Abstract

Two modifying agents, citric acid and EDTA-2Na, were used to modify USY zeolite to obtain the hierarchical USY with high crystallinity. XRD, N2 isothermal sorption, 27Al and 29Si NMR, and TEM were adopted to characterize the dealumination process in the post-treatment of USY. The results showed that all modified USY have increased surface areas and pore volume due to the removal of non-framework Al species. Besides, framework dealumination occurred in the modification process. USY-EC, which was modified by the combined effects of citric acid and EDTA-2Na, has the highest SiO2/Al2O3 ratio of 19.40 and relatively high crystallinity.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Zeolite-containing catalysts have been playing important roles in oil refining and petrochemical fields [1]. Crystalline aluminosilicate Y zeolite has typical microporous structure and three-dimensional channels. Due to its adjustable acidity, high surface area, and thermal/hydrothermal stabilities, Y zeolite has been widely used in many reactions such as fluid catalytic cracking (FCC) [2], hydrocracking [3], alkylation [4] and desulfurization [5]. However, with the crude oil supplies becoming severe and inferior, the micropore of conventional Y zeolite set severe limitation on the diffusion of large-molecule reactants and products [6]. Moreover, the porthole is easily blocked up with the bigger molecules in severe and inferior feedstock, which deactivates the FCC catalyst quickly and reduces the conversion of feedstock. Nanosized zeolite and hierarchical (i.e., micro-, mesoporous) materials can substantially increase the external surface area and shorten the diffusion path length in micropores [7, 8]. Therefore, various strategies have been developed to obtain extra-large-pore zeolites [9, 10], nanosized zeolites [11–13] and hierarchical zeolites [14–16]. For Y zeolite, two approaches have been developed to obtain hierarchical structures, involving direct synthesis using dual templates [17] and post-treatment of Y zeolite by desilication or dealumination using acid or alkali. Hierarchical Y zeolite by acid dealumination has enhanced thermal/hydrothermal stabilities along with the extraction of Al atoms from zeolite lattices [18, 19]. In contrast, desilication of Y zeolite by alkali can generate enough defects and rich mesoporosity in inner zeolite [20]. Various acid and basic agents such as phosphoric acid, citric acid, ammonium fluorosilicate and NaOH have been adopted to modify Y and ZSM-5 zeolites in our previous studies [21–24]. However, one obvious drawback of post-treatment is the great reduction of crystallinity which decreases the structural stability. Therefore, it is a challenge to generate more mesopores on Y zeolite while maintaining its high crystallinity. In this study, the combined action of citric acid and ethylenediaminetetraacetic acid disodium salt (EDTA-2Na) was adopted to modify USY zeolite to create hierarchical USY with high surface area.

Experimental section

Raw materials

A commercial available USY was purchased from Zibo Huaxing Powder Co. Ltd. and its bulk SiO2/Al2O3 was 5.9 (derived from XRF analysis). Citric acid (C6H8O7, AR) and ethylenediaminetetraacetic acid disodium salt (C10H14N2Na2O8·2H2O, EDTA-2Na, AR) were purchased from Sinopharm Chemical Reagent Co. Ltd.

Preparation of hierarchical USY

5.0 g of parent USY zeolite was treated with 50 mL of modifier-containing aqueous solution at 80 °C for 4 h under stirring. EDTA-2Na solution (0.2 mol/L), citric acid solution (0.2 mol/L), and a complex solution of EDTA-2Na (0.1 mol/L) and citric acid (0.1 mol/L) were separately adopted to modify USY. The suspension was then filtered and washed with deionized water. Hierarchical USY was finally obtained after the drying of the filtering cake at 110 °C overnight. Three USY samples were marked as USY-E, USY-C, and USY-EC corresponding to modifiers EDTA-2Na, citric acid, and complex modifiers of EDTA-2Na and citric acid.

Characterization

X-ray diffraction (XRD) patterns were recorded on a Bruker AXS diffractometer (Germany) using Cu–Kα radiation operating at 40 kV and 40 mA, scanning from 5° to 45° and at a speed of 0.01°/s. N2 isothermal sorption was measured at −196 °C on Micrometrics TRISTAR 3000 analyzer. The samples were outgassed at 300 °C for 4 h at vacuum pressure prior to N2 sorption measurement. Specific surface area was calculated by the Brunauer–Emmett–Teller (BET) method using experimental points in the relative pressure range of 0.05–0.25. Solid-state nuclear magnetic resonance (NMR) experiments were performed using Bruker Advance III 400 spectrometer at resonance frequencies 104.0 MHz for 27Al and 29Si. The Bruker 4.0 mm MAS probe was used for acquisition of 10 kHz spectra. The single-pulse sequence with rf-pulse duration of 0.3 μs (π/20°) and recycling time of 0.3 s was used. Transmission electron microscopy (TEM) images were acquired on a JEOL JEM 2100 electron microscope operated at an accelerating voltage of 200 kV.

Results and discussion

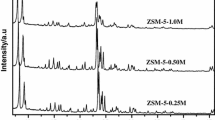

XRD patterns show that all samples possess the faujasite Y phase (Fig. 1a) and the intensities of characteristic peaks rarely change. The calculation results from XRD analysis show that USY-E has higher crystallinity, while USY-C and USY-EC have slightly lower crystallinities compared with parent USY. It is ascribed to the removal of non-framework aluminum species. Besides, the peak positions of faujasite Y phase of modified USY shift to higher degree compared with parent USY. Figure 1b shows the peak position shift of THE (533) lattice plane. It means that the unit cell size of USY becomes smaller. It may be ascribed to the dealumination of framework aluminum by modifying agents, since THE bond length of Al–O (1.75 Å) is bigger than Si–O (1.61 Å). It coincides with the SiO2/Al2O3 derived from NMR results below.

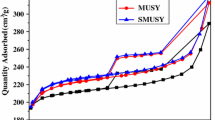

N2 isothermal sorption in Fig. 2 shows that all samples have typical IV-type curves with wide hysteresis loop indicative of mesoporous structures. The results in Table 1 show that the total surface area and micropore surface area of modified USY increase largely, while mesopore surface area of USY-C and USY-EC increase slightly compared with THE parent USY. Pore volumes have the same trends as above. It is worth nothing that only USY-EC has the highest increases of mesopore surface area and mesopore volume. It indicates that the combination effect of two modifiers on dealumination is more effective to clear microporous channels and generate secondary mesopores than one modifying agent.

27Al and 29Si NMR were used to analyze the coordination modes of framework Si and Al atoms (Figs. 3, 4). To discuss the changes of Al species, the peak were deconvoluted into the four types of Al fragments (Fig. 3). The resonance peak at 60 ppm is assigned to framework tetra-coordinated Al (Al(IV)a). The tail resonance peak at ~50 ppm is marked as Al(IV)b, but its assignment is unclear [16, 25–28]: (1) distorted tetra-coordinated framework Al atoms, (2) penta-coordinated aluminum species, and (3) non-framework four-coordinated Al species. The resonance peak at ~35 ppm is attributed to non-framework penta-coordinated Al species (Al(V)). The resonance peaks at ~0 ppm are attributed to extra framework hexa-coordinated Al species [both Al(VI)a and Al(VI)b]. It is obvious that the peaks of Al(VI)a, Al(VI)b, and Al(V) of modified USY decrease largely compared with the parent USY. It is consistent with the increases of surface areas and pore volumes (Table 1) which can be attributed to the removal of non-framework fragments after post-treatment of USY. The comparison of USY-C and USY-E shows that citric acid contributes to the removal of Al(V) atoms, while EDTA-2Na contributes to the removal of Al(VI) atoms. It is known that EDTA is an important complex agent and it is easy to combine with metal ions such as Al3+ (shown in Scheme 1) Besides, it is clear that almost all Al atoms of USY-EC are in the tetra-coordinated framework Al states, indicating that the modification of USY combining with citric acid and EDTA-2Na is more effective to remove non-framework dealumination compared with that with modifier alone.

It is well known that there are four kinds of Si–Al coordination states depending on the number of Si atom connected to Al atoms via bridged oxygen atom [29]. In 29Si NMR spectra, a set of broad signals can be deconvoluted into four peaks at −106, −101, −94, and −89 ppm which in turn correspond to silicon environments of Q4(Si(0Al)), Q3(Si(1Al)), Q2(Si(2Al)), and Q1(Si(3Al)). However, two dominant peaks at −106 and −101 ppm are observed in Fig. 4, indicating all samples possess Q4 and Q3 silicon environments. By calculation from 29Si NMR spectra, the framework SiO2/Al2O3 ratios of modified USY are higher than the parent USY. USY-EC has the highest SiO2/Al2O3 ratio of 19.40, indicative of the effective effects of complex modifying agents on framework dealumination. Another line centered at lower than −110 ppm is assigned to Si(4Si) of silica which belongs to the amorphous silica [30].

An analysis of the 27Al and 29Si NMR spectra shows that USY-E has a lower proportion of non-framework Al(VI) than USY-C (Fig. 3) and the former has undetected amorphous silica (Fig. 4). It indicated that non-framework dealumination occurred on USY-E, while both non-framework and framework dealumination occurred on USY-C, leading to the higher crystallinity of USY-E than USY-C (Table 1. Similarly, the degree of non-framework dealumination of USY-EC is higher than USY-C, which results in higher crystallinity for the former (Table 1).

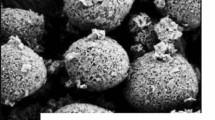

The pore-creating effects of modifying agents on USY were further verified by TEM analysis. The TEM images in Fig. 5 show that some cavities and holes form after modification consistent with the increase of pore volumes. More mesopores are generated on USY-EC than USY, but no damage to the monolithic structure is observed.

Conclusion

An effective method was introduced to obtain hierarchical USY zeolite with high surface area and crystallinity using both citric acid and EDTA-2Na. The results show that modifying agents improve the surface areas and pore volumes due to both non-framework dealumination and framework dealumination. Citric acid has better dealumination effect than EDTA-2Na to generate mesopores; however, the latter has better migrating effect for Al fragments and does not destroy the zeolite structure. Combining the dealumination effect and migration of Al species, the hierarchical USY with improved mesoporosity and relatively high crystallinity was obtained using two agents together.

References

Vermeiren W, Gilson JP (2009) Impact of zeolites on the petroleum and petrochemical industry. Top Catal 52:1131–1161

Cerqueira HS, Caeiro G, Costa L, Ribeiro FR (2008) Deactivation of FCC catalysts. J Mol Catal A: Chem 292:1–13

Shimada H, Sato K, Honna K, Enomoto T, Ohshio N (2009) Design and development of Ti-modified zeolite-based catalyst for hydrocracking heavy petroleum. Catal Today 141:43–51

Anand R, Khaire SS, Maheswari R, Gore KU (2004) Alkylation of biphenyl with t-butylalcohol over modified Y zeolites. J Mol Catal A: Chem 218:241–246

Tian F, Shen Q, Fu Z, Wu Y, Jia C (2014) Enhanced adsorption desulfurization performance over hierarchically structured zeolite Y. Fuel Process Technol 128:176–182

Ruthven DM (2001) Post, Chapter 12 Diffusion in zeolite molecular sieves. In: van Bekkum EMFPAJH, Jansen JC (eds) Studies in Surface Science and Catalysis pp 525–577

Lopez-Orozco S, Inayat A, Schwab A, Selvam T, Schwieger W (2011) Zeolitic materials with hierarchical porous structures. Adv Mater 23:2602–2615

Perez-Ramirez J, Christensen CH, Egeblad K, Christensen CH, Groen JC (2008) Hierarchical zeolites: enhanced utilisation of microporous crystals in catalysis by advances in materials design. Chem Soc Rev 37:2530–2542

Corma A, Diaz-Cabanas MJ, Jorda JL, Martinez C, Moliner M (2006) High-throughput synthesis and catalytic properties of a molecular sieve with 18- and 10-member rings. Nature 443:842–845

Přech J, Kubů M, Čejka J (2014) Synthesis and catalytic properties of titanium containing extra-large pore zeolite CIT-5. Catal Today 227:80–86

Yin X, Chu N, Yang J, Wang J, Li Z (2014) Synthesis of the nanosized MCM-22 zeolite and its catalytic performance in methane dehydro-aromatization reaction. Catal Commun 43:218–222

Abrishamkar M, Izadi A (2013) Nano-ZSM-5 zeolite: synthesis and application to electrocatalytic oxidation of ethanol. Microporous Mesoporous Mater 180:56–60

Awala H, Gilson JP, Retoux R, Boullay P, Goupil JM, Valtchev V, Mintova S (2015) Template-free nanosized faujasite-type zeolites. Nat Mater 14:447–451

Yuan E, Tang Z, Mo Z, Lu G (2014) A new method to construct hierarchical ZSM-5 zeolites with excellent catalytic activity. J Porous Mater 21:957–965

Zhu Y, Hua Z, Zhou J, Wang L, Zhao J, Gong Y, Wu W, Ruan M, Shi J (2011) Hierarchical mesoporous zeolites: direct self-assembly synthesis in a conventional surfactant solution by kinetic control over the zeolite seed formation. Chem-A Eur J 17:14618–14627

Van Aelst J, Haouas M, Gobechiya E, Houthoofd K, Philippaerts A, Sree SP, Kirschhock CEA, Jacobs P, Martens JA, Sels BF, Taulelle F (2014) Hierarchization of USY Zeolite by NH4OH. A Postsynthetic Process Investigated by NMR and XRD. J Phys Chem C 118:22573–22582

García-Martínez J, Li K, Krishnaiah G (2012) A mesostructured Y zeolite as a superior FCC catalyst–from lab to refinery. Chem Commun 48:11841–11843

Francis J, Guillon E, Bats N, Pichon C, Corma A, Simon LJ (2011) Design of improved hydrocracking catalysts by increasing the proximity between acid and metallic sites. Appl Catal A 409:140–147

Ishihara A, Itoh T, Nasu H, Hashimoto T, Doi T (2013) Hydrocracking of 1-methylnaphthalene/decahydronaphthalene mixture catalyzed by zeolite-alumina composite supported NiMo catalysts. Fuel Process Technol 116:222–227

Baojian S, Zhengxing Q, Xionghou G, Feng L, Shuge Z, Wen S, Baojie W, Hongjuan Z, Honghai L (2012) Desilication by alkaline treatment and increasing the silica to alumina ratio of zeolite Y. Chin J Catal 33:152–163

Li XJ, Qiao K, He L, Liu X, Yan ZF, Xing W, Qin L, Dai B, Zhang Z (2014) Combined modification of ultra-stable Y zeolites via citric acid and phosphoric acid. Appl Petrochem Res 4:343–349

Qiao K, Li XJ, He LF, Liu X, Yan ZF, Xing W, Qin L, Dai B, Zhang Z (2014) An efficient modification of ultra-stable Y zeolites using citric acid and ammonium fluosilicate. Appl Petrochem Res 4:373–378

Chang XW, He LF, Liang HN, Liu XM, Yan ZF (2010) Screening of optimum condition for combined modification of ultra-stable Y zeolites using multi-hydroxyl carboxylic acid and phosphate. Catal Today 158:198–204

Peng P, Wang Y, Rood MJ, Subhan F, Yan ZF, Qin L, Zhang Z, Zhang Z, Gao X (2015) Effects of the dissolution alkalinity and self-assembly on ZSM-5-based micro-/mesoporous composites: a study for relationship between porosity, acidity, and catalytic performance. CrystEngComm 17:3820–3828

Agudelo JL, Mezari B, Hensen EJM, Giraldo SA, Hoyos LJ (2014) On the effect of EDTA treatment on the acidic properties of USY zeolite and its performance in vacuum gas oil hydrocracking. Appl Catal A 488:219–230

Van Bokhoven JA, Roest AL, Koningsberger DC, Miller JT, Nachtegaal GH, Kentgens APM (2000) Changes in structural and electronic properties of the zeolite framework induced by extraframework Al and La in H-USY and La (x) NaY: a 29Si and 27Al MAS NMR and 27Al MQ MAS NMR study. J Phys Chem B 104:6743–6754

Katada N, Nakata S, Kato S, Kanehashi K, Saito K, Niwa M (2005) Detection of active sites for paraffin cracking on USY zeolite by 27 Al MQMAS NMR operated at high magnetic field 16 T. J Mol Catal A: Chem 236:239–245

Malicki N, Mali G, Quoineaud AA, Bourges P, Simon LJ, Thibault-Starzyk F, Fernandez C (2010) Aluminium triplets in dealuminated zeolites detected by 27 Al NMR correlation spectroscopy. Microporous Mesoporous Mater 129:100–105

Lippmaa E, Mägi M, Samoson A, Tarmak M, Engelhardt G (1981) Investigation of the structure of zeolites by solid-state high-resolution silicon-29 NMR spectroscopy. J Am Chem Soc 103:4992–4996

Yan Z, Ma D, Zhuang J, Liu X, Liu X, Han X, Bao X, Chang F, Xu L, Liu Z (2003) On the acid-dealumination of USY zeolite: a solid state NMR investigation. J Mol Catal A: Chem 194:153–167

Acknowledgments

This work was financially supported by the PetroChina Refinery Catalyst Key Project (Project No. 2013A–2106) and the Joint Funds of the National Natural Science Foundation of China and China National Petroleum Corporation (Grant No. U1362202).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Qiao, K., Wei, L., Feng, R. et al. Preparation and characterization of hierarchical USY by post-treatment. Appl Petrochem Res 5, 313–319 (2015). https://doi.org/10.1007/s13203-015-0122-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13203-015-0122-1