Abstract

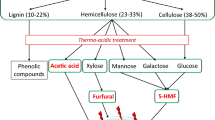

Aiming to decrease the cost of enzymes used to hydrolyze biomass, the liquid stream from the hot-compressed water (HCW) treatment of sugarcane bagasse was used in the growth medium of Aspergillus awamori 2B.361 U2/1. Statistical experimental design was used to determine the HCW1 temperature and residence time for maximum hemicellulose-derived sugar recovery to the liquid stream. The HCW reactor was fed with 10 % (w/v) bagasse, and the treatment was performed under agitation using an initial pressure of 20 bar (N2) at 170 °C for 40 min. The HCW liquid stream (23.70 ± 0.30 g/L xylan) was diluted and used as the culture medium carbon source for fungal enzyme production. In growth medium containing 5 g/L xylan at initial pH 5.0, the fungus produced 46 U/mL of xylanase (EC 3.2.1.8), 3.3 U/mL of β-glucosidase (EC 3.2.1.21), 0.24 U/mL of β-xylosidase (EC 3.2.1.37), and 0.6 U/mL of α-l-arabinofuranosidase (EC 3.2.1.55) in the supernatant. The use of a residual hemicellulosic stream would decrease the cost of enzyme production and by extension favors the economics of ethanol production from lignocellulosic biomass.

Similar content being viewed by others

References

Ni J, Tokuda G (2013) Lignocellulose-degrading enzymes from termites and their symbiotic microbiota. Biotechnol Adv 31:838–850. doi:10.1016/j.biotechadv.2013.04.005

Azadi P, Inderwildi OR, Farnood R, King DA (2013) Liquid fuels, hydrogen and chemicals from lignin: a critical review. Renew Sust Energ Rev 21:506–523. doi:10.1016/j.rser.2012.12.022

Carvalheiro F, Duarte LC, Gírio FM (2008) Hemicellulose biorefineries: a review on biomass pretreatments. J Sci Ind Res 67(11):849–864

Mosier N, Wyman C, Dale B, Elander R, Lee YY, Holtzapple M, Ladisch M (2005) Features of promising technologies for pretreatment of lignocellulosic biomass. BioresourTechnol 96:673–686. doi:10.1016/j.biortech.2004.06.025

Weiqi W, Shubin W, Liguo L (2013) Combination of liquid hot water pretreatment and wet disk milling to improve the efficiency of the enzymatic hydrolysis of eucalyptus. Bioresour Technol 128:725–730. doi:10.1016/j.biortech.2012.08.130

Alvira P, Tomás-Pejó E, Ballesteros M, Negro MJ (2010) Pretreatment technologies for an efficient bioethanol production process based on enzymatic hydrolysis: a review. Bioresour Technol 101:4851–4861. doi:10.1016/j.biortech.2009.11.093

Allen SG, Schulman D, Lichwa J, Antal MJ, Laser M, Lynd LR (2001) A comparison between hot liquid water and steam fractionation of corn fiber. Ind Eng Chem Res 40:2934–2941. doi:10.1021/ie990831h

Allen SG, Kam LC, Zemann AJ, Antal MJ (1996) Fractionation of sugar cane with hot, compressed, liquid water. Ind Eng Chem Res 35:2709–2715. doi:10.1021/ie950594s

Laser M, Schulman D, Allen SG, Lichwa J, Antal MJ Jr, Lynd LR (2002) A comparison of liquid hot water and steam pretreatments of sugar cane bagasse for bioconversion to ethanol. Bioresour Technol 81:33–44. doi:10.1016/S0960-8524(01)00103-1

Pérez JA, Ballesteros I, Ballesteros M, Sáez F, Negro MJ, Manzanares P (2008) Optimizing liquid hot water pretreatment conditions to enhance sugar recovery from wheat straw for fuel-ethanol production. Fuel 87:3640–3647. doi:10.1016/j.fuel.2008.06.009

Klein-Marcuschamer D, Oleskowicz-Popiel P, Simmons BA, Blanch HW (2012) The challenge of enzyme cost in the production of lignocellulosic biofuels. Biotechnol Bioeng 109:1083–1087. doi:10.1002/bit.24370

Juturu V, Wu JC (2012) Microbial xylanases: engineering, production and industrial applications. Biotechnol Adv 30:1219–1227. doi:10.1016/j.biotechadv.2011.11.006

Sørensen HR, Pedersen S, Meyer AS (2007) Synergistic enzyme mechanisms and effects of sequential enzyme additions on degradation of water insoluble wheat arabinoxylan. Enzyme Microb Technol 40:908–918. doi:10.1016/j.enzmictec.2006.07.026

De Vries RP, Visser J (2001) Aspergillus enzymes involved in degradation of plant cell wall polysaccharides. Microbiol Mol Biol Rev 65:497–522. doi:10.1128/MMBR. 65.4.497-522.2001

De Vries RP (2003) Regulation of Aspergillus genes encoding plant cell wall polysaccharide-degrading enzymes; relevance for industrial production. Appl Microbiol Biotechnol 61:10–20. doi:10.1007/s00253-002-1171-9

Bon E, Webb C (1989) Passive immobilization of Aspergillus awamori spores for subsequent glucoamylase production. Enzyme Microb Technol 11:495–499. doi:10.1016/0141-0229(89)90030-6

Bon E, Webb C (1993) Glucoamylase production and nitrogen nutrition in Aspergillus awamori. Appl Biochem Biotechnol 39–40:349–369. doi:10.1007/BF02919002

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2008) Determination of structural carbohydrates and lignin in biomass. National Renewable Energy Laboratory, Golden, CO. http://www.nrel.gov/docs/gen/fy13/42618.pdf. Accessed 27 Sept 2014

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D (2005) Determination of ash in biomass. National Renewable Energy Laboratory, Golden, CO. http://www.nrel.gov/biomass/pdfs/42622.pdf. Accessed 27 Sept 2014

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D (2006) Determination of sugars, byproducts, and degradation products in liquid fraction process samples. National Renewable Energy Laboratory, Golden, CO. http://www.nrel.gov/docs/gen/fy08/42623.pdf. Accessed 27 Sept 2014

Breccia JD, Baigorf MD, Castro GR, Siñeriz F (1995) Detection of endo-xylanase activities in electrophoretic gels with congo red staining. Biotechnol Tech 9:145–148. doi:10.1007/BF00224415

Jones DB, Gersdorff CEF (1925) Proteins of wheat bran—distribution of nitrogen, percentages of amino acids and of free amino nitrogen: a comparison of the bran proteins with the corresponding proteins of wheat endosperm and embryo. J Biol Chem 64:241–251

Nandini CD, Salimath PV (2001) Carbohydrate composition of wheat, wheat bran, sorghum and bajra with good chapati/roti (Indian flat bread) making quality. Food Chem 73:197–203. doi:10.1016/S0308-8146(00)00278-8

Teixeira RSS, Siqueira FG, Souza MV, Filho EXF, Bon EPS (2010) Purification and characterization studies of a thermostable β-xylanase from Aspergillus awamori. J Ind Microbiol Biotechnol 37:1041–1051. doi:10.1007/s10295-010-0751-4

Sumner JB (1925) A more specific reagent for the determination of sugar in urine. J Biol Chem 65:393–395

Sumner JB, Somers GF (1944) Laboratory experiments in biological chemistry. J Chem Educ 21:570. doi:10.1021/ed021p570.3

Teixeira RSS, Da Silva AS, Ferreira-Leitão VS, Bon EPS (2012) Amino acids interference on the quantification of reducing sugars by the 3,5-dinitrosalicylic acid assay mislead carbohydrase activity measurements. Carbohydr Res 363:33–37. doi:10.1016/j.carres.2012.09.024

Ghose TK (1987) Measurement of cellulase activities. Pure Appl Chem 59:257–268. doi:10.1351/pac198759020257

Da Silva AS, Inoue H, Endo T, Yano S, Bon EP (2010) Milling pretreatment of sugarcane bagasse and straw for enzymatic hydrolysis and ethanol fermentation. Bioresour Technol 101:7402–7409. doi:10.1016/j.biortech.2010.05.008

Gulati A, Mahadevan S (2000) Mechanism of catabolite repression in the bgl operon of Escherichia coli: involvement of the anti-terminator BglG, CRP-cAMP and EIIAGlc in mediating glucose effect downstream of transcription initiation. Genes Cells 5:239–250. doi:10.1046/j.1365-2443.2000.00322.x

Stoilova I, Krastanov A, Stanchev V, Daniel D, Gerginova M, Alexieva Z (2006) Biodegradation of high amounts of phenol, catechol, 2,4-dichlorophenol and 2,6-dimethoxyphenol by Aspergillus awamori cells. Enzym Microb Technol 39:1036–1041. doi:10.1016/j.enzmictec.2006.02.006

Stoilova I, Krastanov A, Yanakieva I, Kratchanova M, Yemendjiev H (2007) Biodegradation of mixed phenolic compounds by Aspergillus awamori NRRL 3112. Int Biodeterior Biodegrad 60:342–346. doi:10.1016/j.ibiod.2007.05.011

Haltrich D, Nidetzky B, Kulbe KD, Steiner W, Zupancic S (1996) Production of fungal xylanases. Bioresour Technol 58(2):137–161. doi:10.1016/S0960-8524(96)00094-6

Sun X, Liu Z, Qu Y, Li X (2008) The effects of wheat bran composition on the production of biomass-hydrolyzing enzymes by Penicillium decumbens. Appl Biochem Biotechnol 146:119–128. doi:10.1007/s12010-007-8049-3

Beg QK, Kapoor M, Mahajan L, Hoondal GS (2001) Microbial xylanases and their industrial applications: a review. Appl Microbiol Biotechnol 56:326–338. doi:10.1007/s002530100704

Techapun C, Poosaran N, Watanabe M, Sasaki K (2003) Thermostable and alkaline-tolerant microbial cellulase-free xylanases produced from agricultural wastes and the properties required for use in pulp bleaching bioprocesses: a review. Process Biochem 38:1327–1340. doi:10.1016/S0032-9592(02)00331-X

Rizzatti ACS, Sandrim VC, Jorge JA, Terenzi HF, Polizeli MLTM (2004) Influence of temperature on the properties of the xylanolytic enzymes of the thermo tolerant fungus Aspergillus phoenicis. J Ind Microbiol Biotechnol 31:88–93. doi:10.1007/s10295-004-0120-2

Salles BC, Medeiros RG, Bao SN, Silva FG Jr, Filho EXF (2005) Effect of cellulase-free xylanases from Acrophialophora nainiana and Humicola grisea var. thermoidea on eucalyptus kraft pulp. Process Biochem 40:343–349. doi:10.1016/j.procbio.2004.01.008

Sandrim VC, Rizzatti ACS, Terenzi HF, Jorge JA, Milagres AMF, Polizeli MLTM (2005) Purification and biochemical characterization of two xylanases produced by Aspergillus caespitosus and their potential for kraft pulp bleaching. Process Biochem 40:1823–1828. doi:10.1016/j.procbio.2004.06.061

Siqueira FG, de Siqueira AG, de Siqueira EG, Carvalho MA, Peretti BM, Jaramillo PM, Teixeira RSS, Dias ES, Félix CR, Filho EX (2010) Evaluation of holocellulase production by plant-degrading fungi grown on agro-industrial residues. Biodegradation 21(5):815–824. doi:10.1007/s10532-010-9346-z

Ferreira-Leitão V, Gottschalk LMF, Ferrara MA, Nepomuceno AL, Molinari HBC, Bon EPS (2010) Biomass residues in Brazil: availability and potential uses. Waste Biomass Valor1:65–76. doi:10.1007/s12649-010-9008-8

Tallapragada P, Venkatesh K (2011) Isolation, identification and optimization of xylanase enzyme produced by Aspergillus niger under submerged fermentation. J Microbiol Biotechnol Res 1(4):137–147

Kadowaki MK, Souza CGM, Simaìo RC, Peralta RM (1997) Xylanase production by Aspergillus tamarii. App Biochem Biotechnol 66(2):97–106. doi:10.1007/BF02788755

Souza DF, de Souza CGM, Peralta RM (2001) Effect of easily metabolizable sugars in the production of xylanase by Aspergillus tamarii in solid-state fermentation. Process Biochem 36(8–9):835–838. doi:10.1016/S0032-9592(00)00295-8

Daroit DJ, Silveira ST, Hertz PF, Brandelli A (2007) Production of extracellular β-glucosidase by Monascus purpureus on different growth substrates. Process Biochem 42:904–908. doi:10.1016/j.procbio.2007.01.012

Sunna A, Antranikian G (1997) Xylanolytic enzymes from fungi and bacteria. Crit Rev Biotechnol 17:39–67. doi:10.3109/07388559709146606

Andrade SV, Polizeli MLTM, Terenzi HF, Jorge JÁ (2004) Effect of carbon source on the biochemical properties of β-xylosidases produced by Aspergillus versicolor. Process Biochem 39:1931–1938. doi:10.1016/j.procbio.2003.09.024

Acknowledgments

The Research and Projects Financing (FINEP) of the Brazilian Ministry of Science and Technology, the Brazilian Research Council (CNPq), and the Japan International Cooperation Agency (JICA) supported this work. Complexo Energético Itarumã (sugar mill) is gratefully acknowledged for supplying the sugarcane bagasse for this study. The author is thankful to Ms. Reiko Yoshii and Ms. Miyu Sumii from the Biomass Refinery Research Center at the National Institute of Advanced Industrial Science and Technology (BRRC-AIST) in Japan and Ricardo S. S. Teixeira from the Enzyme Technology Laboratory (ENZITEC-UFRJ) in Brazil for the kindness and help provided during the composition of this paper.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

de Sousa Paredes, R., da Rocha Olivieri de Barros, R., Inoue, H. et al. Production of xylanase, α-l-arabinofuranosidase, β-xylosidase, and β-glucosidase by Aspergillus awamori using the liquid stream from hot-compressed water treatment of sugarcane bagasse. Biomass Conv. Bioref. 5, 299–307 (2015). https://doi.org/10.1007/s13399-015-0159-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-015-0159-5