Abstract

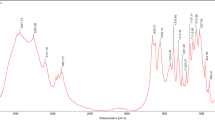

Food wastes are one of the great deals of ever-growing world population. Among them, chitinous wastes are precious for being used as a substrate to produce value-added commodities. In the present work, the deproteinization of shrimp waste together with the production of alkaline protease enzyme by obligate alkalophilic Bacillus marmarensis was investigated. First, we determined optimum conditions including inoculum ratio, temperature, shrimp waste concentration, and fermentation time for alkaline protease production. The highest protease activity (269.48 ± 2.19 U/mL) was obtained with 5% sole shrimp waste pretreated by heating at 100 °C for 20 min at 35 °C and pH 10.0 with inoculum ratio of 6%. Under optimized conditions, B. marmarensis showed a deproteinization capacity of 70.62% at pH 10.0 and 56.52% at pH 12.0, respectively, and the Fourier transform infrared spectroscopy spectrum of chitin obtained from deproteinization by B. marmarensis presented the characteristics of chitin compared to literature. Furthermore, the production of alkaline proteases was performed by using different carbon and nitrogen sources in comparison with the enzyme produced solely from shrimp waste. Among the carbon and nitrogen sources used, the highest activity was obtained from sucrose together with peptone from meat as 239.87 ± 28.35 U/mL, which was lower than the activity obtained from sole shrimp waste. Thus, this work indicates that obligate alkalophilic B. marmarensis can be used to develop sustainable bioprocess to produce alkaline proteases from sole shrimp waste and deproteinization of it. To our knowledge, this is the first work for the valorization of shrimp waste by obligate alkalophilic bacteria.

Similar content being viewed by others

Data availability

The authors confirm that the data and materials that support the findings of this study are available within the manuscript.

Code availability

Not applicable.

References

Awasthi A, Cheela VRS, D’Adamo I, Iacovidou E, Islam MR, Johnson M, Li J (2021) Zero waste approach towards a sustainable waste management. Resour Environ Sustainability 3:100014. https://doi.org/10.1016/j.resenv.2021.100014

Nirmal NP, Santivarangkna C, Rajput MS, Benjakul S (2020) Trends in shrimp processing waste utilization: an industrial prospective. Trends Food Sci Technol 103:20–35. https://doi.org/10.1016/j.tifs.2020.07.001

Aneesh PA, Anandan R, Kumar LR, Ajeeshkumar KK, Kumar KA, Mathew S (2020) A step to shell biorefinery—extraction of astaxanthin-rich oil, protein, chitin, and chitosan from shrimp processing waste. Biomass Convers Biorefin 1-10. https://doi.org/10.1007/s13399-020-01074-5

Cabanillas-Bojórquez LA, Gutiérrez-Grijalva EP, González-Aguilar GA, López-Martinez LX, Castillo-López RI, Bastidas-Bastidas PDJ, Heredia JB (2021) Valorization of fermented shrimp waste with supercritical CO2 conditions: extraction of astaxanthin and effect of simulated gastrointestinal digestion on its antioxidant capacity. Molecules 26:4465. https://doi.org/10.3390/molecules26154465

Santos VP, Marques NS, Maia PC, Lima MABD, Franco LDO, Campos-Takaki GMD (2020) Seafood waste as attractive source of chitin and chitosan production and their applications. Int J Mol Sci 21:4290. https://doi.org/10.3390/ijms21124290

Zhou Y, Guo N, Wang Z, Zhao T, Sun J, Mao X (2021) Evaluation of a clean fermentation-organic acid method for processing shrimp waste from six major cultivated shrimp species in China. J Clean Prod 294:126135. https://doi.org/10.1016/j.jclepro.2021.126135

Kumar PA, Suresh PV (2014) Biodegradation of shrimp biowaste by marine Exiguobacterium sp. CFR26M and concomitant production of extracellular protease and antioxidant materials: production and process optimization by response surface methodology. Mar Biotechnol 16:202–218. https://doi.org/10.1007/s10126-013-9531-2

Lopes C, Antelo LT, Franco-Uría A, Alonso AA, Pérez-Martín R (2018) Chitin production from crustacean biomass: sustainability assessment of chemical and enzymatic processes. J Clean Prod 172:4140–4151. https://doi.org/10.1016/j.jclepro.2017.01.082

Mao X, Guo N, Sun J, Xue C (2017) Comprehensive utilization of shrimp waste based on biotechnological methods: a review. J Clean Prod 143:814–823. https://doi.org/10.1016/j.jclepro.2016.12.042

Mathew GM, Sukumaran RK, Sindhu R, Binod P, Pandey A (2021) Green remediation of the potential hazardous shellfish wastes generated from the processing industries and their bioprospecting. Environ Technol Innov 24:101979. https://doi.org/10.1016/j.eti.2021.101979

Mathew GM, Mathew DC, Sukumaran RK, Sindhu R, Huang CC, Binod P, Sirohi R, Kim SH, Pandey A (2020) Sustainable and eco-friendly strategies for shrimp shell valorization. Environ Pollut 267:115656. https://doi.org/10.1016/j.envpol.2020.115656

Rahimi M, Mir SM, Baghban R, Charmi G, Plummer CM, Shafiei-Irannejad V, Soleymani J, Pietrasik J (2022) Chitosan-based biomaterials for the treatment of bone disorders. Int J Biol Macromol 215:346–367. https://doi.org/10.1016/j.ijbiomac.2022.05.006

Zewude DA, Noguchi T, Sato K, Izawa H (2022) Production of chitin nanoparticles by bottom-up approach from alkaline chitin solution. Int J Biol Macromol 210:123–127. https://doi.org/10.1016/j.ijbiomac.2022.06.079

Yadav M, Goswami P, Paritosh K, Kumar M, Pareek N, Vivekanand V (2019) Seafood waste: a source for preparation of commercially employable chitin/chitosan materials. Bioresour Bioprocess 6:1–20. https://doi.org/10.1186/s40643-019-0243-y

Younes I, Rinaudo M (2015) Chitin and chitosan preparation from marine sources. Structure, properties and applications. Mar Drugs 13:1133–1174. https://doi.org/10.3390/md13031133

Lee DH, Doan CT, Tran TN, Nguyen VB, Nguyen AD, Wang CL, Wang SL (2021) Proteases production and chitin preparation from the liquid fermentation of chitinous fishery by-products by Paenibacillus elgii. Mar Drugs 19:477. https://doi.org/10.3390/md19090477

Sorokulova L, Krumnow A, Globa L, Vodyanoy V (2009) Efficient decomposition of shrimp shell waste using Bacillus cereus and Exiguobacterium acetylicum. J Ind Microbiol 36:1123–1126. https://doi.org/10.1007/s10295-009-0587-y

Doan CT, Tran TN, Wen IH, Nguyen VB, Nguyen AD, Wang SL (2019) Conversion of shrimp head waste for production of a thermotolerant, detergent-stable alkaline protease by Paenibacillus sp. Catalysts 9:798. https://doi.org/10.3390/catal9100798

Liang TW, Hsieh JL, Wang SL (2012) Production and purification of a protease, a chitosanase, and chitin oligosaccharides by Bacillus cereus TKU022 fermentation. Carbohydr Res 362:38–46. https://doi.org/10.1016/j.carres.2012.08.004

Razzaq A, Shamsi S, Ali A, Ali Q, Sajjad M, Malik A, Ashraf M (2019) Microbial proteases applications. Front Bioeng. Biotechnol 7:110. https://doi.org/10.3389/fbioe.2019.00110

Singh S, Bajaj BK (2017) Potential application spectrum of microbial proteases for clean and green industrial production. Energy Ecol Environ 2:370–386. https://doi.org/10.1007/s40974-017-0076-5

Protease Market (2022) Protease market by source and application: global opportunity analysis and industry forecast, 2021–2030. https://www.alliedmarketresearch.com/protease-market-A12830. Accessed 12 August 2022

Denizci AA, Kazan D, Erarslan A (2010) Bacillus marmarensis sp. Nov., an alkaliphilic, protease-producing bacterium isolated from mushroom compost. Int J Syst Evol 60:1590–1594. https://doi.org/10.1099/ijs.0.012369-0

Öner MNK (2009) Purification and characterization of an alkaline protease which isolated from an obligate alkaliphilic Bacillus marmarensis GMBE 72. Ph.D. thesis, Kocaeli University

Haddar A, Hmidet N, Ghorbel-Bellaaj O, Fakhfakh-Zouari N, Sellami-Kamoun A, Nasri M (2011) Alkaline proteases produced by Bacillus licheniformis RP1 grown on shrimp wastes: application in chitin extraction, chicken feather-degradation and as a dehairing agent. Biotechnol Bioprocess Eng 16:669–678. https://doi.org/10.1007/s12257-010-0410-7

Aye KN, Stevens WF (2004) Improved chitin production by pretreatment of shrimp shells. J Chem Technol Biotechnol 79:421–425. https://doi.org/10.1002/jctb.990

Mechri S, Sellem I, Bouacem K, Jabeur F, Laribi-Habchi H, Mellouli L, Hacène H, Bouanane-Darenfed A, Jaouadi B (2020) A biological clean processing approach for the valorization of speckled shrimp Metapenaeus monoceros by-product as a source of bioactive compounds. Environ Sci Pollut Res 27:15842–15855. https://doi.org/10.1007/s11356-020-08076-w

Younes I, Hajji S, Frachet V, Rinaudo M, Jellouli K, Nasri M (2014) Chitin extraction from shrimp shell using enzymatic treatment. Antitumor, antioxidant and antimicrobial activities of chitosan. Int J Biol Macromol 69:489–498. https://doi.org/10.1016/j.ijbiomac.2014.06.013

Özgören T, Pinar O, Bozdağ G, Denizci AA, Gündüz O, Hatır PÇ, Kazan D (2018) Assessment of poly (3-hydroxybutyrate) synthesis from a novel obligate alkaliphilic Bacillus marmarensis and generation of its composite scaffold via electrospinning. Int J Biol Macromol 119:982–991. https://doi.org/10.1016/j.ijbiomac.2018.08.014

Doan CT, Tran TN, Vo TPK, Nguyen AD, Wang SL (2019) Chitin extraction from shrimp waste by liquid fermentation using an alkaline protease-producing strain, Brevibacillus parabrevis. Int J Biol Macromol 131:706–715. https://doi.org/10.1016/j.ijbiomac.2019.03.117

Liu Y, Xing R, Yang H, Liu S, Qin Y, Li K, Yu H, Li P (2020) Chitin extraction from shrimp (Litopenaeus vannamei) shells by successive two-step fermentation with Lactobacillus rhamnoides and Bacillus amyloliquefaciens. Int J Biol Macromol 148:424–433. https://doi.org/10.1016/j.ijbiomac.2020.01.124

Cui D, Yang J, Lu B, Deng L, Shen H (2022) Extraction and characterization of chitin from Oratosquilla oratoria shell waste and its application in Brassica campestris L.ssp. Int J Biol Macromol 198:204–213. https://doi.org/10.1016/j.ijbiomac.2021.12.173

Hongkulsup C, Khutoryanskiy VV, Niranjan K (2016) Enzyme assisted extraction of chitin from shrimp shells (Litopenaeus vannamei). J Chem Technol Biotechnol 91:1250–1256. https://doi.org/10.1002/jctb.4714

Bose A, Pathan S, Pathak K, Keharia H (2014) Keratinolytic protease production by Bacillus amyloliquefaciens 6B using feather meal as substrate and application of feather hydrolysate as organic nitrogen input for agricultural soil. Waste Biomass Valor 5:595–605. https://doi.org/10.1007/s12649-013-9272-5

Bradford MM (1976) A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72:248–254. https://doi.org/10.1016/0003-2697(76)90527-3

Cahyaningtyas HAA, Suyotha W, Cheirsilp B, Prihanto AA, Yano S, Wakayama M (2022) Optimization of protease production by Bacillus cereus HMRSC30 for simultaneous extraction of chitin from shrimp shell with value-added recovered products. Environ Sci Pollut Res 29:22163–22178. https://doi.org/10.1007/s11356-021-17279-8

Ooi CK, Rasit N, Absullah WRW (2021) Optimization of protease from Aspergillus niger under solid-state fermentation utilizing shrimp shell substrate. Biointerface Res Appl Chem 11:14809–14824. https://doi.org/10.33263/BRIAC116.1480914824

Avcı A, Değirmen M, Akcay FA (2022) Investigation of lentil flour utilization for the production of protease by Bacillus subtilis ZBP4. Biocatal Biotransformation 40:75–81. https://doi.org/10.1080/10242422.2020.1870109

Rejisha RP, Murugan M (2021) Alkaline protease production by halophilic Bacillus sp. strain SP II-4 and characterization with special reference to contact lens cleansing. Mater Today: Proc 45:1757–1760. https://doi.org/10.1016/j.matpr.2020.08.624

Jadhav HP, Sonawane MS, Khairnar MH, Sayyed RZ (2020) Production of alkaline protease by rhizospheric Bacillus cereus HP_RZ17 and Paenibacillus xylanilyticus HP_RZ19. Environmental Sustainability 3:5–13. https://doi.org/10.1007/s42398-020-00096-z

Kaur I, Sharma AD, Joshi N, Kocher GS (2020) Alkaline proteases: a review on production optimization parameters and their physicochemical properties. Res Rev Biotechnol Biosci 7:33–59. https://doi.org/10.5281/zenodo.3748473

Pal K, Rakshit S, Mondal KC, Halder SK (2021) Microbial decomposition of crustacean shell for production of bioactive metabolites and study of its fertilizing potential. Environ Sci Pollut Res 28:58915–58928. https://doi.org/10.1007/s11356-021-13109-z

Espoui AH, Larimi SG, Darzi GN (2022) Optimization of protease production process using bran waste using Bacillus licheniformis. Korean J Chem Eng 39:674–683. https://doi.org/10.1007/s11814-021-0965-3

Taokaew S, Zhang X, Chuenkaek T, Kobayashi T (2020) Chitin from fermentative extraction of crab shells using okara as a nutrient source and comparative analysis of structural differences from chemically extracted chitin. Biochem Eng 159:107588. https://doi.org/10.1016/j.bej.2020.107588

Gimenes NC, Silveira E, Tambourgi EB (2021) An overview of proteases: production, downstream processes and industrial applications. Sep Purif Rev 50:223–243. https://doi.org/10.1080/15422119.2019.1677249

Mathew GM, Huang CC, Sindhu R, Binod P, Sirohi R, Awsathi MK, Pillai S, Pandey A (2021) Enzymatic approaches in the bioprocessing of shellfish wastes. 3 Biotech 11:367. https://doi.org/10.1007/s13205-021-02912-7

Maruthiah T, Palavesam A (2017) Characterization of haloalkalophilic organic solvent tolerant protease for chitin extraction from shrimp shell waste. Int J Biol Macromol 97:552–560. https://doi.org/10.1016/j.ijbiomac.2017.01.021

Kalwasińska A, Jankiewicz U, Felföldi T, Burkowska-But A, Brzezinska MS (2018) Alkaline and halophilic protease production by Bacillus luteus H11 and its potential industrial applications. Food Technol Biotechnol 56:553. https://doi.org/10.17113/ftb.56.04.18.5553

Manni L, Jellouli K, Ghorbel-Bellaaj O, Agrebi R, Haddar A, Sellami-Kamoun A, Nasri M (2010) An oxidant-and solvent-stable protease produced by Bacillus cereus SV1: application in the deproteinization of shrimp wastes and as a laundry detergent additive. Appl Biochem Biotechnol 160:2308–2321. https://doi.org/10.1007/s12010-009-8703-z

Funding

The authors acknowledge the financial support received from Marmara University, Scientific Research Project Unit with the project number FYL-2022–10331.

Author information

Authors and Affiliations

Contributions

Investigation: Merve Canpulat, writing—original draft preparation: Merve Canpulat, Orkun Pinar, Zeynep Yilmaz-Sercinoglu, Dilek Kazan, validation: Merve Canpulat, visualization: Orkun Pinar, writing—reviewing and editing: Orkun Pinar, Zeynep Yilmaz-Sercinoglu, Dilek Kazan, formal analysis: Orkun Pinar, Dilek Kazan, resources: Dilek Kazan, project administration: Dilek Kazan, conceptualization: Merve Canpulat, methodology: Orkun Pinar, Dilek Kazan, funding acquisition: Dilek Kazan, supervision: Zeynep Yilmaz-Sercinoglu, Dilek Kazan.

Corresponding author

Ethics declarations

Ethics approval

The manuscript does not contain experiments using animals and human studies. No ethical approval is necessary for this article.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Canpulat, M., Pinar, O., Yilmaz-Sercinoglu, Z. et al. Valorization of shrimp waste by obligate alkaliphilic Bacillus marmarensis. Biomass Conv. Bioref. (2022). https://doi.org/10.1007/s13399-022-03684-7

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13399-022-03684-7