Abstract

Drilling optimization has been broadly developed in terms of influential parameters. The assessment time and the effects of both geomechanical and drilling parameters were vital challenges of investigations. Drilling factors are applied force or rotation of drilling agents such as weight on bit (WOB), and geomechanical features represent mechanical indexes of rocks including unconfined compressive strength (UCS). Optimization efforts have been demonstrated on complex prediction methods whereas the simplicity of classification can offer some optimal ranges utilizing machine learning classifications in an accelerated process. In this study, a novel procedure using the supervised and semi-supervised learning approaches was conducted to classify and optimize the rate of penetration (ROP) and torque on bit (TOB). Firstly, in the case well, user-defined classes were assigned based on geomechanical units (GMU) and the ranges of high ROP and low TOB, thus classes divided drilling factors as GMUs of the case. Secondly, the feature selection was carried out by neural pattern recognition with three multi-objective optimization methods for classification. The inputs of classifications were WOB, hook load, pump pressure, flow rate, UCS, and internal friction angle. Classification approaches were decision trees, support vector machine (SVM), and ensemble learning. Finally, the bagged trees permutation and Laplacian SVM (LapSVM) algorithm separately revealed the significance of parameters and predicted the optimal ROP and TOB regions. Findings showed (1) in supervised classification of the case well, the cubic SVM and bagged trees had the highest area under the curve (AUC) and accuracy, on average 0.97 and 0.96, respectively. (2) The average accuracy of the supervised classifications in a test well was 91% except for the fine SVM, which makes them reliable for the fields with the least information. (3) The permutation outcomes for significant features, flow rate and UCS, exposed influential parameters for ROP and TOB optimization. (4) The semi-supervised method, LapSVM, not only acquired both ROP and TOB labels with an accuracy of 88% but also presented their optimal ranges in 95% of the assessed zones. (5) LapSVM deals with a limited training section perfectly opposed to the supervised version, which is vital for drilling investigation. (6) Implementing machine learning classification approaches with rock properties is a key factor in achieving effective drilling parameters in less time. More importantly, the recommended drilling factors concerning geomechanical properties can ameliorate both drilling performance and perception of upcoming collapse.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The drilling costs are a significant portion of the expenditures in oil and gas projects. In recent years, attention has been given to developing analytical and data-driven models that could estimate and optimize important factors efficiently. The rate of penetration (ROP) that is obtained by recording the drilled depth per unit of time, is an effective feature for drilling optimization, and a higher rate of it can result in the productive rig, detection of possible kicks, and indicating stick–slip (Elkatatny 2019; Hegde et al. 2017). In the process of drilling optimization, torque on bit (TOB) is another critical factor, which is directly related to the amount of applied pressure of the drilling agent (Motahhari et al. 2009). In addition, TOB is a vital part of the prediction of the specific energy (SE) proposed by Teale (1965). According to studies, some efforts have been made to model ROP and TOB, a sort of the results will be briefly explained.

Rate of penetration models

There are two categories of ROP predictive models, including the physics-based and data-driven models. The mathematical formulas are used based on the physics-based or the training of data-driven models via algorithms to obtain ROP. As regards the physics-based model, an ROP model was proposed by Maurer (1962) (namely perfect cleaning) defined a drilling mechanism consisting of the weight-on-bit (WOB), the rotational speed (RPM), TOB, and rock strength. There are studies focused on a cost-effective ROP by gaining the proper WOB and RPM (Galle and Woods 1963). In terms of data-driven models by artificial neural networks (ANN), Bilgesu et al. (1997) played a pioneering role and introduced a methodology to predict ROP. Concerning the usage of artificial intelligence (AI), numerous useful studies were presented with high accuracy (Bezminabadi et al. 2017; Elkatatny 2019). In this way, Table 1 expresses some proposed both physics-based and data-driven studies in terms of ROP prediction and optimization.

In addition, not all of the ROP-affecting parameters have been utilized in previous models due to the complex relationship between ROP and factors. Besides, geomechanical studies have introduced the influence of specific properties of rocks such as the internal friction angle (IFA) and confined compressive strength (CCS) for drilling operations. Implementing vast geomechanical and drilling data, Mehrad et al. (2020) proposed an accurate prediction ROP model by a hybrid machine learning approach. Delavar et al. (2021) introduced an ROP model using a wide range of both the drilling factors and geomechanical properties exerting the ANN and Bayesian approaches. As a result, some procedures were presented for finding the optimum ROP in future drilling operations.

Torque on bit models

The introduced models for TOB have relied on the type of recorded data and the development of measurement tools. The cutting-edge downhole TOB recording tools were an effective invention in advance, Warren (1984) presented a TOB model considering SE in drilling along with using some parameters, including WOB, RPM, ROP, and bit size. The torque and drag (T&D) models, in the chain of TOB studies, were presented to describe the mechanism of torque in drilling. To this extent, a T&D real-time model was proposed by Shahri et al. (2018), which reduced costs and improved drilling performance. Moreover, Hegde and Gray (2018), Oyedere and Gray (2020b), and Delavar et al. (2023) used machine learning including the random forest and support vector machine (SVM) with metaheuristic optimization methods for the TOB models.

Classification benefits and flowchart

Data-driven models of ROP and TOB have been used widely to improve physics-based models or introduce machine learning regression models via the wells data. The impact of influential parameters on ROP and TOB is very complex thus it is necessary to consider various features on the basis of the case study. Classification methods can deal with the mentioned complicated circumstance because their practical predictive models approximate the mapping function from input variables to desired ROP and TOB. Furthermore, the importance of representing classifications lies in the simplicity of predicting ROP and TOB in the evaluation of the drilling operation performance.

Hybrid classification approaches are accurate and feasible manners to determine challenges related to drilling and reservoir engineering (Delavar 2021; Sanei et al. 2023). Reservoir characteristics such as fracture density were classified by machine learning procedures with high accuracy (Li et al. 2018). Using classification, Oyedere and Gray (2020a) proposed ROP and TOB classification models to classify two classes so-called high ROP and low TOB using WOB, RPM, flow rate, and unconfined compressive strength (UCS). Here, the classes were allocated by geomechanical and drilling factors, and more practical drilling factors were determined for hybrid classification approaches.

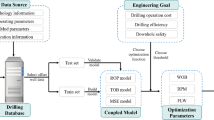

Figure 1 illustrates the steps to achieve the goals of this effort. In the flowchart, first, the geomechanical units (GMU) were established, and they formed the user-defined classes in addition to ROP and TOB bands. Second, in the feature selection, neural pattern recognition (NPR) was combined with three multi-objective optimization methods, thus the features were selected for the classification methods. Next, five supervised classification methods were applied to the dataset, which included the features and labels. As a result, the best classification method was introduced for the zones. Third, the important features for the classification of ROP and TOB in the zones were presented. Finally, based on a semi-supervised method using the revealed significant factors, the optimized drilling parameters were introduced for ROP and TOB.

Geology and data acquisition

The studied well is located in the southwest of Iran in the Dezful embayment. It was drilled in the Marun oilfield situated in the Middle East (Telmadarreie et al. 2012). In Marun, the Asmari reservoir was considered, which is a carbonate reservoir with five zones and four sub-zones. Here, the interval depth of the case well is 3557 to 3924 m, which includes 4 zones and 3 sub-zones. The lithology of the Asmari generally includes limestone, dolomite-limestone, and thin layers of both sandstone and Shale-Marne stone interbedded (Alavi 2004).

For feature selection methods, the conventional logs of the well were corrected gamma-ray (CGR), DT, NPHI, density log (RHOB), formation evaluation photoelectric factor (PEF), and resistivity log (RT). On the other hand, the mud logs and drilling measurements acquired ROP, TOB, WOB, hook-load (HKL), pump pressure (Pump.P), and flow rate (Flow.R). The dataset of the present study obtained from a wellbore included 2952 points as samples and 738 points of ROP and TOB. The petrophysical and drilling logs of the present study are shown in Fig. 2. As regards the lithology of the well (track 2 in Fig. 2), conventional logs such as CGR and RT, illustrated in tracks 3 and 4, are changed through the diversity of rocks. Concerning the drilling parameters in the dataset, the recorded mud logs are shown on tracks 5 and 6.

In addition, despite the fact that a section of the training well was divided to prepare the test part, the dataset of a second well was deemed to verify the performance of classification methods in the vicinity zones. The formations of the second well are carbonate rocks although the distinguishes between the patterns of geomechanical and drilling factors of the training well with the same parameters in the second well can reveal the capability of models. The interval depth of the second well is 257 m, which provides 2313 points for the evaluation of the proposed method.

The strength parameters of rocks (UCS and CCS) usually have opposite trends toward ROP while pressure and depth of drilling could impact their correlation. On the other hand, IFA is associated with both porosity and shale volume, which could impact TOB and WOB (Anemangely et al. 2018; Calhoun and Ewy 2005). Concerning the influential parameters for ROP and TOB classification and prediction, Table 2 shows some features executed in the previous studies. To describe the diversity and density of selected petrophysical logs, probability density function (PDF) graphs of the recorded data are illustrated in “Appendix A”. The diversity of RHOB, DT, PEF, and NPHI was rather than CGR and RT. In fact, the normal shape of a dataset, spread over in wide range with a peak in the middle, has an influence on results effectively. This checking process proved the credibility of the inputs in terms of statistical features for the classification methods.

In this effort, UCS, CCS, and IFA were obtained by the correlations that have been introduced from the carbonate reservoir case. The dynamic Young’s modulus (\(E_{{{\text{dyn}}}}\)) was calculated (Eq. 1) through conventional logs and converted to the static Young’s modulus (\(E_{{{\text{sta}}}}\)) (Eq. 2) (Afsari et al. 2010; Zoback 2007). The UCS test on the rock of adjacent wells showed the ranges of UCS at 50–70 MPa. Also, Eq. 3 was presented for the Marun oilfield to predict the UCS of rocks that had been used here (Anemangely et al. 2018). The IFA and CCS were obtained by laboratory-based equation (Eq. 4) and the bottom-hole rock strength and pressure function (Eq. 8) (Calhoun and Ewy 2005; Plumb 1994). The required functions for the calculation of IFA and CCS are (Eqs. 5–7) (Gholami et al. 2014; Kidambi and Kumar 2016).

where \(E_{{{\text{dyn}}}}\), \(\rho\), \(V_{P}\), \(V_{S}\), \(E_{{{\text{sta}}}}\), \({\text{NPHI}}\), \(V_{{{\text{shale}}}}\), \({\text{GR}}_{{{\text{max}}}}\), and \({\text{GR}}_{{{\text{min}}}}\) represent dynamic elastic modulus, density, compressional wave velocity, shear wave velocity, static elastic modulus, neutron porosity, shale volume, maximum gamma ray, and minimum gamma ray. Also, \({\text{DP}}\), \({\text{CCS}}_{{{\text{DP}}}}\), \({\text{CCS}}_{{{\text{SK}}}}\), \({\text{DP}}_{{{\text{SK}}}}\), and \({\text{PHIE}}\) show differential pressure or confining stress, \({\text{CCS}}\) based on \({\text{DP}}\), \({\text{CCS}}\) based on Skempton pore pressure, \({\text{DP}}\) based on Skempton pore pressure, and effective porosity or porosity index.

Methodology

The drilling and geomechanical factors of the well were acquired in the first step of the study. The methods used for user-defined labeling, classification, feature selection, and optimization will be briefly described.

User-defined classes

Constructing the classes was the initial step of this study, Table 3 expresses the scheme of the labeling process using geomechanical and drilling factors. Firstly, the thresholds of zones were defined based on previous studies on carbonate formations in the region (Alavi 2004), and considering the well logs. They have evident boundaries if the conventional well logs were in access. Secondly, in assigning the labels of the studied well, the geomechanical units (GMU) were specified. Basically, GMU has close geomechanical features; thus the impact of drilling tools on them is defined in a special pattern.

The zones were divided into 21 GMUs, which GMUs 10 to 21 are shown in Fig. 3 and others are available in “Appendix B”. Figure 3 illustrates depth, zones, and GMUs on tracks 1 to 3. Besides, tracks 4 to 7 show the well logs and geomechanical parameters which are a part of the dataset of the well. The GMU’s separation criterion in the zones was the average of parameters. For instance, in Z.3 (Fig. 3), the averages of DT (Sonic interval transmit time) and UCS are depicted as yellow dash-lines, which are the trends of common geomechanical features in the GMU. By assigning GMUs, the labeling process proceeded to step 3 of Table 3. In this way, the averages of ROP and TOB in the entire depth were assessed to set their thresholds. Finally, the classes were achieved by combining the GMUs, dividing the large-scale depth into some particular parts, and evaluating the ROP and TOB bands.

The steps of Table 3 were employed in all of the zones. The changes in the parameters and the average values of ROP and TOB of Z.2 & SZ.2 are respectively illustrated in Figs. 4 and 5, to describe the labeling method of a zone. In the process, first, the zone is divided into specific GMUs (expressed in Fig. 3). Second, in the zone, all GMUs were determined (Fig. 4), and the bands of ROP and TOB were checked via step 4 of Table 3 (Fig. 5). These labels were named for both ROP and TOB classes separately. Therefore, on the ROP side, GMUs 5 and 8 were denoted in class 1 because the differences in ROP in their GMUs were lower than 0.6 m/hr. Where GMU 6 was labeled as class 2 and GMUs 7 and 9 were labeled as class 3 due to staying in the constraint of 0.6 m/hr. For TOB, the classes were named as follows GMUs 5, 8, and 9 in class 1, GMU 6 in class 2, and GMU 7 in class 3 owing to the employed limitations of 300 \({\text{lbf}}.{\text{ft}}\).

The drilling and geomechanical logging data in zone 2 and subzone 2 as an example zone of the well and used for user-defined classes; the formulas of the internal friction angle (IFA) and rock strength features can be found in the "Geology and data acquisition" section

Other zones of the case well were categorized according to the explained procedure and the labels are shown in Table 4. It should be noted that the mentioned labels were used for the supervised classification methods. However, in the semi-supervised method, Laplacian SVM (LapSVM) uses a different scale from the applied manner of the supervised methods (Table 4) for ROP and TOB. Actually, the LapSVM’s thresholds were defined as a certain number dividing ROP and TOB to the high and low zones due to achieving optimal parameters. The different limits of ROP and TOB in LapSVM were assigned because the semi-supervised methods can be trained by a few features and also it was aimed at seeking optimal factors.

The significant influences of geomechanical properties in the supervised and semi-supervised labeling procedures were in the process of categorizing zones to GMUs and acquiring the ROP and TOB contributed to geomechanical features, respectively. The second utilization of geomechanics (semi-supervised) leads the method to indicate the optimal ROP and TOB when the important drilling factors (gained via a method) apply as a pattern of drilling factors from GMU with close geomechanical features. This desirable pattern of drilling parameters was obtained in the labeling process of LapSVM. The details of LapSVM’s classes are described in the following in its specific section. It should be deemed that presenting a certain amount of drilling factors that offer optimum ROP and TOB is almost impossible due to tools limitations; thus the values were introduced as ranges.

Feature selection

Feature selection can be used in the process of prediction, classification, and pattern recognition. Feature selection methods are often based on the ANN combined with optimization approaches. Here, the multi-objective methods were applied for the optimization aimed at minimizing both the number of features and the errors of the classification (Hamdani et al. 2007). The influence of two features for simultaneous optimization was the main reason to utilize the multi-objective methods.

In this study, the NPR approach was the major learning method for the feature selection. The scaled conjugate gradient (SCG) algorithm was applied to the training process including 70% of the dataset. The SCG algorithm is a fast learning method with good convergence (Castillo et al. 2006; Møller 1993). The remaining 30% of the dataset was assigned to the testing and validation process and 20 neurons in the two hidden layers were used for the ANN’s structure in the Matlab software. In the hybrid feature selection methods and classification methods of the present study, training, validation, and testing sections were randomly split because it ensures that the sections are representative of the original dataset. The data normalization step was achieved in Eq. 9, and the cost function of NPR (\(Z\)) is shown in Eq. 9. The weights (\(W_{{{\text{train}}}}\) and \(W_{{{\text{test}}}}\)) were assigned for two types of error consisting of 0.8 and 0.2 for the train and test sections, respectively. The main function is shown in Eq. 10. Knowing that NPR hybridized by the optimization method at each run, different error values (\(EE\)), and hence the average value (\(E_{{{\text{Total}}}}\)) were considered (Eq. 11).

where \(X_{{{\text{nor}}}}\), \(X_{\max }\), \(X_{\min }\), \(W_{{{\text{train}}}}\), \(E_{{{\text{train}}}}\), \(W_{{{\text{test}}}}\), \(E_{{{\text{test}}}}\), \(E\), and \(n_{f}\) represent normal value, maximum value, minimum value, weight of train, error of train, weight of test, error of test, difference of observed and predicted values by NPR, and number of features.

Multi-objective genetic optimization

The non-dominated sorting genetic algorithm II (NSGA-II) is a multi-objective optimization method. The NSGA-II finds the optimal parameters with minimum errors and presents the results as a Pareto-optimal diagram. In the case of complex datasets, this natural-inspired algorithm is useful due to its lower computational costs (Liu et al. 2015). Moreover, the NSGA-II presents the distribution parameters by a novel crowding distance method (Deb et al. 2002; Delavar and Ramezanzadeh 2023).

The flowchart of the NSGA-II algorithm is shown in Fig. 6. First, the problem definition, cost function, and variables limitation were set. Next, the NSGA-II parameters, including mutation percentage, crossover percentage, and mutation rate were set as 0.4, 0.7, and 0.1, respectively. There were some steps for the optimization process of the swarm such as non-dominated sorting. Finally, the main loop of NSGA-II was started by determining the calculations in every mutation to reach the best solution.

The flowchart of the non-dominated sorting genetic algorithm II method, adapted from (Deb et al. 2002)

Multi-objective particle swarm optimization

The multi-objective particle swarm optimization (MOPSO) algorithm is based on heuristic particle swarm optimization (PSO). In MOPSO, there is a population of particles, a repository as external memory, and the definition of the new generation with space of objective. In fact, in MOPSO, the solution of storing each particle is employed instead of the elitism procedure that had been used in NSGA-II (Coello and Lechuga 2002). Figure 7 shows the process of MOPSO where the number of grids per dimension and the inflation rate were set at 7 and 0.1, respectively. Besides, both the leader selection pressure and deletion selection pressure were equal to 2. The mutation rate was also adjusted to 0.1. In the steps of the MOPSO, computations reach the main loop, and the solutions are presented (Coello 2011).

The flowchart of the multi-objective particle swarm optimization method, adapted from (Coello and Lechuga 2002)

Multi-objective Gray wolf optimization

The multi-objective Gray wolf optimizer (MOGWO) presents the hunting behavior of Gray wolves. The main procedure of MOGWO was adapted from the proposed Gray wolf optimizer (GWO) by adding some features. In the algorithm, the alpha (\(\alpha\)), beta (\(\beta\)), and delta (\(\delta\)) are search agents and are updated by the leader (Mirjalili et al. 2016). Figure 8 shows the performance of MOGWO in different steps. First, the cost function was defined; then, three specific parameters of the algorithm, including grid inflation parameters, archive size, and the number of grids were set as 0.1, 100, and 10, respectively. Then, random values were assigned as the initial guess of \(a\), \(A\), and \(C\) (Mirjalili et al. 2016). In the main process of the MOGWO algorithm, the solutions that had been found by search agents were examined at every step.

The flowchart of the multi-objective Gray wolf optimizer method, adapted from (Mirjalili et al. 2016)

Classification methods

The class labeling and feature selection steps to classify ROP and TOB were explained. Here, the applied supervised classification methods will be briefly described.

Fine decision tree classifier

Decision trees classifier (DTC) learns from the general pattern of training data and predicts the class of test via the acquired pattern. In DTC’s elements, the features are nodes that are scattered in the solution spaces (Singh and Singh 2017). The criteria and features of the classifier are expressed in Table 5. Here, the fine DTC was used as follows:

where \({\text{DTC}}_{{{\text{Best}}}}\) shows the best DTC. \(E_{{{\text{DTC}}}}\) represents the error of classification of the tree \(T_{w}\) and \(w\) denotes the tree index number, \(r\left( n \right)\;{\text{and}}\;P\left( n \right)\) are re-substitution prediction errors for the wrong classified nodes and the probability in comparison values with criteria, respectively (Singh and Singh 2017).

Support vector machine classification

The support vector machine (SVM) methods are powerful in nonlinear analysis. There are two types of SVM classifications, linear and nonlinear (Cortes and Vapnik 1995; Tatar et al. 2014). The main function of SVM classification is expressed in Eq. 14. The SVM structure has been modified to utilize kernel function in studies due to its powerful capability (Ding et al. 2017). In this effort, the cubic polynomial and fine Gaussian kernel functions were applied to the SVM, their kernel functions are implied via Eqs. 15 and 16, respectively. The details of the setting for both SVM classification methods are depicted in Table 5.

where \(\emptyset \left( x \right)\) represents the mapping of \(x\) from estimator samples space \(\left( {R^{n} } \right)\) to feature space, \(p\) is the number of predictors, \(\sigma^{2}\) represents the variance of the Gaussian kernel (Kernel scale), \(w\) is weight vector and \(b\) denotes the bias value. Also, \(x_{j}\) and \(x_{k}\) are input variables as features and labels, respectively.

Ensemble classification

In machine learning classification collection, ensemble learning is an improvement in the capability and flexibility of the classifications (Mousavi and Eftekhari 2015). Here, two types of ensemble methods, the RUSBoosted trees (RUSB.T) and bagged trees (Bagged.T) classifications were used. The special parameters of the ensemble models are the number of splits and learners. In fact, by increasing the number of splits, the capability and overfitting of results are improved (Saeed et al. 2019). Table 6 shows the details of ensemble classifications used in the present study. The maximum number of splits in the bagged trees method varies due to using the classification method in different zones of the well.

Semi-supervised learning method

Laplacian SVM (LapSVM) is a semi-supervised learning method that predicts unlabeled data through a few labeled samples (Melacci and Belkin 2011). The LapSVM relies on SVM methods, and the main problem is described in Eq. 17 with three parts. The first part of Eq. 17 is related to the labeled samples, and the two other parts involve unlabeled and labeled samples (Dong et al. 2020). Where \(V\left( {x_{i} ,y_{i} ,f} \right)\) is determined by the SVM function. Also, \(f\) is the decision function of \(f_{A}^{2}\) which formed the kernel of the problem; for other functions and details refer to (Ding et al. 2017; Dong et al. 2020; Melacci and Belkin 2011).

Based on Eq. 17 that is the main function of LapSVM, it can be applied to ROP and TOB analysis. Generally, three labels are typically used for LapSVM: labels ‘1’ and ‘− 1’ for learning the algorithm and label ‘0’ for prediction. First, the zones with proper ROP and TOB ranges, whose averages are higher than 4.6 (m/hr) for ROP and below 3593.5 (\({\text{lbf}}.{\text{ft}}\)) for TOB, were labeled ‘− 1’. Improper regions of ROP and TOB were assigned to label ‘1’. The areas whose LapSVM should be predicted were labeled as ‘0’. Condition 1 has its prediction by LapSVM. In condition 2, the coefficients of drilling features with the same geomechanical characteristics from the proper ROP and TOB (labeled ‘− 1’) were multiplied by the features in the improper area (labeled ‘1’). The results can indicate the optimal ranges of the drilling factors in the labeled zones. Figure 9 illustrates the process of prediction by LapSVM in two mentioned conditions.

Classification analysis methods

The confusion matrix, a classification assessment, indicates the performance matrix, including the true and predicted classes, and it can be explained by Eq. 18 (Chamkalani et al. 2017). Where, \(RR_{i,j}\) is the total number of class \(i\) values, and the principal diagonal elements are \(\left( {RR_{1,1} , \ldots ,RR_{N,N} } \right)\). The performance of classification could be evaluated considering the principal diagonal on the total values as accuracy (Eq. 19). The area under the curve (AUC) is an assessment and is defined as Eq. 20 (Fawcett 2006).

where \(S_{a}\), \(n_{n}\) and \(n_{p}\) are the sum of all positive, the number of negative, and the number of positive values, respectively. Table 7 shows the binary outputs of a classification model (Oyedere and Gray 2020a).

Results and discussion

The user-define classes of the ROP and TOB and also the methodologies of classification approaches were described in "Methodology" section. In the forthcoming sections, the results will be explained.

Feature selection results

The three feature selection methods, including the NPR-NSGA-II, NPR-MOPSO, and NPR-MOGWO, were implemented on the dataset. In the NPR method, the structure was selected by trial and error. The features were WOB, RPM, HKL, Pump.P, Flow.R, UCS, IFA, and CCS where the targets were the ROP and TOB. The number of classes was 7, equal to the number of the well zones. The results are presented in Fig. 10 using a confusion matrix. Figure 10 (sum up of train and test) shows 94.6% and 5.4% for the true classification and misclassification, respectively. Besides, the results of the training and testing parts are shown in “Appendix C”.

Here, the NPR model was implemented with the multi-objective optimization methods, and their results illustrated the options for the features in every scenario. Figure 11 shows the results of NPR-MOGWO with a number of 30 for the population and in 100 iterations using the Pareto-optimal points. The vertical and horizontal labels represent the errors (E) or cost function and number of features (\(n_{f}\)), respectively. The best feature selection with a minimal error occurred by 8 features for NPR-MOGWO (Fig. 11). Concerning the effect of population on optimization, five different populations were tested and the least errors (likewise the point in the right corner of Fig. 11) were gathered. So, the best \(n_{f}\) and minimum errors are listed in Table 8.

Table 8 expresses the results of the three methods. All of the iterations’ numbers of optimization were 100. For every hybrid method, the bolded values are the best option with the minimum error. In the final step, common aspects of the results were considered. Therefore, the features that had been selected two or more times, among the three bolded options, were chosen for ROP and TOB classification. The features were WOB, HKL, Pump.P, Flow.R, UCS, and IFA, which are expressed in Table 9 for the case well by statistical indexes. The statistical aspects of the second well are shown in “Appendix D”.

Classification results

Five classification procedures were applied to the dataset (Table 9). Table 10 shows the results in AUC and the accuracy of supervised methods for ROP. Moreover, the AUC of ROP is depicted in Fig. 12. In Table 10, there are a few zones that their superior classification procedure was not evident. Therefore, in addition to AUC, the accuracy and confusion matrix can indicate the superior method. In Z.1 and Z.3, the AUC values were close thus, Fig. 13 presents the corresponding confusion matrices. As a result, the Bagged.T classified labels better than other methods; its accuracy was also high (Table 10).

Table 11 shows the results of TOB classification in the zones with AUC and accuracy. Moreover, the AUC comparison in Fig. 14 clarifies the assessment. In the zones of Fig. 14, the outperformed classification was not obvious. Figure 15 presents the confusion matrices of the two zones (Z.2 & SZ.2 and Z4), which reveal the superiority of C.SVM. Other accurate and reliable methods for TOB and ROP are presented in Table 12. According to the results, the Bagged.T and C.SVM had the least errors among approaches. Besides, Table 13 shows the outcomes of the ROP and TOB classification methods in the testing section of zones of the well using AUC and accuracy.

In addition, the classification methods were assessed in new zones when they were trained by the case well and tested using the dataset of the second well. Figure 16 shows the outcomes of the given process as the average of ROP and TOB classification where Bagged.T and C.SVM showed the best performance in terms of both AUC and accuracy. Based on the results, the F.SVM method cannot fulfill a reliable classification manner for ROP and TOB classification. Despite the fact that the classification accuracies were dropped around an average of 2–8% for the second well as opposed to the models of the case well, they depicted precise results. Therefore, the superior approaches of the findings, Bagged.T and C.SVM, can be implemented in other carbonate zones to classify ROP and TOB based on controllable drilling factors and geomechanical properties.

The importance of features

The importance of features was examined utilizing the classification-based sensitivity analysis for the best methods (C.SVM and Bagged.T). Based on the results (Table 12), either C.SVM or Bagged.T was the most precise method in every three zones of the well. In fact, the SVM structure maps the dataset into multi-dimensional space, thus it makes the process of feature ranking via C.SVM impossible (Oyedere and Gray 2020a). Consequently, the significance of parameters was determined based on the feature ranking in Matlab software as the permuted predictor importance using classification Bagged.T in 50 cycles.

Figure 17 shows the relative importance of features in Z. 4 for TOB and ROP with bar charts. Flow.R and WOB were the most significant features for ROP and TOB, respectively. The total importance of parameters was gathered in box plots. Figure 18 shows the significance of parameters using classification for ROP and TOB in the zones. As a result of TOB (Fig. 18), the Pump.P had the highest importance although the maximum of Flow.R and WOB were higher than it. Besides, both UCS and IFA are illustrated as minus numbers because of declining the true classification. Concerning ROP (Fig. 18), the order of importance among drilling parameters was Flow.R, Pump.P, HKL, and WOB, the highest to least, respectively. Moreover, the most crucial geomechanical feature was UCS. Comparing the ROP and TOB boxplots (Fig. 18), Flow.R and Pump.P were more important than others in the zones. The higher importance of UCS on ROP classification can be justified by the influence of rock strength on the drilling rate.

Optimization results

In this section, the results of semi-supervised classification, LapSVM, and the optimum ranges of drilling parameters are presented. The details of labels, two conditions ("Semi-supervised learning method" section), and significant factors ("The importance of features" section) were constructed in the algorithm settings. Table 14 expresses the labels of GMU for ROP and TOB. The LapSVM algorithm predicted the GMUs’ classes (for label ‘0’) utilizing the training section (labels ‘1’ and ‘− 1’) in the condition 1. The labels of the condition 1 were selected from a limited number intentionally to depict the capability of the semi-supervised classification as opposed to the supervised methods.

Concerning the condition 2, it expresses a broader range of labels compared the condition 1. Furthermore, in the condition 2, the significant factors that were revealed in previous section, including HKL, Pump.P, and Flow.R, had an important role. Regarding this condition, the LapSVM was trained with the given classes while the coefficients of significant parameters from a similar GMU (shown in Table 14) were multiplied in the improper GMUs (GMUs with low ROP and high TOB). The averages of IFA and UCS established the similar GMU of the zones. Then, a new class prediction of the unseen testing part by LapSVM indicated the intervals where the ROP and TOB were turned to the optimal sections (high ROP and low TOB). The outcomes of both LapSVM’s conditions were interpreted and illustrated.

Figure 19 illustrates the results of LapSVM in 7 tracks. The first and second tracks are depth and GMU, respectively. The third track represents the logs of ROP and TOB in the well. Besides, the 4th and 5th tracks are related to ROP, whereas the 6th and 7th tracks describe two conditions of TOB. In the first condition of ROP (track 4), there are three lines. The left and right dash lines (black color) are labels ‘− 1’ and ‘1’, respectively. The middle lines represent labels ‘0’ which should be predicted by the algorithm. Additionally, the red middle lines show true labels of low ROP, whereas the green ones represent high ROP. Colors can help in the determination of LapSVM-predicted labels. Predicted classes are denoted by blue lines. So, if the green lines (high ROP) are predicted as label ‘1’, they are false (misclassification, blue lines), and the true labels are ‘− 1’. On the other hand, when the red lines (low ROP) are predicted as label ‘1’, they are true (blue lines) while the false labels are ‘− 1’. As a result, most parts (88% of the entire depth) of the studied zones were classified as true labels for ROP and TOB despite the limited training labels in condition 1.

The Laplacian support vector machine predictions for the rate of penetration (ROP) and torque on bit (TOB) in two conditions, left to right, tracks 1 to 3 include depth, geomechanical units, and ROP and TOB, tracks 4 and 5 are predictions of the algorithm in conditions 1 and 2 for ROP, tracks 6 and 7 are the same predictions for TOB, the description of track 4 is the same as track 6 and also, tracks 5 is like track 7

The results of the second condition of ROP are shown on track 5. In this section, same as the condition 1, the testing part was labeled ‘0’ (low ROP, black lines in the middle). As regulation of the condition 2, the important drilling parameters of the intervals (shown in black color in the middle) were multiplied by the same proper GMU (high ROP and low TOB). The training dataset was labeled ‘1’ and ‘− 1’ (black lines on the right and left parts of track 5), including the low and high classes of ROP, respectively. In the results of condition 2, if they are classified as label ‘1’, they did not turn to the optimal class (label ‘− 1’, higher ROP). In this way, the outcomes of the second condition are shown via purple lines on track 5. According to the classification, roughly 95% of the testing section as the label ‘0’ (black middle lines, low ROP) transformed to the label of high ROP (pink lines on the left of the track).

The LapSVM classification of TOB is illustrated to resemble ROP in Fig. 19 in tracks 6 and 7, whereas the low TOB (proper) was labeled as ‘− 1’ (opposite of ROP). The LapSVM for TOB in the target GMUs was as reliable as ROP. In track 6 of Fig. 19, green lines should be predicted as label ‘− 1’, and red lines were expected to be label ‘1’ which occurred in most depths. Moreover, in track 7, approximately entire intervals were optimized (label ‘− 1’, low TOB).

Consequently, three GMUs were employed for acquiring the optimal drilling parameters, which led to the optimization of ROP and TOB, whose ranges are shown in Table 15. Other GMUs were implemented for optimization either ROP or TOB, and also some GMUs were used for training the algorithm. Importantly, target parameters of the optimization method (ROP and TOB) interact in the process of drilling. Therefore, ROP and TOB should be presented in a reasonable range due to the mentioned constraints. The optimal values of the three GMUs were obtained through the optimization process of ROP and TOB (condition 2). These outcomes, Table 15, are practical to reach a desired drilling operation with such geomechanical characteristics. Furthermore, evaluating zones for their classification by using the optimal drilling parameters in the future project not only offers a higher ROP and lower TOB but also protects reservoirs and tools from unforeseen hazards.

Conclusions

Analysis of the rate of penetration (ROP) and torque on bit (TOB) is the primary subject of drilling assessments. In this paper, the given parameters were determined by the nonlinear classification in a carbonate reservoir. The novelty of the study lies in implementing the supervised and semi-supervised machine learning classification approaches and utilizing both geomechanical and drilling factors to establish classes. First, the user-defined labels were assigned to zones. Next, as the feature selection (FS) procedure, a neural pattern recognition (NPR) hybridized with three multi-objective optimization algorithms, the best features were revealed for classification. The supervised classifications were the decision trees classifier (DTC), support vector machine (SVM), and ensemble classifiers. Then, the bagged trees method indicated the importance of features in classification. The findings of this section of the study were as follows:

-

(1)

The combined FS methods depicted the most effective subset of factors for classification with errors of less than 0.02;

-

(2)

The results of classifications showed that bagged trees and cubic SVM had the least errors compared to others;

-

(3)

The results confirmed the credibility of the two superior approaches, their average area under the curve (AUC) of ROP classification were respectively 0.96 and 0.97;

-

(4)

In the importance rate of bagged trees, the flow rate and pump pressure were introduced as the most vital features of drilling factors.

Finally, the semi-supervised method, Laplacian SVM, was trained via a limited number of labels (high/low ROP and TOB) and accuracy was assessed. Next, in similar GMUs, the crucial drilling factors, introduced by bagged trees, were multiplied in non-optimal GMUs. The final step indicated the following results:

-

(1)

The LapSVM showed the classes with an accuracy of 88% despite utilizing half of the inputs in the supervised classification;

-

(2)

The LapSVM exposed the optimal classes in 95% of the studied areas, which recommend optimized values for the zones;

-

(3)

The outcomes proved the classifications can expedite the process of seeking effective drilling parameters concerning geomechanical properties, which is lacking in the previous efforts;

-

(4)

The optimal drilling parameters can be applied to optimize the ROP and TOB although they can be extended with more reservoir characteristics in future efforts.

Abbreviations

- AUC:

-

Area under receiver operating characteristics curve

- Bagged.T:

-

Bagged trees method

- C.SVM:

-

Cubic support vector machine

- DTC:

-

Decision trees classifier

- F.Tree:

-

Fine decision trees classifier

- GMU:

-

Geomechanical units

- GWO:

-

Gray wolf optimizer

- NPR:

-

Neural pattern recognition

- NSGA-II:

-

Second version of the non-dominated sorting genetic algorithm

- PDC:

-

Polycrystalline diamond compact

- PDM:

-

Positive displacement motor

- PSO:

-

Particle swarm optimization

- RBF:

-

Radial basis function

- RUSB.T:

-

RUSBoosted trees

- SVM:

-

Support vector machine

- CALI (inches):

-

Caliper log

- CCS (MPa):

-

Confined compressive strength

- \({\text{CCS}}_{{{\text{DP}}}}\) (MPa):

-

Confined compressive strength based on differential pressure

- \({\text{CCS}}_{{{\text{sk}}}}\) (MPa):

-

Confined compressive strength based on Skempton pore pressure

- DP (MPa):

-

Differential pressure (or confining stress)

- DT \((\upmu {\text{s/ft}})\) :

-

Sonic interval transmit time

- DTCBest (–):

-

Best of decision trees classifier

- E and EE (–):

-

Misclassification error and total error

- E sta (GPa):

-

Static Young’s modulus

- Flow.R (Gal/min):

-

Flow rate

- GR and CGR (API):

-

Gamma-ray and corrected gamma-ray

- HKL (klbf):

-

Hook load

- IFA (degree):

-

Internal friction angle

- MSE (MPa):

-

Mechanical specific energy

- n f (–):

-

Number of selected features

- NPHI (V/V):

-

Neutron porosity

- PEF (–):

-

Formation evaluation photoelectric factor

- PHIE (V/V):

-

Effective porosity

- Pump.P (psi):

-

Pump pressure

- q and b (–):

-

Exponent of cubic and quadratic polynomial kernel functions in SVM and the bias value in SVM function

- RHOB (kg/m3):

-

Density log

- ROP (m/h):

-

Rate of penetration

- RPM (rpm):

-

Rotary speed or bit revolutions per minute

- RT (ohm m):

-

Resistivity log

- RR i , j (–):

-

Total number of class i values

- r(n) and P(n) (–):

-

Re-substitution estimation error for misclassification and probability of any value equal with criteria

- TOB (Lbf.ft):

-

Torque on bit

- UCS (MPa):

-

Unconfined compressive strength

- \(V_{p}\) (m/s):

-

Compressional wave velocity

- \(V_{s}\) (m/s):

-

Shear wave velocity

- V shale (–):

-

Shale volume

- WOB (klbf):

-

Weight on bit

- W train and W test :

-

Weights of the training and test

- X nor, X max, and X min (–):

-

Normal, maximum, and minimum values

- α, β, δ, and ω (–):

-

Alpha, beta, delta, and omega in MOGWO method

- \(\rho\) (kg/m3):

-

Density

- ∅(x) (–):

-

Mapping of x from predictor samples space (Rn) in SVM

- σ 2 (–):

-

The variance of RBF or Gaussian kernel (kernel scale)

References

Abbas AK, Alameedy U, Alsaba M, Rushdi S (2018) Wellbore trajectory optimization using rate of penetration and wellbore stability analysis. In: SPE international heavy oil conference and exhibition, Kuwait City, Kuwait, December 2018. https://doi.org/10.2118/193755-MS

Afsari M, Amani M, Razmgir SAM, Karimi H, Yousefi S (2010) Using drilling and logging data for developing 1d mechanical earth model for a mature oil field to predict and mitigate wellbore stability challenges. In: International oil and gas conference and exhibition in China, Beijing, China, June 2010. https://doi.org/10.2118/132187-MS

Al-AbdulJabbar A, Elkatatny S, Mahmoud M, Abdelgawad K, Al-Majed A (2019) A robust rate of penetration model for carbonate formation. J Energy Resour Technol 141(4):042903

Alali AM, Abughaban MF, Aman BM, Ravela S (2021) Hybrid data driven drilling and rate of penetration optimization. J Petrol Sci Eng 200:108075

Alavi M (2004) Regional stratigraphy of the Zagros fold-thrust belt of Iran and its proforeland evolution. Am J Sci 304(1):1–20

Al-Betairi EA, Moussa MM, Al-Otaibi S (1988) Multiple regression approach to optimize drilling operations in the Arabian Gulf area. SPE Drill Eng 3(01):83–88

Anemangely M, Ramezanzadeh A, Tokhmechi B, Molaghab A, Mohammadian A (2018) Development of a new rock drillability index for oil and gas reservoir rocks using punch penetration test. J Pet Sci Eng 166:131–145

Bezminabadi SN, Ramezanzadeh A, Jalali S-ME, Tokhmechi B, Roustaei A (2017) Effect of rock properties on ROP modeling using statistical and intelligent methods: a case study of an oil well in southwest of Iran. Arch Min Sci 62(1):131–144

Bilgesu H, Tetrick L, Altmis U, Mohaghegh S, Ameri S (1997) A new approach for the prediction of rate of penetration (ROP) values. In: SPE eastern regional meeting, Lexington, Kentucky, October 1997. https://doi.org/10.2118/39231-MS

Bourgoyne AT Jr, Young F Jr (1974) A multiple regression approach to optimal drilling and abnormal pressure detection. Soc Pet Eng J 14(04):371–384

Calhoun W, Ewy R (2005) New confined compressive strength calculation improves bit selection and bit performance. In: Proceeding of the AADE national technical conference and exhibition. Houston, Texas, April 2005

Castillo E, Guijarro-Berdinas B, Fontenla-Romero O, Alonso-Betanzos A, Bengio Y (2006) A very fast learning method for neural networks based on sensitivity analysis. J Mach Learn Res 7(7):1159–1182

Chamkalani A, Zendehboudi S, Amani M, Chamkalani R, James L, Dusseault M (2017) Pattern recognition insight into drilling optimization of shaly formations. J Pet Sci Eng 156:322–339

Coello CC, Lechuga MS (2002) MOPSO: a proposal for multiple objective particle swarm optimization. In: Proceedings of the 2002 congress on evolutionary computation. CEC'02 (Cat. No. 02TH8600), vol 2, pp 1051–1056

Coello CAC (2011) An introduction to multi-objective particle swarm optimizers. In: Soft computing in industrial applications. Springer, pp 3–12

Cortes C, Vapnik V (1995) Support-vector networks. Mach Learn 20(3):273–297

Deb K, Pratap A, Agarwal S, Meyarivan T (2002) A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans Evol Comput 6(2):182–197

Delavar MR (2021) Hybrid machine learning approaches for classification and detection of fractures in carbonate reservoir. J Pet Sci Eng 208:109327

Delavar MR, Ramezanzadeh A (2023) Pore pressure prediction by empirical and machine learning methods using conventional and drilling logs in carbonate rocks. Rock Mech Rock Eng 56(1):535–564

Delavar MR, Ramezanzadeh A, Tokhmechi B (2021) An investigation into the effect of geomechanical properties of reservoir rock on drilling parameters—a case study. Arab J Geosci 14(17):1763. https://doi.org/10.1007/s12517-021-08168-y

Delavar MR, Ramezanzadeh A, Gholami R, Sanei M (2023) Optimization of drilling parameters using combined multi-objective method and presenting a practical factor. Comput Geosci 175:105359

Ding S, Zhu Z, Zhang X (2017) An overview on semi-supervised support vector machine. Neural Comput Appl 28(5):969–978

Dong S, Zeng L, Lyu W, Xu C, Liu J, Mao Z, Tian H, Sun F (2020) Fracture identification by semi-supervised learning using conventional logs in tight sandstones of Ordos Basin, China. J Nat Gas Sci Eng 76:103131

Elkatatny S (2019) Development of a new rate of penetration model using self-adaptive differential evolution-artificial neural network. Arab J Geosci 12(2):19

Fawcett T (2006) An introduction to ROC analysis. Pattern Recogn Lett 27(8):861–874

Galle E, Woods H (1963) Best constant weight and rotary speed for rotary rock bits. In: Drilling and production practice, January 1963

Gholami R, Moradzadeh A, Rasouli V, Hanachi J (2014) Practical application of failure criteria in determining safe mud weight windows in drilling operations. J Rock Mech Geotech Eng 6(1):13–25

Hamdani TM, Won J-M, Alimi AM, Karray F (2007) Multi-objective feature selection with NSGA II. In: International conference on adaptive and natural computing algorithms. Springer, Berlin, pp 240–247

Han J, Sun Y, Zhang S (2019) A data driven approach of ROP prediction and drilling performance estimation. In: International petroleum technology conference

Hareland G, Hoberock L (1993) Use of drilling parameters to predict in-situ stress bounds. In: SPE/IADC drilling conference, Feb 1993

Hegde C, Gray K (2018) Evaluation of coupled machine learning models for drilling optimization. J Nat Gas Sci Eng 56:397–407

Hegde C, Daigle H, Millwater H, Gray K (2017) Analysis of rate of penetration (ROP) prediction in drilling using physics-based and data-driven models. J Pet Sci Eng 159:295–306

Kidambi T, Kumar GS (2016) Mechanical earth modeling for a vertical well drilled in a naturally fractured tight carbonate gas reservoir in the Persian Gulf. J Pet Sci Eng 141:38–51

Li T, Wang R, Wang Z, Zhao M, Li L (2018) Prediction of fracture density using genetic algorithm support vector machine based on acoustic logging data. Geophysics 83(2):D49–D60

Liu T, Gao X, Wang L (2015) Multi-objective optimization method using an improved NSGA-II algorithm for oil–gas production process. J Taiwan Inst Chem Eng 57:42–53

Maurer W (1962) The “perfect-cleaning” theory of rotary drilling. J Pet Technol 14(11):1270–1271,1274

Mehrad M, Bajolvand M, Ramezanzadeh A, Neycharan JG (2020) Developing a new rigorous drilling rate prediction model using a machine learning technique. J Pet Sci Eng 192:107338

Melacci S, Belkin M (2011) Laplacian support vector machines trained in the primal. J Mach Learn Res 12(3):1149–1184

Mirjalili S, Saremi S, Mirjalili SM, Coelho LdS (2016) Multi-objective Gray wolf optimizer: a novel algorithm for multi-criterion optimization. Expert Syst Appl 47:106–119

Møller MF (1993) A scaled conjugate gradient algorithm for fast supervised learning. Neural Netw 6(4):525–533

Motahhari HR, Hareland G, Nygaard R, Bond B (2009) Method of optimizing motor and bit performance for maximum ROP. J Can Pet Technol 48(06):44–49

Mousavi R, Eftekhari M (2015) A new ensemble learning methodology based on hybridization of classifier ensemble selection approaches. Appl Soft Comput 37:652–666

Oyedere M, Gray K (2020a) ROP and TOB optimization using machine learning classification algorithms. J Nat Gas Sci Eng 77:103230

Oyedere M, Gray K (2020b) Torque-on-bit (TOB) prediction and optimization using machine learning algorithms. J Nat Gas Sci Eng 84:103623

Plumb R (1994) Influence of composition and texture on the failure properties of clastic rocks. In: Rock mechanics in petroleum engineering, Delft, Netherlands, August 1994. https://doi.org/10.2118/28022-MS

Rampersad P, Hareland G, Boonyapaluk P (1994) Drilling optimization using drilling data and available technology. In: SPE Latin America/Caribbean petroleum engineering conference, Buenos Aires, Argentina, April 1994. https://doi.org/10.2118/27034-MS

Saeed MS, Mustafa MW, Sheikh UU, Jumani TA, Mirjat NH (2019) Ensemble bagged tree based classification for reducing non-technical losses in Multan electric power company of Pakistan. Electronics 8(8):860

Sanei M, Ramezanzadeh A, Delavar MR (2023) Applied machine learning-based models for predicting the geomechanical parameters using logging data. J Pet Explor Prod Technol 13:1–23

Shahri M, Wilson T, Thetford T, Nelson B, Behounek M, Ambrus A, D’Angelo J, Ashok P (2018) Implementation of a fully automated real-time torque and drag model for improving drilling performance: case study. In: SPE annual technical conference and exhibition, Dallas, Texas, USA, September 2018. https://doi.org/10.2118/191426-MS

Shirkavand F, Hareland G, Aadnoy B (2009) Rock mechanical modeling for a underbalanced drilling rate of penetration prediction. In: 43rd US rock mechanics symposium & 4th US–Canada rock mechanics symposium, Asheville, North Carolina, June 2009

Singh U, Singh SN (2017) Optimal feature selection via NSGA-II for power quality disturbances classification. IEEE Trans Ind Inf 14(7):2994–3002

Tatar A, Yassin MR, Rezaee M, Aghajafari AH, Shokrollahi A (2014) Applying a robust solution based on expert systems and GA evolutionary algorithm for prognosticating residual gas saturation in water drive gas reservoirs. J Nat Gas Sci Eng 21:79–94

Teale R (1965) The concept of specific energy in rock drilling. Int J Rock Mech Min Sci Geomech Abstr 2(1):57–73

Telmadarreie A, Shadizadeh S, Alizadeh B (2012) Research note: investigation of hydrogen sulfide oil pollution source: asmari oil reservoir of marun oil field in the Southwest of Iran. Iran J Chem Eng 9(3):63–74

Warren T (1984) Factors affecting torque for a roller cone bit. J Pet Technol 36(09):1500–1501,1508

Warren T (1987) Penetration rate performance of roller cone bits. SPE Drill Eng. https://doi.org/10.2118/13259-PA,2(01),9-18

Zoback MD (2007) Reservoir geomechanics: Earth stress and rock mechanics applied to exploration. In: Production and wellbore stability, p 449

Funding

All authors certify that they have no affiliations with or involvement in any organization or entity with any financial interest or non-financial interest in the subject matter or materials discussed in this manuscript.

Author information

Authors and Affiliations

Contributions

MRD: conceptualization, software, writing—review and editing, validation, data curation, formal analysis, visualization. AR: review and editing, validation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Delavar, M.R., Ramezanzadeh, A. Machine learning classification approaches to optimize ROP and TOB using drilling and geomechanical parameters in a carbonate reservoir. J Petrol Explor Prod Technol 14, 1–26 (2024). https://doi.org/10.1007/s13202-024-01769-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-024-01769-9