Abstract

This study focuses on the modification of raw coir fibre (RCF) as a bio-adsorbent by partial bleaching to retain its strength with improvement in whiteness index, aesthetic value and surface roughness. The RCF and modified coir fibre (MCF) were examined for morphology, structural properties and tensile strength. The modification leads to the improvement in the whiteness index of RCF by 63.46%. The MCF is further explored for the adsorption of Reactive Orange 122 (RO122) dye by optimising time, concentration of dye, pH which showed 19.89 mg g−1 removal in 90 min at pH 2. The obtained MCF bio-adsorbent was further explored for real-time analysis employing textile effluent. The RCF, MCF and coir fibre after dye adsorption (CFADA) were further examined for potency towards microbial growth targeting a wide range of microbial strains, including both gram-positive and gram-negative bacteria which indicated microbial growth inhibition property of the CFADA. The composite, CFADA and a PVA binder showed a high fractural strength, withstanding up to 240 kg. This novel application puts the modified coir fibre as a low-cost bio-adsorbent capable of efficient dye removal from textile effluents and reuses in the microbial resilient composite formation for industrial applications.

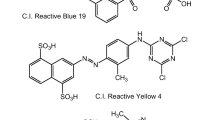

Graphical abstract

Similar content being viewed by others

Data availability

All relevant data are included in the paper.

References

Karthik R, Muthezhilan R, Jaffar Hussain A et al (2016) Effective removal of Methylene Blue dye from water using three different low-cost adsorbents. Desalin Water Treat 57:10626–10631

Mathew ML, Gopalakrishnan A, Aravindakumar CT, Aravind UK (2019) Low–cost multilayered green fiber for the treatment of textile industry waste water. J Hazard Mater 365:297–305

Arun Kumar K, Bharath M, Krishna B (2022) Adsorption kinetics of reactive dye using agricultural waste: banana stem. Water Practice & Technology 17:128–138

Değermenci GD, Değermenci N, Ayvaoğlu V et al (2019) Adsorption of reactive dyes on lignocellulosic waste; characterization, equilibrium, kinetic and thermodynamic studies. J Clean Prod 225:1220–1229

Ahmad T, Danish M (2018) Prospects of banana waste utilization in wastewater treatment: a review. J Environ Manag 206:330–348. https://doi.org/10.1016/j.jenvman.2017.10.061

Yadav S, Yadav A, Bagotia N et al (2021) Adsorptive potential of modified plant-based adsorbents for sequestration of dyes and heavy metals from wastewater—a review. J Water Process Eng 42:102148

Crini G, Lichtfouse E, Wilson LD, Morin-Crini N (2019) Conventional and non-conventional adsorbents for wastewater treatment. Environ Chem Lett 17:195–213

Koli A, Kumar A, Pattanshetti A et al (2023) Hierarchical porous activated carbon from wheat bran agro-waste: applications in carbon dioxide capture, dye removal, oxygen and hydrogen evolution reactions. ChemPlusChem 89(3):e202300373. https://doi.org/10.1002/cplu.202300373

Chavan VD, Aziz J, Kim H et al (2024) Transformation of rust iron into a sustainable product for applications in the electronic, energy, biomedical, and environment fields: towards a multitasking approach. Nano Today 54:102085. https://doi.org/10.1016/j.nantod.2023.102085

Koli A, Pattanshetti A, Mane-Gavade S, et al (2023) Agro-waste management through sustainable production of activated carbon for CO2 capture, dye and heavy metal ion remediation. Waste Manag Bull. https://doi.org/10.1016/j.wmb.2023.12.010

Gawade VV, Sabale SR, Dhabbe RS, Garadkar KM (2023) Environmentally sustainable synthesis of SnO2 nanostructures for efficient photodegradation of industrial dyes. J Mater Sci Mater Electron 34:138. https://doi.org/10.1007/s10854-022-09455-4

Johari K, Saman N, Song ST et al (2016) Adsorption enhancement of elemental mercury by various surface modified coconut husk as eco-friendly low-cost adsorbents. Int Biodeterior Biodegradation 109:45–52

Rethinam P (2019) International scenario of coconut sector. In: Krishnakumar V, Thampan PK, Nair MA (eds) The Coconut Palm (Cocos nucifera L.) - Research and Development Perspectives pp 21–56. Springer Singapore

Nam TH, Ogihara S, Tung NH, Kobayashi S (2011) Effect of alkali treatment on interfacial and mechanical properties of coir fiber reinforced poly (butylene succinate) biodegradable composites. Compos B Eng 42:1648–1656

Akintayo C, Azeez M, Beuerman S, Akintayo E (2016) Spectroscopic, mechanical, and thermal characterization of native and modified nigerian coir fibers. J Nat Fibers 13:520–531

Varghese AG, Paul SA, Latha M (2019) Remediation of heavy metals and dyes from wastewater using cellulose-based adsorbents. Environ Chem Lett 17:867–877

Ray S, Saha P, Nur H et al (2014) Study on the preparation of polymer-grafted coir fibre based adsorbent and its application to remove a reactive dye from aqueous solution. Bangladesh J Sci Ind Res 48:271–280

Nascimento RJ, Pereira KRA, Avelino F (2021) Parametric and modeling studies of Rhodamine-B adsorption using coconut coir-based materials as eco-friendly adsorbents. J Environ Chem Eng 9:105943

Nguyen PXT, Ho KH, Do NHN et al (2022) A comparative study on modification of aerogel-based biosorbents from coconut fibers for treatment of dye- and oil-contaminated water. Mater Today Sustain 19:100175. https://doi.org/10.1016/j.mtsust.2022.100175

Saw SK, Sarkhel G, Choudhury A (2012) Preparation and characterization of chemically modified Jute-Coir hybrid fiber reinforced epoxy novolac composites. J Appl Polym Sci 125:3038–3049

Ru S, Zhao C, Yang S (2022) Multi-objective optimization and analysis of mechanical properties of coir fiber from coconut forest waste. Forests 13:2033

Basu G, Mishra L, Jose S, Samanta AK (2015) Accelerated retting cum softening of coconut fibre. Ind Crops Prod 77:66–73. https://doi.org/10.1016/j.indcrop.2015.08.012

Koli A, Battu AK, Motkuri RK, Sabale S (2022) Hierarchical porous activated carbon derived from agro-waste for potential CO2 capture and efficient dye removal applications. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-022-03067-y

Balakrishnan S, Wickramasinghe D, Wijayapala S (2019) Influence of enzyme and chemical pretreatment processes on the colours of banana fibres, Moratuwa Engineering Research Conference (MERCon), Moratuwa, Sri Lanka, pp 568–572. https://doi.org/10.1109/MERCon.2019.8818786

Tang AY, Lee C, Wang Y, Kan C (2017) Octane-assisted reverse micellar dyeing of cotton with reactive dyes. Polymers 9. https://doi.org/10.3390/polym9120678

Salam A, Reddy N, Yang Y (2007) Bleaching of kenaf and cornhusk fibers. Ind Eng Chem Res 46:1452–1458

Cao Y, Chan F, Chui Xiao W (2012) Characterization of flax fibres modified by alkaline, enzyme, and steam-heat treatments. Bioresources 7:4109–4121. https://doi.org/10.15376/biores.7.3.4109-4121

Abraham E, Deepa B, Pothen L et al (2013) Environmental friendly method for the extraction of coir fibre and isolation of nanofibre. Carbohyd Polym 92:1477–1483

Gazliya N, Aparna K (2021) Microwave-assisted alkaline delignification of banana peduncle. J Nat Fibers 18:664–673. https://doi.org/10.1080/15440478.2019.1645786

Venkatachalam N, Navaneethakrishnan P, Rajsekar R, Shankar S (2016) Effect of pretreatment methods on properties of natural fiber composites: a review. Polym Polym Compos 24:555–566

Saw SK, Sarkhel G, Choudhury A (2011) Surface modification of coir fibre involving oxidation of lignins followed by reaction with furfuryl alcohol: characterization and stability. Appl Surf Sci 257:3763–3769

Misra R, Saw SK, Datta C (2011) The influence of fiber treatment on the mechanical behavior of jute-coir reinforced epoxy resin hybrid composite plate. Mech Adv Mater Struct 18:431–445

Sun C, Liu R, Cao W et al (2015) Impacts of alkaline hydrogen peroxide pretreatment on chemical composition and biochemical methane potential of agricultural crop stalks. Energy Fuels 29:4966–4975. https://doi.org/10.1021/acs.energyfuels.5b00838

Mohamed NH, Tamada M, Ueki Y, Seko N (2013) Effect of partial delignification of kenaf bast fibers for radiation graft copolymerization. J Appl Polym Sci 127:2891–2895. https://doi.org/10.1002/app.37512

Rigueto CVT, Alessandretti I, da Silva DH et al (2021) Agroindustrial wastes of banana pseudo-stem as adsorbent of textile dye: characterization, kinetic, and equilibrium studies. Chem Afr 4:1069–1078. https://doi.org/10.1007/s42250-021-00263-7

Tao J, Zhu Y, Huang T et al (2023) Fe3O4/SiO2/polymer hybrid biosorbent based on an etch-fill strategy for heavy metal ion adsorption. J Ind Text 53:15280837221146292

Koli A, Dhabbe R, Shen J et al (2023) Terminalia catappa shell-based activated carbon: N2 activation strategically enhanced hierarchical porosity for CO2 capture and dye removal applications. Biomass Convers Biorefinery. https://doi.org/10.1007/s13399-023-04140-w

Qu W, He D, Huang H et al (2020) Characterization of amino-crosslinked hypromellose and its adsorption characteristics for methyl orange from water. J Mater Sci 55:7268–7282. https://doi.org/10.1007/s10853-020-04517-6

Tang R, Wen J, Stote RE, Sun Y (2020) Cyanuric chloride-based reactive dyes for use in the antimicrobial treatments of polymeric materials. ACS Appl Mater Interfaces 13:1524–1534

Acknowledgements

Authors are thankful to the Department of Science and Technology and Department of Biotechnology, New Delhi, for the grant under the DST-FIST program (No/SR/FST/College-151/2013(C)) and DBT-Star college scheme to Jaysingpur College, Jaysingpur. Authors (CJ and JP) are thankful to DKTES Textile and Engineering Institute, Ichalkaranji for providing testing facility.

Author information

Authors and Affiliations

Contributions

Chandala Jatkar: investigation, methodology, formal analysis, writing—original draft. Prof. Kalyanrao Garadkar, Dr. Rohant Dhabbe, Dr. Rajendra Kumbhar, Dr. Ravindra Kupwade and Jian Shen: formal analysis, writing—review and editing. Prof. Jaykumar Patil and Dr. Sandip Sabale: supervision, conceptualization, methodology, writing—review and editing.

Corresponding authors

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• The partial bleaching method employed to RCF preserves aesthetic and tensile properties by improving colour index.

• The modified material (MCF) showed 48% removal of RO122 dye with applicability in real-time analysis.

• The post-adsorbed fibre (CFADA) is reused to fabricate composite sheet with 240 kg fractural strength for futuristic industrial applications.

• The developed method is a sustainable approach for bio-adsorbents for environmental remediation along with commercial reusability.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jatkar, C., Dhabbe, R., Garadkar, K. et al. A sustainable approach for tailoring coir-fibre based bio-adsorbent and its composite for industrial applications. Biomass Conv. Bioref. (2024). https://doi.org/10.1007/s13399-024-05620-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-024-05620-3