Abstract

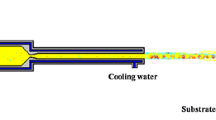

The high pressure—high velocity oxy fuel (HP-HVOF) process is a thermal spraying process (TSP) for developing the high melting point powder ceramic coating over the surface. The mixture of used rare earth, the erbium oxide is an untouched rare earth oxide in the field of metal spraying and the likes of metal spraying such as the HP-HVOF process is a recently industrial opted process; which is the modified form of the HVOF process. This paper articulates the effects of rare earth (La2O3/CeO2/Er2O3−0.4 wt% each) addition on tungsten carbide coatings developed using high pressure-high velocity oxy fuel process on Martensitic steel having grade SS410. These effects have been analyzed using surface (like scanning electron microscope (SEM), porosity, surface roughness, wettability, and energy dispersive spectroscopy (EDS) test) and mechanical (such as tensile, flexural, and hardness test) characterization has been carried out on coated and uncoated samples. The porosity level of the coating was less than one percent, and the static water contact angle for coated sample (≈130º) was higher than the substrate (≈63º). This shows that fabricated coating is hydrophobic in nature. Moreover; the identification of doped elements has been done using EDS. The comparisons between the substrate and the coated samples have been done and the result shows that the coated sample possess enhanced surface and mechanical properties.

Similar content being viewed by others

References

Wall, F.: Rare earth elements. Critical Metals Handbook. 312–339 (2013)

Li, H.; Wang, P.; Lin, G.; Huang, J.: The role of rare earth elements in biodegradable metals: a review. Acta Biomater. 129, 33–42 (2021)

Rasoulnia, P.; Barthen, R.; Lakaniemi, A.-M.: A critical review of bioleaching of rare earth elements: the mechanisms and effect of process parameters. Crit. Rev. Environ. Sci. Technol. 51, 378–427 (2020)

Wang, K.L.; Zhu, Y.M.; Zhang, Q.B.; Sun, M.L.: Effect of rare earth cerium on the microstructure and corrosion resistance of laser cladded nickel-base alloy coatings. J. Mater. Process. Technol. 63, 563–567 (1997)

Yi, W., et al.: Effect of rare earth on oxidation resistance of iron base fluxing alloy spray-welding coating. J. Alloy. Compd. 311, 65–68 (2000)

Wang, K.L.; Zhang, Q.B.; Sun, M.L.; Wei, X.G.; Zhu, Y.M.: Rare earth elements modification of laser-clad nickel-based alloy coatings. Appl. Surf. Sci. 174, 191–200 (2001)

Jyothi, R.K., et al.: Review of rare earth elements recovery from secondary resources for clean energy technologies: grand opportunities to create wealth from waste. J. Clean. Prod. 267, 122048 (2020)

Vishnoi, M.; Murtaza, Q.; Kumar, P.: Effect of rare earth elements on coatings developed by thermal spraying processes (TSP)—a brief review. In: Materials Today: Proceedings vol. 44, Elsevier Ltd, pp. 4053–4058 (2020)

Davis, J.R.: Handbook of Thermal Spray Technology. ASM International, Materials Park (2005)

Fauchais, P.L.; Heberlein, J.V., Boulos, M.I.: Overview of thermal spray. Thermal Spray Fundamentals. 17–72 (2013)

McDonald, A.; Lamontagne, M.; Moreau, C.; Chandra, S.: Impact of plasma-sprayed metal particles on hot and cold glass surfaces. Thin Solid Films 514, 212–222 (2006)

Dewar, M.P.; McDonald, A.G.; Gerlich, A.P.: Interfacial heating during low-pressure cold-gas dynamic spraying of aluminum coatings. J. Mater. Sci. 47, 184–198 (2012)

Schmidt, T.; Gärtner, F.; Assadi, H.; Kreye, H.: Development of a generalized parameter window for cold spray deposition. Acta Mater. 54, 729–742 (2006)

Fauchais, P.; Fukumoto, M.; Vardelle, A.; Vardelle, M.: Knowledge concerning splat formation: an invited review. J. Therm. Spray Technol. 13, 337–360 (2004)

McNaughton, T.G.; Horch, K.W.: Metallized polymer fibers as leadwires and intrafascicular microelectrodes. J. Neurosci. Methods 70, 103–107 (1996)

Siegel, J.; Kotál, V.: Preparation of thin metal layers on polymers. Acta Polytechnica (2007). https://doi.org/10.14311/904

Duguet, T.; Senocq, F.; Laffont, L.; Vahlas, C.: Metallization of polymer composites by metalorganic chemical vapor deposition of Cu: Surface functionalization driven films characteristics. Surf. Coat. Technol. 230, 254–259 (2013)

Gritsenko, K.P.: Metal-polymer optical storage media produced by PECVD. Thin Solid Films 227, 1–2 (1993)

Voyer, J.; Schulz, P.; Schreiber, M.: Electrically conductive flame sprayed aluminum coatings on textile substrates. J. Therm. Spray Technol. 17, 818–823 (2008)

Pawłowski, L.: The Science and Engineering of thermal spray coatings. Wiley, Chichester (2008)

Therrien, D.S.: Heat transfer analysis of flame-sprayed metal-polymer composite structures. Library and Archives Canada = Bibliothèque et Archives Canada, Ottawa (2013)

Fauchais, P.; Montavon, G.: Thermal and cold spray: recent developments. Key Eng. Mater. 384, 1–59 (2008)

Katsoulis, C.; Kandola, B.K.; Myler, P.; Kandare, E.: Post-fire flexural performance of epoxy-nanocomposite matrix glass fibre composites containing conventional flame retardants. Compos. A Appl. Sci. Manuf. 43, 1389–1399 (2012)

Vijay, M.; Selvarajan, V.; Yugeswaran, S.; Ananthapadmanabhan, P.V.; Sreekumar, K.P.: Effect of spraying parameters on deposition efficiency and wear behavior of plasma sprayed alumina-titania composite coatings. Plasma Sci. Technol 11, 666–673 (2009)

Meghwal, A., et al.: Thermal Spray High-Entropy Alloy Coatings: A Review. J. Therm. Spray Technol. 29, 857–893 (2020)

Alkhimov, A. P., Papyrin, A. N., Kosarev, V. F., Nesterovich, N. I., & Shushpanov, M. M.: U.S. Patent No. 5,302,414 (1994)

Darabi, A.; Azarmi, F.: Investigation on relationship between microstructural characteristics and mechanical properties of wire-arc-sprayed Zn-Al coating. J. Therm. Spray Technol. 29, 297–307 (2020)

Gusev, V.M.; Nesterenko, N.S.; Il’ichev, M.V.; Konovalov, P.A.; Tyuftyaev, A.S.: Study of coating corrosion resistance for shelf structural objects and oil industry equipment. Chem. Petrol. Eng. 53, 745–749 (2018)

Papyrin, A.; Fomin, V.M.; Alkhimov, A.; Klinkov, S.; Kosarev, V.: Cold Spray Technology. Elsevier, Oxford (2007)

Bulnes, A.G.; Fuentes, V.A.; Cano, I.G.; Dosta, S.: Understanding the influence of high velocity thermal spray techniques on the properties of different anti-wear wc-based coatings. Coatings 10, 1–17 (2020)

Ang, A.S.M.; Berndt, C.C.: A review of testing methods for thermal spray coatings. Int. Mater. Rev. 59, 179–223 (2014)

Singh, L.; Chawla, V.; Grewal, J.S.: A review on detonation gun sprayed coatings. J. Min. Mater. Characteriz. Eng. 11, 243–265 (2012)

SudharshanPhani, P.; Srinivasa Rao, D.; Joshi, S.V.; Sundararajan, G.: Effect of process parameters and heat treatments on properties of cold sprayed copper coatings. J. Therm. Spray Technol. 16, 425–434 (2007)

Szala, M.; Łatka, L.; Awtoniuk, M.; Winnicki, M.; Michalak, M.: Neural modelling of aps thermal spray process parameters for optimizing the hardness, porosity and cavitation erosion resistance of Al2O3–13 wt% TiO2 coatings. Processes 8, 1–15 (2020)

Kumar, S.; Handa, A.; Chawla, V.; Grover, N.K.; Kumar, R.: Performance of thermal-sprayed coatings to combat hot corrosion of coal-fired boiler tube and effect of process parameters and post-coating heat treatment on coating performance: a review. Surf. Eng. 37, 833–860 (2021)

Vishnoi, M.; Kumar, P.; Murtaza, Q.: A review on coating for hydro-turbine application by HVOF process. Adv. Mater. Eng. Manuf. Process. (2020). https://doi.org/10.1007/978-981-15-4331-9_8

Bhati, P.; Shrama, V.; Jha, R.; Gupta, S.; Vishnoi, M.; Mamatha, T.G.: The coatings developed by thermal spraying technique for hydroturbine applications—a brief review. Lecture Notes Mech. Eng. (2021). https://doi.org/10.1007/978-981-16-0159-0_50

Tripathi, A.; Pandey, A.; Rathore, A.; Singh, A.; Vishnoi, M.: Study on tribological behavior of HVOF developed coatings especially for Hydroturbine Runner application—a concise review. Lecture Notes Mech. Eng. (2021). https://doi.org/10.1007/978-981-16-0159-0_51

Hang, Z.Q.; Xi, N.Y.; Liu, Y.; Liu, Y.; Chen, H.: High-temperature oxidation behavior of HVOF-sprayed rare earth-modified WC–12Co coating. Rare Met. (2018). https://doi.org/10.1007/s12598-018-1075-1

Liu, Y., et al.: Effects of rare earth elements on the microstructure and mechanical properties of HVOF-sprayed WC-Co coatings. J. Therm. Spray Technol. 23, 1225–1231 (2014)

Liu, Y., et al.: Erosion-corrosion property of CeO2-modified HVOF WC-Co coating. J. Therm. Spray Technol. 25, 815–822 (2016)

Sharma, S.P.; Dwivedi, D.K.; Jain, P.K.: Effect of CeO2 addition on the microstructure, hardness, and abrasive wear behaviour of flame-sprayed Ni-based coatings. Proc. Inst. Mech. Eng. Part J 222, 925–933 (2008)

Sharma, S.P.; Dwivedi, D.K.; Jain, P.K.: Effect of La2O3 addition on the microstructure, hardness and abrasive wear behavior of flame sprayed Ni based coatings. Wear 267, 853–859 (2009)

American Society for Testing and Materials (ASTM).: Standard test methods for determining area percentage porosity in thermal sprayed coatings, ASTM E2109–01 (2014)

Wenzel, R.N.: Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 28, 988–994 (1936)

Cassie, A.B.; Baxter, S.: Wettability of porous surfaces. Trans. Faraday Soc. 40, 546 (1944)

Liu, W., et al.: Fabrication of the superhydrophobic surface on aluminum alloy by anodizing and polymeric coating. Appl. Surf. Sci. 264, 872–878 (2013)

Vishnoi, M.; Muthupandi, V.; Murugan, S.S.: Characterization of hydrophobic coating developed by micro arc oxidation on AA2014 alloy. Indian J. Eng. Mater. Sci. 24, 325–330 (2017)

Vishnoi, M.; Kumar, P.; Murtaza, Q.: Surface texturing techniques to enhance tribological performance: a review. Surf. Interfaces. 27, 101463 (2021)

Barthlott, W.; Neinhuis, C.: Purity of the sacred lotus, or escape from contamination in biological surfaces. Planta 202, 1–8 (2017)

Zhang, Y.: The effect of surface roughness parameters on contact and wettability of solid surfaces. (2007)

de Foggi, C.C.; Machado, A.L.; Zamperini, C.A.; Fernandes, D.; Wady, A.F.; Vergani, C.E.: Effect of surface roughness on the hydrophobicity of a denture-base acrylic resin and candida albicans colonization. J. Investig. Clin. Dent. 7, 141–148 (2014)

Kittu, A. T.; Bulut, R.; Puckette, J.: Effects of Surface Roughness on Contact Angle Measurements on a Limestone Aggregate. in 1–8 (American Society of Civil Engineers (ASCE), (2014). https://doi.org/10.1061/9780784478493.001

Acknowledgements

The author wants to thank the JSS Academy of Technical Education, Noida, India for allowing me to pursue Ph.D. from the Department of Mechanical Engineering, Delhi Technological University, Delhi 110042, India. The author would like to thank Precision Manufacturing Lab at Delhi Technological University, Delhi, Metallizing Equipment Company Pvt. Ltd. Jodhpur for the fabrication of the coating, and the Indian Institute of Technology, Kanpur for helping us in the Characterization (Mechanical and Surface) of the coating.

Funding

No funding has been involved in this work.

Author information

Authors and Affiliations

Contributions

MV: conceptualization, investigation, data curation, writing—original draft. PK: review and editing, supervision. QM: review and editing, supervision.

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vishnoi, M., Murtaza, Q. & Kumar, P. Mechanical and Surface Wettability Analysis of Rare Earth Modified Composite Coating Developed Using Metal Spraying. Arab J Sci Eng 49, 2065–2076 (2024). https://doi.org/10.1007/s13369-023-08115-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-023-08115-x