Abstract

Graphene oxide (GO) thin films were prepared by solution-casting of non-reduced suspension on glass substrates at ambient conditions. Films were rendered to conductive both with hydrazine treatment and annealing and the results were compared. Annealed films treated without hydrazine revealed superiority over the others. Surface morphology of these films showed very smooth film texture as seen by scanning electron microscope and atomic force microscope. Different optical and electrical parameters were analyzed. Band gap enhanced from 1.25 to 2.4 eV as the solution concentration was decreased where the transmittance increased. This work, in particular represents a straight forward approach compared to other studies to achieve device-quality GO thin films and the findings are important for various optoelectronic applications.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The discovery of graphene derivatives like graphene oxide (GO) has rejuvenated world wide interest as a potential candidate for large-scale production of transparent conducting electrode due to its remarkable optical and electrical properties (Shen et al. 2011; Matyba et al. 2010; Subrahmanyam et al. 2010; Novoselov et al. 2004, 2005a, b; Zhang et al. 2005; Geim et al. 2007, 2008; Morozov et al. 2008; Du et al. 2008; Bolotin et al. 2008). Knowledge of the optical constants such as optical band gap, absorption co-efficient and refractive index of semiconductors as well as their electrical properties is necessary for designing appropriate heterostructures. There is ongoing research to find out a more straightforward and cheap technique for fabrication of GO thin film to be utilized as transparent electrode. It is well known that GO produced from flake graphite can be easily dispersed in water and, furthermore, the hydrophilic nature of GO allows it to be uniformly placed onto substrates in the form of thin films. Several efforts have been made to assemble GO platelets from their water suspensions to large-area films, like vacuum filtration, spin coating, chemical vapor deposition (Eda et al. 2008a, b; Becerril et al. 2008) etc. In this work, we report a method to obtain centimeter-scale GO thin film by simply solution-casting of aqueous suspension to an appropriate amount onto clean glass substrate. The non-reduced pristine GO showed insulating behavior as usual. Reduction was then necessary to make the layers conductive for different optoelectronic applications. Many different kinds of reducing agents like hydrazine (Stankovich et al. 2007), sodium borohydride (Shin et al. 2009; Gao et al. 2009), and hydrohalic acids (Pei et al. 2010), have been used for this purpose. These chemicals introduce many difficulties in practice. For example, hydrazine reduction introduces C–N bonds (Stankovich et al. 2007), which can act as defect sites in some applications, and sodium borohydride incompletely reduces hydroxyl groups (Shin et al. 2009). In addition, these reducing agents are environmentally burdensome because they are highly toxic and hazardous.

GO single sheet consists of a hexagonal ring based carbon network having both sp2-hybridized carbon atoms and sp3-hybridized carbons bearing hydroxyl and epoxide functional groups on either side of the sheet, whereas the sheet edges are mostly decorated by carboxyl and carbonyl groups. Since GO is a non-stoichiometric compound, the optical and electrical properties depend on its synthesis, processing, and environmental conditions. We synthesized GO by an “improved” synthetic protocol (Marcano et al. 2010) and prepared large area (2.5 × 1.0) cm2 GO thin films by simple solution cast technique that demonstrated well-adhered films with better uniformity, high chemical and thermal stability. The dispersion of graphene or reduced graphene oxide (RGO) in colloidal suspensions offers the potential of making large-area graphene films (Park et al. 2009). This process allows us to control over the film thickness by simply varying the concentrations of the GO in the suspension. Annealing at a temperature as low as 170 °C for 1 h without using any reagent was assessed to be the optimum percolation condition for obtaining GO thin films having required transparency and conductivity. Thus it paves an easier way for mass-production of good quality GO films for practical applications. In the present work GO was reduced both by hydrazine and heat treatment. Thin films were prepared in both cases and optoelectronic properties were extensively studied and compared.

Materials and methods

Materials

Graphite flakes and KMnO4 were purchased from Alfa Aesar and Kanto Chemical, respectively. PTFE membrane filter with a 0.45 μm pore size was purchased from Millipore. Polyester hollow fiber (Tetoron, 90 dtex, 38 mm) was purchased from Teijin Fibers.

Synthesis of GO

Graphene oxide was synthesized with Marcano’s improved method (Marcano et al. 2010). A mixture of concentrated H2SO4/H3PO4 (180/20 mL) was added to a mixture of graphite flakes (1.5 g) and KMnO4 (9.0 g). The reaction was then heated to 50 °C and stirred for 12 h, which then was cooled to room temperature and poured onto ice (200 mL) poured with 30 % H2O2 (1.5 mL). The mixture was filtered through polyester fiber. The filtrate was centrifuged (4,500 rpm for 4 h), and the supernatant was decanted away. The remaining solid material was then washed in succession with 200 mL of water, 200 mL of 30 % HCl, and 200 mL of ethanol; for each wash, the mixture was filtered through polyester fiber with the filtrate being centrifuged (4,500 rpm for 4 h) and the supernatant decanted away. The material remaining after this extended, multiple-wash process was coagulated with 150 mL of ether and the resulting suspension was filtered over a PTFE membrane with a 0.45 μm pore size. The solid obtained on the filter was vacuum-dried overnight at room temperature, yielding 0.5 g of product.

AFM measurements

AFM measurements were performed by using a dynamic force mode atomic force microscope (SII, SPI3800N-400A) with a silicon cantilever (SI-DF3; spring constant 1.3 N m−1, resonance frequency 26 kHz). The frequency of the cantilever was set higher than the resonance frequency. The voltage of 1.0 V was applied to driven the vibration. The amplitude-damping factor was determined to a default value of the apparatus. The substrate was cleaved and dried before sample preparation. A sufficient amount of dispersed GO/H2O solution was deposited onto the glass surface and dried. The thicknesses and surface root mean square (rms) roughness of the GO thin films were measured directly by AFM.

Thin films preparation

Thin films were grown by employing solution-casting of chemically synthesized non-reduced aqueous GO suspension of concentrations 0.5, 0.3, 0.15, and 0.075 mg/ml onto chemically and ultrasonically cleaned glass substrates. A certain amount of GO suspension was first drop casted on the glass and subsequently annealed at elevated temperatures (ranging from 150 to 200 °C, for few hours duration) which resulted to well-adhered uniform thin film of rGO. The casting of solution was controlled carefully concerning that over dropping might result thicker films. The GO thin films were rendered conductive by annealing where thermal reduction was achieved using an oven and kept overnight. The films showed the optimum performance at the annealing condition of 170 °C for 1 h.

Optical characterization

Transmittance, reflectance

Optical transmittance (T) and absolute specular reflectance (R) of the films with wavelength of light incident on them were measured using a dual-beam UV–VIS-NIR recording spectrophotometer (Shimadzu, UV-3100, Japan). Light signals coming from the samples were detected by an integrating sphere.

Electrical characterization

Electrical measurements were conducted in lateral direction by using ‘Ecopia Hall-effect measurement system’ by four-point Van der Pauw approach at ambient condition. Four indium dots of about 0.1 mm were soldered at the four corners on the top surface of each film.

Results and discussion

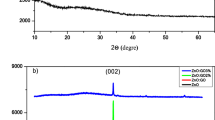

Graphene oxide was synthesized by improved method (Du et al. 2008). Firstly, thin films were prepared by depositing a sufficient amount of GO aqueous suspension with hydrazine treatment. This film became conducting at a temperature of 350 °C for 1.5 h annealing duration. Optical transmittance (%T) spectrum for this film is shown over the photon wavelength ranging between 300 and 2,500 nm in Fig. 1a. The hydrazine-treated GO films exhibit very weak adhesion to the glass substrates. Consequently, on deposition to the surface these films showed non-uniform and defective textures and very poor transmittance. The low transmittance might occur due to the increased scattering of photons by crystal defects.

Absorption co-efficient of this film is plotted as a function of photon wavelength (λ) in Fig. 1b. The hydrazine-treated film has a tendency to absorb light significantly where a steeper absorption region is observed over the entire photon wavelength regime. The optical absorption behavior of GO thin films above the fundamental absorption edge can be interpreted by considering the existence of direct allowed optical transition. Band gap were determined from Tauc’s plot of (αhv)2 versus photon energy (hv) (Fig. 1c) and was determined by extrapolating the linear part of the curves of the incident radiation to intercept the energy axis (at α = 0). The linear dependence of this plot indicates that GO films are direct transition type semiconductors.

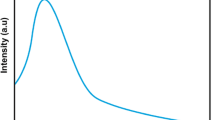

The non-hydrazine-treated GO thin films were reduced by heat treatment at different temperatures. GO thin films were prepared with 0.5 mg/ml concentration for 170 and 195 °C annealing with 45 min duration. In contrast to the hydrazine-treated film, the non-hydrazine-treated annealed films are uniform and more transparent even to the naked eye. This is also confirmed by the transmittance spectra of the films. Figure 2a represents the comparison where the film annealed with 170 °C, gives higher transmittance than the film annealed with 195 °C. The high transparency is normally associated with a good structural homogeneity.

Figure 2b shows transmittance spectra for two other GO thin films prepared with 0.15 mg/ml concentration annealed with 160 °C, 35 min and 170 °C, 1 h duration. It again shows that film produced at 170 °C for 1 h annealing shows better performance than the other does. By considering 170 °C and 1 h duration of annealing as the optimum condition another three films were prepared with 0.3, 0.15 and 0.075 mg/ml concentrations. Figure 3a shows comparative view of transmittance spectra for GO thin films with 0.5, 0.3, 0.15 and 0.075 mg/ml concentrations at this annealing condition. The average thickness of the films measured directly by AFM for 0.5, 0.3, 0.15 and 0.075 mg/ml suspensions are 65, 31.3, 25.7 and 20.4 nm, respectively. It is observed that transmission increases significantly with decreasing solution concentration. The film with the lowest concentration (i.e. 0.075 mg/ml) gives the highest transmittance and at 550 nm the transmittance value is 82 %. The average transmittance is about 82 to 94 % over a wide range of solar spectrum. Absorption co-efficient as a funtion of photon wavelength (λ) for these four GO films is shown in Fig. 3b. It is seen that the direct optical band gap (E g ) has increased from 1.25 to 2.24 eV for the lower concentration of GO suspension. Band gap energy increases almost linearly with the increase of transmittance (Fig. 3c). The decrease of band gap may be attributed to the presence of unstructured defects, which increase the density of localized states in the band gap and consequently decrease the energy. However, there is a shift in the absorption band edge. The shift in the absorption edge can be accounted for in terms of the increase in carrier concentration and blocking of low energy transitions, which causes a Burstein–Moss effect, which enhances the optical band gap. Refractive index (n) versus photon wavelength curve for these GO films is represented in Fig. 3d. The pick value increases with decreasing concentration and shifts towards higher photon wavelength in an irregular manner. All the curves show same pattern except the film with 0.075 mg/ml concentration, giving the highest transmittance. The variation of refractive index with photon wavelength for this film is similar with the results of Shen et al. (2011) where the plot is horizontal over a wider range of photon wavelength. Different optical parameters for the GO films with different maximum optical transmittance studied in this work are given in Table 1 below.

a Transmittance (%T) spectra of GO thin films of 65, 31.3, 25.7 and 20.4 nm thickness (for 0.5, 0.3, 0.15 and 0.075 mg/ml concentrations, respectively) annealed with 170 °C for 1 h. b Absorption co-efficient as a funtion of photon wavelength for these films. c Band gap, Eg as a function of maximum transmittance. d Dependence of refractive index (n) on photon wavelength, λ for these films

SEM micrograph and AFM topography for GO thin film surface for 0.075 mg/ml suspension is displayed in Fig. 4a and b, respectively. The images show wrinkle-free uniform film surface with root mean square roughness of ~1.39 nm. The sheet concentration, electrical conductivity was obtained from Hall measurement data. Figure 5 shows the Hall-effect measurements using the van-der-Pauw method that was performed in order to investigate the electrical properties of the GO thin films. Sheet concentration and electrical conductivity vary similarly with transmittance (Fig. 5a). Figure 5b shows that as the conductivity i.e. sheet concentration increases mobility decreases. In the case of the thin film, it is reasoned that the volatilization of the oxygen atoms for the thin film with lowest concentration would decrease the number of oxygen vacancies during annealing compared to the higher concentrated films, which results in a decrease in the sheet concentration and an increase in the resistance.

As shown in Fig. 5a, if we decrease the solution concentration from 0.5 to 0.075 mg/ml, the sheet concentration decreases from 9.20E + 18 to 3.74E + 18 cm−2 where the conductivity decreases from 200 to 32.50 (Ω cm)−1. It is reasoned that when the solution concentration is decreased, the number of oxygen atoms adsorbed on the thin film will be increased, causing a decrease of the defect density and resulting in a decrease of the sheet concentration. These results imply that as the solution concentration is decreased, the thin films come closer to the stoichiometrical composition and the Hall mobility is increased from 0.138 to 5.183 cm2/Vs. It is reasoned that Hall mobility is more affected by the quality enhancement of the thin film than by the change in its resistance. Figure 5c represents sheet resistance as a function of transmittance. Transmittance and sheet resistance decreased with increasing film thickness (i.e. for 0.5 mg/ml suspension); which is similar in case of graphene transparent electrode as was obtained by Wu et al. (2008). In case of annealed films the lowest sheet resistance of 869.99 (Ω/Sq.) was found at the annealing condition of 160 °C, 35 min, where the transmittance value was low. There is a trade-off between transparency and sheet resistance, since the highest transmittance (~82 % at 550 nm) of GO thin film for transparent conducting applications was found at the optimum annealing condition of 170 °C, 1 h in this work; where the sheet resistance increases (~15 KΩ/Sq.). However, it is noticeable that this low value of optimum annealing condition is favorable in practice as when compared with other studies where GO films were prepared by using various reagents at very high temperatures (Zhu et al. 2009).

Conclusions

GO thin films prepared by simply solution-casting process have properties of transparency and conductivity, which are comparable to those prepared by other methods and are thus eminently suitable for application as a low cost transparent electrode. Different optical and electrical data provide valuable information on GO thin films under this study. It is found that GO films are direct transition type semiconductors in nature. Obtained sheet resistance value (~15 KΩ/Sq.) at a low percolation condition without using any reagent is comparable to other studies (Zhu et al. 2009). Through this study, it was confirmed that GO thin films show device-quality performance by using this compatible technique; and as such skill to develop these films with varying band gap energies are useful for next generation optical component applications like, solar cell.

References

Becerril HA, Mao J, Liu Z, Stoltenberg RM, Bao Z, Chen Y et al (2008) Evaluation of solution-processed reduced graphene oxide films as transparent conductors. ACS Nano 2:463–470

Bolotin KI, Sikes KJ, Jiang Z, Fudenberg G, Hone J, Kim P, Stormer HL et al (2008) Ultrahigh electron mobility in suspended graphene. Sol Stat Commun 146:351–355

Du X, Skachko I, Barker A, Andrei EY et al (2008) Approaching ballistic transport in suspended graphene. Nat Nanotechnol 3:491–495

Eda G, Lin YY, Miller S, Chen CW, Su WF, Chhowalla M et al (2008a) Transparent and conducting electrodes for organic electronics from reduced graphene oxide. Appl Phys Lett 92:233305–233307

Eda G, Fanchini G, Chhowalla M et al (2008b) Large-area ultrathin films of reduced graphene oxide as a transparent and flexible electronic material. Nat Nanotechnol 3:270–274

Gao W, Alemany LB, Ci L, Ajayan PM et al (2009) New insights into the structure and reduction of graphite oxide. Nat Chem 1:403–408

Geim AK, Novoselov KS et al (2007) The rise of graphene. Nat Mater 6:183–191

Geim AK, Kim P et al (2008) Graphene on gallium arsenide: engineering the visibility. Sci Am 298:68–75

Marcano DC, Kosynkin DV, Berlin JM, Sinitskii A, Sun Z, Slesarev A, Alemany LB, Lu W, Tour JM et al (2010) Improved synthesis of graphene oxide. ACS Nano 4:4806–4814

Matyba P, Yamaguchi H, Eda G, Chhowalla M, Edman L, Robinson ND et al (2010) Graphene and mobile ions: the key to all-plastic, solution-processed light-emitting devices. ACS Nano 4:637–642

Morozov SV, Novoselov KS, Katsnelson MI, Schedin F, Elias C, Jaszczak JA, Geim AK et al (2008) Giant intrinsic carrier mobilities in graphene and its bilayer. Phys Rev Lett 100:016602–016605

Novoselov KS, Geim AK, Morozov SV, Jiang D, Zhang Y, Dubonos SV, Grigorieva IV, Firsov AA et al (2004) Electric field effect in atomically thin carbon films. Science 306:666–669

Novoselov KS, Jiang D, Schedin F, Booth TJ, Khotkevich VV, Morozov SV, Geim AK et al (2005a) Two-dimensional atomic crystals. Proc Nat Acad Sci 102:10451–10453

Novoselov KS, Geim AK, Morozov SV, Jiang D, Katsnelson MI, Grigorieva IV, Dubonos SV, Firsov AA et al (2005b) Two-dimensional gas of massless Dirac fermions in graphene. Nature 438:197–200

Park S, Ruoff RS et al (2009) Chemical methods for the production of graphenes. Nat Nanotechnol 4:217–224

Pei S, Zhao J, Du J, Ren W, Cheng H-M et al (2010) Direct reduction of graphene oxide films into highly conductive and flexible graphene films by hydrohalic acids. Carbon 48:4466–4474

Shen Y, Zhou P, Sun QQ, Wan L, Li J et al (2011) Optical investigation of reduced graphene oxide by spectroscopic ellipsometry and the band-gap tuning. Appl Phys Lett 99:141911–141913

Shin H-J, Kim KK, Benayad A, Yoon S-M, Park HK, Jung I-S et al (2009) Efficient reduction of graphite oxide by sodium borohydride and its effect on electrical conductance. Adv Funct Mater 19:1987–1992

Stankovich S, Dikin DA, Piner RD, Kohlhaas KA, Kleinhammes A, Jia Y et al (2007) Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide. Carbon 45:1558–1565

Subrahmanyam KS, Kumar P, Nag A, Rao CNR et al (2010) Blue light emitting graphene-based materials and their use in generating white light. Solid State Commun 150:1774–1777

Wu J, Becerril HA, Bao Z, Liu Z, Chen Y, Peumans P (2008) Organic solar cells with solution-processed graphene transparent electrodes. Appl Phys Lett 92:263302–263304

Zhang YB, Tan YW, Stormer HL, Kim P et al (2005) Experimental observation of the quantum Hall effect and Berry’s phase in graphene. Nature 438:201–204

Zhu Y, Cai W, Piner RD, Velamakanni A, Ruoff RS et al (2009) Transparent self-assembled films of reduced graphene oxide platelets. Appl Phys Lett 95:103104–103106

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 2.0 International License (https://creativecommons.org/licenses/by/2.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

About this article

Cite this article

Chowdhury, F.A., Morisaki, T., Otsuki, J. et al. Annealing effect on the optoelectronic properties of graphene oxide thin films. Appl Nanosci 3, 477–483 (2013). https://doi.org/10.1007/s13204-012-0144-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-012-0144-2