Abstract

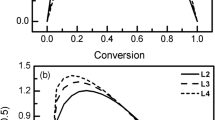

The aim of the present study is to explore the thermal degradation behaviour and investigate the kinetic and thermodynamic parameters for pyrolysis of peanut shell (PS). Proximate, ultimate composition and calorific value of PS were employed to determine the energy potential of PS. Pyrolysis tests were performed in a thermogravimetric analyzer at heating rates of 10, 20 and 30 °C/min in inert (N2) atmosphere. Thermal analysis of PS confirms that the thermal degradation of PS occurred in three stages and major weight loss found in 200 to 600 °C. The pyrolysis kinetic parameters (activation energy and pre-exponential factor) and thermodynamic parameters (changes in enthalpy, Gibb’s free energy and entropy) were determined by Ozawa-Flynn-Wall (OFW), Kissinger, Kissinger-Akahira-Sunose (KAS) and Coats-Redfern methods. The value of activation energy (Ea) evaluated by the Kissinger method was 109.05 kJ/mol, while the average Ea calculated by OFW and KAS was 109.94 and 96.93 kJ/mol, respectively. Result showed that the Ea varies with the degree of conversion. The pre-exponential factors were obtained in the range of 2.99 × 1012–7 × 1013 min−1, increased with the rate of heating and decreased with conversion. The results of this study suggest that PS has potential to be used as a pyrolysis feedstock.

Graphical abstract

Similar content being viewed by others

References

Alhumade H, da Silva JC, Ahmad MS, Çakman G, Yıldız A, Ceylan S, Elkamel A (2019) Investigation of pyrolysis kinetics and thermal behavior of Invasive Reed Canary (Phalaris arundinacea) for bioenergy potential. J Anal Appl Pyrolysis 140:385–392

Danje S (2011) Fast pyrolysis of corn residues for energy production. Doctoral dissertation, Stellenbosch University

Sudha P, Ravindranath NH (1999) Land availability and biomass production potential in India. Biomass Bioenergy 16(3):207–221

Varma AK, Mondal P (2016a) Physicochemical characterization and kinetic study of pine needle for pyrolysis process. J Therm Anal Calorim 124(1):487–497

Garba MU, Inalegwu A, Musa U, Aboje AA, Kovo AS, Adeniyi DO (2018) Thermogravimetric characteristic and kinetic of catalytic co-pyrolysis of biomass with low-and high-density polyethylenes. Biomass Convers Biorefinery 8(1):143–150

Kumar A, Prasad R (2015) Production of renewable energy and waste water management from vetiver grass. In Management of Water, Energy and Bio-resources in the Era of Climate Change: Emerging Issues and Challenges Springer, Cham 169–181

Raju NJ, Gossel W, Ramanathan AL, Sudhakar M (2014) Management of water, energy and bio-resources in the era of climate change: emerging issues and challenges. Springer

Perea-Moreno MA, Manzano-Agugliaro F, Hernandez-Escobedo Q, Perea-Moreno AJ (2018) Peanut shell for energy: properties and its potential to respect the environment. Sustainability 10(9):3254

Web Link-1, https://www.atlasbig.com/en-in/countries-by-peanut-production. Accessed 15 Apr 2020

Abdulrazak S, Otie D, Oniwapele YA (2014) Proximate analysis and anti-nutritional factors of groundnut and melon husk. Online J Anim Feed Res 4:25–28

Zhu G, Zhu X, Xiao Z, Zhou R, Zhu Y, Wan X (2014) Kinetics of peanut shell pyrolysis and hydrolysis in subcritical water. J Mater Cycles Waste Manag 16(3):546–556

Sinha R, Kumar S, Singh RK (2013) Production of biofuel and biochar by thermal pyrolysis of linseed seed. Biomass Convers Biorefinery 3(4):327–335

Ceylan S, Topçu Y (2014) Pyrolysis kinetics of hazelnut husk using thermogravimetric analysis. Bioresour Technol 156:182–188

Özsin G, Pütün AE, Pütün E (2019) Investigating the interactions between lignocellulosic biomass and synthetic polymers during co-pyrolysis by simultaneous thermal and spectroscopic methods. Biomass Convers Biorefinery 9(3):593–608

Varma AK, Mondal P (2016b) Physicochemical characterization and pyrolysis kinetics of wood sawdust. Energy Sources Part A 38:2536–2544

Sharma R, Sheth PN (2018) Multi reaction apparent kinetic scheme for the pyrolysis of large size biomass particles using macro-TGA. Energy 151:1007–1017

Thakur LS, Varma AK, Mondal P (2018) Analysis of thermal behavior and pyrolytic characteristics of vetiver grass after phytoremediation through thermogravimetric analysis. J Therm Anal Calorim 131:3053–3064

Varma AK, Mondal P (2016c) Physicochemical characterization and pyrolysis kinetic study of sugarcane bagasse using thermogravimetric analysis. J Energy Resour Technol 138:052205

Pradhan RR, Garnaik PP, Regmi B, Dash B, Dutta A (2017) Pyrolysis kinetics of Sal (Shorea robusta) seeds. Biomass Convers Biorefinery 7(2):237–246

Ahmad MS, Mehmood MA, Al Ayed OS, Ye G, Luo H, Ibrahim M, Rashid U, Nehdi IA, Qadir G (2017) Kinetic analyses and pyrolytic behavior of Para grass (Urochloa mutica) for its bioenergy potential. Bioresour Technol 224:708–713

Jaroenkhasemmeesuk C, Tippayawong N (2016) Thermal degradation kinetics of sawdust under intermediate heating rates. Appl Thermal Eng 103:170–176

Santos NA, Magriotis ZM, Saczk AA, Fássio GT, Vieira SS (2015) Kinetic study of pyrolysis of castor beans (Ricinus communis L.) presscake: an alternative use for solid waste arising from the biodiesel production. Energy Fuel 29:2351–2357

Mishra G, Bhaskar T (2014) Non isothermal model free kinetics for pyrolysis of rice straw. Bioresour Technol 169:614–621

Lopez-Velazquez MA, Santes V, Balmaseda J, Torres-Garcia E (2013) Pyrolysis of orange waste: a thermo-kinetic study. J Anal Appl Pyrolysis 99:170–177

Wu ZQ, Wang SZ, Zhao J, Chen L, Meng HY (2014) Pyrolytic behavior and kinetic analysis of wheat straw and lignocellulosic biomass model compound. Adv Mater Res Trans Tech Publ Ltd 860:550–554

Slopiecka K, Bartocci P, Fantozzi F (2012) Thermogravimetric analysis and kinetic study of poplar wood pyrolysis. Appl Energy 97:491–497

Mukherjee A, Das P, Minu K (2014) Thermogravimetric analysis and kinetic modelling studies of selected agro-residues and biodiesel industry wastes for pyrolytic conversion to bio-oil. Biomass Convers Biorefinery 4(3):259–268

Damartzis T, Vamvuka D, Sfakiotakis S, Zabaniotou A (2011) Thermal degradation studies and kinetic modeling of cardoon (Cynara cardunculus) pyrolysis using thermogravimetric analysis (TGA). Bioresour Technol 102:6230–6238

Ma Y, Wang J, Zhang Y (2018) TG-FTIR study on pyrolysis of Enteromorpha prolifera. Biomass Convers Biorefinery 8(1):151–157

Zhang X, Xu M, Sun R, Sun L (2006) Study on biomass pyrolysis kinetics. Proceedings of GT, 493–496

Bonelli PR (2003) Slow pyrolysis of nutshells: characterization of derived chars and of process kinetics. Energy Sources 25(8):767–778

Taşar Ş, Fatih KA, Ahmet ÖZ (2015) A study on the pyrolysis of peanut shells at different isothermal conditions and determination of the kinetic parameters. Pamukkale Üniversitesi Mühendislik Bilimleri Dergisi 21(7):306–313

Collins S, Ghodke P (2018) Kinetic parameter evaluation of groundnut shell pyrolysis through use of thermogravimetric analysis. J Environ Chem Eng 6(4):4736–4742

Ogunsuyi HO, Adejumobi IB (2020) Pyrolysis of groundnut peels and shells for bio-based products (bio-oil and bio-char). Int J Res Innov Appl Sci 5(2):75–78

Bhavanam A, Sastry RC (2015) Kinetic study of solid waste pyrolysis using distributed activation energy model. Bioresour Technol 178:126–131

Yao X, Xu K, Liang Y (2016) Analytical pyrolysis study of peanut shells using TG-MS technique and characterization for the waste peanut shell ash. J Residuals Sci Technol 13(4):295–305

Torres-García E, Ramírez-Verduzco LF, Aburto J (2020) Pyrolytic degradation of peanut shell: Activation energy dependence on the conversion. Waste Manag 106:203–212

Cai J, He Y, Yu X, Banks SW, Yang Y, Zhang X, Yu Y, Liu R, Bridgwater AV (2017) Review of physicochemical properties and analytical characterization of lignocellulosic biomass. Renew Sust Energ Rev 76:309–322

Blaine RL, Kissinger HE (2012) Homer Kissinger and the Kissinger equation. Thermochim Acta 540:1–6

Vyazovkin S (2020) Kissinger method in kinetics of materials: things to beware and be aware of. Molecules. 25(12):2813

Straszko J, Olszak-Humienik M, Możejko J (1997) Kinetics of thermal decomposition of ZnSO4· 7H2O. Thermochim Acta 292(1-2):145–150

Olszak-Humienik M, Mozejko J (2000) Thermodynamic functions of activated complexes created in thermal decomposition processes of sulphates. Thermochim Acta 344(1-2):73–79

Saikia N, Bardalai M (2018) Thermal analysis and kinetic parameters determination of biomass using differential thermal gravimetric analysis in N2 atmosphere. Mater Today Proc 5:2146–2156

Müsellim E, Tahir MH, Ahmad MS, Ceylan S (2018) Thermo kinetic and TG/DSC-FTIR study of pea waste biomass pyrolysis. Appl Thermal Engin 137:54–61

Dhaundiyal A, Singh SB, Hanon MM, Rawat R (2018) Determination of kinetic parameters for the thermal decomposition of parthenium hysterophorus. Environ Clim Technol 22:5–21

Dorge S, Jeguirim M, Trouvé G (2011) Thermal degradation of Miscanthus pellets: kinetics and aerosols characterization. Waste Biomass Valoriz 2:149–155

Suriapparao DV, Vinu R (2018) Effects of biomass particle size on slow pyrolysis kinetics and fast pyrolysis product distribution. Waste Biomass Valoriz 9:465–477

Feng Q, Lin Y (2017) Integrated processes of anaerobic digestion and pyrolysis for higher bioenergy recovery from lignocellulosic biomass: a brief review. Renew Sust Energ Rev 77:1272–1287

Sbirrazzuoli N (2019) Advanced isoconversional kinetic analysis for the elucidation of complex reaction mechanisms: a new method for the identification of rate-limiting steps. Molecules 24(9):1683

Guerrero MB, da Silva Paula MM, Zaragoza MM, Gutiérrez JS, Velderrain VG, Ortiz AL, Collins-Martínez V (2014) Thermogravimetric study on the pyrolysis kinetics of apple pomace as waste biomass. Int J Hydrog Energy 39:16619–16627

Alwani MS, Khalil HA, Sulaiman O, Islam MN, Dungani R (2014) An approach to using agricultural waste fibres in biocomposites application: thermogravimetric analysis and activation energy study. BioResour 9:218–230

Sriram A, Swaminathan G (2018) Pyrolysis of Musa balbisiana flower petal using thermogravimetric studies. Bioresour Technol 265:236–246

Chandrasekaran A, Ramachandran S, Subbiah S (2017) Determination of kinetic parameters in the pyrolysis operation and thermal behavior of Prosopis juliflora using thermogravimetric analysis. Bioresour Technol 233:413–422

Islam MA, Asif M, Hameed BH (2015) Pyrolysis kinetics of raw and hydrothermally carbonized Karanj (Pongamia pinnata) fruit hulls via thermogravimetric analysis. Bioresour Technol 179:227–233

Zhu F, Feng Q, Xu Y, Liu R, Li K (2015) Kinetics of pyrolysis of ramie fabric wastes from thermogravimetric data. J Therm Anal Calorim 119:651–657

Huang X, Cao JP, Zhao XY, Wang JX, Fan X, Zhao YP, Wei XY (2016) Pyrolysis kinetics of soybean straw using thermogravimetric analysis. Fuel 169:93–98

Williams CL, Westover TL, Emerson RM, Tumuluru JS, Li C (2016) Sources of biomass feedstock variability and the potential impact on biofuels production. BioEnergy Res 9(1):1–14

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Varma, A.K., Singh, S., Rathore, A.K. et al. Investigation of kinetic and thermodynamic parameters for pyrolysis of peanut shell using thermogravimetric analysis. Biomass Conv. Bioref. 12, 4877–4888 (2022). https://doi.org/10.1007/s13399-020-00972-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-020-00972-y