Abstract

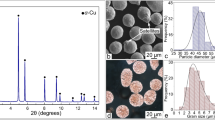

Low-pressure cold spraying was used to deposit aluminum particles (~25 μm diameter) on to low carbon steel, and the particle–particle interactions of the aluminum coating were analyzed. A simplified energy conservation model was developed to estimate the temperature at the interface of the deformed particle during deposition of the powder. The Johnson–Cook model was used to calculate the particle flow stress, which was used to estimate the total energy dissipated via plastic deformation during impact and spreading of the particle. Microstructural analysis was conducted to show that plastic deformation occurred mainly at the interfacial regions of the deformed particles. By coupling microstructural observations of the cold-sprayed particles with the energy conservation model, it was found that the interface between the aluminum particles contained recrystallized ultra-fine and nanocrystalline grain structures that were likely formed at temperatures above 260 °C, but the majority of particles likely achieved interfacial temperatures which were lower than the melting point of aluminum (660 °C). This suggests that local melting is not likely to dominate the inter-particle bonding mechanism, and the resulting interfacial regions contain ultra-fine grain structures, which significantly contribute to the coating hardness.

Similar content being viewed by others

Abbreviations

- A :

-

Yield stress (MPa)

- A p :

-

Projected area normal to gas flow (m2)

- A s :

-

Surface area of particle (m2)

- B :

-

Johnson–Cook strain hardening constant (Pa)

- Bi :

-

Biot number

- c p :

-

Specific heat capacity (J kg−1 K−1)

- C :

-

Johnson–Cook strain rate constant

- C D :

-

Drag coefficient

- d p :

-

Particle diameter (m)

- d splat :

-

Splat diameter, after spreading (m)

- D nozzle :

-

Nozzle diameter (m)

- E k :

-

Kinetic energy (J)

- E p :

-

Plastic deformation energy (J)

- h :

-

Heat transfer coefficient (W m−2 K−1)

- k :

-

Thermal conductivity (W m−1 K−1)

- k g :

-

Thermal conductivity of free stream carrier gas (W m−1 K−1)

- L x :

-

Distance traveled by particle (m)

- m p :

-

Particle mass (kg)

- M :

-

Mach number

- n :

-

Hardening exponent

- Nu :

-

Nusselt number, Nu = hd p/k g

- P g :

-

Absolute gas pressure (Pa)

- Pr :

-

Prandtl number, Pr = c p μ/k g

- r :

-

Recovery factor

- R :

-

Gas constant (kJ kg−1 K−1)

- \( Re_{{d_{\text{p}} }} \) :

-

Reynolds number based on particle diameter, \( Re_{{d_{\text{p}} }} = \rho_{\text{g}} (V_{\text{g}} - V_{\text{p}} )d_{\text{p}} /\mu_{\text{g}} \)

- t c :

-

Contact time (s)

- t i :

-

Time at iteration i

- t x :

-

Time traveled by particle (s)

- T aw :

-

Adiabatic-wall temperature (K)

- T g :

-

Free stream carrier gas temperature (K)

- T i :

-

Temperature at increment i (K)

- T initial :

-

Initial particle temperature prior to impact (K)

- T interface :

-

Particle–substrate interface temperature (°C)

- T bulk :

-

Temperature in the interior of the particle during deformation (°C)

- T m :

-

Melting temperature (K)

- T o :

-

Ambient temperature (K)

- T sub :

-

Temperature of substrate (K)

- V g :

-

Carrier gas velocity (m/s)

- V i :

-

Particle velocity at increment i

- V p :

-

Particle velocity (m/s)

- X :

-

Nozzle length (m)

- α:

-

Thermal diffusivity (m2s−1)

- γ:

-

Specific heat ratio

- δ:

-

Lamellae thickness (m)

- εf :

-

Final von Mises equivalent strain

- εi :

-

Equivalent strain at increment i

- ε i *:

-

Strain rate at increment i

- θ:

-

Non-dimensional interface temperature

- μg :

-

Viscosity of free stream carrier gas (kg m−1 s−1)

- μs :

-

Viscosity of gas at particle surface (kg m−1 s−1)

- μo :

-

Reference viscosity of gas (kg m−1 s−1)

- ξ:

-

Non-dimensional particle diameter

- ρ:

-

Particle/splat density (kg m−3)

- ρg :

-

Gas density (kg m−3)

- σ:

-

Von Mises equivalent flow stress (Pa)

- Ω:

-

Particle volume (m3)

- Ωsplat :

-

Volume of a particle after impact and deformation on the substrate (m3)

References

Alkhimov A, Kosarev V, Papyrin A (1990) Dokl Akad Nauk SSSR 315:1062

Schmidt T, Gärtner F, Assadi H, Kreye H (2006) Acta Mater 54:729

Klinkov S, Kosarev V, Rein M (2005) Aerosp Sci Technol 9:582

Grujicic M (2007) In: Champagne V (ed) Fundamentals of cold-gas dynamic spray. Woodhead Publishing Limited, London

Assadi H, Gartner F, Stoltenhoff T, Kreye H (2003) Acta Mater 51:4379

Papyrin A, Kosarev V, Klinkov S, Alkhimov A, Fomin V (2007) Cold spray technology. Elsevier, Amsterdam

Tokarev A (1996) Met Sci Heat Treat 38:136

Vlcek J, Gimeno L, Huber H, Lugscheider E (2003) In: International thermal spray conference 2003: advancing the science and applying the technology, Orlando

Zhang D, Shipway PH, McCartney DG (2003) In: International thermal spray conference 2003: advancing the science and applying the technology, Orlando

Li C-J, Li W-Y, Xi’an PRC, Fukanuma H, Saitama J (2004) In: International thermal spray conference 2004: advances in technology and application, Osaka

Vlcek J, Gimeno L, Huber H, Lugscheider E (2005) J Therm Spray Technol 14(1):125

Hussain T, McCartney D, Shipway P, Zhang D (2009) J Therm Spray Technol 18:364

Schmidt T, Assadi H, Gärtner F, Richter H, Stoltenhoff T, Kreye H, Klassen T (2009) J Therm Spray Technol 18:794

Barradas S, Guipont V, Molins R, Jeandin M, Arrigoni M, Boustie M, Bolis C, Berthe L, Ducos M (2007) J Therm Spray Technol 16:548

King P, Zahiri S, Jahedi M (2008) Acta Mater 56:5617

Borchers C, Gartner F, Stoltenhoff T, Kreye H (2004) J Appl Phys 96:4288

Zou Y, Qin W, Irissou E, Legoux J-G, Yue S, Szpunar J (2009) Scr Mater 61:899

Li C, Li W, Wang Y (2005) Surf Coat Technol 198:469

Hall A, Brewer L, Roemer T (2008) J Therm Spray Technol 17:352

Koch C (2007) Structural nanocrystalline materials: fundamentals and applications. Cambridge University Press, Cambridge

Ajdelsztajn L, Jodoin B, Kim G, Schoenung J (2005) Metall Mater Trans A 36A:657

Grujicic M, Zhao C, DeRosset W, Helfritch D (2004) Mater Des 25:681

Goldbaum D, Chromik R, Yue S, Irissou E, Legoux J-G (2011) J Therm Spray Technol 20:486

Borchers C, Gärtner F, Stoltenhoff T, Assadi H, Kreye H (2003) J Appl Phys 93:10064

Kapoor R, Nemat-Nasser S (1998) Mech Mater 27:1

Johnson G, Cook W (1983) In: 7th international symposium on ballistics, The Hague

Raybould D (1981) J Mater Sci 16:589. doi:10.1007/BF02402774

Jiji L (2009) Heat conduction, 3rd edn. Springer, Berlin

Shapiro A (1953) The dynamics and thermodynamics of compressible fluid flow, vol I. The Ronald Press Company, New York

Kaye J (1954) J Aeronaut Sci 21:117

Shapiro A (1954) The dynamics and thermodynamics of compressible fluid flow, vol II. The Ronald Press Company, New York

Dykhuizen R, Smith M (1998) J Therm Spray Technol 7:205

Legoux J-G, Irissou E, Moreau C (2007) J Therm Spray Technol 16:619

Akarca S, Song X, Altenhof W, Alpas A (2008) Proc Inst Mech Eng L 222:209

Boyer H, Gall T (1985) Metals Handbook, vol 2. ASM International, Materials Park

Gerlich A, Yue L, Mendez P, Zhang H (2010) Acta Mater 58:2176

Gerlich A, Shibayanagi T (2009) Scr Mater 60:236

Kaibyshev O (2000) Scientific bases, achievements and promises of superplastic deformation. Gilem, Ufa

Humphreys F, Hatherly M (2002) Recrystallization and related annealing phenomena. Pergamon Press, Oxford

Dimitrov O, Fromegeau R, Dimitrov C (1978) In: Haessner F (ed) Recrystallization of metallic materials. Dr. Riederer-verlag GmbH, Stuttgart

Lancaster J (1999) Metallurgy of welding. Abington Publishing, Cambridge

Acknowledgements

Funding for this project was provided by the Natural Sciences and Engineering Research Council of Canada (NSERC), the Government of Alberta Small Equipment Grants Program (SEGP), and the Canada Foundation for Innovation (CFI). The authors gratefully acknowledge the assistance of Dr. Eric Irissou with DPV-2000 measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dewar, M.P., McDonald, A.G. & Gerlich, A.P. Interfacial heating during low-pressure cold-gas dynamic spraying of aluminum coatings. J Mater Sci 47, 184–198 (2012). https://doi.org/10.1007/s10853-011-5786-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5786-z