Abstract

The current research on hydraulic fracturing with unstable injection mainly focuses on laboratory experiments or field tests. However, due to the difference in scale, some conclusions derived from laboratory experiments are not suitable for field applications. Besides, there is little research on coupling analysis of transient flow in tubing and seepage in reservoir during fracturing. In this paper, the transient dynamic model of fluid in tubing and the model of unsteady seepage in reservoir were established, respectively. Furthermore, the simulation model was established by parameters coupling, which took into account the influence of reservoir breakdown on permeability. The variation of fluid pressure in the tubing of different scale was analyzed during unstable injection. Simultaneously, the amplitude frequency characteristics of fluid in the tubing were also compared between laboratory scale and field scale. The results show that the simulation model can be used to calculate the fluid pressure variation in the whole process of hydraulic fracturing. And the simulation results are basically consistent with the experimental results. The scale difference has a significant impact on the variation of fluid pressure in tubing. To improve the fluctuation amplitude of outlet pressure, it is necessary to design the frequency according to the amplitude frequency characteristics of the corresponding scale model. It can also be achieved by reducing the resistance coefficient. The research can provide guidance for parameters design in field applications. It is conducive to understand the difference between laboratory experiments and field applications.

Similar content being viewed by others

References

Josifovic, A.; Roberts, J.J.; Corney, J.; Bruce, D.; Shipton, Z.K.: Reducing the environmental impact of hydraulic fracturing through design optimisation of positive displacement pumps. Energy 115, 1216–1233 (2016)

Jordan,C.; Debotyam, M.; Iraj, S.: Variable pump rate fracturing leads to improved production in the marcellus shale. In: SPE Hydraulic Fracturing Technology Conference, Texas, USA, 1–11 (2016)

Zhuang, L.; Kim, K.Y.; Jung, S.G.; Jung, S.G.; Diaz, M.; Min, K.B.; Zang, A.; Stephansson, O.; Zimmermann, G.; Yoon, J.S.; Hofmann, H.: Cyclic hydraulic fracturing of pocheon granite cores and its impact on breakdown pressure, acoustic emission amplitudes and injectivity. Int. J. Rock Mech. Min. Sci. 122, 1–8 (2019)

Zhuang, L.; Jung, S.G.; Diaz, M.; Kim, K.Y.; Hofmann, H.; Min, K.B.; Zang, A.; Stephansson, O.; Zimmermann, G.; Yoon, J.S.: Laboratory true triaxial hydraulic fracturing of granite under six fluid injection schemes and grain-scale fracture observations. Rock Mech. Rock Eng. (2020). https://doi.org/10.1007/s00603-020-02170-8

Zhuang, L.; Kim, K.Y.; Jung, S.G.; Diaz, M.; Diaz, M.: Effect of water infiltration, injection rate and anisotropy on hydraulic fracturing behavior of granite. Rock Mech. Rock Eng. 52(2), 575–589 (2019)

Patel, S.M.; Sondergeld, C.H.; Rai, C.S.: Laboratory studies of hydraulic fracturing by cyclic injection. Int. J. Rock Mech. Min. Sci. 95, 8–15 (2017)

Zhou, Z.L.; Zhang, G.Q.; Dong, H.R.; Liu, Z.B.; Nie, Y.X.: Creating a network of hydraulic fractures by cyclic pumping. Int. J. Rock Mech. Min. Sci. 97, 52–63 (2017)

Zhou, Z.L.; Zhang, G.Q.; Xing, Y.K.; Fan, Z.Y.; Zhang, X.; Kasperczyk, D.: A laboratory study of multiple fracture initiation from perforation clusters by cyclic pumping. Rock Mech. Rock Eng 52(3), 827–840 (2019)

Hou, B.; Chen, M.; Li, Z.; Wang, Y.G.; Diao, C.: Propagation area evaluation of hydraulic fracture networks in shale gas reservoirs. Pet. Explor. Dev. 41(6), 833–838 (2014)

Hou, B.; Zhang, R.; Tan, P.; Song, Y.; Fu, W.N.; Chang, Z.; Kao, J.: Characteristics of fracture propagation in compact limestone formation by hydraulic fracturing in central Sichuan. China. J. Nat. Gas Sci. Eng. 57, 122–134 (2018)

Li, Q.; Lin, B.; Zhai, C.: The effect of pulse frequency on the fracture extension during hydraulic fracturing. J. Nat. Gas Sci. Eng. 21, 296–303 (2014)

Zhai, C.; Yu, X.; Xiang, X.; Li, Q.G.; Wu, S.L.; Xu, J.Z.: Experimental study of pulsating water pressure propagation in CBM reservoirs during pulse hydraulic fracturing. J. Nat. Gas Sci. Eng. 25, 15–22 (2015)

Xu, J.Z.; Zhai, C.; Lei, Q.: Mechanism and application of pulse hydraulic fracturing in improving drainage of coalbed methane. J. Nat. Gas Sci. Eng. 40, 79–90 (2017)

Zang, A.; Stephansson, O.; Stenberg, L.; Plenkers, K.; Specht, S.; Milkereit, C.; Kwiatek, G.; Dresen, G.; Zimmermann, G.; Dahm, T.: Hydraulic fracture monitoring in hard rock at 410 m depth with an advanced fluid-injection protocol and extensive sensor array. Geophys. J. Int. 208(2), 790–813 (2017)

Hofmann, H.; Zimmermann, G.; Farkas, M.; Huenges, E.; Zang, A.; Leonhardt, M.; Kwiatek, G.; Patricia, M.G.; Min, B.M.; KB, Fokker P, Westaway, R, Bethmann F, Meier P, Yoon KS, Choi JW, Lee TJ, Kim KY, : First field application of cyclic soft stimulation at the Pohang Enhanced Geothermal System site in Korea Geophys. J. Int 217(2), 926–949 (2019)

Yoon, J.S.; Zimmermann, G.; Zang, A.: Numerical investigation on stress shadowing in fluid injection-induced fracture propagation in naturally fractured geothermal reservoirs. Rock Mech. Rock Eng. 48(4), 1439–1454 (2015)

Yoon, J.S.; Zimmermann, G.: Zang, A: Discrete element modeling of cyclic rate fluid injection at multiple locations in naturally fractured reservoirs. Int. J. Rock Mech. Min. Sci. 74, 15–23 (2015)

Tong, S.K.; Gao, D.L.; Yue, Y.F.: Dynamic response of coiled tubing perforation under unstable fluid injection. Arab. J. Sci. Eng. 44(12), 10467–10480 (2019)

Zou, J.P.; Chen, W.Z.; Yuan, J.Q.; Yang, D.S.; Yang, J.P.: 3-D numerical simulation of hydraulic fracturing in a CBM reservoir. J. Nat. Gas Sci. Eng. 37, 386–396 (2017)

Liu, H.; Zhang, G.M.; Zhang, J.; Biao, F.J.; Wu, H.A.; Wang, X.X.: Friction loss calculation and surface pressure prediction in oil well hydraulic fracturing. Chin. J. of Rock Mech. Eng. 29, 2833–2839 (2010)

Wu, Y.; Huang, Z.; Zhao, K.; Zeng, W.; Gu, Q.X.: Unsteady seepage solutions for hydraulic fracturing around vertical wellbores in hydrocarbon reservoirs. Int. J. Hydrog. Energy. 45(16), 9496–9503 (2020)

He, P.; Xiong, J.Y.; Lu, Z.H.; Pan, L.H.; Qin, D.W.: Study of Pulse wave propagation and attenuation mechanism in shale reservoirs during pulse hydraulic fracturing. Arab. J. Sci. Eng. 43(11), 6509–6522 (2018)

Liu, W.C.; Liu, Y.W.; Niu, C.C.; Han, G.F.; Wan, Y.Z.: Numerical investigation of a coupled moving boundary model of radial flow in low-permeable stress-sensitive reservoir with threshold pressure gradient. Chin. Phys. B. 25(2), 262–270 (2016)

Ghidaoui, M.S.; Zhao, M.; McInnis, D.A.; Axworthy, D.H.: A review of water hammer theory and practice. Appl. Mech. Rev. 58(1), 49–76 (2005)

Liang, T.B.; Yang, Z.; Zhou, F.J.; Liu, Z.Y.; Qu, H.Y.; Yang, K.: A new approach to predict field-scale performance of friction reducer based on laboratory measurements. J. Petrol. Sci. Eng. 159, 927–933 (2017)

Bergant, A.; Simpson, A.R.; Vitkovsky, J.: Developments in unsteady pipe flow friction modeling. J. Hydraul. Res. 39, 249–257 (2001)

Vitkovsky, J.; Lambert, M.; Simpson, A.; Bergant, A.: Advances in unsteady friction modelling in transient pipe flow. In: The 8th International Conference on Pressure Surges, Hague Netherlands, 1–14 (2000)

Sampath, K.H.S.M.; Perera, M.S.A.; Ranjith, P.G.: Theoretical overview of hydraulic fracturing break-down pressure. J. Nat. Gas Sci. Eng. 58, 251–265 (2018)

Liu, Y.K.; Chang, L.P.; Zhou, F.B.; Tan, D.S.; Liu, L.; Kang, J.H.; Tian, H.: Numerical modeling of gas flow in deformed well casing for the prediction of local resistance coefficients pertinent to longwall mining and its engineering evaluation. Environ. Earth Sci. 76(20), 1–15 (2017)

Wahba, E.M.: On the two-dimensional characteristics of laminar fluid transients in viscoelastic pipes. J. of Fluids and Struct. 68, 113–124 (2017)

Liu, C.F.; Wu, H.M.; Li, F.; Yang, A.M.: Parallel fourth-order Runge-Kutta method to solve differential equations. Int. Conf. Inf. Comput. Appl. 7030, 192–199 (2011)

Acknowledgements

The authors gratefully acknowledge the financial support from Postgraduate Innovation Funding Project of Hebei Province (No. CXZZBS2020052).

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A: Derivation of Mass Conservation Equation

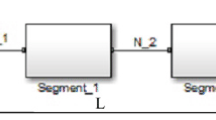

As shown in Fig. 1, based on the principle of mass conservation, the difference between the inflow and outflow mass of the control unit is equal to the mass variation in it within the same unit time.

where A is the cross-sectional area of the tubing, m2.

According to the definition of substantial (material) derivative [24], the following formula can be obtained:

Substitute Eqs. (27) and (28) into Eq. (26)

The state equation of the fluid is as follows

The following formula is obtained by transforming Eq. (31):

The equilibrium relation between the pressure force and the circumferential stress force per unit pipe length can be expressed as [24]

where σ θ is the circumferential stress in the tubing, MPa.

The elastic stress–strain relation

where

Substitute Eqs. (34), (35) and (36) into Eq. (33):

Substituting Eqs. (32) and (37) into Eq. (30), the following formula can be obtained:

According to Eq. (38), the propagation velocity of pressure wave can be expressed as

Substituting Eqs. (29) and (39) into Eq. (38)

Appendix B: Numerical Simulation Method

In order to facilitate programming, the discretized Eqs. (22), (23), and (24) are written as follows:

where y(1) represents ps. y(2) represents vs. y(3) represents pr.

The fourth-order-accurate Runge–Kutta method is then used to integrate Eqs. (41), (42) and (43) in time. This method has good stability and convergence. The calculation formula is as follows [31]:

where

where m is the time node. △t is the time step. f(t,y) represents dy.

The initial conditions are as follows

At the end of each time step, the seepage velocity of fluid in the reservoir is calculated according to the following formula:

The numerical solution follows the flowchart shown in Fig. 3. The calculation formulas in each time step are shown above.

Rights and permissions

About this article

Cite this article

Zhu, G., Dong, S. Coupling Simulation Model of Transient Flow in Tubing and Unsteady Seepage in Reservoir During Hydraulic Fracturing with Unstable Injection. Arab J Sci Eng 47, 10981–10991 (2022). https://doi.org/10.1007/s13369-021-05535-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-05535-5