Abstract

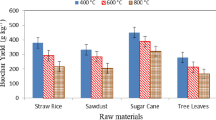

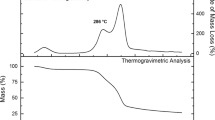

In the present study, seven diverse biomasses of Indian origin were characterized and pyrolyzed at 450 °C to produce biochars. The biochars were thoroughly characterized using a variety of techniques to assure their potential energy and environmental and agricultural applications. Biochars derived from crop wastes with low lignin content, viz., rice husk biochar (RHB), rice straw biochar (RSB), maize stover biochar (MSB), and sugarcane biochar (SCB), possessed high ash content, high pH, and low fixed carbon making them suitable for soil amelioration. RSB, RHB, and MSB recorded high cation exchange capacity, making their potential utilization as liming material and removal of heavy metal contaminants. Elemental O/C ratios for all biochars, except maize stover biochar, were in the range of 0.27–0.32, which showed better stability and half-life period. Thermogravimetric analysis (TGA) was carried out to evaluate the thermal stability of biochars up to 900 °C, and the overall mass loss varied in the range of 16–27 wt%. Biochars from eucalyptus (EB), lantana (LB), and pine needle (PNB) were found to have high higher heating values (HHVs) (23–28 MJ/kg), higher fixed carbon, and lower ash content. Correlations were constructed between HHV of biochars and their volatile matter, ash, and fixed carbon content with high but negative correlation with ash content. Rice straw, rice husk, maize stover, and sugarcane trash were poor substrates, as the resultant biochars contained ≤ 60 wt% fixed carbon, high ash, and a relatively low HHV. It is shown that RHB, RSB, MSB, and SCB can be potential materials for soil amendment and plant nutrient, while PNB, LB, and EB are suitable for renewable solid fuel purpose.

Similar content being viewed by others

References

Brosowski A, Thran D, Mantau U, Mahro B, Erdmann G, Adler P, Stinner W, Reinhold G, Hering T, Blanke C (2016) A review of biomass potential and current utilisation status quo for 93 biogenic wastes and residues in Germany. Biomass Bioenergy 95:257–272

Zhang Y, Ghaly AE, Li B (2012) Availability and physical properties of residue from major agricultural crops for energy conversion through thermochemical processes. Am J Agric Biol Sci 7:312–321

Kumar G, Shobana S, Chen WH, Bach QV, Kim SH, Atabani A, Chang JS (2016) A review of thermochemical conversion of microalgal biomass for biofuels: chemistry and processes. Green Chem 19:46–47

Shakya A, Agarwa T (2017) Poultry litter biochar: an approach towards poultry litter management-a review. Int J Curr Microbiol App Sci 6:2657–2668

Qian C, Lia Q, Zhang Z, Wang X, Hua J, Cao W (2020) Prediction of higher heating values of biochar from proximate and ultimate analysis. Fuel 265:116925

Liu X, Liao J, Song H, Yang Y, Guan G, Zhang Z (2019) A biochar-based route for environmentally friendly controlled release of nitrogen: urea-loaded biochar and bentonite composite. Sci Rep 9:9548–9558

Dong D, Wang C, Zwieten LV, Wang H, Jiang P, Zhou M, Wu W (2020) An effective biochar-based slow-release fertilizer for reducing nitrogen loss in paddy fields. J Soils Sediments 20:3027–3040

Martin SL, Clarke ML, Othman M, Ramsden SJ, West HM (2015) Biochar-mediated reductions in greenhouse gas emissions from soil amended with anaerobic digestates. Biomass Bioenergy 79:39–49

Devi S, Gupta C, Jat SL, Parmar MS (2017) Crop residue recycling for economic and environmental sustainability: the case of India. Open Agric 2:486–494

Lehmann J, Joseph S (2009) Biochar for environmental management: an introduction. In: Lehmann J, Joseph S (eds) Biochar for environmental management: science and technology. Routledge, Abingdon, p 416

Thines KR, Abdullah EC, Mubarak NM, Ruthiraan M (2017) Synthesis of magnetic biochar from agricultural waste biomass to enhancing route for waste water and polymer application: a review. Renew Sust Energ Rev 67:257–276

Chen TW, Luo L, Deng SH, Shi GZ, Zhang SR, Zhang YZ, Deng OP, Wang IL, Zhang J, Wei LY (2018) Sorption of tetracycline on H3PO4 modified biochar derived from rice straw and swine manure. Bioresour Technol 267:431–437

Gwenzi W, Chaukura N, Noubactep C, Mukome FND (2017) Biochar-based water treatment systems as a potential low-cost and sustainable technology for clean water provision. J Environ Manag 197:732–749

Shanmugarajah B, Chew IM, Mubarak NM, Choong TS, Yoo C, Tan K (2019) Valorization of palm oil agro-waste into cellulose biosorbents for highly effective textile effluent remediation. J Clean Prod 210:697–709

Lian F, Xing B (2017) Black carbon (biochar) in water/soil environments: molecular structure, sorption, stability, and potential risk. Sci Total Environ 51:13517–13532

Thines KR, Abdullah EC, Ruthiraan M, Mubarak NM, Tripathi M (2016) A new route of magnetic biochar-based polyaniline composites for supercapacitor electrode materials. J Anal Appl Pyrolysis 121:240–257

Mubarak NM, Kundu A, Sahu JN, Abdullah EC, Jayakumar NS (2014) Synthesis of palm oil empty fruit bunch magnetic pyrolytic char impregnating with FeCl3bymicrowave heating technique. Biomass Bioenergy 261:265–275

Yin Q, Wang RK, Zhao ZH (2018) Application of Mg-Al-modified biochar for simultaneous removal of ammonium, nitrate, and phosphate from eutrophic water. J Clean Prod 176:230–240

Tripathi M, Bhatnagar A, Mubarak MN, Sahu JN, Ganesan P (2020) RSM optimization of microwave pyrolysis parameters to produce OPS char with high yield and large BET surface area. Fuel 277:118184

Zhao J, Shen X, Domene X, Alcaniz JM, Liao X, Palet C (2019) Comparison of biochars derived from different types of feedstock and their potential for heavy metal removal in multiple-metal solutions. Sci Rep 9:9869

Singh S, Chaturvedi S, Dhyani VC, Datta D (2019) Biochar: an ecofriendly residue management approach. Indian Farming 69:27–29

Spokas KA, Novak JM, Stewart CE, Cantrell KB, Uchimiya M, DuSaire MG, Ro KS (2011) Qualitative analysis of volatile organic compounds on biochar. Chemosphere 85:869–882

Keiluweit M, Nico PS, Johnson MG, Kleber M (2010) Dynamic molecular structure of plant biomass-derived black carbon (biochar). Environ Sci Technol 44:1247–1253

Yargicoglu EN, Sadasivam BY, Reddy KR, Spokas K (2015) Physical and chemical characterization of waste wood derived biochars. Waste Manag 36:256–268

Siddiqui MT, Baloch HA, Nizamuddin S, Haris M, Mubarak NM, Michaelczajka KM, Griffin GJ, Srinivasan M (2020) Synthesis of novel magnetic carbon nano-composite from waste biomass: a comparative study of industrially adoptable hydro/solvothermal co-precipitation route. J Environ Chem Eng 8:103519

Yin QQ, Zhang BD, Wang RK, Zhao ZH (2017) Biochar as an adsorbent for inorganic nitrogen and phosphorus removal from water: a review. Environ Sci Pollut Res 24:26297–26309

Hairuddin MN, Mubarak NM, Khalid M, Abdullah EC, Walvekar R, Karri RR (2019) Magnetic palm kernel biochar potential route for phenol removal from wastewater. Environ Sci Pollut Res 26:35183–35197

Singh S, Chaturvedi S, Dhyani VC, Govindaraju K (2020) Pyrolysis temperature influences the characteristics of rice straw and husk biochar and sorption/desorption behaviour of their biourea composite. Bioresour Technol 314:123674

Nguyen BT, Lehmann J (2009) Black carbon decomposition under varying water regimes. Org Geochem 40:846–853

Hamer U, Marschner B, Brodowski S, Amelung W (2004) Interactive priming of black carbon and glucose mineralisation. Org Geochem 35:823–830

ASTM D3172-13 (2013) Standard practice for proximate analysis of coal and coke. ASTM International, West Conshohocken

ASTM D3176-09 (2009) Standard practice for ultimate analysis of coal and coke. ASTM International, West Conshohocken

Mandal S, Bhattacharya TK, Verma AK, Haydary J (2017) Optimization of process parameters for bio-oil synthesis from pine needles (Pinus roxburghii) using response surface methodology. Chem Pap 72:603–616

Jin W, Singh K, Zondlo J (2013) Pyrolysis kinetics of physical components of wood and wood-polymers using isoconversion method. Agriculture 3:12–32

Bordoloi N, Narzari R, Chutia RS, Bhaskar T, Kataki R (2015) Pyrolysis of Mesua ferrea and Pongamia glabra seed cover: characterization of bio-oil and its sub-fractions. Bioresour Technol 178:83–89

Schimmelpfennig S, Glaser B (2012) One step forward toward characterization: some important material properties to distinguish biochars. J Environ Qual 41:1001–1013

Spokas KA (2010) Review of the stability of biochar in soils: predictability of O: C molar ratios. Carbon Manag 1:289–300

ASTM D240–02 (2002) Standard test method for heat of combustion of liquid hydrocarbon fuels by bomb calorimeter. ASTM International, West Conshohocken

Gomez KA, Gomez AA (1984) Statistical procedure for agriculture research. Willey, New York

Houben D, Evrard L, Sonnet P (2013) Mobility, bioavailability and pH-dependent leaching of cadmium, zinc and lead in a contaminated soil amended with biochar. Chemosphere 92:1450–1457

Tan C, Yaxin Z, Hongtao W, Wenjing L, Zeyu Z, Yuancheng Z, Lulu E (2014) Influence of pyrolysis temperature on characteristics and heavy metal adsorptive performance of biochar derived from municipal sewage sludge. Bioresour Technol 164:47–54

Huff MD, Lee JW (2016) Biochar-surface oxygenation with hydrogen peroxide. J Environ Manag 165:17–21

Song W, Guo M (2012) Quality variations of poultry litter biochar generated at different pyrolysis temperatures. J Anal Appl Pyrolysis 94:138–145

Xu G, Sun J, Shao H, Chang SX (2014) Biochar had effects on phosphorus sorption and desorption in three soils with differing acidity. Ecol Eng 62:54–60

Gani A, Naruse A (2007) Effect of cellulose and lignin content on pyrolysis and combustion characteristics for several types of biomass. Renew Energy 32:649–661

Lee Y, Park J, Ryu C, Gang KS, Yang W, Park YK, Jung J, Hyun S (2013) Comparison of biochar properties from biomass residues produced by slow pyrolysis at 500 °C. Bioresour Technol 148:196–201

Lopez A, de Marco I, Caballero BM, Laresgoiti MF, Adrados A (2011) Influence of time and temperature on pyrolysis of plastic wastes in a semi-batch reactor. Chem Eng J 173:62–71

Yu S, Park J, Kim M, Ryu C, Park J (2019) Characterization of biochar and byproducts from slow pyrolysis of hinoki cypress. Biores Technol Rep 6:217–222

Jahirul MI, Rasul MG, Chowdhury AA, Ashwath N (2012) Biofuels production through biomass pyrolysis - a technological review. Energies 5:4952–5001

Elnour AY, Alghyamah AA, Shaikh HM, Poulose AM, Al-Zahrani SM, Anis A, Al Wabel MI (2019) Effect of pyrolysis temperature on biochar microstructural evolution, physicochemical characteristics, and its influence on biochar/polypropylene composites. Appl Sci 9:1149

Domingues RR, Trugilho PF, Silva de Melo ICNA, Melo LCA, Magriotis ZM, Sanchez-Monedero MA (2017) Properties of biochar derived from wood and high-nutrient biomasses with the aim of agronomic and environmental benefits. PLoS One 12:e0176884

Mukome FND, Zhang X, Lucas CRS, Six J, Parikh SJ (2013) Use of chemical and physical characteristics to investigate trends in biochar feedstocks. J Agric Food Chem 61:2196–2204

Guo J, Chen B (2014) Insights on the molecular mechanism for the recalcitrance of biochar: interactive effects of carbon and silicon components. Environ Sci Technol 48:9103–9101

Cui XQ, Hao HL, Zhang CK, He ZL, Yang XE (2016) Capacity and mechanisms of ammonium and cadmium sorption on different wetland-plant derived biochars. Sci Total Environ 539:566–575

Wu W, Li J, Niazi NK, Muller K, Chu Y, Zhang L, Yuan G, Lu K, Song Z, Wang H (2016) Influence of pyrolysis temperature on lead immobilization by chemically modified coconut fiber-derived biochars in aqueous environments. Environ Sci Pollut Res 23:22890–22896

Qian K, Kumar A, Patil K, Bellmer D, Wang D, Yuan W, Huhnke RL (2013) Effects of biomass feedstocks and gasification conditions on the physiochemical properties of char. Energies 6:3972–3986

IEA (2020) Coal Information Database. http://wds.iea.org/wds/pdf/coal_documentation.pdf

Nizamuddin S, Baloch HA, Mubarak NM, Riaz S, Siddiqui MHT, Takkalkar P, Tunio MM, Mazari S, Bhutto AW (2019) Solvothermal liquefaction of corn stalk: physico-chemical properties of bio-oil and biochar. Waste Biomass Valoriz 10:1957–1968

Yang X, Wang H, Strong PJ, Xu S, Liu S, Lu K, Sheng K, Guo J, Che L, He L, Ok YS, Yuan G, Shen Y, Chen X (2017) Thermal properties of biochars derived from waste biomass generated by agricultural and forestry sectors. Energies 10:469

Qian X, Lee S, Soto A, Chen G (2018) Regression model to predict the higher heating value of poultry waste from proximate analysis. Resources 7:39

Duan F, Chyang C, Zhang L, Yin S (2015) Bed agglomeration characteristics of rice straw combustion in a vortexing fluidized-bed combustor. Bioresour Technol 183:195–202

Sohni S, Norulaini NAN, Hashim R, Khan SB, Fadhullah W, Omar AKM (2018) Physicochemical characterization of Malaysian crop and agro-industrial biomass residues as renewable energy resources. Ind Crop Prod 111:642–650

Gominho J, Lourenço A, Luís A, Neiva D, Domingues F, Duarte AP, Pereira H (2015) Eucalyptus stumpwood as biomass source within a biorefinery. 7th international colloquium on Eucalyptus pulp, Vitoria, Espirito Santo, Brazil

Intani K, Latif S, Zebin Cao Z, Müller J (2018) Characterisation of biochar from maize residues produced in a self-purging pyrolysis reactor. Bioresour Technol 265:224–235

Mundike J, Collard FX, Gorgens JF (2017) Pyrolysis of Lantana camara and Mimosa pigra: influences of temperature, other process parameters and incondensable gas evolution on char yield and higher heating value. Bioresour Technol 243:284–293

Wang MJ, Huang YF, Chiueh PT, Kuan WH (2012) Microwave-induced torrefaction of rice husk and sugarcane residues. Energy 37:177–184

Creamer AE, Gao B, Zhang M (2014) Carbon dioxide capture using biochar produced from sugarcane bagasse and hickory wood. Chem Eng J 249:174–179

Dong D, Feng Q, McGrouther K, Yang M, Wang H, Wu W (2015) Effects of biochar amendment on rice growth and nitrogen retention in a waterlogged paddy field. J Soils Sediments 15:153–162

Siddiqui MTH, Nizamuddin S, Mubarak NM, Shirin K, Aijaz M, Hussain M, Baloch HA (2019) Characterization and process optimization of biochar produced using novel biomass, waste pomegranate peel: a response surface methodology approach. Waste Biomass Valoriz 10:521–532

Sun K, Ro K, Guo MX, Novak J, Mashayekhi H, Xing B (2011) Sorption of bisphenol A, 17a ethinyl estradiol and phenanthrene on thermally and hydrothermally produced biochars. Bioresour Technol 102:5757–5763

Yap MW, Mubarak NM, Sahu JN, Abdullah EC (2017) Microwave induced synthesis of magnetic biochar from agricultural biomass for removal of lead and cadmium from wastewater. J Ind Eng Chem 45:287–295

Yang Z, Xu M, Liu Y, He F, Gao F, Su Y, Wei H, Zhang Y (2014) Nitrogen-doped, carbon-rich, highly photoluminescent carbon dots from ammonium citrate. Nanoscale 6:1890–1895

Van Zwieten L, Kimber S, Morris S, Chan KY, Downie A, Rust J, Joseph S, Cowie A (2010) Effects of biochar from slow pyrolysis of papermill waste on agronomic performance and soil fertility. Plant Soil 327:235–246

Ahmad M, Rajapaksha AU, Lim JE, Zhang M, Bolan N, Mohan D, Vithanage M, Lee SS, Ok YS (2014) Biochar as a sorbent for contaminant management in soil and water: a review. Chemosphere 99:19–33

Zhao SX, Ta N, Wang XD (2017) Effect of temperature on the structural and physicochemical properties of biochar with apple tree branches as feedstock material. Energies 10:1293

Melo LCA, Coscione AR, Abreu CA, Puga AP, Camargo OP (2013) Influence of pyrolysis temperature on cadmium and zinc sorption capacity of sugar cane straw-derived biochar. Bioresources 8:4992–5004

Acknowledgments

Authors gratefully acknowledged ICAR-NICRA, Hyderabad, Government of India for financial support to carry out the work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chaturvedi, S., Singh, S.V., Dhyani, V.C. et al. Characterization, bioenergy value, and thermal stability of biochars derived from diverse agriculture and forestry lignocellulosic wastes. Biomass Conv. Bioref. 13, 879–892 (2023). https://doi.org/10.1007/s13399-020-01239-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-01239-2