Abstract

The nanocrystalline BaFe12O19 powders were obtained from citrate sol–gel combustion-derived powder upon annealing at 800–1100 °C, and explored their structural, micro-structural, optical and magnetic properties. The thermal decomposition of citrate sol–gel combustion product was verified by means of thermogravimetric and differential thermal analysis. Structural identification of the citrate sol–gel combustion powder and annealed samples were investigated by powder X-ray diffraction. Though the combustion product exhibits cubic spinel phase material, the annealed powder yields good quality nanocrystalline hexagonal BaFe12O19 phase materials. The thin plate-like flakes morphology with random particle sizes of ~100–200 nm with slightly agglomerated particles of BaFe12O19 phase is analyzed by high resolution scanning electron microscopy for the good quality annealed sample. Photoluminescence emission spectrum of BaFe12O19 material reveals broad emission peak at ~360 nm under the excitation wavelength of 270 nm. Interestingly, the near infrared relative reflectivity of the nanocrystalline BaFe12O19 materials obtained by citrate sol-gel synthesis method is higher than the nanocrystalline BaFe12O19 materials obtained by mechano-thermal and co-precipitation method. The present dark brown colored BaFe12O19 materials can be applied as a ceramic color pigment which includes several applications. The room temperature magnetic hysteresis loop of the annealed BaFe12O19 sample exhibits a ferromagnetic saturation magnetization, M s of 55.774 emu/g at 15 kOe.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Barium hexa-ferrite, BaFe12O19 is a permanent magnetic material which has extensively used in many interesting magnetic device applications (Durmus et al. 2011; Jiang et al. 2010; Shang et al. 2007; Vinod et al. 2011) due to its high chemical stability, corrosion resistivity, low cost, high resistivity, superior and anti-erosion properties and mechanical hardness. For the application of the material in different fields, the material has to be synthesized in pure form, and subsequently well characterized by different techniques. For example, different preparation techniques, such as solid state reaction (Qiu et al. 2005), mechano-thermal (Balamurugan et al. 2015), molten salt method (Topal et al. 2007), co-precipitation method (Radwan et al. 2007), citrate sol–gel (Mali and Ataie 2005), hydrothermal method (Wang et al. 2004) and reverse micelle technique (Xu et al. 2008) have been followed to design and develop the micro and nanoscale BaFe12O19 materials. Among these different methods, we have selected citrate sol–gel method as it has many advantages which include relatively simple, cost effective and independence of the processing parameters, etc. (Mali and Ataie 2005). Hitherto there have been several investigations reported for the citrate sol–gel processed BaFe12O19 materials (Durmus et al. 2011; Mali and Ataie 2005; Birsoza et al. 2010; Xu et al. 2006; Sozeri et al. 2012; Jiang and Ai 2010; Mali and Ataie 2004; Qiu and Gu 2006). To obtain the BaFe12O19 materials, different molar ratio of Ba:Fe:citricacid have been adopted (Durmus et al. 2011; Jiang et al. 2010; Xu et al. 2006; Mali and Ataie 2004; Chen et al. 2012; Ting and Wu 2010; Mali and Ataie 2005). According to the previous reports, the sol–gel processed materials are characterized by X-ray diffraction (Murthy et al. 2012; Liu and Xiang 2010; Song et al. 2010; Ping et al. 2008; Ebrahimi et al. 2012), thermal gravimetric analysis (Yu and Huang 2003; Yu and Liu 2006), Fourier-transform infrared, scanning electron microscope (Liu and Xiang 2010; Song et al. 2010; Ebrahimi et al. 2012), transmission electron microscope (Murthy et al. 2012), magnetometer (Durmus et al. 2011; Mali and Ataie 2005; Birsoza et al. 2010; Xu et al. 2006; Sozeri et al. 2012; Jiang and Ai 2010; Mali and Ataie 2004; Qiu and Gu 2006) for quality, phase formation, thermal decomposition, surface morphology, and magnetic property of the synthesized BaFe12O19 materials. From our recent near infrared (NIR) reflectivity study (Balamurugan et al. 2015), the BaFe12O19 material obtained by mechano-thermal process has been identified as NIR reflective color pigment due to its high NIR reflectivity in the region of wavelength 1750–2000 nm. Subsequent to our recent study, in the present work we have explored the detailed studies on the synthesis and characterization of citrate sol–gel derived BaFe12O19 materials by powder XRD, TG–DTA, FT-IR, NIR, PL, HRSEM-EDX, and vibrating sample magnetometer.

Experimental

Materials preparation

The nanocrystalline BaFe12O19 powders were prepared by citrate sol–gel auto combustion method using Ba(NO3)2, Fe(NO3)3.9H2O and citric acid as precursors in the molar ratio of 1:12:13. The appropriate amount of commercially available Ba(NO3)2 (1 g) and Fe(NO3)3.9H2O (18.5436 g) were first dissolved in minimum quantity (20 ml) of deionized water in separate borosil glass beaker. The pH of the solutions of Ba(NO3)2 and Fe(NO3)3.9H2O were 6 and 1, respectively. Then, 10.4531 g of citric acid was dissolved in deionized water and its pH value noted as 2. Then, both nitrate solutions were mixed together and stirred well using a magnetic stirrer at 300 rpm for 15 min. After mixing, the citric acid solution was added dropwise in the nitrate solution and stirred well for 30 min which resulted in a deep red solution with a pH value of 2. The ammonia solution was added dropwise to the above solution to adjust the pH value to 7. The resulting solution was stirred for 30 min at ~75 °C in a magnetic stirrer and continued the heating in a heating mantle until it gets ignited. The temperature was monitored using the thermometer. Time variation and temperature were noted during gel formation, fuming, ignition and combustion processes. Gel formed at ~150 °C and ignition started at ~170 °C. Reddish yellow combustion flame was appeared inside the beaker when the temperature reached about 190 °C. After completion of combustion above ~360 °C, the ash color powder was obtained. The final citrate combustion product was collected from the beaker, and subsequently annealed at 800, 900, 1000 and 1100 °C for 2 h in a in a groove rolled muffle furnace. After completion of annealing, the furnace was cooled to room temperature.

Materials characterization

The quality and phases of present samples were examined by means of powder X-ray diffraction (Bruker, D8 Advanced) method using Cu Kα radiation (λ = 1.54156 Ǻ) at room temperature. The XRD raw data were analyzed with the JANA2006 software (Petricek et al. 2006), from which the cell parameters were calculated by the least-square method. The thermal decomposition of the combustion product was traced by thermal gravimetric and differential thermal analyses in air atmosphere from room temperature to 1000 °C in a thermal analysis system (TG/DTA6300 module EXSTAR series, Seiko Instruments Inc., Japan). The Fourier-transform infrared (FT–IR) spectra were recorded on a Perkin-Alpha optic instrument equipped with KBr beam splitter spectrometer at a resolution of 4 cm−1. A very small amount of present series powder sample was mixed finely with little amount of KBr and pressed in a cylindrical (13 mm) die under three ton pressure to obtain a thin disk like pellet. The FT-IR spectra were recorded at ambient conditions in the wavelenumber range from 4000 to 400 cm−1. The photoluminescence (PL) spectra of the annealed powder samples were performed in a spectrofluorometer (ELICO SL 174) using 150 Watt Xenon Arc lamp as the excitation light source. The near infrared (NIR) spectra of all the combustion product and annealed materials were performed in an NIR spectrophotometer (ELICO SL 153) using a quartz halogen lamp as the light source. The surface morphological images and the elements present in the selected BaFe12O19 powder sample were analyzed by the field emission scanning electron microscope; FESEM (F E IQuanta FEG 200) attached with energy dispersive X-ray analyzer. The magnetic hysteresis curve of the selected BaFe12O19 powder was measured by vibrating sample magnetometer (VSM) with a maximum applied field of 15 kOe at room temperature.

Results and discussion

Thermogravimetric analysis of citrate sol–gel combustion product

The combustion product obtained by citrate sol–gel method was studied by TG–DTA analysis and their respective TG and DTA curves are demonstrated in Fig. 1. The weight loss of ~1.6 % is seen in the TG curve from the initiation up to ~400 °C. This weight loss can be assigned for the liberation of the surface absorbed species of the as-prepared combustion product. Followed by about ~2.8 % of weight loss is seen between ~400 and ~780 °C. This weight loss may be related to the removal of residual volatile species present in the combustion product. No significant weight loss (~0.2 %) is observed between ~780 and ~850 °C. Further no weight loss is noticed in the TG curve above 900 °C, which is confirming the formation of main BaFe12O19 phase material. The weight losses seen in the TGA curve concur with endothermic thermal events seen in the DTA curve at ~375, ~500 and ~850 °C. A small exothermic-like peak is observed at ~850 °C in DTA curve is due to the phase formation temperature of BaFe12O19 materials (Vinod et al. 2011).

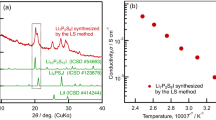

Powder XRD structural analysis

Figure 2a–e illustrates the powder XRD patterns of as-prepared citrate sol–gel combustion product, and subsequently annealed at different temperature powder samples. The XRD pattern of as-prepared (Fig. 2a) material clearly indicates that the expected BaFe12O19 phase was not formed in the combustion process. From the literature, we learnt that the formation of BaFe12O19 phase was found to involve two steps, that is the formation of BaFe2O4 phase, followed by the reaction between BaFe2O4 and iron oxide (α- or γ-Fe2O3) (Shang et al. 2007; Mali and Ataie 2004, 2005; Qiu and Gu 2006). According to Mali and Ataie (2005), the XRD pattern of their as-burnt powder indicates the presence of γ-Fe2O3 as a major phase and some other minor phases, namely α-Fe2O3, BaCO3, BaO2 and BaFe12O19. At first sight we can say that the XRD pattern of our citrate sol–gel combustion product implies the formation of cubic spinel phase. Therefore, we tried to identify the formation of cubic spinel phase for the possible nominal composition BaFe2O4 and Fe3O4 from the XRD pattern of combustion product, though BaFe2O4 is not reported as a cubic phase in literature. First, we tried to extract the lattice parameters for the composition, BaFe2O4 for a cubic structure using space group, Fd-3m (227) with formula unit, Z = 8, taking MgFe2O4 as standard cubic phase (Ohbayashi and Iida 1967). All the reflections of combustion product match for the cubic spinel phase (for example, BaFe2O4), except one strong impurity peak (2θ = 23.94°). Using JANA 2006 software, the cubic lattice parameter, a = 0.835(1) nm is obtained which is in good agreement with the cubic spinel phase (Ohbayashi and Iida 1967). While the BaFe2O4 phase is reported (Candeia et al. 2007; Pawar and Pardeshi 2014) as an orthorhombic spinel like space group, Bb21m (36) with lattice parameters, a = 1.9042 nm, b = 0.53838 nm and c = 0.84445 nm (JCPDS 46-0113), our citrate sol–gel combustion product material exhibits almost cubic spinel type BaFe2O4 phase (see, Fig. 3a). A strong peak seen at 2θ = 23.94° in Fig. 2a is owing due to the presence of BaCO3 phase (Pawar and Pardeshi 2014). Quite similar cubic spinel structure of CoFe2O4 phase was found in the literature for the cobalt substituted, Ba1−x Co x Fe12O19 phase (x = 1.0) (Chavan et al. 2016). Further, we tried to find out the formation of cubic spinel Fe3O4 phase from the XRD pattern of combustion product which exhibits a = 0.836(1) nm, is in good agreement with the cubic spinel (Fe3O4) phase (see, Fig. 3b). Therefore, we believe that our citrate sol–gel combustion product is crystallized mainly in cubic phase (with the nominal composition either BaFe2O4 or Fe3O4). But other possible phase cannot be completely ruled out as there is a signature for the growth of extra peaks (2θ = 34.11°, 34.74° and 44.76°) and its intensities are close to the background level. As we are interested in the main phase (BaFe12O19) materials, we believe that it is needless to stress much about the citrate sol–gel combustion product.

To obtain the BaFe12O19 phase, the citrate sol–gel combustion product was annealed at four different temperatures, such as 800, 900, 1000 and 1100 °C for 2 h. Interestingly, the annealing treatment enhanced the BaFe12O19 phase formation. The sample annealed at 800 °C exhibits a small peak at 2θ = 33.1° due to α-Fe2O3 impurity phase in addition to the main BaFe12O19 phase. Upon increasing the annealing temperature, the impurity (α-Fe2O3) peak is almost disappeared and only the BaFe12O19 phase was present in the annealed powders. Further. the crystalline nature of BaFe12O19 phase is improved by annealing at 1000 and 1100 °C. The indexed peaks (Fig. 2d) are due to hexagonal BaFe12O19 phase (Balamurugan et al. 2015). High temperature annealing results the formation of phase pure BaFe12O19 materials, but it increases the crystallinity/crystalline size which is supposed less nanostructured. As the phase formation of nanostructured BaFe12O19 materials is rather complicated and sensitive to many parameters, it is rather difficult to predict the ideal annealing temperature of BaFe12O19 materials. However, from our present study we confirm that 1000 °C is the ideal annealing temperature for the formation of phase pure nanocrystalline BaFe12O19 materials. Further from the literature (Jiang et al. 2010; Balamurugan et al. 2015; Topal et al. 2007; Radwan et al. 2007; Mali and Ataie 2005) we learnt that many reports suggest 1000 °C is the ideal annealing temperature for the formation of phase pure BaFe12O19 materials. The structural parameters, such as lattice parameter, cell volume, density, average crystalline size, dislocation density, lattice strain, micro strain and stacking fault of the present series samples are extracted from the structural refinement using the XRD data. The crystalline size (D) was extracted by the Debye–Scherrer equation which is expressed as D = Kλ/βcosθ, where K = 0.9, λ is the wavelength of X-ray radiation (Cu Kα) used for diffraction, β is the full width half maxima (FWHM), and θ is the diffraction angle. The average crystalline size (D) is found in the range of 32–42 nm for the annealed samples (see Table 1). The value of D increases with increase of annealing temperature. The dislocation density, lattice strain, micro strain, and stacking fault for the present series samples are extracted from δ = 1/D 2 (Sathyamoorthy et al. 2006; Sharma et al. 2011; Touati et al. 2014; Bindu and Thomas 2014), ε = β/4 × tanθ (Thool et al. 2014), ε = β × cosθ/4 (Sathyamoorthy et al. 2006; Sharma et al. 2011) and SF = 2π2/45√(3tanθ) (Touati et al. 2014; Thool et al. 2014), respectively, and their values are given in Table 1. From Table 1 we notice that the dislocation density, lattice strain, micro strain, and stacking fault for the annealed samples decrease with the increase of annealing temperature.

HRSEM micrographs and EDX quantitative analysis of BaFe12O19 nanomaterials

The surface morphology of the selected (annealed at 1000 °C) good quality nanocrystalline BaFe12O19 material was examined using HRSEM and EDX techniques. The different HRSEM images taken under different magnifications are presented in Fig. 4a–d. The lower magnification images (a, b) seem thin plate-like flakes morphology with random sizes with moderate agglomeration of nanoparticles. Under higher magnification, the micro images (c, d) also reveal the same features with the measured size of the range of 100–200 nm. Agglomeration seems unavoidable due to the magnetic interaction between the nanocrystalline BaFe12O19 particles (Jiang and Ai 2010; Sathyamoorthy et al. 2006). In some cases, the micro image crystalline/grain sizes of samples are larger than the crystalline size estimated by XRD (Ebrahimi et al. 2012; Balamurugan and Melba 2015). For example, the XRD crystalline size of present BaFe12O19 nanomaterials is found to be ~44 nm, whereas the HRSEM micrograph showed 100–200 nm. The inconsistency in crystalline sizes obtained from XRD and SEM/TEM is ascribed to the non-isometric shape of BaFe12O19 nanomaterials (Yu and Lin 2004) and polycrystalline nature of the materials (Ebrahimi et al. 2012; Balamurugan and Melba 2015). The wide range of XRD crystalline sizes of BaFe12O19 nanomaterials are reported as 95 nm (Murthy et al. 2012), 38.2–72.1 nm (Liu and Xiang 2010), 32.6–71.1 nm (Song et al. 2010), 44–53 nm (Ebrahimi et al. 2012), and 33 nm (Yu and Lin 2004) for the citrate sol–gel processed materials by different research groups. The literature survey on the morphological images we could see the wide range (30–500 nm and in somes ~6 μm) of particle/grain sizes for the citrate sol–gel processed BaFe12O19 materials. The particles in different shapes, namely spherical, polygonic, plate-like shape with random orientation, hexagonal, small elongated, polyhedrons with clear cut boundaries, hollow spherical, flaky are reported for the BaFe12O19 materials. Though agglomeration of nanoparticles appears unavoidable in most of the combustion derived nanocrystalline materials, it is possible to prevent the agglomeration by surface functionalization of the nano ferrites with various types of organic ligands for example polymers, proteins, pepetides and small organic molecules (Durmus et al. 2011; Jiang et al. 2010; Birsoza et al. 2010; Ting and Wu 2010). In the present citrate sol–gel synthesis, citric acid acts as fuel to complete the combustion reaction. By modifying the synthesis condition, the surface functionalization of nano hexa-ferrites with the organic ligands is possible to prevent the agglomeration (Durmus et al. 2011; Jiang et al. 2010). However, this should be confirmed by conducting further experiments. The surface morphology of the hybrid hexa-ferrite materials should be evaluated by comparing of hexa ferrite material before and after the functionalization.

The energy dispersive X-ray (EDX) analysis was performed on the present surfaces of thin plate-like flakes materials to examine the presence of elemental composition and the EDX spectrum is displayed in Fig. 5. The EDX spectrum reveals the presence of Ba, Fe, and O elements in the BaFe12O19 materials at the correct proportion without any impurity phases. The extracted EDX quantitative data are given in the Table 2. The appearance of carbon (C) peak is owing to the carbon grid used as a sample holder.

FT-IR spectra of present series samples

Figure 6 exhibits the FT-IR spectra taken in the wavenumber range of 4000–400 cm−1 for the combustion product and annealed (800, 900, 1000, and 1100 °C) materials. The FT-IR spectra of all the present samples show two IR characteristics bands between 420 and 600 cm−1 which are attributed to the Fe–O stretching vibration of ferrite materials (Jiang et al. 2010; Parkin et al. 2001). Further few additional FT-IR bands are seen between 1000 and 4000 cm−1 in all the present samples due to the stretching vibrations of atmospheric species (H2O/OH and CO3 2−) adsorbed on the surface of the materials (Huang et al. 2003; Hong et al. 2004; Qiu et al. 2005). A minor broad IR bandseen at ~3480 cm−1 in all the samples is due to O–H stretching band of H2O (Huang et al. 2003). The IR bands seen at ~1640 and ~1452 cm−1 for all samples can be indexed for the anti symmetrical and symmetrical stretching vibrations of carbonate species (Hong et al. 2004). The band lying from 1380 to 1400 cm−1 corresponds to the antisymmetrical and symmetrical stretching vibrations of COO− (Huang et al. 2003).

PL emission spectra of BaFe12O19 materials

The room temperature PL emission spectra of different annealed (at different temperatures such as 800, 900, 1000, and 1100 °C) BaFe12O19 materials are presented in Fig. 7. The PL emission spectra are taken under the excitation wavelength, λ ex = 270 nm for all annealed samples. The PL emission spectrum of BaFe12O19 material exhibits a broad emission peak at ~360 nm. Similar to the present BaFe12O19, the BaFe12O19 material prepared by co-precipitation method has also shown a PL emission peak at ~360 nm under excitation wavelengths of 270 nm (Balamurugan and Resmi 2015). The fluorescence intensity increases upon annealing the combustion product at 900 °C, and then decreases significantly with increasing annealing temperature to 1100 °C.

NIR spectra of BaFe12O19 materials

The NIR spectra measured in the spectral region, 1500–2500 nm for the combustion product as well as different annealed BaFe12O19 materials are shown in Fig. 8a–e. From this figure we notice that the annealed hexagonal BaFe12O19 phase materials reveal high (85–110 %) NIR relative reflectivity at ~1750 nm, whereas the combustion product shows ~28 % NIR relative reflectivity in the wavelength range, 1500–2500 nm. Among the different annealed samples, the BaFe12O19 material obtained after annealing at 800 °C shows higher (~110 %) NIR relative reflectance than other annealed samples. Though annealing yielded single phase of BaFe12O19, it suppressed the NIR reflectivity of the annealed materials which may be due to the increase in the crystalline size of the annealed samples. The visual appearance (dark brown color) of the present series samples are shown in Fig. 9a–e. From this we could see no significant variation in color of the present pigments. It is important to note that the NIR relative reflectivity of the nanocrystalline BaFe12O19 materials obtained by citrate sol–gel synthesis method is higher than the nanocrystalline BaFe12O19 materials obtained by mechano-thermal (Qiu et al. 2005) and co-precipitation method (Balamurugan and Resmi 2015). The present dark brown colored BaFe12O19 materials can be applied as ceramic color pigment which includes several applications.

Like the present hexa-ferrite, BaFe12O19 materials, there are several spinel ferrites and other ferrites are also found to use as NIR pigment (Candeia et al. 2007; Chaudhry et al. 2015; Benda and Kalendová 2013; Costa et al. 2008; Opuchovic et al. 2015; Liu et al. 2015). As the NIR pigment has found potential applications in solar reflective and color pigment, currently the research is focused to identify the different novel pigments. Our recent article summarizes the literature survey on the NIR reflectivity of some binary oxides and complex oxide systems (Balamurugan et al. 2016). Generally, binary oxides show high NIR reflectivity in the NIR region. However, some complex oxide systems (Balamurugan et al. 2016) also show high NIR reflectivity. Due to the impact of citrate sol–gel synthesis method, the present hexa-ferrite BaFe12O19 materials have also competent to binary oxides to show high NIR reflectivity.

Magnetic properties of nanocrystalline BaFe12O19 material

The magnetic hysteresis loop (M–H) for the selected (1000 °C) BaFe12O19 sample was recorded at room temperature with increasing magnetic fields up to ±15 kOe; −15 kOe ≤ H ≤ 15 kOe. The M–H curve is depicted in Fig. 10. The resultant magnetic values of the coercive field, (H c), magnetization (M s), and retentivity (M r) are found to be 3705.3 Oe, 55.774, and 30.313 emu/g, respectively. These M s, M r, and H c values are comparable to the literature values reported for the BaFe12O19 phase materials (Durmus et al. 2011; Jiang et al. 2010; Shang et al. 2007; Vinod et al. 2011; Mali and Ataie 2005; Birsoza et al. 2010; Xu et al. 2006; Sozeri et al. 2012; Jiang and Ai 2010; Mali and Ataie 2004; Qiu and Gu 2006; Parkin et al. 2001; Hong et al. 2004; Rafique et al. 2013; Castro et al. 1997; Ounnunkad and Winotai 2006). The ratio M r/M s of the present BaFe12O19 sample is found to be 0.543 which is comparable to the reported values (Shang et al. 2007; Birsoza et al. 2010). The wasp-waist-like shape of the hysteresis loop reveals that the major BaFe12O19 phase may contains trace amount of magnetic impurity (α- or γ-Fe2O3) phase that cannot be detected by the limit of XRD technique. Such a wasp-waist-like shape of the hysteresis loop was reported in the literature for the BaFe12O19 phase (Mali and Ataie 2005; Wang et al. 2007). Table 3 summarizes the room temperature magnetic properties of the hexagonal BaFe12O19 phase materials obtained by sol–gel combustion methods (Durmus et al. 2011; Jiang et al. 2010; Shang et al. 2007; Vinod et al. 2011; Mali and Ataie 2004, 2005; Birsoza et al. 2010; Xu et al. 2006; Sozeri et al. 2012; Jiang and Ai 2010; Qiu and Gu 2006; Parkin et al. 2001; Hong et al. 2004; Rafique et al. 2013; Castro et al. 1997; Ounnunkad and Winotai 2006). From this Table 3 we notice the important magnetic characteristics of BaFe12O19 and/or some doped BaFe12O19 phase materials.

Though the BaFe12O19 materials have been synthesized largely by citrate sol–gel method and characterized by various techniques, to our knowledge the optical studies based on NIR reflectivity and photoluminescence characterizations have not been reported for the citrate sol–gel synthesized BaFe12O19 materials. Thus, we believe that the NIR reflectivity and photoluminescence characterizations presented here for the citrate sol–gel synthesized BaFe12O19 materials is the novelty of this work. Further, the TG/DTA thermograms (Fig. 1) of our citrate sol–gel synthesized combustion product are rather different from the literature reports (Durmus et al. 2011; Vinod et al. 2011; Mali and Ataie 2004, 2005; Song et al. 2010) as it shows the plausible formation of cubic phase which is confirmed by XRD analysis (Fig. 3).

Conclusion

The present citrate sol–gel synthesis method yielded good quality hexagonal phase BaFe12O19 nanomaterials upon annealing the as-prepared combustion product at 800–1000 °C for 2 h. The powder XRD, TG, FT-IR, HRSEM-EDX, NIR, PL, magnetization, and UV-visible absorption techniques were used for the characterization of the present work. From the XRD results, we noticed that the phase transformation of cubic spinel phase of the combustion product to hexagonal BaFe12O19 phase for the annealed materials. Thin plate-like flakes morphology with random sizes of around 100–200 nm particles are seen in the BaFe12O19 materials. The present BaFe12O19 nanomaterial has potential application in NIR reflective color pigment as this citrate sol–gel method has significantly enhanced the NIR reflectivity of the annealed materials. The field depend magnetization of the annealed BaFe12O19 sample exhibited a M s of 55.774 emu/g under the extreme applied magnetic field of 15 kOe.

References

Balamurugan S, Melba K (2015) Zn1-x Cu x O (0.02 ≤ x ≤ 0.1) nanomaterials prepared by ball milling, citrate sol–gel, and molten salt flux methods. J Nanosci Nanotechnol 15:4632–4640

Balamurugan S, Resmi SP (2015) Synthesis of nanocrystalline BaFe12O19 materials by co-precipitation method using KOH and K2CO3 as precipitating agent. Adv Sci Eng Med 7:183–189

Balamurugan S, Brightlin BC, Kiruba VSA (2015) Synthesis of BaFe12O19 materials by mechano-thermal route: novel inorganic pigment with high near-infrared reflectance. J Nanosci Nanotechnol 15:9494–9499

Balamurugan S, Dheebikha K, Gokul Raja TS (2016) Nanocrystalline Gd2Ti2O7 pyrochlore material for NIR reflective pigment application: micro-structural and optical studies. J Nanosci Nanotechnol 16:677–688

Benda P, Kalendová A (2013) Anticorrosion properties of pigments based on ferrite coated zinc particles. Phys Proced 44:185–194

Bindu P, Thomas S (2014) Estimation of lattice strain in ZnO nanoparticles: X-ray peak profile analysis. J Theor Appl Phys 8:123–134

Birsoza B, Baykala A, Sozerib H, Toprakc MS (2010) Synthesis and characterization of polypyrrole–BaFe12O19 nanocomposite. J Alloys Compd 493:481–485

Candeia RA, Souza MAF, Bernardi MIB, Maestrelli SC, Santos IMG, Souza AG, Longo E (2007) Monoferrite BaFe2O4 applied as ceramic pigment. Ceram Int 33:521–525

Castro S, Gayoso M, Rodroguez C (1997) A study of the combustion method to prepare fine ferrite particles. J Solid State Chem 134:227–231

Chaudhry Ali U, Mittal Vikas, Mishra Brajendra (2015) Nano nickel ferrite (NiFe2O4) as anti-corrosion pigment for API 5L X-80 steel: an electrochemical study in acidic and saline media. Dyes Pigm 118:18–26

Chavan VC, Shirsath SE, Mane ML, Kadam RH, More SS (2016) Transformation of hexagonal to mixed spinel crystal structure and magnetic properties of Co2+ substituted BaFe12O19. J Magn Magn Mater 398:32–37

Chen W, Zheng J, Li Y (2012) Synthesis and electromagnetic characteristics of BaFe12O19/ZnO composite material. J Alloys Compd 513:420–424

Costa ACFM, Leite AMD, Ferreira HS, Kiminami RHGA, Cava S, Gama L (2008) Brown pigment of the nanopowder spinel ferrite prepared by combustion reaction. J Eur Ceram Soc 28:2033–2037

Durmus Z, Unal B, Toprak MS, Sozeri H, Baykal A (2011) Synthesis and characterization of poly(3-thiophenyl acetic acid) (P3TAA)–BaFe12O19 nanocomposite. Polyhedron 30:1349–1359

Ebrahimi Y, Alvani AAS, Sarabi AA, Sameie H, Salimi R, Alvani MS, Moosakhani S (2012) A comprehensive study on the magnetic properties of nanocrystalline SrCo0.2Fe11.8O19 ceramics synthesized via diverse routes. Ceram Int 38:3885–3892

Hong YS, Ho CM, Hsu HY, Liu CT (2004) Synthesis of nanocrystalline Ba(MnTi) x Fe12-x O19 powders by the sol–gel combustion method in citrate acid–metal nitrates system (x = 0, 0.5, 1.0, 1.5, 2.0). J Magn Magn Mater 279:401–410

Huang J, Zhuang H, Li WL (2003) Synthesis and characterization of nano crystalline BaFe12O19 powders by low temperature combustion. Mater Res Bull 38:149–159

Jiang J, Ai LH (2010) Facile synthesis, characterization and properties of Ba-hexaferrite/ZnO hybrid structures. Phys B 405:2640–2642

Jiang J, Ai LH, Liu L-Y (2010) Poly(aniline-co-o-toluidine)/BaFe12O19 composite: preparation and characterization. Mater Lett 64:888–890

Liu M, Xiang J (2010) Formation and characterization of magnetic barium ferrite hollow fibers with high specific surface area via sol-gel process. Solid State Sci 12:1603–1607

Liu L, Han A, Ye M, Feng W (2015) The evaluation of thermal performance of cool coatings colored with high near-infrared reflective nano-brown inorganic pigments: magnesium doped ZnFe2O4 compounds. Sol Energy 113:48–56

Mali A, Ataie A (2004) Influence of the metal nitrates to citric acid molar ratio on the combustion process and phase constitution of barium hexaferrite particles prepared by sol–gel combustion method. Ceram Int 30:1979–1983

Mali A, Ataie A (2005a) Structural characterization of nano-crystalline BaFe12O19 powders synthesized by sol–gel combustion route. Scripta Mater 53:1065–1070

Mali A, Ataie A (2005b) Influence of Fe/Ba molar ratio on the characteristics of Ba-hexaferrite particles prepared by sol–gel combustion method. J Alloys Compd 399:245–250

Murthy JK, Mitra C, Ramc S, Venimadhav A (2012) Temperature dependent magnetic and dielectric properties of M-type hexagonal B aFe12O19 nanoparticles. J Alloys Compd 545:225–230

Ohbayashi K, Iida S (1967) Oxygen content and thermomagnetic properties in Cu1-x Mg x Fe2O4. J Phys Soc Jpn 23:776–785

Opuchovic Olga, Kreiza Gediminas, Senvaitiene Jurate, Kazlauskas Karolis, Beganskiene Aldona, Kareiva Aivaras (2015) Sol-gel synthesis, characterization and application of selected sub-microsized lanthanide (Ce, Pr, Nd, Tb) ferrites. Dyes Pigment 118:176–182

Ounnunkad S, Winotai P (2006) Properties of Cr-substituted M-type barium ferrites prepared by nitrate–citrate gel-autocombustion process. J Magn Magn Mater 301:292–300

Parkin IP, Elwin G, Kuznetsov MV, Pankhurst QA, Bui QT, Forster GD, Barquin LF, Komarov AV, Morozov YG (2001) Self-propagating high temperature synthesis of MFe12O19 M = (Sr, Ba) from the reactions of metal superoxides and iron metal. J Mater Proc Technol 110:239–243

Pawar RY, Pardeshi SK (2014) Selective oxidation of styrene to benzaldehyde using soft BaFe2O4 synthesized by citrate gel combustion method. Arab J Chem. doi:10.1016/j.arabjc.2014.08.012

Petricek V, Dusek M, Palatinus L (2006) Jana 2006. The crystallographic computing system. Institute of Physics, Praha

Ping JW, Ying L, Lin ZM, Jie QY, Tian X (2008) Comparison of the sol-gel method with the coprecipitation technique for preparation of hexagonal barium ferrite. Chem Res Chin Univ 24(5):525–528

Qiu J, Gu M (2006) Crystal structure and magnetic properties of barium ferrite synthesized using GSPC and HEBM. J Alloys Compd 415:209–212

Qiu J, Haigen S, Gu M (2005a) Microwave absorption of nanosized barium ferrite particles prepared using high-energy ball milling. Powder Technol 154:116–119

Qiu J, Liang L, Gu M (2005b) Nanocrystalline structure and magnetic properties of barium ferrite particles prepared via glycine as a fuel. Mater Sci Eng, A 393:361–365

Radwan M, Rashad MM, Hessien MM (2007) Synthesis and characterization of barium hexaferrite nanoparticles. J Mater Proc Technol 181:106–109

Rafique MS, Anjum S, Siraj K (2013) Magnetic anisotropy in nano-crystalline BaFe12O19 thin films deposited under various applied magnetic fields. Thin Sol Film 545:608–613

Sathyamoorthy R, Chandramohan S, Sudhagar P, Kanjilal D, Kabiraj D, Asokan K (2006) Structural and photoluminescence properties of swift heavy ion irradiated CdS thin films. Sol Energy Mater Sol Cel 90:2297–2304

Shang H, Wang J, Liu Q (2007) Synthesis and characterization of nanocrystalline BaFe12O19 obtained by using glucose as a fuel. Mater Sci Eng, A 456:130–132

Sharma G, Gosavi SW, Lochab SP, Singh N (2011) Effect of swift heavy ion irradiation on Ce doped CaS nanophosphors. AIP conference proceedings 1391, 558. doi:10.1063/1.3643609

Song F, Shen X, Xiang J, Zhu Y (2010) Characterization and magnetic properties of Ba x Sr1−x Fe12O19 (x = 0–1) ferrite hollow fibers via gel-precursor transformation process. J Alloys Compd 507:297–301

Sozeri H, Durmus Z, Baykal A, Uysal E (2012) Preparation of high quality, single domain BaFe12O19 particles by the citrate sol–gel combustion route with an initial Fe/Ba molar ratio of 4. Mater Sci Eng, B 177:949–955

Thool GS, Singh AK, Singh RS, Gupta A, Susan MABH (2014) Facile synthesis of flat crystal ZnO thin films by solution growth method: a micro-structural investigation. J Saudi Chem Soc 18:712–721

Ting T-H, Wu K-H (2010) Synthesis, characterization of polyaniline/BaFe12O19 composites with microwave-absorbing properties. J Magn Magn Mater 322:2160–2166

Topal U, Ozkan H, Dorosinskii L (2007) Finding optimal Fe/Ba ratio to obtain single phase BaFe12O19 prepared by ammonium nitrate melt technique. J Alloys Compd 428:17–21

Touati R, Rabeh MB, Kanzari M (2014) Structural and optical properties of the new absorber Cu2ZnSnS4 thin films grown by vacuum evaporation method. Energy Proced 44:44–51

Vinod ND, Mane ML, Babrekar MK, Kale CM, Jadhav KM (2011) Influence of chromium substitution on structural and magnetic properties of BaFe12O19 powder prepared by sol–gel auto combustion method. J Alloys Compd 509:4394–4398

Wang J, Chen Q, Che S (2004) Magnetic properties in BaFe12O19 nanoparticles prepared under a magnetic field. J Magn Magn Mater 280:281–286

Wang J, Wu Y, Zhu Y, Wang P (2007) Formation of rod-shaped BaFe12O19 nanoparticles with well magnetic properties. Mater Lett 61:1522–1525

Xu G, Ma H, Zhong M, Zhou J, Yue Y, He Z (2006) Influence of pH on characteristics of BaFe12O19 powder prepared by sol–gel auto-combustion. J Magn Magn Mater 301:383–388

Xu P, Han X, Zhao H, Liang Z, Wang J (2008) Effect of stoichiometry on the phase formation and magnetic properties of BaFe12O19 nanoparticles by reverse micelle technique. Mater Lett 62:1305–1308

Yu H-F, Huang K-C (2003) Effects of pH and citric acid contents on characteristics of ester-derived BaFe12O19 powder. J Magn Magn Mater 260:455–461

Yu H-F, Lin H-Y (2004) Preparation and thermal behavior of aerosol-derived BaFe12O19 nanoparticles. J Magn Magn Mater 283:190–198

Yu H-F, Liu P-C (2006) Effects of pH and calcination temperatures on the formation of citrate-derived hexagonal barium ferrite particles. J Alloys Compd 416:222–227

Acknowledgments

The author S. Balamurugan is thankful to Tamilnadu State Council for Science and Technology (TNSCST) (Ref.: AR/PS/2012–2013/209) for the partial support to the present work. The Pondicherry University, Central Instrumentation Facility (CIF) is acknowledged for extending the analytical service in the form of VSM measurement. The HRSEM-EDX for the present sample was performed at the nanotechnology research centre of SRM University, India is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Brightlin, B.C., Balamurugan, S. The effect of post annealing treatment on the citrate sol–gel derived nanocrystalline BaFe12O19 powder: structural, morphological, optical and magnetic properties. Appl Nanosci 6, 1199–1210 (2016). https://doi.org/10.1007/s13204-016-0531-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-016-0531-1