Abstract

In this study, hollow nanospheres of titanium dioxide (TiO2) are prepared and utilized as potential nucleating agents in supercritical carbon dioxide (scCO2) foaming process of thermoplastic polyurethanes (TPUs) at different foaming temperatures and saturation pressures. To produce the hollow nanospheres of titanium dioxide (TiO2), well-defined spheres of polystyrene (PS) with a diameter of about 300 nm are first synthesized as templates using surfactant-free emulsion polymerization. A layer of titanium tetraisopropoxide (TTIP) is then uniformly coated on the PS spheres followed by calcination in a furnace to convert the titania layer to the titanium oxide layer. Hollow nanospheres of titanium dioxide with a well-defined morphology are prepared by calcination at high temperatures, as the PS spheres completely decompose. Interestingly, highly porous structures, which give rise to high surface area for trapping scCO2, are generated on the surface of the TiO2 nanoparticles during the thermal treatment. The dispersion of TiO2 nanospheres in the TPU matrix is successful, serving as heterogeneous nucleating agents that influence the cell density and morphology of the extended TPU in the foaming process.

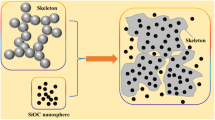

Graphical abstract

In this study, hollow nanospheres of titanium dioxide (TiO2) with unique porous surface are prepared and utilized as potential nucleating agents in supercritical carbon dioxide (scCO2) foaming process of thermoplastic polyurethanes (TPUs) to control various foaming parameters including foaming ratio, cell size, cell density etc.

Similar content being viewed by others

References

L. Lee, C. Zeng, X. Cao, X. Han, J. Shen, G. Xu, Compos. Sci. Technol. 65(15–16), 2344–2363 (2005). https://doi.org/10.1016/j.compscitech.2005.06.016

M. Sauceau, J. Fages, A. Common, C. Nikitine, E. Rodier, Prog. Polym. Sci. 36(6), 749–766 (2011). https://doi.org/10.1016/j.progpolymsci.2010.12.004

S.K. Goel, E.J. Beckman, Polym. Eng. Sci. 34(14), 1137–1147 (1994). https://doi.org/10.1002/pen.760341407

S.K. Goel, E.J. Beckman, Polym. Eng. Sci. 34(14), 1148–1156 (1994). https://doi.org/10.1002/pen.760341408

S.-K. Yeh, Y.-C. Liu, C.-C. Chu, K.-C. Chang, S.-F. Wang, Ind. Eng. Chem. Res. 56(30), 8499–8507 (2017). https://doi.org/10.1021/acs.iecr.7b00942

K.A. Arora, A.J. Lesser, T.J. McCarthy, Macromolecules 31(14), 4614–4620 (1998). https://doi.org/10.1021/ma971811z

D.D. Luong, D. Pinisetty, N. Gupta, Compos. B Eng. 44(1), 403–416 (2013). https://doi.org/10.1016/j.compositesb.2012.04.060

Z. Xing, G. Wu, S. Huang, S. Chen, H. Zeng, J. Supercrit. Fluids 47(2), 281–289 (2008). https://doi.org/10.1016/j.supflu.2008.08.009

R.W. Seymour, S.L. Cooper, Macromolecules 6(1), 48–53 (1973). https://doi.org/10.1021/ma60031a008

R.W. Seymour, G.M. Estes, S.L. Cooper, Macromolecules 3(5), 579–583 (1970). https://doi.org/10.1021/ma60017a021

S.L. Cooper, A.V. Tobolsky, J. Appl. Polym. Sci. 10(12), 1837–1844 (1966). https://doi.org/10.1002/app.1966.070101204

V. Kumar, J. Weller, J. Eng. Ind. 116(4), 413–420 (1994). https://doi.org/10.1115/1.2902122

S. Doroudiani, C.B. Park, M.T. Kortschot, Polym. Eng. Sci. 38(7), 1205–1215 (1998). https://doi.org/10.1002/pen.10289

W. Zhai, J. Yu, L. Wu, W. Ma, J. He, Polymer 47(21), 7580–7589 (2006). https://doi.org/10.1016/j.polymer.2006.08.034

R. Pop-Iliev, G.M. Rizvi, C.B. Park, Polym. Eng. Sci. 43(1), 40–54 (2003). https://doi.org/10.1002/pen.10003

A.I. Cooper, J. Mater. Chem. 10(2), 207–234 (2000). https://doi.org/10.1039/a906486i

J.S. Colton, N.P. Suh, Polym. Eng. Sci. 27(7), 485–492 (1987). https://doi.org/10.1002/pen.760270702

J.S. Colton, N.P. Suh, Polym. Eng. Sci. 27(7), 493–499 (1987). https://doi.org/10.1002/pen.760270703

P. Spitael, C.W. Macosko, R.B. McClurg, Macromolecules 37(18), 6874–6882 (2004). https://doi.org/10.1021/ma049712q

M. Okamoto, P.H. Nam, H. Okamoto, Nano Lett. 9(1), 503–505 (2001). https://doi.org/10.1021/nl010051+

W. Wang, S. Guo, M. Penchev, I. Ruiz, K.N. Bozhilov, D. Yan, M. Ozkan, C.S. Ozkan, Nano Energy 2(2), 294–303 (2013). https://doi.org/10.1016/j.nanoen.2012.10.001

Z. Chen, C. Xu, C. Ma, W. Ren, H.-M. Cheng, Adv. Mater. 25(9), 1296–1300 (2013). https://doi.org/10.1002/adma.201204196

S. Siripurapu, J.M. DeSimone, S.A. Khan, R.J. Spontak, Macromolecules 38(6), 2271–2280 (2005). https://doi.org/10.1021/ma047991b

Z. He, L. Zhou, G. Li, X. Zeng, T. An, G. Sheng, J. Fu, Z. Bai, J. Hazard. Mater. 167(1–3), 275–281 (2009). https://doi.org/10.1016/j.jhazmat.2008.12.116

A. Imhof, Langmuir 17(12), 3579–3585 (2001). https://doi.org/10.1021/la001604j

Z.-M. Xu, X.-L. Jiang, T. Liu, G.-H. Hu, L. Zhao, Z.-N. Zhu, W.-K. Yuan, J. Supercrit. Fluids 41(2), 299–310 (2007). https://doi.org/10.1016/j.supflu.2006.09.007

Y. Guo, N. Hossieny, R.K.M. Chu, C.B. Park, N. Zhou, Chem. Eng. J. 214, 180–188 (2013). https://doi.org/10.1016/j.cej.2012.10.043

S. Liu, R. Eijkelenkamp, J. Duvigneau, G.J. Vancso, ACS Appl. Mater. Interfaces 9(43), 37929–37940 (2017). https://doi.org/10.1021/acsami.7b11248

Acknowledgements

This research was partly supported by Gyeonggi Regional Research Center (GRRC) Program (GRRC DANKOOK 2016-B02), the National Research Foundation of Korea (NRF) grant funded by the Korean Government (2021R1F1A1064058) and Research-Focused Department Promotion & Interdisciplinary Convergence Research Project as a part of the University Innovation Support Program for Dankook University in 2023.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shim, J.S., Kim, H., Chang, T. et al. Preparation of hollowTiO2 nanospheres with highly porous surface for effective nucleating agents in supercritical carbon dioxide foaming of thermoplastic polyurethanes. Macromol. Res. (2024). https://doi.org/10.1007/s13233-024-00269-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s13233-024-00269-3