Abstract

A two-dimensional finite element analysis was adopted to assess the effect of T-stress on predicting crack initiation angle in a quasi-brittle material. Asymmetric semicircular PMMA specimen containing a vertical edge crack subjected to three-point bending was employed. The specimen was assumed as an isotropic and homogeneous material. Relative crack length ratios of 0.3, 0.4, 0.5, 0.6 and 0.7 were examined. Several relative bottom span ratios were included to develop a wide range of mixed-mode I/II loading conditions. The conventional maximum tangential stress (MTS) criterion could not precisely predict the crack initiation angle through the total range of pure mode I to pure mode II. The generalized maximum tangential stress (GMTS) criterion showed a significant effect of T-stress on the numerical prediction of the crack initiation angles in PMMA specimens. In the present study, neglecting the T-stress in the MTS criterion overestimates the crack initiation angle. The numerical predictions using the GMTS criterion showed a good agreement with the relevant experimental data found in the literature. The ability of GMTS in predicting the crack initiation angle is improved by considering the T-stress.

Similar content being viewed by others

Data availability

The numerical data required to reproduce these findings cannot be shared at this time due to technical limitations.

Abbreviations

- ASCB:

-

Asymmetric semicircular bend specimen

- EMTSN:

-

Extended maximum tangential strain

- FE:

-

Finite element

- MTS:

-

Maximum tangential stress

- MTSN:

-

Maximum tangential strain

- GMTS:

-

Generalized maximum tangential stress

- GSED:

-

Generalized strain energy density

- PMMA:

-

Polymethylmethacrylate

- SCB:

-

Semicircular bend specimen

- SED:

-

Minimum strain energy density

- SIF:

-

Stress intensity factor

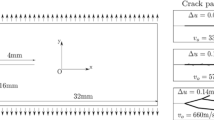

- a :

-

Crack length

- da :

-

Smallest element size

- a/R :

-

Ratio of crack length to disk radius

- E :

-

Modulus of elasticity

- G :

-

Maximum energy release rate

- K I, K II :

-

Mode I and mode II SIFs, respectively

- K IC :

-

Mode I fracture toughness

- M e :

-

Mode mixity parameter

- P :

-

Applied vertical load

- R :

-

Semi-disk radius

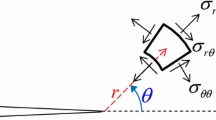

- r, θ :

-

Polar coordinate components

- r c :

-

Fracture process zone size

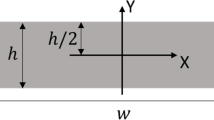

- S 1 , S 2 :

-

Left and right bottom span lengths, respectively

- S 1 /R, S 2 /R :

-

Ratio of left span distance to disk radius and right span distance to disk radius, respectively

- t :

-

Semi-disk thickness

- T* :

-

Normalized T-stress

- Y I , Y II :

-

Mode I and mode II geometry factors, respectively

- ν :

-

Poisson’s ratio

- θ o :

-

Crack initiation angle

- σ t :

-

Uniaxial tensile strength

References

Hammouda, M.M.I.; Fayed, A.S.: Modes I/II SIF of a diametrically compressed Brazilian disc having a central inclined crack with frictional surfaces. Fatigue Fract. Eng. Mater. Struct. 41, 856–868 (2018). https://doi.org/10.1111/ffe.12733

Fayed, A.S.: Numerical analysis of mixed mode I/II stress intensity factors of edge slant cracked plates. Eng. Solid Mech. 5, 61–70 (2017). https://doi.org/10.5267/j.esm.2016.8.001

Aliha, M.R.M.; Hosseinpour, G.R.; Ayatollahi, M.R.: Application of cracked triangular specimen subjected to three-point bending for investigating fracture behavior of rock materials. Rock Mech. Rock Eng. 46, 1023–1034 (2013). https://doi.org/10.1007/s00603-012-0325-z

Hammouda, M.M.I.; Pasha, R.A.; Fayed, A.S.: Modelling of cracking sites/development in axial dovetail joints of aero-engine compressor discs. Int. J. Fatigue 29, 30–48 (2007). https://doi.org/10.1016/j.ijfatigue.2006.02.049

Lim, I.L.; Johnston, I.W.; Choi, S.K.; Boland, J.N.; Introduction, I.: Fracture testing of a soft rock with semi-circular specimens under three-point bending. Part 1-mode I. Int. J. Rock Mech. Min. Sci. 31, 185–197 (1994). https://doi.org/10.1016/0148-9062(94)90463-4

Shahani, A.R.; Tabatabaei, S.A.: Computation of mixed mode stress intensity factors in a four-point bend specimen. Appl. Math. Model. (2008). https://doi.org/10.1016/j.apm.2007.04.001

Chang, S.H.; Lee, C.I.; Jeon, S.: Measurement of rock fracture toughness under modes I and II and mixed-mode conditions by using disc-type specimens. Eng. Geol. 66, 79–97 (2002). https://doi.org/10.1016/S0013-7952(02)00033-9

Khan, K.; Al-Shayea, N.A.: Effect of specimen geometry and testing method on mixed mode I–II fracture toughness of a limestone rock from Saudi Arabia. Rock Mech. Rock Eng. 33, 179–206 (2000). https://doi.org/10.1007/s006030070006

Wei, M.D.; Dai, F.; Xu, N.W.; Liu, J.F.; Xu, Y.: Experimental and numerical study on the cracked chevron notched semi-circular bend method for characterizing the mode I fracture toughness of rocks. Rock Mech. Rock Eng. 49, 1595–1609 (2016). https://doi.org/10.1007/s00603-015-0855-2

Mirsayar, M.M.M.; Berto, F.; Aliha, M.R.M.R.M.; Park, P.: Strain-based criteria for mixed-mode fracture of polycrystalline graphite. Eng. Fract. Mech. 156, 114–123 (2016). https://doi.org/10.1016/j.engfracmech.2016.02.011

Elghazel, A.; Taktak, R.; Bouaziz, J.: Combined numerical and experimental mechanical characterization of a calcium phosphate ceramic using modified Brazilian disc and SCB specimen. Mater. Sci. Eng. A 670, 240–251 (2016). https://doi.org/10.1016/j.msea.2016.06.020

Smith, D.J.; Ayatollahi, M.R.; Pavier, M.J.: On the consequences of T-stress in elastic brittle fracture. Proc. R. Soc. A Math. Phys. Eng. Sci. 462, 2415–2437 (2006). https://doi.org/10.1098/rspa.2005.1639

Chong, K.P.; Kuruppu, M.D.: New specimen for fracture toughness determination for rock and other materials. Int. J. Fract. 26, R59–R62 (1984). https://doi.org/10.1007/BF01157555

Xie, Y.; Cao, P.; Jin, J.; Wang, M.: Mixed mode fracture analysis of semi-circular bend (SCB) specimen: a numerical study based on extended finite element method. Comput. Geotech. 82, 157–172 (2017). https://doi.org/10.1016/j.compgeo.2016.10.012

Kuruppu, M.D.; Obara, Y.; Ayatollahi, M.R.; Chong, K.P.; Funatsu, T.: ISRM-suggested method for determining the mode I static fracture toughness using semi-circular bend specimen. Rock Mech. Rock Eng. 47, 267–274 (2014). https://doi.org/10.1007/s00603-013-0422-7

Kataoka, M.; Mahdavi, E.; Funatsu, T.; Takehara, T.; Obara, Y.; Fukui, K.; Hashiba, K.: Estimation of mode I fracture toughness of rock by semi-circular bend test under confining pressure condition. Procedia Eng. 191, 886–893 (2017). https://doi.org/10.1016/j.proeng.2017.05.258

Wu, P.F.; Liang, W.G.; Li, Z.G.; Cao, M.T.; Yang, J.F.: Investigations on mechanical properties and crack propagation characteristics of coal and sandy mudstone using three experimental methods. Rock Mech. Rock Eng. 50, 215–223 (2017). https://doi.org/10.1007/s00603-016-1048-3

Mahdavi, E.; Obara, Y.; Ayatollahi, M.R.: Numerical investigation of stress intensity factor for semi-circular bend specimen with chevron notc. Eng. Solid Mech. 3, 235–244 (2015). https://doi.org/10.5267/j.esm.2015.7.001

Ayatollahi, M.R.; Aliha, M.R.M.; Saghafi, H.: An improved semi-circular bend specimen for investigating mixed mode brittle fracture. Eng. Fract. Mech. 78, 110–123 (2011). https://doi.org/10.1016/j.engfracmech.2010.10.001

Darban, H.; Haghpanahi, M.; Assadi, A.: Determination of crack tip parameters for ASCB specimen under mixed mode loading using finite element method. Comput. Mater. Sci. 50, 1667–1674 (2011). https://doi.org/10.1016/J.COMMATSCI.2010.12.027

Sutton, M.A.; Deng, X.; Ma, F.; Newman Jr., J.C.; James, M.: Development and application of a crack tip opening displacement-based mixed mode fracture criterion. Int. J. Solids Struct. (2000). https://doi.org/10.1016/s0020-7683(99)00055-4

Hussain, M.; Pu, S.; Underwood, J.: Strain energy release rate for a crack under combined Mode I and Mode II. Fract. Anal. (1974). https://doi.org/10.1520/stp33130s

Khan, S.M.A.; Khraisheh, M.K.: Analysis of mixed mode crack initiation angles under various loading conditions. Eng. Fract. Mech. 67, 397–419 (2000). https://doi.org/10.1016/s0013-7944(00)00068-0

Theocaris, P.S.; Andrianopoulos, N.P.: The T-criterion applied to ductile fracture. Int. J. Fract. (1982). https://doi.org/10.1007/bf01130617

Ma, F.S., Deng, X.M., Sutton, M.A.A., Newman Jr., J.C., Newman, J.C.: A CTOD-based mixed-mode fracture criterion. In: Mixed-mode crack behavior, pp. 86–110 (1999)

Sajjadi, S.H.; Ostad Ahmad Ghorabi, M.J.; Salimi-Majd, D.: A novel mixed-mode brittle fracture criterion for crack growth path prediction under static and fatigue loading. Fatigue Fract. Eng. Mater. Struct. 38, 1372–1382 (2015). https://doi.org/10.1111/ffe.12320

Maiti, S.K.; Smith, R.A.: Criteria for brittle fracture in biaxial tension. Eng. Fract. Mech. 19, 793–804 (1984). https://doi.org/10.1016/0013-7944(84)90162-0

Wu, X.; Li, X.: Analysis and modification of fracture criteria for mixed-mode crack. Eng. Fract. Mech. 34, 55–64 (1989). https://doi.org/10.1016/0013-7944(89)90242-7

Ayatollahi, M.R.; Berto, F.; Campagnolo, A.; Gallo, P.; Tang, K.: Review of local strain energy density theory for the fracture assessment of V-notches under mixed mode loading. Eng. Solid Mech. 5, 113–132 (2017). https://doi.org/10.5267/j.esm.2017.3.001

Berto, F.; Gomez, J.: Notched plates in mixed mode loading (I + II): a review based on the local strain energy density and the cohesive zone model. Eng. Solid Mech. 5, 1–8 (2017). https://doi.org/10.5267/j.esm.2016.11.002

Aliha, M.R.M.; Ayatollahi, M.R.: Mixed mode I/II brittle fracture evaluation of marble using SCB specimen. Procedia Eng. 10, 311–318 (2011). https://doi.org/10.1016/j.proeng.2011.04.054

Ayatollahi, M.R.; Aliha, M.R.M.: On determination of mode II fracture toughness using semi-circular bend specimen. Int. J. Solids Struct. 43, 5217–5227 (2006). https://doi.org/10.1016/j.ijsolstr.2005.07.049

Ayatollahi, M.R.; Aliha, M.R.M.; Hassani, M.M.: Mixed mode brittle fracture in PMMA: an experimental study using SCB specimens. Mater. Sci. Eng. A 417, 348–356 (2006). https://doi.org/10.1016/j.msea.2005.11.002

Ayatollahi, M.R.; Aliha, M.R.M.M.: Mixed mode fracture in soda lime glass analyzed by using the generalized MTS criterion. Int. J. Solids Struct. 46, 311–321 (2009). https://doi.org/10.1016/j.ijsolstr.2008.08.035

Aliha, M.R.M.M.; Ayatollahi, M.R.: Analysis of fracture initiation angle in some cracked ceramics using the generalized maximum tangential stress criterion. Int. J. Solids Struct. 49, 1877–1883 (2012). https://doi.org/10.1016/j.ijsolstr.2012.03.029

Ayatollahi, M.R.; Saboori, B.: T-stress effects in mixed mode I/II/III brittle fracture. Eng. Fract. Mech. 144, 32–45 (2015). https://doi.org/10.1016/j.engfracmech.2015.06.070

Smith, D.J.; Ayatollahi, M.R.; Pavier, M.J.: The role of T-stress in brittle fracture for linear elastic materials under mixed-mode loading. Fatigue Fract. Eng. Mater. Struct. 24, 137–150 (2001). https://doi.org/10.1046/j.1460-2695.2001.00377.x

Mirsayar, M.M.: A new mixed mode fracture test specimen covering positive and negative values of T-stress. Eng. Solid Mech. 2, 67–72 (2014). https://doi.org/10.5267/j.esm.2014.2.006

Mirsayar, M.M.M.; Park, P.: Mixed mode brittle fracture analysis of high strength cement mortar using strain-based criteria. Theor. Appl. Fract. Mech. 86, 233–238 (2016). https://doi.org/10.1016/j.tafmec.2016.07.007

Ayatollahi, M.R.R.; Aliha, M.R.M.R.M.: Fracture toughness study for a brittle rock subjected to mixed mode I/II loading. Int. J. Rock Mech. Min. Sci. 44, 617–624 (2007). https://doi.org/10.1016/j.ijrmms.2006.10.001

Mirsayar, M.M.M.; Joneidi, V.A.A.; Petrescu, R.V.V.V.V.; Petrescu, F.I.T.I.T.; Berto, F.: Extended MTSN criterion for fracture analysis of soda lime glass. Eng. Fract. Mech. 178, 50–59 (2017). https://doi.org/10.1016/j.engfracmech.2017.04.018

Ayatollahi, M.R.R.; Rashidi Moghaddam, M.; Berto, F.: A generalized strain energy density criterion for mixed mode fracture analysis in brittle and quasi-brittle materials. Theor. Appl. Fract. Mech. 79, 70–76 (2015). https://doi.org/10.1016/j.tafmec.2015.09.004

Kaung Jain Chang: On the maximum strain criterion-a new approach to the angled crack problem. Eng. Fract. Mech. 14, 107–124 (1981). https://doi.org/10.1016/0013-7944(81)90021-7

Ayatollahi, M.R.; Abbasi, H.: Prediction of fracture using a strain based mechanism of crack growth. Build. Res. J. 49, 167–180 (2001)

Aliha, M.R.M.; Bahmani, A.; Akhondi, S.: Mixed mode fracture toughness testing of PMMA with different three-point bend type specimens. Eur. J. Mech. A/Solids. 58, 148–162 (2016). https://doi.org/10.1016/j.euromechsol.2016.01.012

Fayed, A.S.: Numerical evaluation of mode I/II SIF of quasi-brittle materials using cracked semi-circular bend specimen. Eng. Solid Mech. 6, 175–186 (2018). https://doi.org/10.5267/j.esm.2018.1.002

Saghafi, H.; Zucchelli, A.; Minak, G.: Evaluating fracture behavior of brittle polymeric materials using an IASCB specimen. Polym. Test. 32, 133–140 (2013). https://doi.org/10.1016/j.polymertesting.2012.09.013

Aliha, M.R.M.R.M.; Berto, F.; Bahmani, A.; Gallo, P.: Mixed mode I/II fracture investigation of Perspex based on the averaged strain energy density criterion. Phys. Mesomech. 20, 149–156 (2017). https://doi.org/10.1134/s1029959917020059

ABAQUS: Analysis user’s guide—Version 6.14. Dassault Systèmes (2013). https://doi.org/10.1177/0886260505276833

Anderson, T.L.: Fracture Mechanics: Fundamentals and Applications. CRC Press, Boca Raton (2017)

Erdogan, F.; Sih, G.C.: On the crack extension in plates under plane loading and transverse shear. J. Basic Eng. 85, 519 (1963). https://doi.org/10.1115/1.3656897

Ayatollahi, M.R.; Aliha, M.R.M.: On the use of Brazilian disc specimen for calculating mixed mode I-II fracture toughness of rock materials. Eng. Fract. Mech. 75, 4631–4641 (2008). https://doi.org/10.1016/j.engfracmech.2008.06.018

Taylor, D.; Merlo, M.; Pegley, R.; Cavatorta, M.P.: The effect of stress concentrations on the fracture strength of polymethylmethacrylate. Mater. Sci. Eng. A 382, 288–294 (2004). https://doi.org/10.1016/j.msea.2004.05.012

Golos, K.; Wasiluk, B.: Role of plastic zone in crack growth direction criterion under mixed mode loading. Int. J. Fract. 102, 341–353 (2000). https://doi.org/10.1023/A:1007663728926

Aliha, M.R.M.; Ayatollah, M.R.; Smith, D.J.; Pavier, M.J.: Geometry and size effects on fracture trajectory in a limestone rock under mixed mode loading. Eng. Fract. Mech. 77, 2200–2212 (2010). https://doi.org/10.1016/j.engfracmech.2010.03.009

Wei, M.D.; Dai, F.; Xu, N.W.; Liu, Y.; Zhao, T.: Fracture prediction of rocks under mode I and mode II loading using the generalized maximum tangential strain criterion. Eng. Fract. Mech. 186, 21–38 (2017). https://doi.org/10.1016/j.engfracmech.2017.09.026

Bahmani, A.; Aliha, M.R.M.: Rock fracture toughness study under mixed mode I/III loading. Rock Mech. Rock Eng. (2017). https://doi.org/10.1007/s00603-017-1201-7

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

See Table 1.

Rights and permissions

About this article

Cite this article

Fayed, A.S. Numerical Analysis of Crack Initiation Direction in Quasi-brittle Materials: Effect of T-Stress. Arab J Sci Eng 44, 7667–7676 (2019). https://doi.org/10.1007/s13369-019-03860-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-019-03860-4