Abstract

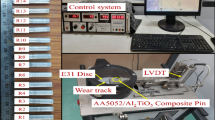

Current research investigates the effect of casehardening, plasma nitriding and T6 heat treatment condition on the dry sliding behaviour of microwave-assisted T6-AA2900-α-Al2O3composite material against aircraft disc material. Composite samples without post-treatment were also considered for the evaluation. Experiments were carried out with a pin-on-disc wear tester at maximum brake operation temperature of 450 °C. The results show that formation of Al4C3 and AlN on the surface and near subsurface influences the coefficient of friction and the specific wear rate regimes close to aircraft brake operating parameters. The developed composite material featuring homogeneously dispersed α-Al2O3, homogeneously nucleated Al4C3exhibits a better behaviour, as compared to surface formed AlN. The results were obtained comparing explicit characteristics (i.e. braking COF-wear and temperature effects) of the surface modification on T6-composite under the aircraft braking conditions. Counter disc characterisation was also carried out to understand the impact of the surface modification, temperature effects and microwave T6 condition.

Similar content being viewed by others

References

Brake Friction Material - Restrictions on Use, Substitute Senate Bill 6557, 2010.

Kumar, M.; Bijwe, J.: Non-asbestos organic (NAO) friction composites: role of copper; its shape and amount. Wear 270, 269–280 (2011). https://doi.org/10.1016/j.wear.2010.10.068

Barros, L.Y.; Poletto, J.C.; Neis, P.D.; Ferreira, N.F.; Pereira, C.H.S.: Influence of copper on automotive brake performance. Wear 426, 741–749 (2019).

Filip, P.; Kovarik, L.; Wright, M.A.: Automotive brake lining characterization. SAE Tech. Pap. Ser. (2010). https://doi.org/10.4271/973024

Chan, D.; Stachowiak, G.W.: Review of automotive brake friction material. Proc. Inst. Mech. Eng. - Part D J. Automob. Eng. 218, 953–966 (2004). https://doi.org/10.1243/0954407041856773

Eriksson, M.; Bergman, F.; Jacobson, S.: On the nature of tribological contact in automotive brakes. Wear 252, 26–36 (2002). https://doi.org/10.1016/S0043-1648(01)00849-3

Osterle, W.; Deutsch, C.; Gradt, T.; Orts-Gil, G.; Schneider, T.; Dmitriev, A.I.: Tribological screening tests for the selection of raw materials for automotive brake pad formulations. Tribol. Int. 73, 148–155 (2014). https://doi.org/10.1016/j.triboint.2014.01.017

Rohatgi PK. 9th edCast metal matrix composites, metal hand book, Vol 15. ASM International; 1988.

Wang, A.; Rack, H.J.: Transition wear behaviour of SiC-particulate and SiC- whisker-reinforced 7091 Al metal matrix composites. Mater. Sci. Eng. A147, 211–224 (1991)

Pan, Y.M.; Fine, M.E.; Gheng, H.S.: Aging effects on the wear behaviour of P/M aluminu alloy SiC particle composite. ScrMetall 24, 1341–1345 (1990)

Pan, Y.M.; Fine, M.E.; Gheng, H.S.: Sliding wear of an alloy SiC whisker composite. Tribol Trans 35, 482–490 (1992)

Ma, B.; Wang, J.; Lee, T.H.; Dorris, S.E.; Wen, J.; Balachandran, U.: Microstructural characterization of Al4C3 in aluminum–graphite composite prepared by electron-beam melting. J. Mater. Sci. 53, 10173–10180 (2018)

Chan, D.S.E.A.; Stachowiak, G.W.: Review of automotive brake friction materials. Proc. Inst. Mech. Eng., Part D: J. Automob. Eng. 218, 953–966 (2004)

Telang, A.K.; Rehman, A.; Dixit, G.; Das, S.: Alternate materials in automobile brake disc applications with emphasis on Al composites–a technical review. J. Eng. Res. Stud. 1, 35–46 (2010)

Tan, C.; Kuang, T.; Zhou, K.; Zhu, H.; Deng, Y.; Li, X.; Cai, P.; Liu, Z.: Fabrication andcharacterization of in-situ duplex plasma-treated nanocrystalline Ti/AlTiNcoatings. Ceram. Int. 42, 10793–10800 (2016)

Enes, A.; Ali, G.; Gökhan, Y.: Effects of cooling rate on strength and microstructure of powder metallurgy superalloys. Period. Eng. Nat. Sci. 5, 15–27 (2017)

Gadow, R.; Jiménez, M.: Carbon fiber-reinforced carbon composites for aircraft brakes. Am. Ceram. Soc. Bull. 98, 28–34 (2019)

Hiremath, A.: A study to evaluate the effect of carburization on LM13 aluminium alloy–quartz composites anupama A. Int. J. Eng. and Technol. (UAE) 7, 145–149 (2018)

Sahin, Y.; Kilicli, V.: Abrasive wear behaviour of SiCp/Al alloy composite in comparison with ausferritic ductile iron. Wear 271(11–12), 2766–2774 (2011)

Miyajima, T.; Iwai, Y.: Effects of reinforcements on sliding wear behavior of aluminum matrix composites. Wear 255(1–6), 606–616 (2003)

Ashwath, P.; Joel, J.; Jeyapandiarajan, P.; Xavior, A.; Rajendran, R.: Frictional property evaluation of aluminium alloy based metal matrix composites under dry braking condition in pin—on—disc system. Mater. Res. Expr. 7(1), 016509 (2019)

Ashwath, P.; Anthony Xavior, M.: Effect of microwave heat treating processing on frictional behaviour of aluminium alloy 2900 composites. Tribol-Mater., Surf. Interf. 12(2), 85–96 (2018)

Yang, L.J.: Wear coefficient equation for aluminium-based matrix composites against steel disc. Wear 255(1–6), 579–592 (2003)

Yang, L.J.: A methodology for the prediction of standard steady-state wear coefficient in an aluminium-based matrix composite reinforced with alumina particles. J. Mater. Process. Technol. 162, 139–148 (2005)

Dileep, B.P.; Vitala, H.R.; Megalingam, A.; Karthik, K.: Mechanical and tribological characterization nitrided Al-7075/Al2O3 metal matrix composites. Period. Eng. Nat. Sci. 6(2), 64–70 (2018)

Darsono, Febri Budi, TeguhTriyono, and EkoSurojo. "The effect of case hardening treatment on aluminum 7075 toward its hardness and tensile strength." In AIP Conference Proceedings, vol. 1931, no. 1, p. 030058. AIP Publishing LLC, 2018.

Guo, B.; Chen, B.; Zhang, X.; Cen, Xi.; Wang, X.; Song, M.; Ni, S.; Yi, J.; Shen, T.; Yong, Du.: Exploring the size effects of Al4C3 on the mechanical properties and thermal behaviors of Al-based composites reinforced by SiC and carbon nanotubes. Carbon 135, 224–235 (2018)

Visuttipitukul, P.; Aizawa, T.; Kuwahara, H.: Feasibility of plasma nitriding for effective surface treatment of pure aluminum. Mater. Trans. 44(7), 1412–1418 (2003)

Bishop, D.P.; Li, X.Y.; Tandon, K.N.; Caley, W.F.: Dry sliding wear behaviour of aluminum alloy 2014 microalloyed with Sn and Ag. Wear 222(2), 84–92 (1998)

HülyaKaçar, D.; Meric, C.: Age-hardening behavior of powder metallurgy AA2014 alloy. Mater Des 28(3), 982–986 (2007)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ashwath, P., Xavior, M.A. Dry Sliding Wear Behaviour of T6-Aluminium Alloy Composites Compared with Existing Aircraft Brake Pads. Arab J Sci Eng 46, 11971–11984 (2021). https://doi.org/10.1007/s13369-021-05770-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-05770-w