Abstract

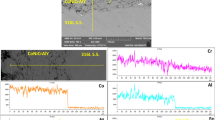

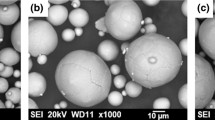

Aluminide intermetallics with superior mechanical and thermal properties can be produced using various techniques. Laser-remelted coating surfaces provide lower porosity and superior adhesion to the substrate. In the present study, Fe and Al powders were sprayed on the 316L stainless steel substrate using high-velocity oxygen liquid fuel (HVOLF) technique. The produced composite coating was subjected to laser heat treatment for the remelting of the coating layer. HVOLF Fe/Al coating, the remelted coating and the substrate were exposed to isothermal oxidation tests at 950 °C for 5, 25, 50 and 100 h. Before and after the oxidation tests, the samples were characterized using x-ray diffraction, scanning electron microscopy (SEM) and SEM elemental mapping analysis. Fe and Al were alloyed with the substrate via laser melting, and thus, an alumina-forming surface layer was obtained. Besides, the surface hardness of the substrate was increased by the remelting process. After the oxidation tests, the obtained results showed that the laser-remelted coating exhibits better oxidation performance compared to the substrate material and HVOLF Fe/Al coating with the effect of the formation of the protective alumina oxide layer.

Similar content being viewed by others

References

M.R. Dorfman, Thermal Spray Coatings, Handbook of Environmental Degradation of Materials, M. Kutz, Ed., William Andrew Publishing, 2005, p 405–422

L. Pawlowski, The Science and Engineering of Thermal Spray Coatings, 2nd ed., Wiley, New York, 2008

H. Singh, M.S. Grewal, H.S. Sekhon, and R.G. Rao, Sliding Wear Performance of High-Velocity Oxy-Fuel Spray A12O3/TiO2 and Cr2O3 Coatings, Proc. Inst. Mech. Eng. Part J J. Eng. Tribol., 2008, 222(4), p 601–610. https://doi.org/10.1243/13506501jet362

M.E. Aalamialeagha, S.J. Harris, and M. Emamighomi, Influence of the HVOF Spraying Process on the Microstructure and Corrosion Behaviour of Ni-20%Cr Coatings, J. Mater. Sci., 2003, 38(22), p 4587–4596

T. Sudaprasert, P.H. Shipway, and D.G. McCartney, Sliding Wear Behaviour of HVOF Sprayed WC-Co Coatings Deposited with Both Gas-Fuelled and Liquid-Fuelled Systems, Wear, 2003, 255(7-12), p 943–949

J.A. Cabral-Miramontes, C. Gaona-Tiburcio, F. Almeraya-Calderón, F.H. Estupiñan-Lopez, G.K. Pedraza-Basulto, and C.A. Poblano-Salas, Parameter Studies on High-Velocity Oxy-Fuel Spraying of CoNiCrAlY Coatings Used in the Aeronautical Industry, Int. J. Corros., 2014, 2014, p 1–8

B. Song, M. Bai, K.T. Voisey, and T. Hussain, Role of Oxides and Porosity on High-Temperature Oxidation Of Liquid-Fueled HVOF Thermal-Sprayed Ni50Cr Coatings, J. Therm. Spray Technol., 2017, 26, p 554–568

M. Vostrák, M. Hruška, and Š. Houdková, Laser Re-melting of HVOF Sprayed NiCrBSi Coatings, in METAL 2013—22nd International Conference on Metallurgy and Materials, Conference Proceedings (2013) pp. 921–925

I.D. Utu and G. Marginean, Effect of Electron Beam Remelting on the Characteristics of HVOF sprayed Al2O3-TiO2 Coatings Deposited on Titanium Substrate, Colloids Surf. A Physicochem. Eng. Asp., 2017, 526, p 70–75

M. Afzal, M. Ajmal, A. Nusair Khan, A. Hussain, and R. Akhter, Surface Modification of Air Plasma Spraying WC-12%Co Cermet Coating by Laser Melting Technique, Opt. Laser Technol., 2014, 56, p 202–206

E. Yasa, J. Deckers, and J.P. Kruth, The Investigation of the Influence of Laser Re-melting on Density, Surface Quality and Microstructure of Selective Laser Melting Parts, Rapid Prototyp. J., 2011, 17(5), p 312–327

R. González, M. Cadenas, R. Fernández, J.L. Cortizo, and E. Rodríguez, Wear Behaviour of Flame Sprayed NiCrBSi Coating Remelted by Flame or by Laser, Wear, 2007, 262(3-4), p 301–307

Z. Brytan, M. Bonek, L.A. Dobrzański, D. Ugues, and M.A. Grande, The Laser Surface Remelting of Austenitic Stainless Steel, Mater. Sci. Forum, 2010, 654–656, p 2511–2514

Q. Han and Y. Jiao, Effect of Heat Treatment and Laser Surface Remelting on AlSi10Mg Alloy Fabricated by Selective Laser Melting, Int. J. Adv. Manuf. Technol., 2019, 102(9-12), p 3315–3324. https://doi.org/10.1007/s00170-018-03272-y

Z. Wang, Q. Zhang, P. Guo, X. Gao, L. Yang, and Z. Song, Effects of Laser Surface Remelting on Microstructure and Properties of Biodegradable Zn-Zr Alloy, Mater. Lett., 2018, 226, p 52–54

M. Rakhes, E. Koroleva, and Z. Liu, Improvement of Corrosion Performance of HVOF MMC Coatings by Laser Surface Treatment, Surf. Eng., 2011, 27(10), p 729–733. https://doi.org/10.1179/1743294411Y.0000000001

H.T. Wang, C.J. Li, G.J. Yang, and C.X. Li, Effect of Heat Treatment on the Microstructure and Property of Cold-Sprayed Nanostructured FeAl/Al2O3 Intermetallic Composite Coating, Vacuum, 2008, 83(1), p 146–152

C. Senderowski, Nanocomposite Fe-Al Intermetallic Coating Obtained by Gas Detonation Spraying of Milled Self-Decomposing Powder, J. Therm. Spray Technol., 2014, 23(7), p 1124–1134

T. Chmielewski, P. Siwek, M. Chmielewski, A. Piątkowska, A. Grabias, and D. Golański, Structure and Selected Properties of Arc Sprayed Coatings Containing In-situ Fabricated Fe-Al Intermetallic Phases, Metals (Basel), 2018, 8(12), p 1059. https://doi.org/10.3390/met8121059

Q. Zhang, C.J. Li, X.R. Wang, Z.L. Ren, C.X. Li, and G.J. Yang, Formation of NiAl Intermetallic Compound by Cold Spraying of Ball-Milled Ni/Al Alloy Powder Through Postannealing Treatment, J. Therm. Spray Technol., 2008, 17, p 715–720

H.Y. Lee, S.H. Jung, S.Y. Lee, and K.H. Ko, Fabrication of Cold Sprayed Al-Intermetallic Compounds Coatings by Post Annealing, Mater. Sci. Eng. A, 2006, 433(1-2), p 139–143

H.T. Wang, C.J. Li, G.J. Yang, and C.X. Li, Cold Spraying of Fe/Al Powder Mixture: Coating Characteristics and Influence of Heat Treatment on the Phase Structure, Appl. Surf. Sci., 2008, 255(5 PART 1), p 2538–2544

T. Chmielewski and D.A. Golański, New Method of In-situ Fabrication of Protective Coatings Based on Fe-Al Intermetallic Compounds, Proc. Inst. Mech. Eng. Part B J. Eng. Manuf., 2011, https://doi.org/10.1177/2041297510394050

H. Buscail, R. Rolland, and S. Perrier, Cyclic Oxidation of AISI, 316L Stainless Steel—Influence of Water Vapour Between 800 and 1000 °C, Corros. Eng. Sci. Technol., 2014, 49(3), p 169–179. https://doi.org/10.1179/1743278213y.0000000111

Y.Z. Liu, X.B. Hu, S.J. Zheng, Y.L. Zhu, H. Wei, and X.L. Ma, Microstructural Evolution of the Interface Between NiCrAlY Coating and Superalloy During Isothermal Oxidation, Mater. Des., 2015, 2015(80), p 63–69

N. Pilling and R. Bedworth, The Oxidation of Metals at High Temperatures, J. Inst. Met., 1923, 29, p 529

M. Daroonparvar, M.A.M. Yajid, N.M. Yusof, M.S. Hussain, and H.R.B. Rad, Formation of a Dense and Continuous Al2O3 Layer in nano thermal barrier coating systems for the Suppression of Spinel Growth on the Al2O3 Oxide Scale During Oxidation, J. Alloys Compd., 2013, 571, p 205–220

K. Messaoudi, A.M. Huntz, and B. Lesage, Diffusion and Growth Mechanism of Al2O3 Scales on Ferritic Fe-Cr-Al Alloys, Mater. Sci. Eng. A, 1998, 247(1-2), p 248–262

M.P. Brady, Y. Yamamoto, M.L. Santella, and B.A. Pint, Effects of Minor Alloy Additions and Oxidation Temperature on Protective Alumina Scale Formation in Creep-Resistant Austenitic Stainless Steels, Scr. Mater., 2007, 57(12), p 1117–1120

M.P. Brady, J. Magee, Y. Yamamoto, D. Helmick, and L. Wang, Co-Optimization of Wrought Alumina-Forming Austenitic Stainless Steel Composition Ranges for High-Temperature Creep and Oxidation/Corrosion Resistance, Mater. Sci. Eng. A, 2014, 590, p 101–115

X. Guo, K. Chen, W. Gao, Z. Shen, and L. Zhang, Corrosion Behavior of Alumina-Forming and Oxide Dispersion Strengthened Austenitic 316 Stainless Steel in Supercritical Water, Corros. Sci., 2018, 138, p 297–306

T. Yener, K.M. Doleker, and A. Erdogan, High Temperature Oxidation Behavior of Low Temperature Aluminized Mirrax® ESR Steel, Mater. Res. Express, 2019, 6, p 116407

K.M. Doleker, Y. Ozgurluk, H. Ahlatci, and A.C. Karaoglanli, Evaluation of Oxidation and Thermal Cyclic Behavior of YSZ, Gd2Zr2O7 and YSZ/Gd2Zr2O7 TBCs, Surf. Coat. Technol., 2019, 371, p 262–275. https://doi.org/10.1016/j.surfcoat.2018.11.055

H.J. Grabke, Oxidation of NiAl and FeAl, Intermetallics, 1999, 7(10), p 1153–1158

J.M. Guilemany, N. Cinca, S. Dosta, and C.R.C. Lima, High-Temperature Oxidation of Fe40Al Coatings Obtained by HVOF Thermal Spray, Intermetallics, 2007, 15(10), p 1384–1394

Z. Liu, W. Gao, and F. Wang, Oxidation Behaviour of FeAl Intermetallic Coatings Produced by Magnetron Sputter Deposition, Scr. Mater., 1998, 39(11), p 1497–1502. https://doi.org/10.1016/S1359-6462(98)00360-1

X. Xu, H. Wei, J. Xiang, L. Wang, M. Liu, H. Zhang, D. Men, and J. An, Oxidation Mechanism of Three Fe-Al Alloys with and Without Addition of 0.1 At% Y at 800 °C, J. Rare Earths (2019). https://doi.org/10.1016/j.jre.2019.10.007

P. Guo, Y. Shao, C. Zeng, M. Wu, and W. Li, Oxidation Characterization of FeAl Coated 316 Stainless Steel Interconnects by High-Energy Micro-Arc Alloying Technique for SOFC, Mater. Lett., 2011, 65(19-20), p 3180–3183

A.M. Hodge and D.C. Dunand, Synthesis of Nickel-Aluminide Foams by Pack-Aluminization of Nickel Foams, Intermetallics, 2001, 9(7), p 581–589

E. Huttunen-Saarivirta, F.H. Stott, V. Rohr, and M. Schütze, Erosion-Oxidation Behaviour of Pack-Aluminized 9% Chromium Steel Under Fluidized-Bed Conditions at Elevated Temperature, Corros. Sci., 2007, 49(7), p 2844–2865

B.A. Pint, W.D. Porter, and I.G. Wright, The Effect of Thermal Expansion on Spallation Behavior of Fe-Base Alumina-Forming Alloys, Mater. Sci. Forum, 2008, 595–598, p 1083–1092

P.Y. Hou, The Reactive Element Effect—Past, Present and Future, Mater. Sci. Forum, 2011, 696, p 39–44

K. Przybylski, S. Chevalier, P. Juzoń, A. Galerie, G. Borchardt, O. Heintz, and J.P. Larpin, The Role of Zr in the High-Temperature Oxidation of Fe3Al, Mater. Sci. Forum, 2008, 595–598, p 1103–1110

A. Hotař, P. Kejzlar, M. Palm, and J. Mlnařík, The Effect of Zr on High-Temperature Oxidation Behaviour of Fe3Al-Based Alloys, Corros. Sci., 2015, 100, p 147–157

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Doleker, K.M. The Examination of Microstructure and Thermal Oxidation Behavior of Laser-Remelted High-Velocity Oxygen Liquid Fuel Fe/Al Coating. J. of Materi Eng and Perform 29, 3220–3232 (2020). https://doi.org/10.1007/s11665-020-04873-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04873-z