acids from OFMSW hydrolysate slurry. Additionally, only S. cerevisiae was capable of utilizing sugars and organic acids in full OFMSW hydrolysate without the separation of solids. An investigation of biomass production revealed that all strains were able to produce biomass on hydrolysate slurry, the most prominent being S. cerevisiae and Y. lipolytica. Furthermore, due to the significant yeast biomass formation by S. cerevisiae, cultivation was scaled up to a 5-L bioreactor, confirming the conversion of glucose, organic acids, and ethanol into cell mass. Achieved biomass productivity with S. cerevisiae on OFMSW hydrolysate was one of the highest reported yeast biomass productivities, making it an interesting option for single-cell protein production. This claim is further supported by the 1.7-fold higher biomass formation obtained after cultivation on hydrolysate slurry compared to YPD media. Future research should prioritize the optimization of operational parameters such as pH, agitation rate, and aeration rate in bioreactors to enhance yeast cell production. Moreover, other microorganisms should be screened for their ability to grow in OFMSW hydrolysate. The presented study on the valorization of abundantly generated OFMSW into microbial biomass using S. cerevisiae holds significant promise for alternative fodder production in the form of single-cell protein, thereby advancing biowaste recycling practices and promoting sustainable and circular food production.

Data availability

Data will be available on request to the corresponding author.

References

Campuzano R, González-Martínez S (2016) Characteristics of the organic fraction of municipal solid waste and methane production: a review. Waste Manage 54:3–12. https://doi.org/10.1016/J.WASMAN.2016.05.016

Ebrahimian F, Denayer JFM, Mohammadi A et al (2023) A critical review on pretreatment and detoxification techniques required for biofuel production from the organic fraction of municipal solid waste. Bioresour Technol 368:128316. https://doi.org/10.1016/J.BIORTECH.2022.128316

Sharma P, Melkania U (2017) Impact of furan derivatives and phenolic compounds on hydrogen production from organic fraction of municipal solid waste using co-culture of Enterobacter aerogenes and E. coli. Bioresour Technol 239:49–56. https://doi.org/10.1016/J.BIORTECH.2017.04.113

Stamogiannou I, Van Camp J, Smagghe G et al (2021) Impact of phenolic compound as activators or inhibitors on the enzymatic hydrolysis of cellulose. Int J Biol Macromol 186:174–180. https://doi.org/10.1016/J.IJBIOMAC.2021.07.052

Dornau A, Robson JF, Thomas GH, McQueen-Mason SJ (2020) Robust microorganisms for biofuel and chemical production from municipal solid waste. Microb Cell Fact 19:1–18. https://doi.org/10.1186/S12934-020-01325-0/TABLES/4

Jojoa-Unigarro GD, González-Martínez S (2022) Kinetic analysis of the methanization of the byproducts from OFMSW fermentation. J Chem Technol Biotechnol 97:1555–1566. https://doi.org/10.1002/JCTB.6921

Agrawal R, Verma A, Singhania RR et al (2021) Current understanding of the inhibition factors and their mechanism of action for the lignocellulosic biomass hydrolysis. Bioresour Technol 332:125042. https://doi.org/10.1016/J.BIORTECH.2021.125042

MaulanaHidayatullah I, Setiadi T, Tri Ari PeniaKresnowati M, Boopathy R (2020) Xylanase inhibition by the derivatives of lignocellulosic material. Bioresour Technol 300:122740. https://doi.org/10.1016/J.BIORTECH.2020.122740

Goldstein DB (1986) Effect of alcohol on cellular membranes. Ann Emerg Med 15:1013–1018. https://doi.org/10.1016/S0196-0644(86)80120-2

Santiesteban-López NA, Gómez-Salazar JA, Santos EM et al (2022) Natural antimicrobials: a clean label strategy to improve the shelf life and safety of reformulated meat products. Foods 11:2613. https://doi.org/10.3390/FOODS11172613

Crowley S, Mahony J, Van Sinderen D (2013) Current perspectives on antifungal lactic acid bacteria as natural bio-preservatives. Trends Food Sci Technol 33:93–109. https://doi.org/10.1016/J.TIFS.2013.07.004

Narendranath NV, Thomas KC, Ingledew WM (2001) Effects of acetic acid and lactic acid on the growth of Saccharomyces cerevisiae in a minimal medium. J Ind Microbiol Biotechnol 26:171–177. https://doi.org/10.1038/SJ.JIM.7000090

Kumar V, Yadav SK, Kumar J, Ahluwalia V (2020) A critical review on current strategies and trends employed for removal of inhibitors and toxic materials generated during biomass pretreatment. Bioresour Technol 299:122633. https://doi.org/10.1016/J.BIORTECH.2019.122633

Zhai R, Hu J, Jin M (2022) Towards efficient enzymatic saccharification of pretreated lignocellulose: enzyme inhibition by lignin-derived phenolics and recent trends in mitigation strategies. Biotechnol Adv 61:108044. https://doi.org/10.1016/J.BIOTECHADV.2022.108044

Oviedo-Ocaña ER, Soto-Paz J, Domínguez I et al (2022) A systematic review on the application of bacterial inoculants and microbial consortia during green waste composting. Waste Biomass Valor 13(8):3423–3444. https://doi.org/10.1007/S12649-022-01687-Z

Maqsood Q, Sumrin A, Waseem R et al (2023) Bioengineered microbial strains for detoxification of toxic environmental pollutants. Environ Res 227:115665. https://doi.org/10.1016/J.ENVRES.2023.115665

Raj T, Chandrasekhar K, Morya R et al (2022) Critical challenges and technological breakthroughs in food waste hydrolysis and detoxification for fuels and chemicals production. Bioresour Technol 360:127512. https://doi.org/10.1016/J.BIORTECH.2022.127512

Kumari D, Singh R (2018) Pretreatment of lignocellulosic wastes for biofuel production: a critical review. Renew Sustain Energy Rev 90:877–891. https://doi.org/10.1016/J.RSER.2018.03.111

Prorot A, Julien L, Christophe D, Patrick L (2011) Sludge disintegration during heat treatment at low temperature: a better understanding of involved mechanisms with a multiparametric approach. Biochem Eng J 54:178–184. https://doi.org/10.1016/J.BEJ.2011.02.016

Rudnyckyj S, Chaturvedi T, Thomsen MH (2023) Low-dosage enzymatic hydrolysis of organic municipal waste for sugar and ethanol production. Biomass Convers Biorefin 1:1–17. https://doi.org/10.1007/S13399-023-04858-7/TABLES/8

Petersen MØ, Larsen J, Thomsen MH (2009) Optimization of hydrothermal pretreatment of wheat straw for production of bioethanol at low water consumption without addition of chemicals. Biomass Bioenergy 33:834–840. https://doi.org/10.1016/J.BIOMBIOE.2009.01.004

Chen T, Jin Y, Liu F et al (2012) Effect of hydrothermal treatment on the levels of selected indigenous microbes in food waste. J Environ Manage 106:17–21. https://doi.org/10.1016/J.JENVMAN.2012.03.045

Nwobi A, Cybulska I, Tesfai W et al (2015) Simultaneous saccharification and fermentation of solid household waste following mild pretreatment using a mix of hydrolytic enzymes in combination with Saccharomyces cerevisiae. Appl Microbiol Biotechnol 99:929–938. https://doi.org/10.1007/S00253-014-5977-Z/FIGURES/8

Ebrahimian F, Karimi K, Kumar R (2020) Sustainable biofuels and bioplastic production from the organic fraction of municipal solid waste. Waste Manage 116:40–48. https://doi.org/10.1016/J.WASMAN.2020.07.049

Mahmoodi P, Karimi K, Taherzadeh MJ (2018) Hydrothermal processing as pretreatment for efficient production of ethanol and biogas from municipal solid waste. Bioresour Technol 261:166–175. https://doi.org/10.1016/J.BIORTECH.2018.03.115

López-Gómez JP, Latorre-Sánchez M, Unger P et al (2019) Assessing the organic fraction of municipal solid wastes for the production of lactic acid. Biochem Eng J 150:107251. https://doi.org/10.1016/J.BEJ.2019.107251

Fontanille P, Kumar V, Christophe G et al (2012) Bioconversion of volatile fatty acids into lipids by the oleaginous yeast Yarrowialipolytica. Bioresour Technol 114:443–449. https://doi.org/10.1016/J.BIORTECH.2012.02.091

Kolouchová I, Kolouchová K, Schreiberová O et al (2015) Biotransformation of volatile fatty acids by oleaginous and non-oleaginous yeast species. FEMS Yeast Res 15:76. https://doi.org/10.1093/FEMSYR/FOV076

Coleman SM, Cordova LT, Lad BC et al (2023) Evolving tolerance of Yarrowialipolytica to hydrothermal liquefaction aqueous phase waste. Appl Microbiol Biotechnol 107:2011–2025. https://doi.org/10.1007/S00253-023-12393-8/TABLES/2

Gao R, Li Z, Zhou X et al (2020) Enhanced lipid production by Yarrowialipolytica cultured with synthetic and waste-derived high-content volatile fatty acids under alkaline conditions. Biotechnol Biofuels 13:1–16. https://doi.org/10.1186/S13068-019-1645-Y/TABLES/5

Yang R, Chen Z, Hu P et al (2022) Two-stage fermentation enhanced single-cell protein production by Yarrowialipolytica from food waste. Bioresour Technol 361:127677. https://doi.org/10.1016/J.BIORTECH.2022.127677

Pereira AS, Lopes M, Duarte MS et al (2023) Integrated bioprocess of microbial lipids production in Yarrowialipolytica using food-waste derived volatile fatty acids. Renew Energy 202:1470–1478. https://doi.org/10.1016/J.RENENE.2022.12.012

Johnravindar D, Karthikeyan OP, Selvam A et al (2018) Lipid accumulation potential of oleaginous yeasts: a comparative evaluation using food waste leachate as a substrate. Bioresour Technol 248:221–228. https://doi.org/10.1016/J.BIORTECH.2017.06.151

Lopes HJS, Bonturi N, Miranda EA (2021) Induction of resistance mechanisms in Rhodotorulatoruloides for growth in sugarcane hydrolysate with high inhibitor content. Appl Microbiol Biotechnol 105:9261–9272. https://doi.org/10.1007/S00253-021-11687-Z/TABLES/5

Ma X, Gao Z, Gao M et al (2018) Microbial lipid production from food waste saccharified liquid and the effects of compositions. Energy Convers Manag 172:306–315. https://doi.org/10.1016/J.ENCONMAN.2018.07.005

Krikigianni E, Matsakas L, Rova U et al (2022) Investigating the bioconversion potential of volatile fatty acids: use of oleaginous yeasts Rhodosporidiumtoruloides and Cryptococcus curvatus towards the sustainable production of biodiesel and odd-chain fatty acids. Appl Sci 12:6541. https://doi.org/10.3390/APP12136541

Osorio-González CS, Saini R, Hegde K et al (2022) Furfural degradation and its effect on Rhodosporidium toruloides-1588 during microbial growth and lipid accumulation. Bioresour Technol 359:127496. https://doi.org/10.1016/J.BIORTECH.2022.127496

Gao Z, Ma Y, Ma X et al (2019) A novel variable pH control strategy for enhancing lipid production from food waste: biodiesel versus docosahexaenoic acid. Energy Convers Manag 189:60–66. https://doi.org/10.1016/J.ENCONMAN.2019.03.078

Chen N, Xie Y, Liang Z, Shim H (2023) Biodiesel production and properties estimation from food waste and domestic wastewater by Rhodosporidium toruloides. J Environ Manage 348:119368. https://doi.org/10.1016/J.JENVMAN.2023.119368

Ma X, Gao Z, Gao M et al (2019) Microbial lipid production from food waste saccharified liquid under two-stage process. Bioresour Technol 289:121626. https://doi.org/10.1016/J.BIORTECH.2019.121626

Tomás-Pejó E, Morales-Palomo S, González-Fernández C (2023) Cutaneotrichosporon curvatum and Yarrowia lipolytica as key players for green chemistry: efficient oil producers from food waste via the carboxylate platform. Bioengineered 14:2286723. https://doi.org/10.1080/21655979.2023.2286723

Llamas M, Dourou M, González-Fernández C et al (2020) Screening of oleaginous yeasts for lipid production using volatile fatty acids as substrate. Biomass Bioenergy 138:105553. https://doi.org/10.1016/J.BIOMBIOE.2020.105553

Broos W, Wittner N, Dries J et al (2024) Rhodotorulakratochvilovae outperforms Cutaneotrichosporonoleaginosum in the valorisation of lignocellulosic wastewater to microbial oil. Process Biochem 137:229–238. https://doi.org/10.1016/J.PROCBIO.2024.01.009

Liu J, Liu JN, Yuan M et al (2016) Bioconversion of volatile fatty acids derived from waste activated sludge into lipids by Cryptococcus curvatus. Bioresour Technol 211:548–555. https://doi.org/10.1016/J.BIORTECH.2016.03.146

Zeng D, Jiang Y, Su Y, Zhang Y (2022) Upcycling waste organic acids and nitrogen into single cell protein via brewer’s yeast. J Clean Prod 369:133279. https://doi.org/10.1016/J.JCLEPRO.2022.133279

Delcourt F, Taillandier P, Vidal F, Strehaiano P (1995) Influence of pH, malic acid and glucose concentrations on malic acid consumption by Saccharomyces cerevisiae. Appl Microbiol Biotechnol 43:321–324. https://doi.org/10.1007/BF00172832

Wang K, Liu Y, Wu Z et al (2023) Investigating formate tolerance mechanisms in Saccharomyces cerevisiae and its application. Green Carbon 1:65–74. https://doi.org/10.1016/J.GREENCA.2023.08.003

Pham THB, Larsson G, Enfors S (2000) Growth and energy metabolism in aerobic fed-batch cultures of Saccharomyces cerevisiae: simulation and model verification. Biotechnol Bioeng 60:474–482. https://doi.org/10.1002/(SICI)1097-0290(19981120)60:4%3C474::AID-BIT9%3E3.0.CO;2-J

Silva JB, Sauvageau D (2014) Bacteriophages as antimicrobial agents against bacterial contaminants in yeast fermentation processes. Biotechnol Biofuels 7:1–11. https://doi.org/10.1186/S13068-014-0123-9/FIGURES/9

Monteiro de Oliveira P, Aborneva D, Bonturi N, Lahtvee PJ (2021) Screening and growth characterization of non-conventional yeasts in a hemicellulosic hydrolysate. Front Bioeng Biotechnol 9:659472. https://doi.org/10.3389/FBIOE.2021.659472/BIBTEX

Xenopoulos E, Giannikakis I, Chatzifragkou A et al (2020) Lipid production by yeasts growing on commercial xylose in submerged cultures with process water being partially replaced by olive mill wastewaters. Processes 8:819. https://doi.org/10.3390/PR8070819

Xavier MCA, Coradini ALV, Deckmann AC, Franco TT (2017) Lipid production from hemicellulose hydrolysate and acetic acid by Lipomycesstarkeyi and the ability of yeast to metabolize inhibitors. Biochem Eng J 118:11–19. https://doi.org/10.1016/J.BEJ.2016.11.007

Calvey CH, Su YK, Willis LB et al (2016) Nitrogen limitation, oxygen limitation, and lipid accumulation in Lipomycesstarkeyi. Bioresour Technol 200:780–788. https://doi.org/10.1016/J.BIORTECH.2015.10.104

Karimi K, Zamani A (2013) Mucor indicus: biology and industrial application perspectives: a review. Biotechnol Adv 31:466–481. https://doi.org/10.1016/J.BIOTECHADV.2013.01.009

Karimi K, Emtiazi G, Taherzadeh MJ (2006) Production of ethanol and mycelial biomass from rice straw hemicellulose hydrolyzate by Mucorindicus. Process Biochem 41:653–658. https://doi.org/10.1016/J.PROCBIO.2005.08.014

Borujeni NE, Karimi K, Denayer JFM, Kumar R (2022) Apple pomace biorefinery for ethanol, mycoprotein, and value-added biochemicals production by Mucorindicus. Energy 240:122469. https://doi.org/10.1016/J.ENERGY.2021.122469

Kurcz A, Błażejak S, Kot AM et al (2018) Application of industrial wastes for the production of microbial single-cell protein by fodder yeast Candida utilis. Waste Biomass Valor 9:57–64. https://doi.org/10.1007/S12649-016-9782-Z/TABLES/2

Aggelopoulos T, Katsieris K, Bekatorou A et al (2014) Solid state fermentation of food waste mixtures for single cell protein, aroma volatiles and fat production. Food Chem 145:710–716. https://doi.org/10.1016/J.FOODCHEM.2013.07.105

Bhatia SK, Gurav R, Choi TR et al (2019) Effect of synthetic and food waste-derived volatile fatty acids on lipid accumulation in Rhodococcus sp. YHY01 and the properties of produced biodiesel. Energy Convers Manag 192:385–395. https://doi.org/10.1016/J.ENCONMAN.2019.03.081

Prabhu AA, Gadela R, Bharali B et al (2019) Development of high biomass and lipid yielding medium for newly isolated Rhodotorulamucilaginosa. Fuel 239:874–885. https://doi.org/10.1016/J.FUEL.2018.11.088

Sluiter A, Hames B, Hyman D et al (2008) Determination of total solids in biomass and total dissolved solids in liquid process samples. NREL laboratory analytical procedure. http://www.nrel.gov/bioenergy/biomass-compositional-analysis.html

Jones DB, Munsey VE, Walker LE (1942) Report of committee on protein factor. J AOAC Int 25:118–120. https://doi.org/10.1093/JAOAC/25.1.118

Van Wychen S, Ramirez K, Laurens LML (2013) Determination of total lipids as fatty acid methyl esters (FAME) by in situ transesterification. NREL laboratory analytical procedure. https://doi.org/10.2172/1118085

Sluiter A, Hames B, Ruiz R et al (2008) Determination of structural carbohydrates and lignin in biomass. NREL laboratory analytical procedure. http://www.nrel.gov/bioenergy/biomass-compositional-analysis.html

Sluiter A, Hames B, Ruiz R et al (2006) Determination of sugars, byproducts, and degradation products in liquid fraction process samples. NREL laboratory analytical procedure. http://www.nrel.gov/bioenergy/biomass-compositional-analysis.html

Alassali A, Cybulska I, Galvan AR, Thomsen MH (2017) Wet fractionation of the succulent halophyte Salicornia sinus-persica, with the aim of low input (water saving) biorefining into bioethanol. Appl Microbiol Biotechnol 101:1769–1779. https://doi.org/10.1007/S00253-016-8049-8/METRICS

R Core Team (2020) R: a language and environment for statistical computing. R foundation for statistical computing. https://www.r-project.org/

Jach ME, Serefko A, Ziaja M, Kieliszek M (2022) Yeast protein as an easily accessible food source. Metabolites 12:63. https://doi.org/10.3390/METABO12010063

Nzeteu C, Joyce A, Thorn C et al (2021) Resource recovery from the anaerobic digestion of food waste is underpinned by cross-kingdom microbial activities. Bioresour Technol Rep 16:100847. https://doi.org/10.1016/J.BITEB.2021.100847

Vázquez-Fernández A, Suárez-Ojeda ME, Carrera J (2022) Review about bioproduction of volatile fatty acids from wastes and wastewaters: influence of operating conditions and organic composition of the substrate. J Environ Chem Eng 10:107917. https://doi.org/10.1016/J.JECE.2022.107917

Soomro AF, Abbasi IA, Ni Z et al (2020) Influence of temperature on enhancement of volatile fatty acids fermentation from organic fraction of municipal solid waste: synergism between food and paper components. Bioresour Technol 304:122980. https://doi.org/10.1016/J.BIORTECH.2020.122980

Eryildiz B, Lukitawesa TMJ (2020) Effect of pH, substrate loading, oxygen, and methanogens inhibitors on volatile fatty acid (VFA) production from citrus waste by anaerobic digestion. Bioresour Technol 302:122800. https://doi.org/10.1016/J.BIORTECH.2020.122800

Mlaik N, Khoufi S, Hamza M et al (2019) Enzymatic pre-hydrolysis of organic fraction of municipal solid waste to enhance anaerobic digestion. Biomass Bioenergy 127:105286. https://doi.org/10.1016/J.BIOMBIOE.2019.105286

Williams AG (1983) Organic acids, biochemical oxygen demand and chemical oxygen demand in the soluble fraction of piggery slurry. J Sci Food Agric 34:212–220. https://doi.org/10.1002/JSFA.2740340303

Hou W, Li L, Bao J (2017) Oxygen transfer in high solids loading and highly viscous lignocellulose hydrolysates. ACS Sustain Chem Eng 5:11395–11402. https://doi.org/10.1021/ACSSUSCHEMENG.7B02503/ASSET/IMAGES/LARGE/SC-2017-02503N_0007.JPEG

De Deken RH (1966) The Crabtree effect: a regulatory system in yeast. J Gen Microbiol 44:149–156. https://doi.org/10.1099/00221287-44-2-149

Xu Y, Wang X, Li Z et al (2022) Potential of food waste hydrolysate as an alternative carbon source for microbial oil synthesis. Bioresour Technol 344:126312. https://doi.org/10.1016/j.biortech.2021.126312

Zeng Y, Bian D, Xie Y et al (2017) Utilization of food waste hydrolysate for microbial lipid and protein production by Rhodosporidiumtoruloides Y2. J Chem Technol Biotechnol 92:666–673. https://doi.org/10.1002/JCTB.5049

Ghanavati H, Nahvi I, Karimi K (2015) Organic fraction of municipal solid waste as a suitable feedstock for the production of lipid by oleaginous yeast Cryptococcus aerius. Waste Manage 38:141–148. https://doi.org/10.1016/J.WASMAN.2014.12.007

Acknowledgements

Authors would like to express their gratitude to Julaine Tania Enas and Lilian Melo Bondig for their support and expertise during their analytical work. Furthermore, the author would like to thank Ragn-Sells Denmark A/S for providing organic waste material for research.

Funding

Open access funding provided by Aalborg University. This project has received funding from the European Union’s Horizon 2020 research and innovation program under Grant Agreement No. 101007130 as part of the FLEXI-GREEN FUEL project.

Author information

Authors and Affiliations

Contributions

All authors contributed to the manuscript. Stanislav Rudnyckyj: experimental work, data processing, visualization, writing—original draft preparation. Tanmay Chaturvedi: supervision, reviewing, and editing. Mette Hedegaard Thomsen: fundraising, conceptualization, supervision, methodology, validation, and reviewing. All authors approved the final manuscript version.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rudnyckyj, S., Chaturvedi, T. & Thomsen, M.H. Microbial biomass production from enzymatically saccharified organic municipal waste and present microbial inhibitors. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05980-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05980-w