Abstract

The work presents the results of research on the formation of a hydrogel polymer matrix during the gelatin crosslinking with a dioxirane derivative of poly(ethylene glycol) and experiments on studying their properties. The crosslinking process of type A gelatin using poly(ethylene glycol) diglycidyl ether (PEGDE 500) was optimized by changing the gelatin: PEGDE ratio without using any other factors. The properties of the obtained hydrogels were studied, in particular the gel fraction amount, the degree of swelling in different media, mechanical properties, pore size, cytotoxicity, the ability to absorb and release antiseptic drugs, and bactericidal properties of hydrogel samples filled with an antiseptic agent (chlorhexidine). The crosslinking reaction has been found to be the most efficient at gelatin: PEGDE 500 ratio ranging from 1:3 to 1:5. In this case, the formation of highly elastic hydrogels with maximum fraction amount and high mechanical properties was observed (the samples were not destroyed under compression). Moreover, only within this ratio range, the obtained hydrogels retained their shape when heated to 40 °C. The pore sizes of the swollen hydrogel clearly depend on the crosslinker content. The high values of the degree of swelling in the exudate-simulating fluid in combination with mechanical strength allow the development of wound dressings based on hydrogels of the developed composition. Crosslinking of gelatin with PEGDE 500 allows to obtain gelatin-based hydrogels in a controlled manner which does not require subsequent purification steps. The resulting material does not exhibit cytotoxicity during in vitro studies on living cells. The hydrogel filled with an antiseptic drug is capable of releasing it by 50% within the first day into the medium of saline and exudate-simulating fluid. The antimicrobial properties of the hydrogel containing chlorhexidine are confirmed by the effective inhibition of the growth of Escherichia coli and Staphylococcus aureus bacteria.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Wound healing is a complex process that is not fully understood and can often be accompanied by a number of complications that prolong treatment time (Koehler et al. 2018). Wound infection is particularly negative, as it causes increased inflammation and leads to prolonged and incomplete healing. To overcome and prevent these processes, antibacterial wound dressings are used to treat wounds. There is a wide variety of problems associated with the use of traditional forms of dressings, which for various reasons are not capable of long-term controlled release of antibacterial drugs. Therefore, new multifunctional materials are being developed to create new types of antibacterial dressings for wound treatment, in particular, based on polymer hydrogels (Bal-Öztürk et al. 2020; Gul et al. 2021; Li et al. 2020; Catoira et al. 2019). Hydrogels have properties that mimic living body tissues (Lee and Kim 2018; Suberlyak et al. 2020a, b), and also have other attractive and unique physicochemical properties that make them suitable for biomedical applications, in particular for use in tissue engineering (Masood et al. 2022; Prelipcean et al. 2022), for the development of drugs delivery system, and for the production of modern dressings (Jacob et al. 2021; Qi et al. 2022). According to these applications, hydrogels must be biocompatible and preferably biodegradable (Demirci et al. 2022), which is achieved using natural polymers for their synthesis, such as collagen, gelatin, fibrinogen, alginate, etc. (Zagórska-Dziok and Sobczak 2020; Bukartyk et al. 2022; Dron et al. 2022; Montalbano et al. 2018).

Hydrogel-based dressings are able to implement the concept of effective wet wound healing and can combine a number of properties, such as absorption of wound exudate, creation of a barrier that protects the wound from infection, and prolonged release of a wide range of therapeutic drugs. Despite the recognized advantages, the use of hydrogels as therapeutic dressings has certain limitations due to a number of problems identified during their use. These include low mechanical properties, which deteriorate significantly when the dressing swells (prolonged use) and limited ability to absorb specific wound fluids (exudates, transudates, etc.) (Suberlyak et al. 2020a, b, Maikovych et al. 2021; Manon et al. 2022).

This research aims to create gelatin-based antibacterial hydrogel treatment dressings using dioxirane derivative poly(ethylene glycol) as a crosslinking agent. The dressings should have satisfied mechanical properties and high capacity to absorb wound secretion.

Natural polymers are very commonly used to create modern materials for pharmaceuticals and medicine, as they are usually derived from living organisms or plants. Natural polymers are non-toxic, biocompatible, and do not cause inflammatory reactions in the body. In particular, gelatin (a protein obtained by collagen hydrolysis) is an attractive object for the preparation of hydrogels used in biomedical applications, since it contains a large number of functional groups, making it easy to be crosslinked. There are a number of reports on crosslinked gelatin hydrogels for use in biomedical applications (Kang and Park 2021; Mushtaq et al. 2022; Bovone et al. 2021).

Chemical and physical crosslinking are used to form gelatin-based hydrogels. To date, chemical crosslinking is the most common method of gelatin conversion into irreversible and stable gels. Covalent crosslinking of gelatin involves the introduction of functional chemicals into the gelatin network structure, usually by linking free amino groups of lysine or unlinked carboxylic acid groups of glutamic and aspartic acids. Aldehydes (including formaldehyde, glyceraldehyde, and glutaraldehyde (GTA)), isocyanates, polypropoxides, and natural compounds such as genipin, have all been used as crosslinking agents for this type of interaction (Dash et al. 2013; Thakur et al. 2017).

However, the crosslinking agents are mostly toxic chemicals and require the use of accompanying substances such as catalysts, initiators, pH regulators, the presence of which is a problem for in vivo applications. This requires thorough purification and significantly lengthens and increases the cost of hydrogel production.

Thus, hydrogels that can be produced without the use of potentially toxic additives and do not require purification steps are of interest today.

Experimental part

Materials

Gelatin (type A) isolated from pork skin was purchased from Aldrich and used without additional purification. The moisture content is 9.2%, an isoelectric point is ∼ 8 and a Bloom strength is 180.

Poly(ethylene glycol) diglycidyl ether (PEGDE 500) with molar mass of 500 g/mol was purchased from Sigma-Aldrich and used without additional purification.

Chlorhexidine bigluconate (20% solution in water) manufactured by Sigma-Aldrich (catalog number C9394) was used without additional purification.

Exudate-simulating fluid with pH = 7.4–7.5 was prepared in accordance with the following procedure: 0.222 g of CaCl2, 2.3376 g of NaCl, 0.968 g of TPIC (2-amino-2-hydroxymethyl-propane-1,3-diol) and 2 g of albumin 5% aqueous solution (BSA) were loaded into a 100 ml flask and brought up to the mark with water. When stored in a refrigerator at 2–4 °C, the resulting solution is suitable for 7 days C (Rezvanian et al. 2017).

Saline is a 0.9% aqueous solution of sodium chloride produced by Aldrich, which was used without additional purification.

Methods of synthesis

Synthesis of gelatin hydrogels

To synthesize the hydrogel, we used gelatin of type A, PEGDE 500 as a crosslinking agent, and distilled water. An aqueous solution of gelatin with a concentration of 20.0% was prepared by stirring in a water bath at 40 °C for 30 min. PEGDE 500, gelatin solution, and water were weighed into pre-prepared containers, the percentage load is shown in Table 1, the total polymer content in each hydrogel sample was 18.0%, and the remaining 82.0% was distilled water. The composition was homogenized, the containers were sealed and heated at 80 °C for 4 h.

Synthesis of gelatin hydrogels with chlorhexidine

To study the chlorhexidine release and antiseptic properties of the hydrogels, the samples were synthesized similarly to the method described above (Sample No. 6, Table 1) by adding chlorhexidine bigluconate solution to the mixture at the synthesis stage to replace the corresponding proportion of distilled water. The percentage loading is shown in Table 2.

Methods of analysis

Gel fraction

The gel fraction was determined by extraction of the soluble component from the samples. The samples (~ 2.5 g) were weighed with an accuracy of 0.0001 g to determine the initial mass of polymers (W1) in the hydrogel: W1 = Ws × 18 / 100, where Ws is the initial weight of the sample, 18 is the polymer content in the hydrogel (%). The extraction was carried out in distilled water at 50 °C for 24 h with the water: hydrogel ratio of 100:1, w/w. The water was changed three times. The resulting insoluble fraction was dried to a constant weight in an oven at 100 °C. The gel fraction (Gf, %) was determined by the equation: Gf = W2/W1 × 100%, where W1 is the initial mass of polymers, W2 is the mass of polymers after extraction.

Fourier-Transform infrared spectroscopy (FTIR)

Fourier-Transform Infrared Spectroscopy analysis was recorded at a FTIR Vertex 70 V (Bruker, USA) spectrometer with the use of the Attenuated Total Reflectance (ATR) technique. The ATR instrument is equipped with a diamond crystal. The absorption bands were recorded in the range of 400–4000 cm−1 with 256 scans and a resolution of 2 cm−1.

Mechanical properties

Determination of mechanical properties was performed using a stepwise uniaxial compressive load with a step of 500 μm at a contact area of 0.95 cm2 with the registration of the force. To determine the mechanical properties, standardized samples of hydrogels with a diameter of 11 mm and a height of ~ 5.5 mm were used (Bukartyk et al. 2022; Nosova et al. 2016).

Rheology

The rheological measurements have been done on a TA Instrument rheometer (ARES G2) with a 20 mm parallel plate (Peltier plate Aluminum AR2000 SN 983940). Measurements have been done with a deformation rate belonging to the linear domain and with frequency varied from 10–2 Hz to 101 Hz. All measurements have been done at 20 °C.

Scanning electron microscopy (SEM)

The scanning electron microscope used is a JEOL, JSM 6510 LV instrument. The samples were frozen with liquid nitrogen, lyophilized (the materials were lyophilized in a Christ freeze-dryer alpha 2–4 LSC at − 85 °C and 0.37 mbar), sectioned to visualize the hydrogel morphology, and were covered by a golden film before examination. Images of the hydrogel were analyzed using ImageJ software (National Institutes of Health (NIH) and the Laboratory for Optical and Computational Instrumentation (LOCI), University of Wisconsin, USA).

Swelling ability

Liquid absorption capacity of hydrogel samples (SA) was measured by the conventional gravimetric method in distilled water, saline and model exudate. pH of liquids was 6.5, 7.0, and 7.5, respectively. The samples of 1 cm in diameter and 0.5 cm in height were weighed, and placed in 50 mL of distilled water/saline/exudate at 20 °C and 37 °C.

After an appropriate incubation time (1, 2, 4, 8, 12, 24 h), the excess of water/saline/exudate was removed, weighed, and placed in 50 mL of distilled water/saline/exudate at 20 °C and 37 °C. The liquid content of the scaffolds was determined as the ratio of the swollen sample weight (WW − WP) to the weight (WP) of the dry polymers. Each value was averaged over three parallel measurements. Swelling ability was calculated in accordance with the following equation: SA = (WW − WP)/WP, where WW and WP are the weight of the swollen sample and dry polymers, respectively.

Cytotoxicity

Hydrogel cytotoxicity was examined through cultivation of bull sperms in direct contact with hydrogel samples. The separated surveys of crosslinking agent (PEGDE 500) cytotoxicity were conducted, which is used to receive hydrogels. For research, bull sperm samples were selected, which have the following physiological characteristics:

-

Volume − 3 to 4 ml;

-

Sperm concentration − 0.6 to 1.1 × 109 cells/ml;

-

Number of alive germ cells − 80 to 85%.

Sperm samples were divided into pieces: control–dissolved phosphate-salt buffer (hereinafter – FSB) including NaCl—0.8 g, KCl—0.02 g, Na2HPO4—0.11 g, KH2PO4—0.02 g, MgCl2—0.01 g, distilled water—up to 100 ml) and experimental (Stetsyshyn et al. 2020; Raczkowska et al. 2017). In the experimental samples, the chopped hydrogel was added by doses: 10, 20, and 50 mg per 1 mg of dissolved bull sperm sample (Bukartyk et al. 2022).

Sorption and release of chlorhexidine bigluconate

Product release from the hydrogel sample (diameter ~ 1 cm, height ~ 0.7 cm, weight ~ 0.7 g) was conducted in the medium of water, saline, exudate, and octanol. The product-enriched samples were placed into a container in which the appropriate medium was added (water/saline/exudate/octanol) following the bath index 30. At specified time intervals, the solutions were medium sized by shaking and a 0.4 g sample (mp) was taken. The sample was dissolved approximately 10 times with distilled water and methanol for samples with octanol and the solution optical density (D) was measured using spectrophotometer ULAB 102UV. The measurements were conducted at the wavelength λ = 257 nm (for methanol-dissolved samples) and λ = 253 nm (for water-dissolved samples). The quantitative assessment of the product content in the solution was conducted using the appropriate calibration addiction C = (D + 0.0029)/338.38 for chlorhexidine in methanol and C = (D + 0.0007)/300.3 for chlorhexidine in water. The release degree (Rd) was determined by the formula:

where mdss is the weight of diluted sample solution;

C is the concentration of diluted sample solution;

mss is the weight of starting solution;

ms is the weight of sample;

mch is the weight of chlorhexidine in the hydrogel sample.

Bactericidal properties

Bactericidal properties were studied using the disc-diffusion method (diffusion in agar gel). Gelatin hydrogel discs (diameter 5 mm and height 1–2 mm) with 0.1, 0.25, and 1.0% chlorhexidine bigluconate (introduced at the synthesis stage) and two test strains of microorganisms (gram-positive Staphylococcus aureus ATCC 26923 and gram-negative Escherichia coli ATCC 25922) were used for microbiological tests. In the work, nutrient media of the following composition were used: (1) for cultivation—1% meat peptone agar (MPA) with 4% glucose; (2) for preparing to inoculate—4% glucose with 1% meat peptone broth (nutrient broth Pharmreaktiv). The microbial load was 107 microbial cells per 1 ml of medium.

Statistical analysis

Experiments were performed in triplicate and mean ± SD was reported. Mean values were compared using independent samples Student’s t test. P values of less than 0.05 were considered to be statistically significant.

Results and discussion

We have proposed a method for obtaining a gelatin hydrogel using water-soluble poly(ethylene glycol) diglycidyl ether as a crosslinker (the scheme is shown in Fig. 1). This method has several advantages:

-

hydrogels are formed in a single step without controlling the hydrogen index;

-

no stage of purification from the unreacted crosslinking agent is required;

-

it is also possible to control the degree of crosslinking, swelling, mechanical characteristics, and morphology by varying only the content of the crosslinking agent in the initial composition.

The hydrogels were synthesized using poly(ethylene glycol) diglycidyl ether (PEGDE 500). The choice of this particular crosslinking agent is based on the results of primary model syntheses of gelatin hydrogels performed using several agents of this type that differed in molecular weight: PEGDE 300, PEGDE 500, PEGDE 700, and PEGDE 1100 (the experimental results are given in the supplementary information). It is shown that using PEGDE 300 and PEGDE 1100 as crosslinking agents, hydrogels with low mechanical properties and gel fraction of 25–30% and 5–10%, respectively, are obtained. Moreover, these samples are destroyed after 9 h of exposure to water. The gelatin hydrogels obtained using PEGDE 500 and PEGDE 700 have properties that are practically the same, so poly(ethylene glycol) diglycidyl ether (PEGDE 500) was chosen for further research due to its commercial availability.

The syntheses were performed at pH of the reaction mixture ranged from 5.5 to 6.0. Under these conditions, the hydroxyl and carboxyl groups of gelatin most likely do not react, and crosslinking occurs through the interaction of the crosslinker with the amino group of lysine. Water-soluble epoxy compounds are quite unstable to hydrolysis at pH values other than neutral ones, so attempts to conduct synthesis under other conditions, in this case, were unsuccessful.

According to the procedure described in the experimental section, the hydrogel samples were obtained at different ratios of the crosslinking agent to gelatin (in the range from 1:0.8 to 1:25) and their properties were studied.

The determination of the gel fraction for hydrogels of different compositions indicates that under certain synthesis conditions and ratios in the range of 1:2–1:6, the maximum number of crosslinks is realized with the formation of heat-resistant and water-swollen samples. Unlike the non-closslinked gelatin the synthesized hydrogels do not dissolve in water (Fig. 2).

Thus, the above-mentioned synthesis conditions were chosen for further research, because they ensured the maximum involvement of reagents in the three-dimensional polymer network.

ATR FTIR spectroscopy (Fig. 3) confirmed the presence of both crosslinker and gelatin fragments in a polymer network. For the product, which is a gel fraction from a hydrogel obtained at PEGDE 500: gelatin ratio of 1:2 (sample 3, Table 1), after removing all water-soluble components, the absorption bands belonging to both components of the hydrogel are clearly observed. Absorption band at 1095 cm−1 refers to C–O–C group vibrations of PEGDE (it is absent in the gelatin spectrum). Moreover, the increase in the intensity of absorption bands at 2907 cm−1 and 2953 cm−1, which are related to stretching vibrations of > CH2 groups of this PEGDE fragment is well observed. Bands at 1637 cm−1, which are typical of stretching vibrations of carbonyl (C=O) group of gelatin amide group (Amide I), deformation vibrations of N–H group at 1542 cm−1 (Amide II) and stretching vibrations of C–N group at 1248 cm−1 (Amide III) remained present in the spectrum with a slightly modified ratio of functional groups compared to the starting gelatin.

Several authors confirmed that hydrogel mechanical strength has a significant impact on cell behavior, in particular, their proliferation, cell morphology, and creation of new tissues (Hadjipanayi et al. 2009; Branco da Cunha et al. 2014; Karamichos et al. 2007; El-Mohri et al. 2017). Hydrogel of non-crosslinked gelatin has a relatively low melting temperature resulting in the formation of thermo-reversible hydrogels that lose their shape stability at temperatures close to the human body temperature (Van Den Bulcke et al. 2000).

To improve the physical and mechanical properties of gelatin-based hydrogels, targeted modification, crosslinking, and/or filling with reinforcing elements are used, as well as using it only as an additive in multicomponent materials (Maikovych et al. 2021; Samaryk et al. 2017; Grytsenko et al. 2021).

It was found in the previous research that 4 h at 80 °C is sufficient for the crosslinking processes in the selected system to be completed (the properties of gelatin-based hydrogels no longer change significantly) and are determined by the ratio of the reactive components. The study of the mechanical properties of the hydrogel samples at a temperature of 20 °C (Fig. 4) showed that the maximum force at uniaxial loading of the samples is achieved at PEGDE 500:gelatin ratio of 1:5 (sample 6, Table 1). At the same time, high values are also demonstrated by the samples obtained at 1:2 and 1:3 ratios (samples 3 and 4, respectively, Table 1). It is worth noting here that the hydrogel synthesized under these conditions is very elastic and is not destructed during such tests. After the applied force is removed, hydrogel restores its shape. The samples obtained at higher ratios, the same as hydrogel of pure gelatin, have lower mechanical strength, are not elastic, and are destroyed during the tests. The same figure shows the test results at 37 °C. For the samples of crosslinked PEGDE 500, the dependence of mechanical properties on temperature is observed. At the same time, the samples obtained at 1:6 and higher ratios completely lose their mechanical strength, as well as the hydrogel of non-crosslinked gelatin. Increasing the crosslinker content beyond the range of 1:2–1:5 obviously significantly unbalances the ratio of reactive groups, which leads to a smaller number of effective bonds that form the polymer matrix of the hydrogel and also leads to a loss of strength.

At body temperature, although the obtained hydrogels do not lose their shape stability, their elasticity decreases significantly, and, accordingly, the forces required for their deformation decrease by 5.5–17 times, depending on the crosslinker content. In this case, an inverse relation occurs. Thus, within the range of ratios from 1:2 to 1:5, both at room and elevated temperatures, the highest mechanical properties and the maximum values of gel fraction are observed for the hydrogel with the lowest crosslinker content.

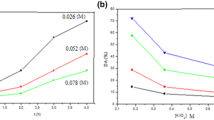

Dynamic mechanical analysis performed on hydrogel plate provides quantitative information about the viscoelastic and rheological properties of the material by measuring the mechanical response of the specimens during periodic deformation. The elastic (real or cumulative) modulus G' and the viscous (apparent or loss) modulus Gʺ are presented. In the figure, Gʹ and Gʺ are plotted as a function of radial frequency, a graph known as a “mechanical spectrum” (Fig. 5). The data obtained for the gelatin–PEGDE 500 systems are characterized by the storage modulus Gʹ, which demonstrates a pronounced plateau in the frequency range studied, and the loss modulus Gʺ, the values of which are much lower. The obtained mechanical spectra of gelatin-based hydrogels are characteristic of a well-developed elastic polymer network.

At the same time, as can be seen from the data obtained in the range of optimal ratios (1:3–1:5), the values of the Gʹ and Gʺ modules depend inversely on the crosslinker amount in the initial composition: an increase in the amount of the crosslinking agent leads to a decrease in both the cumulative G' and loss modulus Gʹ. It should be noted here that the formation of a gelatin-based hydrogel primarily involves physical intermolecular interaction and, as a result, the formation of spiral configurations similar to those of collagen (Scott 2002). However, in the hydrogel formed from gelatin and PEGDE 500, two different types of interaction are assumed: one is the formation of covalent crosslinks between gelatin and crosslinker, and the other is the formation of physical crosslinks between the chains of gelatin macromolecules. Changing the amount of crosslinking agent affects both processes. It should also be taken into account that for the same ratios, the obtained values of gel fraction (Fig. 2) are high and quite close, which indicates a sufficiently well-developed polymer network at all three ratios.

Based on these facts, it can be concluded that an increase in the proportion of the crosslinking agent in the initial mixture correspondingly reduces the proportion of gelatin (Table 1), which reduces the possibility of physical interactions between gelatin macromolecules involved in the formation of a hydrogel of the 2nd kind. On the other hand, a hydrophilic crosslinker of non-zero length in this system simultaneously performs the function of a plasticizer (Campiglio et al. 2019). Due to the fact that crosslinks are formed by flexible hydrophilic polyoxyethylene fragments, the use of such a crosslinker-plasticizer to some extent neutralizes (masks) the effects of increasing the crosslink density with an increase in its proportion in the initial mixture because of the intermolecular plasticization effects.

Thus, at the optimal ratio of reactive groups in the initial mixture, the maximum number of transverse intermolecular bonds is realized during the formation of a hydrogel. Beyond this range, stable hydrogels with improved mechanical properties are not formed. This can be explained either by an insufficient amount of crosslinker, at ratios higher than 1:5 (i.e., an insufficient number of crosslinks in the formed spatial network of the hydrogel) or by an excessive amount of crosslinker, when intermolecular interaction is impossible due to steric effects. In the case of ratios less than 1:3, it is obvious that the formation of gelatin comb-like macromolecules with side substituents from crosslinker molecules, which interacted by one epoxy group with all available amino groups, is the predominant process, thereby excluding the possible formation of crosslinks and three-dimensional structures (Vargas et al.2008). Gelatin usually contains a large number of functional groups of different natures capable of interacting with epoxides under certain conditions. However, according to this synthesis procedure, the formation of covalent bonds can be predicted only for amino groups. If other groups participate under these conditions (pH = 5.5–6), their amounts are very insignificant.

Usually, the increase in the strength of polymeric hydrogels assumes the increase in the number of crosslinks in their structural framework, but this often leads to a significant deterioration of other characteristics (reduction of the rate and equilibrium degree of swelling, rate and completeness of drug sorption and desorption). Therefore, we performed comprehensive studies to determine the change in the swelling degree of hydrogels depending on the crosslinker amount during the synthesis. Since it is assumed that gelatin-based hydrogels will be suitable for use as wound care products, it is important to know about their ability to swell in saline, as well as to absorb exudate.

Table 3 summarizes the results of swelling studies in different fluids at two temperatures and represents SEM images (500 × magnification) of the hydrogel microstructures at different swelling degrees.

The hydrogel sample obtained at 1:5 ratio (sample 6, Table 1) in the state of maximum swelling is characterized by the smallest regular pores, which is symbiotic with the maximum value of the compressive strength and the highest value of the storage modulus G'. At the same time, in the range of ratios under study, this hydrogel sample has the lowest swelling values in different fluids. Moreover, the difference in this parameter for water, saline, and exudate is the smallest compared to other samples and indicates the maximum realized structuring potential (Table 3). The pore sizes in the samples obtained at 1:3 and 1:2 ratios (samples 4 and 3, respectively, Table 1) are significantly larger—12 μm and 15 μm, but the regularities of swelling in different fluids are the same. The maximum degree of swelling is observed for the hydrogel obtained with the highest content of crosslinking agent—1:2 (in the studied range).

Thus, the gelatin-based hydrogel dressing made by the proposed method is capable of absorbing up to 45 g/dm2 of wound secretions, which is quite sufficient for the care of medium- and low-exuding wounds.

Cytotoxic studies

The gelatin-based hydrogels obtained in this work will be used for wound treatment, and it is known that the main requirements for materials that are supposed to have direct contact with the tissues of living organisms are their non-toxicity and biological compatibility. Therefore, the primary task is to predict and experimentally evaluate their impact on the body and its components. One of the ways is to determine hydrogel effect on the metabolic processes of living cells and their viability in vitro.

The cytotoxicity was evaluated for both crosslinked gelatin and the crosslinking agent PEGDE 500 according to the procedure described in the experimental part. The experimental results are shown in Table 4.

The results indicate that the crosslinking agent and the hydrogels obtained with its use have no toxic effect; cell survival is at the level of the control test and practically does not depend on the sample amount.

The biocompatibility of the obtained hydrogels is ensured by the use of a natural polymer, in particular gelatin, which is a protein polymer. It is a biocompatible and biodegradable polymer that can be a source of amino acids or short peptides, due to which the formation of new connective tissue occurs in the regeneration processes of damaged living tissues (Catoira et al. 2019).

Study of bactericidal properties

Despite all the positive aspects of using hydrogels in wound healing, it is often necessary to introduce drugs into their composition. For hydrogel dressings intended for the care of difficult-to-heal wounds, it is important to introduce drugs that can inhibit the development of pathological bacteria. One of the most common drugs of this class is chlorhexidine bigluconate. Chlorhexidine is active against vegetative forms of gram-negative and gram-positive bacteria, as well as yeasts, dermatophytes, and lipophilic viruses. It is used for treatment and prevention of wound infections in surgery, traumatology, combustiology, and dentistry (Karpiński and Szkaradkiewicz 2015; Hao et al. 2022). The preparation of hydrogel samples with chlorhexidine and the study of release processes were carried out according to the methods described in the experimental part.

All the obtained dependences of chlorhexidine release from the tested hydrogel samples show its gradual release. For example, Fig. 6 shows the curves of chlorhexidine release from the hydrogel sample (sample 16, Table 2) into the simulated exudate as a function of time. The obtained results suggest that the release curve consists of two clearly defined areas. In the first interval, which lasts 11–13 h, there is a rapid release of 16–18% of the amount of the drug introduced into the hydrogel, and during the next 80 h, there is a diffusion-controlled directly proportional release of up to 32–37% of chlorhexidine. It is clear that these are the primary evaluation results, which in the practical use of hydrogels will depend on many factors: temperature, presence or absence of skin damage, type of wound and stage of healing, exudate composition, etc.

A number of experiments were conducted to study the release of chlorhexidine from the composition of the obtained hydrogels into the medium of octanol, saline, and simulated exudate. The study of release into octanol simulates the release into problem areas without skin damage, i.e., into wounds without exudation (bedsores, hematomas, etc.). The release into saline and model exudate demonstrates the possibility of drug release into exuding wounds with different exudate compositions (Wiegand et al. 2015).

Figure 7 shows the data on the chlorhexidine release into different media after 5 h at 37 °C. The studies confirm the release of the antiseptic drug from the plate while maintaining its initial parameters (degree of absorption by water and exudate, as well as mechanical properties). The obtained hydrogels with chlorhexidine have a high potential for use in wound treatment and are expected to be suitable for the successful treatment of a wide range of infections that accompany poorly healing wounds.

To test the bactericidal properties of the obtained hydrogel plates, we conducted studies using samples with a diameter of 5 mm and a thickness of 2 mm cut from gelatin hydrogels containing different amounts of the bactericidal drug—chlorhexidine (Table 2). The samples were placed in a medium contaminated with Escherichia coli ATCC 25922 (E. coli) and Staphylococcus aureus ATCC 23923 (S. aureus). The radius of microbial growth inhibition was measured.

The results of the study showed that chlorhexidine, which is present in the samples of gelatin hydrogels, when released, inhibits the growth of E. coli and S. aureus bacteria (Table 5).

Depending on the antiseptic content and the bacteria type of, the radius of growth inhibition varies from 10 to 12.5 mm for S. aureus, and from 15 to 17.5 mm for E. coli.

Moreover, with an increase in the chlorhexidine content in gelatin hydrogel, the duration of the bactericidal effect of the sample increases, i.e., a prolonged release of chlorhexidine from the hydrogel matrix is ensured. The maximum zone of inhibition of microbial growth for all doses of the antiseptic is observed on the 2nd–3rd days. For a sample with an active ingredient content of 1%, an effective growth inhibition lasts for 7 days.

Conclusions

Hydrogel materials were obtained using gelatin and PEGDE 500. The preparation conditions were established and the optimal ratio of biopolymer and crosslinking agent in the hydrogel matrix was determined to obtain maximum strength values while maintaining the ability to swell in water, saline, and exudate. The in vitro cytotoxicity assay showed that the obtained hydrogels do not affect the metabolic processes of living cells and their viability. The possibility of obtaining hydrogels with the introduction of chlorhexidine at the stage of their synthesis was shown and data on its release into different media were obtained. The antibacterial properties of the obtained hydrogels were confirmed on cultures of S. aureus and E. coli bacteria, and effective inhibition of microbial growth was observed for 7 days.

The results suggest that the obtained material can be the basis of a specialized hydrogel dressing for the treatment of chronic and infected wounds.

Data availability

The authors confirm that the data supporting the findings of this study are available within the article and its supplementary materials.

References

Bal-Öztürk A, Özkahraman B, Özbaş Z, Yaşayan G, Tamahkar E, Alarçin E (2020) Advancements and future directions in the antibacterial wound dressings: a review. J Biomed Mater Res Part B. https://doi.org/10.1002/jbm.b.34736

Bovone G, Dudaryeva OY, Marco-Dufort B, Tibbitt MW (2021) Engineering hydrogel adhesion for Biomedical Applications via chemical design of the junction. ACS Biomater Sci Eng 7(9):4048–4076. https://doi.org/10.1021/acsbiomaterials.0c01677

Branco da Cunha C, Klumpers DD, Li WA, Koshy ST, Weaver JC, Chaudhuri O, Granja PL, Mooney DJ (2014) Influence of the stiffness of three-dimensional alginate/collagen-I interpenetrating networks on fibroblast biology. Biomaterials 35(32):8927–8936. https://doi.org/10.1016/j.biomaterials.2014.06.047

Bukartyk M, Nosova N, Maikovych O, Bukartyk N, Stasiuk A, Dron I, Fihurka N, Khomyak S, Ostapiv D, Vlizlo V, Samaryk V, Varvarenko S (2022) Preparation and research of properties of combined alginate/gelatin hydrogels. J Chem Technol 30(1):11–20. https://doi.org/10.15421/jchemtech.v30i1.242230

Campiglio CE, ContessiNegrini N, Farè S, Draghi L (2019) Cross-linking strategies for electrospun gelatin scaffolds. Materials 12(15):2476. https://doi.org/10.3390/ma12152476

Catoira MC, Fusaro L, Di Francesco D, Ramella M, Boccafoschi F (2019) Overview of natural hydrogels for regenerative medicine applications. J Mater Sci. https://doi.org/10.1007/s10856-019-6318-7

Dash R, Foston M, Ragauskas AJ (2013) Improving the mechanical and thermal properties of gelatin hydrogels cross-linked by cellulose nanowhiskers. Carbohyd Polym 91(2):638–645. https://doi.org/10.1016/j.carbpol.2012.08.080

Demirci G, Niedźwiedź MJ, Kantor-Malujdy N, El Fray M (2022) Elastomer-hydrogel systems: from bio-inspired interfaces to medical applications. Polymers 14(9):1822. https://doi.org/10.3390/polym14091822

Dron I, Nosova N, Fihurka N, Bukartyk N, Nadashkevych Z, Varvarenko S, Samaryk V (2022) Investigation of hydrogel sheets based on highly esterified pectin. Chem Technol 16(2):220–226. https://doi.org/10.23939/chcht16.02.220

El-Mohri H, Wu Y, Mohanty S, Ghosh G (2017) Impact of matrix stiffness on fibroblast function. Mater Sci Eng C 74:146–151. https://doi.org/10.1016/j.msec.2017.02.001

Grytsenko O, Pukach P, Suberlyak O, Shakhovska N, Karovič V Jr (2021) Usage of mathematical modeling and optimization in development of hydrogel medical dressings production. Electronics 10(5):620. https://doi.org/10.3390/electronics10050620

Gul K, Gan R-Y, Sun C-X, Jiao G, Wu D-T, Li H-B, Kenaan A, Corke H, Fang Y-P (2021) Recent advances in the structure, synthesis, and applications of natural polymeric hydrogels. Crit Rev Food Sci Nutr. https://doi.org/10.1080/10408398.2020.1870034

Hadjipanayi E, Mudera V, Brown RA (2009) Close dependence of fibroblast proliferation on collagen scaffold matrix stiffness. J Tissue Eng Regen Med 3(2):77–84. https://doi.org/10.1002/term.136

Hao W, Wang Y, Xi Y, Yang Z, Zhang H, Ge X (2022) Activity of chlorhexidine acetate in combination with fluconazole against suspensions and biofilms of Candida auris. J Infect Chemother 28(1):29–34. https://doi.org/10.1016/j.jiac.2021.09.018

Jacob S, Nair AB, Shah J, Sreeharsha N, Gupta S, Shinu P (2021) Emerging role of hydrogels in drug delivery systems. Tissue Eng Wound Manag Pharm 13(3):357. https://doi.org/10.3390/pharmaceutics13030357

Kang JI, Park KM (2021) Advances in gelatin-based hydrogels for wound management. J Mater Chem B 9(6):1503–1520. https://doi.org/10.1039/d0tb02582h

Karamichos D, Brown RA, Mudera V (2007) Collagen stiffness regulates cellular contraction and matrix remodeling gene expression. J Biomed Mater Res Part A 83A(3):887–894. https://doi.org/10.1002/jbm.a.31423

Karpiński TM, Szkaradkiewicz AK (2015) Chlorhexidine-pharmaco-biological activity and application. Eur Rev Med Pharmacol Sci 19(7):1321–1326

Koehler J, Brandl FP, Goepferich AM (2018) Hydrogel wound dressings for bioactive treatment of acute and chronic wounds. Eur Polym J 100:1–11. https://doi.org/10.1016/j.eurpolymj.2017.12.046

Lee J-H, Kim H-W (2018) Emerging properties of hydrogels in tissue engineering. J Tissue Eng 9:204173141876828. https://doi.org/10.1177/2041731418768285

Li J, Wu C, Chu PK, Gelinsky M (2020) 3D printing of hydrogels: Rational design strategies and emerging biomedical applications. Mater Sci Eng 140:100543. https://doi.org/10.1016/j.mser.2020.100543

Maikovych OV, Nosova NG, Yakoviv MV, Dron IA, Stasiuk AV, Samaryk VY, Varvarenko SM, Voronov SA (2021) Composite materials based on polyacrylamide and gelatin reinforced with polypropylene microfiber. Voprosy Khimii i Khimicheskoi Tekhnol 1:45–54. https://doi.org/10.32434/0321-4095-2021-134-1-45-54

Manon M, Van Vlierberghe S, Dubruel P, Mignon A (2022) Commercial wound dressings for the treatment of exuding wounds: an in-depth physico-chemical comparative study. Burns Trauma. https://doi.org/10.1093/burnst/tkac024

Masood F, Makhdoom MA, Channa IA, Gilani SJ, Khan A, Hussain R, Batool SA, Konain K, Rahman SU, Wadood A, Bin Jumah MN, Rehman MAU (2022) Development and characterization of chitosan and chondroitin sulfate based hydrogels enriched with garlic extract for potential wound healing/skin regeneration applications. Gels 8(10):676. https://doi.org/10.3390/gels8100676

Montalbano G, Toumpaniari S, Popov A, Duan P, Chen J, Dalgarno K, Scott WE, Ferreira AM (2018) Synthesis of bioinspired collagen/alginate/fibrin based hydrogels for soft tissue engineering. Mater Sci Eng C 91:236–246. https://doi.org/10.1016/j.msec.2018.04.101

Mushtaq F, Raza ZA, Batool SR, Zahid M, Onder OC, Rafique A, Nazeer MA (2022) Preparation, properties, and applications of gelatin-based hydrogels (GHS) in the environmental, technological, and biomedical sectors. Int J Biol Macromol 218:601–633. https://doi.org/10.1016/j.ijbiomac.2022.07.168

Nosova N, Samaryk V, Varvarenko S, Ferens M, Voronovska A, Nagornyak M, Khomyak S, Nadashkevych Z, Voronov S (2016) Porous polyacrylamide hydrogels: preparation and properties. Voprosy Khimii i Khimicheskoi Tekhnol 5–6:78–86

Prelipcean A-M, Iosageanu A, Gaspar-Pintiliescu A, Moldovan L, Craciunescu O, Negreanu-Pirjol T, Negreanu-Pirjol B, Mitran R-A, Marin M, D’Amora U (2022) Marine and Agro-industrial by-products valorization intended for topical formulations in wound healing applications. Materials 15(10):3507. https://doi.org/10.3390/ma15103507

Qi L, Zhang C, Wang B, Yin J, Yan S (2022) Progress in Hydrogels for skin wound repair. Macromol Biosci 22(7):2100475. https://doi.org/10.1002/mabi.202100475

Raczkowska J, Stetsyshyn Y, Awsiuk K, Lekka M, Marzec M, Harhay K, Ohar H, Ostapiv D, Sharan M, Yaremchuk I, Bodnar Y, Budkowski A (2017) Temperature-responsive grafted polymer brushes obtained from renewable sources with potential application as substrates for tissue engineering. Appl Surf Sci 407:546–554. https://doi.org/10.1016/j.apsusc.2017.03.001

Rezvanian M, Ahmad N, Mohd Amin MCI, Ng S-F (2017) Optimization, characterization, and in vitro assessment of alginate-pectin ionic cross-linked hydrogel film for wound dressing applications. Int J Biol Macromol 97:131–140. https://doi.org/10.1016/j.ijbiomac.2016.12.079

Samaryk V, Varvarenko S, Nosova N, Fihurka N, Musyanovych A, Landfester K, Popadyuk N, Voronov S (2017) Optical properties of hydrogels filled with dispersed nanoparticles. Ch&ChT 11(4):449–453. https://doi.org/10.23939/chcht11.04.449

Scott G (2002) Degradable polymers. Springer. https://doi.org/10.1007/978-94-017-1217-0

Stetsyshyn Y, Raczkowska J, Harhay K, Awsiuk K, Shymborska Y, Nastyshyn S, Ohar H, Vasilyev V, Ostapiv D, Sharan M, Sharan O, Voronov S, Budkowski A (2020) Grafted polymer brush coatings for growth of cow granulosa cells and oocyte-cumulus cell complexes. Biointerphases 15(3):031006. https://doi.org/10.1116/6.0000183

Suberlyak O, Baran N, Melnyk Y, Grytsenko O, Yatsulchak H (2020a) Influence of the molecular weight of polyvinylpyrrolidone on the physicomechanical properties of composite polyamide hydrogel membranes. Mater Sci 55(5):758–764. https://doi.org/10.1007/s11003-020-00368-3

Suberlyak O, Grytsenko O, Baran N, Yatsulchak G, Berezhnyy B (2020b) Formation features of tubular products on the basis of composite hydrogels. Chem Technol 14(3):312–317. https://doi.org/10.23939/chcht14.03.312

Thakur S, Govender PP, Mamo MA, Tamulevicius S, Thakur VK (2017) Recent progress in gelatin hydrogel nanocomposites for water purification and beyond. Vacuum 146:396–408. https://doi.org/10.1016/j.vacuum.2017.05.032

Van Den Bulcke AI, Bogdanov B, De Rooze N, Schacht EH, Cornelissen M, Berghmans H (2000) Structural and rheological properties of methacrylamide modified gelatin hydrogels. Biomacromol 1(1):31–38. https://doi.org/10.1021/bm990017d

Vargas G, Acevedo JL, López J, Romero J (2008) Study of cross-linking of gelatin by ethylene glycol diglycidyl ether. Mater Lett 62(21–22):3656–3658. https://doi.org/10.1016/j.matlet.2008.04.020

Wiegand C, Hipler U-C, Elsner P, Tittelbach J (2015) Clinical efficacy of dressings for treatment of heavily exuding chronic wounds. Chronic Wound Care Manag Res. https://doi.org/10.2147/cwcmr.s60315

Zagórska-Dziok M, Sobczak M (2020) Hydrogel-based active substance release systems for cosmetology and dermatology application: a review. Pharmaceutics 12(5):396. https://doi.org/10.3390/pharmaceutics12050396

Acknowledgements

The authors would like to express their gratitude to the Armed Forces of Ukraine for providing security to us and our families and the possibility to perform this work.

Funding

There was funding from Erasmus+. The MSCA4Ukraine grant, ID number 1232572, which is funded by the European Union.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Ethical standards

This article does not contain any studies with human participants or animals performed by any of the authors.

Informed consent

There was no patient care involved in this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Maikovych, O., Nosova, N., Bukartyk, N. et al. Gelatin-based hydrogel with antiseptic properties: synthesis and properties. Appl Nanosci 13, 7611–7623 (2023). https://doi.org/10.1007/s13204-023-02956-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-023-02956-6