Abstract

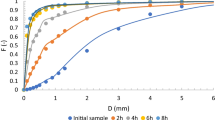

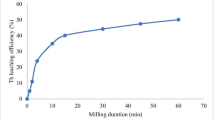

The purpose of this study was to investigate the effect of working volume in the high-energy ball-milling process on the breakage characteristics (i.e., particle size, morphology, and chemical composition) and adsorption performance of rice straw ash. This study was conducted to confirm working volume issue since this parameter has correlations with the scaling-up process, the amount of input/output in the ball-milling process, and the breakage characteristics of the material. Rice straw ash was selected as a model of size-destructed material because this material is porous and chemically and thermally inert; thus, the evaluation can be effectively done without any chemical reaction and time-consuming process. To obtain the outcome precisely, the study varied working volume under constant other processing parameters (i.e., ball-to-rice straw ash, milling speed/rotation, temperature, ball size) in the batch-typed conventional ball-milling process. The results showed that the ball-milling process is effective to reduce particle sizes to several micrometers and further nanometers. Precise control of the final particle size was achieved by the adjustment of working volume, in which the less working volume results in the generation of smaller particles. The prospect control of final particle size is due to the control of shear stress and collision phenomena during the ball-milling process. The evaluation was also completed with theoretical approximation and adsorption performance of the product. In addition to varying working volume, this study examined the product yield since it can be a contributive factor to determine the optimum condition of the ball-milling process.

Similar content being viewed by others

References

Lyu, H.; Gao, B.; He, F.; Zimmerman, A.R.; Ding, C.; Huang, H.; Tang, J.: Effects of ball milling on the physicochemical and sorptive properties of biochar: experimental observations and governing mechanisms. Environ. Pollut. 233, 54–63 (2018)

Kuziora, P.; Wyszyńska, M.; Polanski, M.; Bystrzycki, J.: Why the ball to powder ratio (BPR) is insufficient for describing the mechanical ball milling process. Int. J. Hydrogen Energy 39(18), 9883–9887 (2014)

Enayati, M.; Aryanpour, G.; Ebnonnasir, A.: Production of nanostructured WC–Co powder by ball milling. Int. J. Refract. Met. Hard Mater. 27(1), 159–163 (2009)

Islam, S.; Al-Eshaikh, M.; Huda, Z.: Synthesis and characterization of high-energy ball-milled tungsten heavy alloy powders. Arab. J. Sci. Eng. 38(9), 2503–2507 (2013)

Aydın, D.Y.; Gürü, M.; Ipek, D.; Özyürek, D.: Synthesis and characterization of zinc fluoroborate from zinc fluoride and boron by mechanochemical reaction. Arab. J. Sci. Eng. 42(10), 4409–4416 (2017)

Dalmis, R.; Cuvalci, H.; Canakci, A.; Guler, O.; Celik, E.: The effect of mechanical milling on graphite-boron carbide hybrid reinforced ZA27 nanocomposites. Arab. J. Sci. Eng. 43, 1113–1124 (2017)

Kutuk, S.; Kutuk-Sert, T.: Effect of PCA on nanosized ulexite material prepared by mechanical milling. Arab. J. Sci. Eng. 42(11), 4801–4809 (2017)

Chen, Y.; Gerald, J.F.; Williams, J.; Bulcock, S.: Synthesis of boron nitride nanotubes at low temperatures using reactive ball milling. Chem. Phys. Lett. 299(3–4), 260–264 (1999)

Bid, S.; Pradhan, S.: Preparation of zinc ferrite by high-energy ball-milling and microstructure characterization by Rietveld’s analysis. Mater. Chem. Phys. 82(1), 27–37 (2003)

Glushenkov, A.; Zhang, H.-Z.; Zou, J.; Lu, G.; Chen, Y.: Efficient production of ZnO nanowires by a ball milling and annealing method. Nanotechnology 18(17), 175604 (2007)

Salah, N.; Habib, S.S.; Khan, Z.H.; Memic, A.; Azam, A.; Alarfaj, E.; Zahed, N.; Al-Hamedi, S.: High-energy ball milling technique for ZnO nanoparticles as antibacterial material. Int. J. Nanomed. 6, 863 (2011)

Amirkhanlou, S.; Ketabchi, M.; Parvin, N.: Nanocrystalline/nanoparticle ZnO synthesized by high energy ball milling process. Mater. Lett. 86, 122–124 (2012)

Ying, D.; Zhang, D.: Processing of Cu–Al\(_{2}\)O\(_{3}\) metal matrix nanocomposite materials by using high energy ball milling. Mater. Sci. Eng. A 286(1), 152–156 (2000)

Sievert, T.; Wolter, A.; Singh, N.: Hydration of anhydrite of gypsum (CaSO4. II) in a ball mill. Cem. Concr. Res. 35(4), 623–630 (2005)

Gheisari, K.; Javadpour, S.; Oh, J.; Ghaffari, M.: The effect of milling speed on the structural properties of mechanically alloyed Fe-45% Ni powders. J. Alloys Compd. 472(1–2), 416–420 (2009)

Peng, Y.-X.; Ni, X.; Zhu, Z.-C.; Yu, Z.-F.; Yin, Z.-X.; Li, T.-Q.; Liu, S.-Y.; Xu, J.: Friction and wear of liner and grinding ball in iron ore ball mill. Tribol. Int. 115, 506–517 (2017)

Nath, A.; Jiten, C.; Singh, K.C.: Influence of ball milling parameters on the particle size of barium titanate nanocrystalline powders. Phys. B Condens. Matter 405(1), 430–434 (2010)

Kurniawan, T.; Muraza, O.; Hakeem, A.S.; Al-Amer, A.M.: Mechanochemical route and recrystallization strategy to fabricate mordenite nanoparticles from natural zeolites. Cryst. Growth Des. 17(6), 3313–3320 (2017)

Kurniawan, T.; Muraza, O.; Bakare, I.A.; Sanhoob, M.A.; Al-Amer, A.M.: Isomerization of n-butane over cost-effective mordenite catalysts fabricated via recrystallization of natural zeolites. Ind. Eng. Chem. Res. 57(6), 1894–1902 (2018)

Javadinejad, H.R.; Rizi, M.S.; Mobarakeh, E.A.; Ebrahimian, M.: Thermal stability of nano-hydroxyapatite synthesized via mechanochemical treatment. Arab. J. Sci. Eng. 42(10), 4401–4408 (2017)

Deniz, V.; Onur, T.: Investigation of the breakage kinetics of pumice samples as dependent on powder filling in a ball mill. Int. J. Miner. Process. 67(1–4), 71–78 (2002)

Gupta, V.; Sharma, S.: Analysis of ball mill grinding operation using mill power specific kinetic parameters. Adv. Powder Technol. 25(2), 625–634 (2014)

Sheng-Yong, L.; Qiong-Jing, M.; Zheng, P.; Xiao-Dong, L.; Jian-Hua, Y.: Simulation of ball motion and energy transfer in a planetary ball mill. Chin. Phys. B 21(7), 078201 (2012)

Venkataraman, K.; Narayanan, K.: Energetics of collision between grinding media in ball mills and mechanochemical effects. Powder Technol. 96(3), 190–201 (1998)

Schnatz, R.: Optimization of continuous ball mills used for finish-grinding of cement by varying the L/D ratio, ball charge filling ratio, ball size and residence time. Int. J. Miner. Process. 74, S55–S63 (2004)

Austin, L.: Understanding ball mill sizing. Ind. Eng. Chem. Process Des. Dev. 12(2), 121–129 (1973)

Zhang, D.: Processing of advanced materials using high-energy mechanical milling. Prog. Mater. Sci. 49(3–4), 537–560 (2004)

Rosenkranz, S.; Breitung-Faes, S.; Kwade, A.: Experimental investigations and modelling of the ball motion in planetary ball mills. Powder Technol. 212(1), 224–230 (2011)

Nandiyanto, A.B.D.; Putra, Z.; Andika, R.; Bilad, M.R.; Kurniawan, T.; Zulhijah, R.; Hamidah, I.: Porous activated carbon particles from rice straw waste and their adsorption properties. J. Eng. Sci. Technol. 12, 1–11 (2017)

Permatasari, N.; Sucahya, T.N.; Nandiyanto, A.B.D.: Agricultural wastes as a source of silica material. Indones. J. Sci. Technol. 1(1), 82–106 (2016)

Weeber, A.; Bakker, H.: Amorphization by ball milling. A review. Phys. B Condens. Matter 153(1–3), 93–135 (1988)

Stolle, A.; Szuppa, T.; Leonhardt, S.E.; Ondruschka, B.: Ball milling in organic synthesis: solutions and challenges. Chem. Soc. Rev. 40(5), 2317–2329 (2011)

Fathy, M.; Moghny, T.A.; Mousa, M.A.; El-Bellihi, A.-H.A.; Awadallah, A.E.: Synthesis of transparent amorphous carbon thin films from cellulose powder in rice straw. Arab. J. Sci. Eng. 42(1), 225–233 (2017)

Nandiyanto, A.B.D.; Wiryani, A.S.; Rusli, A.; Purnamasari, A.; Abdullah, A.G.; Riza, L.S.: Decomposition behavior of curcumin during solar irradiation when contact with inorganic particles. IOP Conf. Ser. Mater. Sci. Eng. 180, 012135 (2017)

Nandiyanto, A.B.D.; Wiryani, A.S.; Rusli, A.; Purnamasari, A.; Abdullah, A.G.; Widiaty, I.; Hurriyati, R.: Extraction of curcumin pigment from Indonesian local turmeric with its infrared spectra and thermal decomposition properties. IOP Conf. Ser. Mater. Sci. Eng. 180, 012136 (2017)

Nandiyanto, A.B.D.; Zaen, R.; Oktiani, R.: Correlation between crystallite size and photocatalytic performance of micrometer-sized monoclinic WO3 particles. Arab. J. Chem. (2017) (in press)

Nandiyanto, A.B.D.; Sofiani, D.; Permatasari, N.; Sucahya, T.N.; Wiryani, A.S.; Purnamasari, A.; Rusli, A.; Prima, E.C.: Photodecomposition profile of organic material during the partial solar eclipse of 9 March 2016 and its correlation with organic material concentration and photocatalyst amount. Indones. J. Sci. Technol. 1(2), 132–155 (2016)

Nandiyanto, A.B.D.; Permatasari, N.; Sucahya, T.N.; Abdullah, A.G.; Hasanah, L.: Synthesis of potassium silicate nanoparticles from rice straw ash using a flame-assisted spray-pyrolysis method. IOP Conf. Ser. Mater. Sci. Eng. 180, 012133 (2017)

Nandiyanto, A.B.D.; Permatasari, N.; Sucahya, T.N.; Purwanti, S.T.; Munawaroh, H.S.H.; Abdullah, A.G.; Hasanah, L.: Preparation of potassium-posphate-embedded amorphous silicate material from rice straw waste. IOP Conf. Ser. Mater. Sci. Eng. 180, 012138 (2017)

Nandiyanto, A.B.D.; Rahman, T.; Fadhlulloh, M.A.; Abdullah, A.G.; Hamidah, I.; Mulyanti, B.: Synthesis of silica particles from rice straw waste using a simple extraction method. IOP Conf. Ser. Mater. Sci. Eng. 128, 012040 (2016)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nandiyanto, A.B.D., Zaen, R. & Oktiani, R. Working Volume in High-Energy Ball-Milling Process on Breakage Characteristics and Adsorption Performance of Rice Straw Ash. Arab J Sci Eng 43, 6057–6066 (2018). https://doi.org/10.1007/s13369-018-3265-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-018-3265-4