Abstract

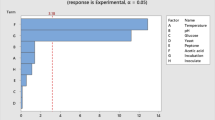

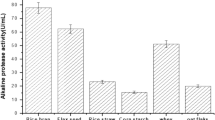

This study describes the cellulases (CLS), hemicellulases (HCS), and reducing sugars (RS) production by Pleurotus ostreatus PLO6 growth under solid state fermentation (SSF) using stems and leaves mixture of Alstroemeria sp. (AW) as lignocellulosic (LC) substrate (also named biomass). SSF involved, at the same time, CLS and HCS biosynthesis, and its subsequent action over the substrate in order to obtain RS, which are considered as precursors of bioethanol and other bioproducts. The first stage of this research was performed to verify simultaneous obtaining of hemicellulolytic and cellulolytic enzymes, and RS by means of univariate experimentation (response variables: hemicellulolytic and cellulolytic enzyme activities and RS concentration, factor: time). In this preliminary study, P. ostreatus PLO6 was able to synthesize endoglucanases, exoglucanases, β-glucosidases, endoxylanases, β-xylosidases, and RS concurrently. Afterwards, temperature (T), substrate concentration (SC), and time (t) effects on simultaneous obtaining of hemicellulolytic and cellulolytic enzymes and RS were assessed. A statistical factorial design 23 was developed using the same response variables indicated at the preliminary phase. With a significance level of 0.05, temperature was the most significant effect on enzymatic activities (excepting β-xylosidases) and RS production. CLS activities and RS production were maximized at 24 °C, while HCS activities were better at 32 °C. The SC was statistically significant too, when it was maintained at 30%, the CLS (excepting endoglucanases) and HCS production was favorable. The RS highest production was of 44.8 mg·g−1 (respective to raw AW) and 124.3 mg·g−1 (respective to cellulose) at 24 °C, 20% of SC and 8 days of SSF.

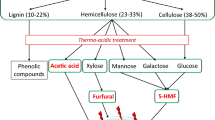

Graphical abstract

Similar content being viewed by others

References

BP, (2020) Statistical review of world energy. Pureprint Group Limited, London

EIA (2020) Where greenhouse gases come from. https://www.eia.gov/energyexplained/energy-and-the-environment/where-greenhouse-gases-come-from.php. Accessed 15 Mar 2021

Guedes F, Szklo A, Rochedo P et al (2019) Climate-energy-water nexus in Brazilian oil refineries. Int J Greenh Gas Control 90:1–11. https://doi.org/10.1016/j.ijggc.2019.102815

Flórez Pardo LM, López Galán JE, Lozano Ramírez T (2018) Saccharide biomass for biofuels, biomaterials, and chemicals. In: Vaz S (ed) Biomass and green chemistry: building a renewable pathway. Springer International Publishing, Cham, pp 11–30

Shimizu FL, Zamora HDZ, Schmatz AA et al (2020) Biofuels generation based on technical process and biomass quality. In: Srivastava N, Srivastava M, Mishra PK, Gupta VK (eds) Biofuel production technologies: critical analysis for sustainability. Springer, Singapore, pp 37–64

Hirani AH, Javed N, Asif M et al (2018) A review on first- and second-generation Biofuel Productions. In: Kumar A, Ogita S, Yau Y-Y (eds) Biofuels: greenhouse gas mitigation and global warming. Springer India, New Delhi, pp 141–154

Groves C, Sankar M, Thomas PJ (2018) Second-generation biofuels: exploring imaginaries via deliberative workshops with farmers. J Responsible Innov 5:149–169. https://doi.org/10.1080/23299460.2017.1422926

Sharma D, Saini A (2020) Lignocellulosic waste valorization and biorefineries concept. In: Sharma D, Saini A (eds) Lignocellulosic ethanol production from a biorefinery perspective: sustainable valorization of waste. Springer, Singapore, pp 195–215

Junqueira AH, Peetz MDS (2017) Brazilian consumption of flowers and ornamental plants: habits, practices and trends. Ornam Hortic 23:178–184. https://doi.org/10.14295/oh.v23i2.1070

Arevalo Celis. L del P (2006) Implementación del código de conducta florverde en los niveles 1 y 2 de los programas de manejo de suelos y residuos en flores San Juan S.A., C.I. Universidad de La Salle

Loyola CE, Dole JM, Dunning R (2019) South and Central America cut flower production and postharvest survey. Horttechnology 29:898–905. https://doi.org/10.21273/HORTTECH04484-19

Zamora Zamora HD, de Freitas C, Bueno D et al (2021) Biomass fractionation based on enzymatic hydrolysis for biorefinery systems. In: Verma P (ed) Biorefineries: A Step Towards Renewable and Clean Energy. Springer, Singapore, pp 217–254

Felipuci JP, de Freitas C, Zamora Zamora HD et al (2021) Biotechnological aspects of microbial pretreatment of lignocellulosic biomass. In: Verma P (ed) Biorefineries: a step towards renewable and clean energy. Springer, Singapore, pp 121–150

Bhardwaj N, Kumar B, Verma P (2019) A detailed overview of xylanases: an emerging biomolecule for current and future prospective. Bioresour Bioprocess 6:1–36. https://doi.org/10.1186/s40643-019-0276-2

Sharma D, Saini A (2020) Saccharification fermentation and process integration. In: Sharma D, Saini A (eds) Lignocellulosic ethanol production from a biorefinery perspective: sustainable valorization of waste. Springer, Singapore, pp 111–158

Kaschuk JJ, de Alexandria SD, Frollini E et al (2020) Influence of pH, temperature, and sisal pulp on the production of cellulases from Aspergillus sp. CBMAI 1198 and hydrolysis of cellulosic materials with different hemicelluloses content, crystallinity, and average molar mass. Biomass Convers Biorefinery 10:483–494. https://doi.org/10.1007/s13399-019-00440-2

Frassatto PAC, Casciatori FP, Thoméo JC et al (2021) β-Glucosidase production by Trichoderma reesei and Thermoascus aurantiacus by solid state cultivation and application of enzymatic cocktail for saccharification of sugarcane bagasse. Biomass Convers Biorefinery 11:503–513. https://doi.org/10.1007/s13399-020-00608-1

Steudler S, Werner A, Cheng JJ (2019) Solid state fermentation. Springer, Cham

Mitchell DA, Pitol LO, Biz A et al (2019) Design and operation of a pilot-scale packed-bed bioreactor for the production of enzymes by solid-state fermentation. In: Steudler S, Werner A, Cheng JJ (eds) Solid state fermentation: research and industrial applications. Springer International Publishing, Cham, pp 27–50

Peralta RM, da Silva BP, Gomes Côrrea RC et al (2017) Chapter 5 - Enzymes from Basidiomycetes—peculiar and efficient tools for biotechnology. In: Brahmachari G (ed) Biotechnology of microbial enzymes. Academic Press, Cambridge, pp 119–149

Kurt S, Buyukalaca S (2010) Yield performances and changes in enzyme activities of Pleurotus spp. (P. ostreatus and P. sajor-caju) cultivated on different agricultural wastes. Bioresour Technol 101:3164–3169. https://doi.org/10.1016/j.biortech.2009.12.011

Khalil MI, Hoque MM, Basunia MA et al (2011) Production of cellulase by Pleurotus ostreatus and Pleurotus sajor-caju in solid state fermentation of lignocellulosic biomass. Turkish J Agric For 35:333–341. https://doi.org/10.3906/tar-1002-684

Ozcirak Ergun S, Ozturk Urek R (2017) Production of ligninolytic enzymes by solid state fermentation using Pleurotus ostreatus. Ann Agrar Sci 15:273–277. https://doi.org/10.1016/j.aasci.2017.04.003

Chukwuma OB, Rafatullah M, Tajarudin HA, Ismail N (2020) Lignocellulolytic enzymes in biotechnological and industrial processes: a review. Sustainability 12:1–31. https://doi.org/10.3390/su12187282

Leite P, Sousa D, Fernandes H et al (2021) Recent advances in production of lignocellulolytic enzymes by solid-state fermentation of agro-industrial wastes. Curr Opin Green Sustain Chem 27:1–25. https://doi.org/10.1016/j.cogsc.2020.100407

Deswal D, Gupta R, Nandal P, Kuhad RC (2014) Fungal pretreatment improves amenability of lignocellulosic material for its saccharification to sugars. Carbohydr Polym 99:264–269. https://doi.org/10.1016/j.carbpol.2013.08.045

Arora A, Priya S, Sharma P et al (2016) Evaluating biological pretreatment as a feasible methodology for ethanol production from paddy straw. Biocatal Agric Biotechnol 8:66–72. https://doi.org/10.1016/j.bcab.2016.08.006

Sartori T, Tibolla H, Prigol E et al (2015) Enzymatic saccharification of lignocellulosic residues by cellulases obtained from solid state fermentation using Trichoderma viride. Biomed Res Int 2015:1–10. https://doi.org/10.1155/2015/342716

Puchart V, Fraňová L, Mørkeberg Krogh KBR et al (2018) Action of different types of endoxylanases on eucalyptus xylan in situ. Appl Microbiol Biotechnol 102:1725–1736. https://doi.org/10.1007/s00253-017-8722-6

Martínez DA, Buglione MB, Filippi MV et al (2015) Evaluación del crecimiento micelial de Pleurotus ostreatus y Agrocybe aegerita sobre orujos de pera. An Biol 2015:1–10. https://doi.org/10.6018/analesbio.37.1

Browning B (1967) Methods of wood chemistry. Interscience Publishers, New York

Milne T, Brennan AH, Glenn BH (1990) Sourcebook of methods of analysis for biomass and biomass conversion processes. Elsevier Science Publishers LTD, Amsterdam

Aslam S, Asgher M (2011) Partial purification and characterization of ligninolytic enzymes produced by Pleurotus ostreatus during solid state fermentation. African J Biotechnol 10:17875–17883. https://doi.org/10.5897/AJB11.2233

Karp SG, Faraco V, Amore A et al (2015) Statistical optimization of laccase production and delignification of sugarcane bagasse by Pleurotus ostreatus in solid-state fermentation. Biomed Res Int 2015:1–9. https://doi.org/10.1155/2015/181204

Liguori R, Ionata E, Marcolongo L et al (2015) Optimization of Arundo donax saccharification by (Hemi) cellulolytic enzymes from Pleurotus ostreatus. Biomed Res Int 2015:1–15. https://doi.org/10.1155/2015/951871

Pérez LCR, Piñeros-Castro Y, Lozano MEV (2011) Producción de azúcares fermentables a partir de fibra prensada de palma de aceite pretratada biológicamente por Pleurotus ostreatus y Phanerochaete chrysosporium. Rev ion 24:29–35

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428. https://doi.org/10.1021/ac60147a030

Coral Medina JD, Woiciechowski A, Zandona Filho A et al (2015) Lignin preparation from oil palm empty fruit bunches by sequential acid/alkaline treatment – a biorefinery approach. Bioresour Technol 194:172–178. https://doi.org/10.1016/j.biortech.2015.07.018

Dos Santos BSL, Gomes AFS, Franciscon EG et al (2015) Thermotolerant and mesophylic fungi from sugarcane bagasse and their prospection for biomass-degrading enzyme production. Braz J Microbiol 46:903–910. https://doi.org/10.1590/S1517-838246320140393

De Oliveira RP, De Cássia PJ, Dos Santos DQ et al (2017) Synergistic action of an Aspergillus (hemi-)cellulolytic consortium on sugarcane bagasse saccharification. Ind Crops Prod 109:173–181. https://doi.org/10.1016/j.indcrop.2017.08.031

Montgomery DC (2009) Design and analysis of experiments, 5th edn. John Wiley & Sons, New York

Silva TAL, Zamora HDZ, Varão LHR et al (2018) Effect of steam explosion pretreatment catalysed by organic acid and alkali on chemical and structural properties and enzymatic hydrolysis of sugarcane bagasse. Waste Biomass Valoriz 9:2191–2201. https://doi.org/10.1007/s12649-017-9989-7

García CA, Peña Á, Betancourt R, Cardona CA (2018) Energetic and environmental assessment of thermochemical and biochemical ways for producing energy from agricultural solid residues: coffee cut-stems case. J Environ Manag 216:160–168. https://doi.org/10.1016/j.jenvman.2017.04.029

Coral Medina JD, Woiciechowski AL, Zandona Filho A et al (2016) Biological activities and thermal behavior of lignin from oil palm empty fruit bunches as potential source of chemicals of added value. Ind Crops Prod 94:630–637. https://doi.org/10.1016/j.indcrop.2016.09.046

Cutrim FM, Ramos ECSS, Abreu MCC et al (2019) A study of chemical composition and enzymatic hydrolysis of solid organic waste from agrosilvopastoral systems. J Braz Chem Soc 30:1955–1963. https://doi.org/10.21577/0103-5053.20190110

Baldrian P, Valášková V, Merhautová V, Gabriel J (2005) Degradation of lignocellulose by Pleurotus ostreatus in the presence of copper, manganese, lead and zinc. Res Microbiol 156:670–676. https://doi.org/10.1016/j.resmic.2005.03.007

Quevedo-Hidalgo B, Pedroza-Rodríguez AM, Velásquez-Lozano ME (2015) Production of lignocellulolytic enzymes from floriculture residues using Pleurotus ostreatus. Univ Sci 20:117–127. https://doi.org/10.11144/Javeriana.SC20-1.eple

Bin Y, Hongzhang C (2010) Effect of the ash on enzymatic hydrolysis of steam-exploded rice straw. Bioresour Technol 101:9114–9119. https://doi.org/10.1016/j.biortech.2010.07.033

Li X, Yu H, Sun D et al (2015) Comparative study of enzymatic hydrolysis properties of pulp fractions from waste paper. BioResources 10:3818–3830. https://doi.org/10.15376/biores.10.3.3818-3830

Koutrotsios G, Mountzouris KC, Chatzipavlidis I, Zervakis GI (2014) Bioconversion of lignocellulosic residues by Agrocybe cylindracea and Pleurotus ostreatus mushroom fungi–assessment of their effect on the final product and spent substrate properties. Food Chem 161:127–135. https://doi.org/10.1016/j.foodchem.2014.03.121

Ruilova MB, Hernández A (2014) Evaluación de residuos agrícolas para la producción del hongo Pleurotus ostreatus. ICIDCA 48:54–59

Rizki M, Tamai Y (2011) Effects of different nitrogen rich substrates and their combination to the yield performance of oyster mushroom (Pleurotus ostreatus). World J Microbiol Biotechnol 27:1695–1702. https://doi.org/10.1007/s11274-010-0624-z

Rytioja J, Hildén K, Yuzon J et al (2014) Plant-polysaccharide-degrading enzymes from basidiomycetes. Microbiol Mol Biol Rev 78:614–649. https://doi.org/10.1128/MMBR.00035-14

Goldbeck R, Ramos MM, Pereira GAG, Maugeri-Filho F (2013) Cellulase production from a new strain Acremonium strictum isolated from the Brazilian biome using different substrates. Bioresour Technol 128:797–803. https://doi.org/10.1016/j.biortech.2012.10.034

de Oliveira RP, dos Santos BV, Costa L et al (2017) Xylanase and β-glucosidase production by Aspergillus fumigatus using commercial and lignocellulosic substrates submitted to chemical pre-treatments. Ind Crops Prod 95:453–459. https://doi.org/10.1016/j.indcrop.2016.10.055

Moretti MMS, Bocchini-Martins DA, Da SR et al (2012) Selection of thermophilic and thermotolerant fungi for the production of cellulases and xylanases under solid-state fermentation. Braz J Microbiol 43:1062–1071. https://doi.org/10.1590/S1517-83822012000300032

de Oliveira RP, Gurgel LVA, Pasquini D et al (2020) Lignocellulose-degrading enzymes production by solid-state fermentation through fungal consortium among Ascomycetes and Basidiomycetes. Renew Energy 145:2683–2693. https://doi.org/10.1016/j.renene.2019.08.041

De Lima FV, Luis FA (2013) Produção e uso de enzimas derivadas do fungo Pleurotus ostreatus na hidrólise de bagaço de cana pré-tratado por processo quimiotermomecânico. Universidade de São Paulo

Sánchez-Santillán P, Meneses M, Torres-Salado N (2015) Production of lignocellulolytic enzymes with Pleurotus ostreatus-IE8 by solid fermentation and its effect on the chemical composition of sugarcane bagasse. Life Sci J 12:37–41. https://doi.org/10.7537/j.issn.1097-8135

Da Luz JMR, Nunes MD, Paes SA et al (2012) Lignocellulolytic enzyme production of Pleurotus ostreatus growth in agroindustrial wastes. Braz J Microbiol 43:1508–1515. https://doi.org/10.1590/S1517-83822012000400035

Xin D, Sun Z, Viikari L, Zhang J (2015) Role of hemicellulases in production of fermentable sugars from corn stover. Ind Crops Prod 74:209–217. https://doi.org/10.1016/j.indcrop.2015.05.017

Hu J, Arantes V, Saddler JN (2011) The enhancement of enzymatic hydrolysis of lignocellulosic substrates by the addition of accessory enzymes such as xylanase: is it an additive or synergistic effect? Biotechnol Biofuels 4:1–13. https://doi.org/10.1186/1754-6834-4-36

Aro N, Pakula T, Penttilä M (2005) Transcriptional regulation of plant cell wall degradation by filamentous fungi. FEMS Microbiol Rev 29:719–739. https://doi.org/10.1016/j.femsre.2004.11.006

Qian S, Zhang C, Zhu Z et al (2020) White rot fungus Inonotus obliquus pretreatment to improve tran-1,4-polyisoprene extraction and enzymatic saccharification of Eucommia ulmoides leaves. Appl Biochem Biotechnol 192:719–733. https://doi.org/10.1007/s12010-020-03347-1

Geankoplis C (1998) Procesos de transporte y operaciones unitarias, 3th ed. Compañia Editorial Continental S.A., México D.F.

Taghizadeh-Alisaraei A, Motevali A, Ghobadian B (2019) Ethanol production from date wastes: adapted technologies, challenges, and global potential. Renew Energy 143:1094–1110. https://doi.org/10.1016/j.renene.2019.05.048

Zeitsch KJ (2000) 2. The reactions leading to furfural. In: Zeitsch KJ (ed) The chemistry and technology of furfural and its many by-products. Elsevier, Amsterdam, pp 3–7

Guerra G, Casado MR-LG, Arguelles J et al (2006) Cellulase production with sugarcane straw byTrichoderma citrinoviride on solid bed. Sugar Tech 8:30–35. https://doi.org/10.1007/BF02943738

Sharma R, Rawat R, Bhogal RS, Oberoi HS (2015) Multi-component thermostable cellulolytic enzyme production by Aspergillus niger HN-1 using pea pod waste: appraisal of hydrolytic potential with lignocellulosic biomass. Process Biochem 50:696–704. https://doi.org/10.1016/j.procbio.2015.01.025

Yoon LW, Ang TN, Ngoh GC, Chua ASM (2014) Fungal solid-state fermentation and various methods of enhancement in cellulase production. Biomass Bioenerg 67:319–338. https://doi.org/10.1016/j.biombioe.2014.05.013

Bari E, Nazarnezhad N, Kazemi SM et al (2015) Comparison between degradation capabilities of the white rot fungi Pleurotus ostreatus and Trametes versicolor in beech wood. Int Biodeterior Biodegrad 104:231–237. https://doi.org/10.1016/j.ibiod.2015.03.033

Iandolo D, Amore A, Birolo L et al (2011) Fungal solid state fermentation on agro-industrial wastes for acid wastewater decolorization in a continuous flow packed-bed bioreactor. Bioresour Technol 102:7603–7607. https://doi.org/10.1016/j.biortech.2011.05.029

Azzouz Z, Bettache A, Djinni I et al (2020) Biotechnological production and statistical optimization of fungal xylanase by bioconversion of the lignocellulosic biomass residues in solid-state fermentation. Biomass Convers Biorefinery 2020:1–13. https://doi.org/10.1007/s13399-020-01018-z

Montoya S, Patiño A, Sánchez ÓJ (2021) Production of lignocellulolytic enzymes and biomass of Trametes versicolor from agro-industrial residues in a novel fixed-bed bioreactor with natural convection and forced aeration at pilot scale. Processes 9:1–19. https://doi.org/10.3390/pr9020397

Singhajutha S, Bangyeekhun E, Romruen U (2020) Xylanase production by Aspergillus fumigatus UR01 by solid state fermentation of rice straw. Asian J Agric Biol 8:422–427. https://doi.org/10.35495/ajab.2019.06.273

Nurika I, Suhartini S, Barker GC (2020) Biotransformation of tropical lignocellulosic feedstock using the brown rot fungus Serpula lacrymans. Waste Biomass Valoriz 11:2689–2700. https://doi.org/10.1007/s12649-019-00581-5

Acknowledgements

The authors are grateful to the National Council for Scientific and Technological Development (CNPq), Studies and Projects Funding Agency (FINEP), Research Supporting Foundation of Minas Gerais State (FAPEMIG), Improvement Coordination of Higher Education Personnel (CAPES) and Organization of American States (OAS) for their financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

–Simultaneous synthesis of cellulases, hemicellulases, and reducing sugars using one-pot solid state fermentation

–First assessment of Alstroemeria sp. waste as substrate for concurrent production of reducing sugars, cellulases, and hemicellulases

–Obtaining of reducing sugars without pretreatment stage

–Pleurotus ostreatus PLO6 was able to synthesize endoglucanases

Statement of novelty

In relation to valorize vegetable biomass wastes and to avoid their disposal in soil or landfill, this research is the first one performed in Brazil that assessed simultaneous production of hemi(cellulolytic) enzymes (CLS and HCS) and RS from AW by Pleurotus ostreatus PLO6 growth using solid state fermentation (SSF). In addition, this research is pioneer in physical–chemical characterization of Brazilian flower waste and, from biological and chemical viewpoints, in harnessing this kind of waste to obtain CLS, HCS, and RS concurrently. Monosaccharides contained in RS, analyzed by this research, have a starring role in different industries due to they are potential precursors for biofuels and others bioproducts obtaining.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Zamora Zamora, H.D., Silva, T.A.L., Varão, L.H.R. et al. Simultaneous production of cellulases, hemicellulases, and reducing sugars by Pleurotus ostreatus growth in one-pot solid state fermentation using Alstroemeria sp. waste. Biomass Conv. Bioref. 13, 4879–4892 (2023). https://doi.org/10.1007/s13399-021-01723-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01723-3