Abstract

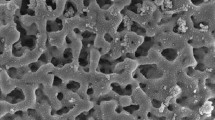

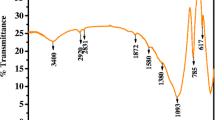

Present invention was indented for characterization and adsorptive (batch and column) treatment of sugar industry distillery spent wash to remove COD (chemical oxygen demand) and color using sugarcane industrial waste, bagasse fly ash (BFA). Distillery spent wash was extremely polluted including acidic pH and very high value of COD, BOD (biological oxygen demand) and color. Sophisticated techniques such as BET (Brunauer–Emmett–Teller) surface area, pore volume, pore diameter, particle size distribution, porosity, FTIR (Fourier-transform infrared spectroscopy), chemical composition by XRF (X-ray fluorescence) and SEM (scanning electron microscopy) were utilized to analyze BFA as an adsorbent and revealed that BFA surface was highly porous and consisted of various oxides. In batch treatment, different process parameters such as contact duration and temperature w.r.t adsorbent dose, thermodynamic studies and isotherms (Langmuir and Freundlich model) were analyzed. Column adsorption was performed using various variables (bed height, particle size distribution and flow rate), breakthrough parameters and isotherms (Thomas, Yoon–Nelson, BDST and Adams and Bohart model). Adsorption capacities were increased with increasing BFA dose, contact duration, temperature, bed height and decreasing flow rate and average particle size. The maximum adsorption capacity of Langmuir and Thomas model was achieved up to 124.5 mg g−1 and 0.1394 mg g−1, respectively, for COD and 109.8 (Hazen L) gm−1 and 0.2547 (Hazen L) gm−1, respectively, for color. Sugar Industry wastewater stream, i.e., distillery spent wash was shown to be feasible using own industrial solid waste, BFA.

Similar content being viewed by others

References

Parkash, A.: Modeling of Ethanol Production from Molasses: A Review. Ind. Chem. 01(02), 1–6 (2015)

Fito, J.; Tefera, N.; Van Hulle, S.W.H.: Sugarcane biorefineries wastewater: bioremediation technologies for environmental sustainability. Chem. Biol. Technol. Agric. (2019). https://doi.org/10.1186/s40538-019-0144-5

Raut, N.B.; Saini, D.K.; Shinde, G.B.: Environmental informatics and soft computing paradigm: processing of cocos nucifera shell derived activated carbon for treatment of distillery spent wash-a solution to environmental issue. Adv. Environ. Chem. (2014). https://doi.org/10.1016/j.jece.2017.10.009

Fito, J.; Tefera, N.; Van Hulle, S.W.H.: Adsorption of distillery spent wash on activated bagasse fly ash: Kinetics and thermodynamics. J. Environl. Chem. Eng. (2017). https://doi.org/10.1016/j.jece.2017.10.009

David, C.; Narlawar, R.; Arivazhagan, M.: Performance evaluation of moringa oleifera seed extract (MOSE) in conjunction with chemical coagulants for treating distillery spent wash. Indian Chem. Eng. (2015). https://doi.org/10.1080/00194506.2015.1006147

Prasad, R.K.: Color removal from distillery spent wash through coagulation using Moringa oleifera seeds: use of optimum response surface methodology. J. Hazard. Mater. (2009). https://doi.org/10.1016/j.jhazmat.2008.10.068

Mohite, D.D.; Salimath, S.S.: Performance optimization of anaerobic continuous stirred-tank reactor operating on distillery spent wash. J. Environ. Eng. (2019). https://doi.org/10.1061/(ASCE)EE.1943-7870.0001570

Nandy, T.; Kaul, S.N.; Pathe, P.P.; Deshpande, C.V.; Daryapurkar, R.A.: Pilot plant studies on fixed bed reactor system for biomethanation of distillery spent wash. Int. J. Environ. Sci. 41(1–2), 87–107 (1992)

David, C.; Arivazhagan, M.; Tuvakara, F.: Decolorization of distillery spent wash effluent by electro oxidation (EC and EF) and Fenton processes: A comparative study. Ecotoxicol. Environ. Saf. (2015). https://doi.org/10.1080/00207239208710748

Srivastava, S.; Bose, P.; Tare, V.: Enhancement of chemical-oxygen demand and color removal of distillery spent-wash by ozonation. Water. Environ. Res. 78(4), 409–420 (2006)

Sharma, P.; Joshi, H.: Membrane autopsy based bio-fouling investigation of distillery spent wash RO treatment plant. Environ. Technol. (2014). https://doi.org/10.1080/21622515.2014.929747

Kumar, A.; Saroj, D.P.; Tare, V.; Bose, P.: Treatment of distillery spent-wash by ozonation and biodegradation: significance of pH reduction and inorganic carbon removal before ozonation. Water Environ. Re.s 78(9), 994–1004 (2006)

Kaur, J.; Singh, H.; Benbi, D.; Sharma, S.; Banta, G.: Effect of Distillery Effluent, Biomethanated Spent Wash, on Microbial Activity Parameters in Soil Under Rice–Wheat Cropping System. Proc. Natl. Acad. Sci. India Sect. B Biol. Sci. (2015). doi: https://doi.org/10.1007/s40011-015-0587-9

Anbarasan, T.; Jayanthi, S.; Ragina, Y.: Investigation on synthesis of biodiesel from distillery spent wash using oleaginous yeast metschnikowia pulcherrima. Mater. Today: Proceedings (2018). https://doi.org/10.1016/j.matpr.2018.11.063

Krishna, S.V.; Kumar, P.K.; Verma, K.; Bhagawan, D.; Himabindu, V.; Narasu, M.L., et al.: Enhancement of biohydrogen production from distillery spent wash effluent using electrocoagulation process. Energ. Ecol. Environ. 4(4), 160–165 (2019)

Balakumar, S.; Arasaratnam, V.: Palmyrah distillery spent wash for ethanol production by a thermotolerant Saccharomyces cerevisiae S1 at 40°C. J. Inst. Brew. 117(3), 451–455 (2011)

Chandra, R.; Kumar, V.: Detection of Bacillus and Stenotrophomonas species growing in an organic acid and endocrine-disrupting chemical-rich environment of distillery spent wash and its phytotoxicity. Environ. Monit. Assess. 189(1), 26 (2017)

Freitas, J.V.; Ruotolo, L.A.M.; Farinas, C.S.: Adsorption of inhibitors using a CO2-activated sugarcane bagasse fly ash for improving enzymatic hydrolysis and alcoholic fermentation in biorefineries. Fuel (2019). https://doi.org/10.1016/j.fuel.2019.04.032

Chingono, K.E.; Sanganyado, E.; Bere, E.; Yalala, B.: Adsorption of sugarcane vinasse effluent on bagasse fly ash: A parametric and kinetic study. J. Environ. Manage. (2018). https://doi.org/10.1016/j.jenvman.2018.07.042

Choosri, S.; Sombatsompop, N.; Wimolmala, E.; Thongsang, S.: Potential use of fly ash and bagasse ash as secondary abrasives in phenolic composites for eco-friendly brake pads applications. P. I. Mech. Eng D-J. Aut. (2018). https://doi.org/10.1177/0954407018772240

Franco-Lujan, V.A.; Maldonado-García, M.A.; Mendoza-Rangel, J.M.; Montes-Garcia, P.: Chloride-induced reinforcing steel corrosion in ternary concretes containing fly ash and untreated sugarcane bagasse ash. Constr. Build Mater. (2019). https://doi.org/10.1016/j.conbuildmat.2018.12.004

Patel, H.: Environmental valorisation of bagasse fly ash: a review. RSC Adv. (2020). https://doi.org/10.1039/D0RA06422J

Rice, E.W.; Baird, R.B.; Eaton, A.D.; Clesceri, L.S.: Standard Methods for Examination of Water and Wastewater, 22nd edn. APHA, AWWA, WEF, Washington (2012)

Patel, H.; Vashi, R.T.: Equilibrium, kinetic and thermodynamic studies on adsorption of reactive dyes onto activated guava leaf powder. Fresenius Environmen. Bull. 20(3), 561–568 (2011)

Zhang, Y.; Jin, F.; Shen, Z.; Lynch, R.; Al-Tabbaa, A.: Kinetic and equilibrium modelling of MTBE (methyl tert-butyl ether) adsorption on ZSM-5 zeolite: Batch and column studies. J. Hazard. Mater. 347, 461–469 (2018)

Unuabonah, E.I.; Olu-Owolabi, B.I.; Fasuyi, E.I.; Adebowale, K.O.: Modeling of fixed-bed column studies for the adsorption of cadmium onto novel polymer-clay composite adsorbent. J. Hazard. Mater. (2010). doi: https://doi.org/10.1016/j.jhazmat.2010.03.020

Gupta, V.K.; Mohan, D.; Sharma, S.: Removal of lead from wastewater using bagasse Fly Ash—A sugar industry waste material. Sep. Sci. Technol. 33(9), 1331–1343 (1998)

Patel, H.; Vashi, R.T.: Adsorption of crystal violet dye onto tamarind seed powder. E-Journal of Chemistry 7(3), 975–984 (2010)

Ahmad, M.A.; Ahmad Puad, N.A.; Bello, O.S.: Kinetic, equilibrium and thermodynamic studies of synthetic dye removal using pomegranate peel activated carbon prepared by microwave-induced KOH activation. Water Resour. Ind. (2014). https://doi.org/10.1016/j.wri.2014.06.002

Patel, H.; Vashi, R.T.: Fixed bed column adsorption of ACID Yellow 17 dye onto tamarind seed powder. Can. J. Chem. Eng. (2012). https://doi.org/10.1002/cjce.20518

Patel, H.: Fixed-bed column adsorption study: a comprehensive review. Appl. Water Sci. 9(3) (2019).

Kaushik, G.; Thakur, I.S.: Adsorption of colored pollutants from distillery spent wash by native and treated fungus: Neurospora intermedia. Environ. Sci. Pollut. R. 20, 1070–1078 (2013)

Jagtap, Y.S.; Kankal, S.B.: Investigation of optimum operating parameters for pollutant removal from distillery spent wash. Int. J. Eng. Res. Technol. 3(7), 1566–1570 (2014)

Venkatachalam, D.; Gounder, S.K.: A composite approach for remediation of cane distillery spent wash using chitosan modified biomass, electrolysis, and Oscillatoria boryana. J. Appl. Polym. Sci. (2017). https://doi.org/10.1002/app.44546

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The author declares no competing interests.

Rights and permissions

About this article

Cite this article

Patel, H. Characterization and adsorptive treatment of distillery spent wash using bagasse fly ash. Arab J Sci Eng 47, 5521–5531 (2022). https://doi.org/10.1007/s13369-021-05497-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-021-05497-8