Abstract

Most of oil reservoirs in the world have faced decrease in production and they are in the second half of their life cycle. Therefore, tertiary and enhanced oil recovery (EOR) techniques are needed for continuous production from these reservoirs. As choosing the most appropriate EOR methods for a reservoir is a challenging task for reservoir engineers, screening of EOR approaches is of high importance before any full field simulation and experiments. Enhanced oil recovery screening is a multiple criteria decision-making (MCDM) problem and hence, a systematic statistical algorithm based on MCDM can be used for this purpose. In this study, for the first time, a new EOR screening method is proposed by using VIKOR and Monte-Carlo algorithms. The approach used a large database of successful EOR projects around the world and was applied to 12 various EOR methods including a wide range of conditions and properties. Pre-processing was performed on the gathered database and then based on reservoir engineering analyses and using a pairwise comparison matrix, initial weights were considered for the parameters in each EOR method. Afterward, these weights were used in the proposed VIKOR MCDM calculation algorithm and the corresponding numerical values of EOR techniques for each reservoir were obtained. Finally, the EOR method with the highest corresponding value was selected as the most suitable method. Results demonstrated that by using the presented approach, a high classification accuracy of 98% was obtained for different cases, which shows the proficiency and robustness of the developed screening algorithm. In addition, the reliability of the developed method was validated using data obtained from 11 oil reservoirs in the southwest of Iran. Also, the results were compared with the results of previous studies and they were in a very good match. The developed approach is less expensive and faster than full field simulation method and can be used as an efficient EOR screening approach for reservoirs with different properties in the world.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Matured oil fields are the main sources of the large portion of the produced oil around the world. However, production from these oil fields is decreasing and most of them are in their second-half life. Global demand for energy is growing and replacing new resources is difficult. Therefore, oil is expected to be the dominating energy resource. Conventional methods for oil production from the current fields cannot suffice the high energy demands. In addition, after primary and secondary oil recovery, more than 60% of the initial oil in-place remain in the reservoir. In this situation, tertiary recovery approaches, called enhanced oil recovery (EOR) methods, have shown capacity to create a balance between demand and supply in the worldwide energy market (Dickson et al. 2010; Zendehboudi et al. 2011; Bhatti et al. 2019; Khan et al. 2020; AlRassas et al. 2022).

Different EOR methods have been proposed during the last decades and depending on the fluid, geological, and rock characteristics of a candidate reservoir, specific enhanced oil recovery methods are suitable for that reservoir. Since determining the most appropriate EOR method is a challenging task for engineers, EOR screening is used before any full field simulation. Screening of EOR methods is a process that considers influencing factors and all possible approaches and finally suitable methods are introduced for further studies and experiments. Therefore, at early steps of a reservoir development process, EOR screening is of high importance and has been shown to be an effective method (Bang 2013).

Enhanced oil recovery screening process in which the best EOR scenarios are found, has been performed before and there exist several researches in literature that provide clear strategies and procedures for screening criteria of different enhanced oil recovery operations and petroleum production methods (Taber et al. 1997; Jensen et al. 2000; Alvarado et al. 2002; Teletzke et al. 2005; Adasani and Bai 2011; Zerafat et al. 2011; Parada and Ertekin 2012; Mashayekhizadeh et al. 2014; Zhang et al. 2019; Khazali et al. 2019). Studying similar projects that have been carried out successfully is one of the main steps of any EOR screening process. This process considers three main aspects; technical aspects, projects location, and economic aspects. In technical screening, fluid, rock, and petrophysical properties of the candidate reservoir are compared with reservoirs that have undergone successful improved recovery processes. Enhanced oil recovery projects are time-consuming and costly and due to technical complexity, they might be exposed to failure risk (Bourdarot and Ghedan 2011). Therefore, location optimization is another aspect that needs to be considered for reducing the risk of failure during managing an EOR project. Technical screening is also necessary for evaluating EOR approach from an economical point of view. After carrying out the desired EOR method, recovery factor would be increased and the incremental production must be analyzed and investigated so that the operational cost could be compensated. According to literature, there exist two general methods for EOR screening, which are categorized as conventional EOR screening and advanced EOR screening. In the conventional method, some criteria are pre-defined and possibility of different EOR methods is determined based on these criteria. Acceptable ranges of reservoir fluid and rock characteristics are included in the considered criteria. Taber et al. (1997) study was the pioneer of this kind of screening criteria approach. In their study, criteria were proposed by analyzing different projects of EOR implementation before 1997. Economic limitations had sensible impact in their defined criteria. These criteria have been used and updated by many researchers for years. Al Adasani and Bai (2011) updated and adopted these by considering EOR projects after 1998 and Mashayekhizadeh et al. (2014) extracted some pessimistic and optimistic criteria by combining important criteria. With progress in computer science and also increasing the number of successful EOR projects, new tools such as machine learning and data-driven models can be extensively used for EOR screening. This approach is considered as advanced EOR screening. In this method, data-driven models are utilized for clustering EOR projects and finding relationships between the implemented EOR technique and reservoir properties. The conducted study by Alvarado et al. (2002) was the earliest work in advanced approaches for EOR screening. They used clustering and dimension reduction techniques for determining the most suitable EOR methods. Zerafat et al. (2011) used Taber screening criteria and predicted appropriate EOR methods by Bayesian Belief network. Khazali et al. (2019) trained a fuzzy decision tree for EOR screening. They use data of 548 worldwide EOR projects. Cheraghi et al. (2021) used several machine learning approaches such as deep and shallow artificial neural networks, decision tree, random forest, Naïve Bayes, etc. and a database of more than 1000 EOR projects for selecting most appropriate EOR methods.

Lots of successful EOR projects have been performed on various reservoirs with different properties and characteristics since 1959; however, these methods are still limited in deployment around the world (Alemi et al. 2010; Rbeawi 2013). Enhanced oil recovery screening techniques have been done using different approaches, which include statistical methods, artificial intelligence and machine learning, clustering, simulation, and other hybrid methods (Dickson et al. 2010; Adasani and Bai 2011; Warrlich et al. 2012; Hama 2014; Saleh et al. 2014; Khojastehmehr et al 2019; Cheraghi et al. 2021). In this study, data of 746 successful EOR projects around the world was effectively carried out. Pre-processing was performed on the gathered data and the combination of VIKOR and Monte-Carlo algorithms, which is a multi-criteria decision-making (MCDM) approach, was used for screening EOR methods. 12 different EOR methods, including N2 injection, hydrocarbon gas injection, CO2 injection, immiscible gas injection, polymer flooding, in-situ combustion, steam, alkaline, surfactant, alkaline/surfactant/polymer (ASP) flooding, steam-assisted gravity drainage (SAGD), and microbial EOR were considered in the developed model. The proposed and developed screening algorithm was then tested using the data of 11 oil reservoirs in the southwest of Iran and the obtained results were compared with the results of Mashayekhizadeh et al. (2014) work in order to show the performance and proficiency of the presented algorithm.

Methodology

Data gathering

The data pertaining to reservoirs worldwide where enhanced oil recovery has been effectively implemented and published in an oil and gas journal were extracted. Then, the data were normalized by carrying out the steps outlined below. Representing real-world projects, being large enough to develop a generalized model, and containing the required and relevant input variables were the main conditions for data gathering. No single source exists to gather all the required information for the used EOR methods as well as reservoirs characteristics. Therefore, in this study, different references have been used to create a suitable dataset. The main sources used for data collection were Oil and Gas Journal biannual EOR surveys (ETTINMUNGON 2006; Koottungal 2008, 2012, 2014; Moritis 1996, 1998; Worldwide 2002, 2004). These resources provide a suitable dataset for projects such as hydrocarbon injection, CO2 and N2 injection, steam injection, and combustion. Due to the lack of data for some EOR projects such as chemical enhanced oil recovery approaches, the works published by Sheng (2010; 2013; 2014) and Standnes and Skjevrak (2014) were used to complete the dataset. Most of the reservoirs in the used dataset are conventional and unconventional fractured reservoirs. Due to the lack of data, only a few special reservoirs such as shale oil were considered; therefore, the gathered dataset cannot be a good representative for such reservoirs. Success or failure of projects were considered in the gathered data. Successful EOR projects were filtered and used in this study. Each project was characterized by fluid and rock properties as input parameters and the implemented recovery method as the output.

Data pre-processing

In this study, data of 746 successful EOR projects around the world was effectively carried out. For each reservoir, parameters containing missing data were eliminated. Before injection, ten reservoir parameters were utilized, these include porosity, permeability, gravity, viscosity, temperature, depth, lithology, composition, thickness, and oil saturation.

Reservoirs with fewer than nine parameters out of the ten specified parameters were eliminated. The methods of enhanced oil recovery, whose number of reservoirs was very small, were also eliminated.

Weighting effective parameters in each EOR approach

The significance of several elements in the execution of a particularly enhanced oil recovery should be ranked. Some factors may be so crucial that, even if all other parameters meet the screening criteria, the method will be rejected for the reservoir under consideration if a single parameter is out of range. For instance, the tank depth parameter is a crucial and extremely critical component for water vapor injection operations. Because if the reservoir is deep enough, the heat transfer of the water vapor with the well wall during injection could cause the water to boil and remove the enthalpy of vaporization, which is crucial for reducing the viscosity of the oil in the reservoir and causing it to flow, leading to the failure of the operation. Consequently, it is essential to value (weight) the screening parameters. Several researchers have performed this. For instance, Rivas et al. (1994) and Diaz et al. (1996) allocated weights to reservoir parameters for carbon dioxide gas injection method (Tables 1 and 2). Now we must address a new issue. How should the weighting of factors for enhancing oil recovery screening be determined?

To conduct this research, an initial weight for each parameter of the reservoir for each extraction method is required. Consequently, the pairwise comparison matrix generates the basic weight values of each reservoir parameter. This method compares indicators pairwise and determines their relative weight (related to the decision's primary objective). According to engineers and reservoir specialists, it has been utilized to determine pairwise comparison values. The initial weights are then optimized using the algorithm outlined in the next section in order to match the outputs of the model with the actual project data.

Multi-criteria decision analysis

In recent decades, academics have focused on multi-criteria models for making complicated decisions. In these circumstances, multiple optimality measurement criteria may be used instead of a single criterion. In other words, most managers' decisions are influenced by a variety of quantitative and qualitative variables that frequently conflict with one another, and they attempt to select the optimal option from several alternatives.

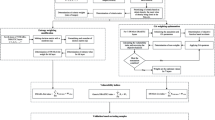

Multi-criteria decision-making problems are inherently challenging to solve and difficult to accomplish. Multi-criteria decision-making (MCDM) diagram is shown in Fig. 1. Increasing the desirability of one can diminish the desirability of another, especially when most of the desired criteria compete with one another. For this reason, methodologies such as multi-criteria decision making and particularly “multiple attribute decision making” have been created to resolve these issues. Various strategies are utilized at different phases of decision making by multi-index methods. In these procedures, numerous alternatives are examined based on various criteria; the optimal option or an appropriate sequence of options is chosen. Prioritizing the available options, multi-indicator decision-making methods based on mathematical reasons determine the optimal decision-making option.

Steps to solve multiple attribute problems

In order to resolve problems involving multiple indices, the following steps have been considered:

Define the objective of the problem.

The first step in solving problems with multiple attributes is to define the problem's objective precisely.

Establishment of evaluation indicator

It is possible to collect information on indicators that are effective in achieving the problem's objective and from which it is possible to collect their data.

-

Qualitative and quantitative attributes

-

Positive and negative attributes

A positive attribute indicates that we want to increase its value in the model. A negative attribute indicates that we want to decrease its value in the model.

-

Quality attribute range:

In order to perform calculations on qualitative attributes, they must be converted to a quantitative value.

Option determination

Either the options are already known and only a decision needs to be made, or they are determined by investigating the problem's scope. Then, the decision-making options that have the capability to collect information about them are chosen.

Determining the scoring method for attributes

After identifying the decision options and attributes, we must choose how to score the attributes. Choosing a method at this level will dictate the methods utilized in subsequent steps. There are two general approaches for achieving this, which will be discussed below.

-

Decision matrix: In this technique, a matrix of options and attributes are created, with the options typically placed in the rows and the attributes in the columns. The decision-maker specifies the quantity required for quantitative attributes and his choice for qualitative attributes in each matrix cell

-

Pairwise comparison matrix: In this technique, the decision-maker inserts her relative preferences for each of the criteria into a matrix known as the matrix of paired comparisons.

Evaluation of attributes

After identifying the attributes and setting the scoring mechanism for those attributes, we evaluate them.

Normalization of attributes

As previously indicated, each quantitative attribute has its own measuring scale, making it impossible to compare their respective values. In order to perform the comparison, they must therefore, be measured independently of the unit. There are three approaches mentioned for this purpose.

-

Normalization using norm

The square of the sum of the squares of the elements in each column is used to divide each element of the decision matrix in this method. The row in front of each option is then split into two parts using a table (attributes-options). The decision matrix values are displayed in the upper part, and the normalized value is displayed in the lower part.

-

Linear normalization

In this procedure, we invert the values of the negative attributes and then divide each matrix value by the column's maximum value. Obviously, suppose all attributes have a negative aspect. In that case, there is no need to compute the inverse of each value, and it is possible (in addition to the previous way) to divide the value of each cell in the matrix by the highest value of the corresponding column and subtract one from the result. It is evident that the values obtained are between 0 and 1. This method of normalization has the advantage of being linear and converting all results to a linear ratio. Thus the existing relative order of the results is maintained.

-

Fuzzy normalization

In this procedure, normalized values for positive and negative attributes are distinct.

The norms were used for normalization in this study.

Attribute weighting

After normalizing the values of each index, it is necessary to assess the relative significance of each attribute. For this reason, the matrix method of paired comparisons was utilized in this study.

VIKOR algorithm

Opricovic and Tzheng (2004) created VIKOR algorithm, a multi-criteria decision-making technique, to address a discrete decision-making problem with inconsistent criteria (different measurement units). VIKOR denotes a compromise solution and multi-criteria optimization. This method was created for optimizing complex systems with multiple criteria. This strategy focuses on categorizing and selecting from a set of options, as well as determining compromise solutions for an issue with competing criteria, in order to assist decision-makers in reaching a conclusion. In this case, the compromise solution is the justifiable solution that is closest to the ideal solution, where compromise refers to a mutual agreement. This compromise method presents a multi-criteria ranking index based on the relative proximity to the optimal solution (Chu et al. 2007).

The steps of VIKOR algorithm are as follows:

Construction of the decision matrix

The decision matrix or option scoring matrix is based on criteria.

X represents the decision matrix, whereas Xij represents each element. The values of each criterion for each option are denoted by Xij.

C1,…., Cn = Criteria

A1,…., An = Alternatives

Data normalization

The subsequent step involves normalizing the decision matrix using the following formula:

where Xij represents the value of each option's criterion. The numbers will appear in a new table after powering the numbers and the sum of each column and taking the square root of the sum of each column.

Identifying the ideal positive and negative points

We determine the best and worst solutions for each criterion and label them f+ and f−, accordingly. If the criterion is appropriate, we will have the following:

Calculating benefits and losses

In VIKOR calculations, Opricovic (1998) has suggested two key concepts: benefit or usefulness (S) and regret (loss) (R). The usefulness value (S) indicates the i-th option's relative distance from the ideal location, whereas the regret value (R) represents the i-th option's maximum discomfort from the ideal position. These values can be found by using the following formulas.

\({{\varvec{w}}}_{{\varvec{j}}}\) = Standard weight of j-th

VIKOR index calculation

The VIKOR index (Q) is calculated as (Opricovic 1998):

V = 0.5, v €\(\left[0, 1\right]\)

In the above equation, V is the weight for strategy of maximum group utility, and it is usually equal to 0.5. When V > 0.5, the index of \({Q}_{i}\) will tend to majority agreement and clearly when V < 0.5, the index of \({Q}_{i}\) will indicate majority negative attitude.

Two ultimate decision-making conditions for the VIKOR algorithm

In the final stage of VIKOR method, the options are arranged into three groups depending on their Q, R, and S values, from small to large. The optimal option is the one with the smallest Q if the two conditions below are met:

Condition one: If options A1 and A2 rank first and second among m options, respectively, the following relationship must be established:

Condition two: Option A1 must be ranked first in at least one of the R and S groups. If the first condition is not met, both options are preferable. If the second requirement is not met, both options A1 and A2 are chosen as the best (Tavana et al. 2016).

Monte-Carlo method

The Monte-Carlo approach relies on repeated sampling to compute results. In fact, they are a type of computing algorithm that calculate their results through repeated random sampling. Due to their dependence on iterative computations and random numbers, Monte-Carlo methods are frequently developed to be executed by a computer. Methods based on Monte-Carlo are also effective for modeling phenomena with a high degree of uncertainty in the inputs, such as the calculation of business risk. Using Monte-Carlo approach necessitates a large number of random numbers. Numerous engineering calculations can be performed using the Monte-Carlo approach.

All Monte-Carlo algorithms follow the same pattern:

-

Step 1: Establish a set of inputs.

This indicates that we have a set of variables and the possible values for them or observations that are part of a dataset.

-

Step 2: Inputs are generated at random (values of variables or a set of observations)

The generation of data at random based on a probability distribution.

-

Step 3: Run some calculations on these inputs.

Calculates on the input data.

-

Step 4: Repetition of steps 2 and 3.

Steps 2 and 3 are repeated numerous times (usually more than 10,000 times) until convergence is attained.

-

Step 5: Align the previous step's results with a final computation.

Each computational execution's results are incorporated into the final response (Kumar et al. 2015).

Also, note two additional frequent characteristics of the Monte-Carlo method:

-

Calculations rely on accurate random numbers

-

Gradual convergence to more accurate estimations as additional data are simulated.

Structure of the proposed algorithm

Figure 2 illustrates how to obtain optimal coefficients using the proposed algorithm. This method's general approach is based on the extraction of appropriate weights derived from the results and experiences of previous successful enhanced oil recovery operations. In this procedure, the methods of enhanced oil recovery are ranked using VIKOR algorithm and basic weights and then compared to the actual oil recovery to determine the percentage of matching methods. By generating random weights and employing the Monte-Carlo method, we will attempt to obtain the optimal weights for selecting the optimal enhanced oil recovery method. In simpler terms, the purpose of this study is to simulate the process of selecting a method for oil recovery by comparing it to the selection of a product or method based on past experiences. As a straightforward illustration, selecting a watermelon is based on the ability to identify the sound of watermelons being knocked.

This algorithm is divided into four stages, which are as follows:

-

The first phase involves determining the initial base weights and the acceptable weight range

-

The second phase consists of an initial calculation using the VIKOR method

-

The third stage is to generate random weights

-

The fourth stage involves comparing and determining the best weight.

Phase 1

-

Selecting the base weight for each reservoir parameter based on the opinions of reservoir experts

The pairwise comparison matrix method is utilized to compute the basic weight values of every reservoir parameter. This method compares indicators pairwise and determines their relative weight (relative to the decision's primary objective). The Pairwise comparison values were determined based on the advice of reservoir experts.

Phase 2

-

Calculating and determining the ranking of enhanced oil recovery methods using the VIKOR algorithm

At this stage, after performing the calculations according to VIKOR algorithm, the basic weights for each of the reservoir parameters are used to rank each enhanced oil recovery method. Then, we calculate and record the corresponding percentage of the results obtained with the enhanced oil recovery technique.

Phase 3

-

Producing random weights from base weights

At this point, new weights are obtained for use in VIKOR algorithm while taking into consideration the acceptable range for the weight of each parameter, in the expert's opinion.

-

Calculate using the updated weights.

At this stage, we calculate the rank of each enhanced oil recovery method using new weights and record the percentage of matches with the list of successful methods.

Phase 4

-

Comparison with earlier calculations and selection of weights with the highest proportion of matches

In this step, the matching percentages obtained in previous steps are compared, and the largest percentage is determined in order to select the optimal weights so far. The optimal weights are then used as the new base weights.

-

Repetition of the third phase of the proposed algorithm 10,000 times with the Monte-Carlo method

-

Analyzing the weights and matching percentages obtained, making necessary adjustments as needed, and repeating the algorithm loop until the highest matching percentage is reached and in accordance with professional judgment

-

Declaring as optimal the weights with the highest percentage of matching.

Results and discussion

This study collected data of 746 reservoir samples from around the world, where one of the enhanced oil recovery processes was successfully implemented. Table 3 provides a summary of the successful reservoirs around the globe.

Ten parameters of these reservoirs including porosity, permeability, gravity, viscosity, temperature, depth, oil saturation prior to injection, lithology, composition, and thickness were used in this study. Other rock and fluid properties can also be used; however, due to the lack of data for large numbers of reservoirs in the used dataset, these properties were ignored.

Development of the pairwise comparison matrix and determining the parameter weights

In this study, the pairwise comparison matrix method is utilized to determine the base weight values for each reservoir parameter. In this technique, indicators are compared pairwise, and their relative weight (relative to the decision's primary objective) is determined. According to reservoir engineering analysis, the results of determining the pairwise comparison values can be seen in Table 4. The base weight values will then be determined based on the generated pairwise comparison matrix and experts' opinion. Saaty (1990) method was used for this purpose. Table 5 shows these values. For pairwise comparison matrix, consider that the decision-maker finds the superiority of composition over gravity is equal. The value of this judgment will be (1) If the superiority of composition over depth is near equal or intermediate, then it will be (2) Also, if composition is moderate important than porosity, the value of the judgment will be (3) One should note that in the above matrix, the self-superiority of each element equals 1.

The method for calculating the weights involves first calculating the sum of each column and then dividing the value of each column by its own sum. This is to normalize the matrix. Afterward, the final weight is then calculated by averaging each element in the row of the normalized matrix. The formula for calculating weight is as follows:

dj is the value of the jth row of the matrix of pairwise comparisons, where j = 1, 2,…, n. The outcome of the calculations is shown in Table 6.

Determining the ideal values for each parameter and its value

To choose the enhanced oil recovery method based on calculations and the advice of experts as the input of the VIKOR algorithm, ideal values for each parameter were taken into consideration prior to beginning the suggested process. In other words, for any EOR technique, each criterion has an ideal value and the reservoir parameters similarity with respect to this value leads to the applicability of that EOR approach for the reservoir. Table 7 displays the intended results.

In this study, the ideal values for each EOR method have been determined by studying various successful EOR projects around the world that are reported in Oil and Gas Journal in years 1998–2014 and the key screening criteria reported in Taber et al. (1997) and Adasani and Bai (2011) were used. Since, according to VIKOR algorithm, it is necessary to determine the positive or negative effect of each parameter relative to the ideal value in the final solution, according to reservoir engineering knowledge, the formula for calculating the ratio of each parameter's value to the ideal value is calculated separately for each of the methods and parameters. This is called the effectiveness of the parameter in the EOR method. For example, for gravity, the following formula is used. If there is no value for the parameter, the effectiveness will equal to 5.

If (reservoir oil gravity > ideal value), then effectiveness of gravity = 9.

ELSE

Effectiveness of gravity = (reservoir oil gravity/ideal gravity)*9.

Using VIKOR algorithm for EOR screening of a sample reservoir

As discussed in previous sections, first of all, the pairwise comparison matrix was developed and the parameters' weights were determined. Then for each EOR method, the ideal values were defined based on calculations and the advice of experts. These values are the inputs of VIKOR algorithm. After determining the formulas corresponding to each approach, the effect of each parameter can be calculated. Using data from a representative (sample) reservoir, we will demonstrate how the VIKOR algorithm operates. Using the appropriate formulas discussed in previous section for calculating the effectiveness of each parameter in EOR methods, the determined values of each index are listed in Table 8.

Table 9 provides the values of various parameters for the sample reservoir.

First, apply evaluation formulas to Table 7, and then raise the resulting values to power 2. The outcome is displayed in Table 10.

At this point, the values of Table 8 are divided by the square root of the sum of each column in Table 10. Then, the obtained values are multiplied by the values in the last column (weight) of Table 6 to yield Table 11, which is the weighted matrix for the sample reservoir. This table is illustrated below.

The best value (F Max), the worst value (F min), and the difference between the two for each parameter can now be determined. Results are illustrated in Table 12.

Because the quantity of each parameter has its own scale, it is required to compute the benefit and loss values according to the following formulae for each EOR method so that the scales have no influence.

The results for each EOR method are shown in Table 13.

At this point, the final value of each enhanced oil recovery approach is computed based on the parameters of the reservoir using the following formula. The results are shown in Table 14 in descending order.

Enhanced oil recovery methods with highest score have the major possibility of success. As shown in Table 14, for the sample reservoir, CO2 injection has the highest possibility of success as an EOR scheme for the sample reservoir and nitrogen (N2) injection would be the least to succeed as it has the lowest score.

Evaluation of the proposed method

The majority of large reservoirs, which are responsible for a significant portion of oil production, have reached the end of their productive lives and are gradually losing productivity. In order to protect existing resources and increase production capacity or prevent a decline in production from these reservoirs, enhanced oil recovery processes are strategically important.

Enhanced oil recovery involves the injection of fluids such as gases, chemicals, and hot fluids into the reservoir in order to extract a fraction of the reservoir fluid that cannot be extracted naturally. Consequently, the amount of oil recovered from reservoirs increases when enhanced oil recovery techniques are applied. Selecting an efficient enhanced oil recovery technique is the first and most crucial step in the process.

In the first phase of this study, a database of information gathered from reservoirs where enhanced oil recovery procedures were successful was compiled. Then, the proposed algorithm was implemented using a table of 12 EOR methods with the most statistical data among the executed methods.

According to the proposed algorithm, each method of enhanced oil recovery was calculated for all existing reservoirs using the beginning weight specified by an expert, and at the conclusion of each round of execution, the total matching percentage was calculated. The program then continued with new random weights to get a larger percentage of matches. After every 1000 iterations, the generated results were evaluated, and the algorithm's parameters were updated as necessary.

In the first 10,000 iterations of the algorithm's execution, 25%, then 51%, and finally 81% matching were obtained, as shown in Table 15.

Table 16 displays the amount of obtained weights as well as the normalized amount of these weights in the third round, which corresponds to a matching percentage of 81.

At this stage, the matching percentage was determined and analyzed separately for each of the enhanced oil recovery technique. The percentage of matches can be found in Table 17.

Despite the high level of total adaptation, the percentage obtained for five methods of enhanced oil recovery is zero. Therefore, the approaches can be divided into two distinct groups and hence, the proposed algorithm can be applied independently for each group. Tables 18 and 19 display the list of the defined groups.

In the first stage of applying the suggested algorithm for the second group of methods, weights with complete matching were obtained in 41% of cases, and in the second stage, weights with complete matching were obtained in 100% of cases. The resulting weights are shown in Table 20.

The algorithm was then run again for the initial group. The outcome of the first round was 98%, and after a full round, no better result was attained; hence, the same weights were determined to be optimal for the first group. Table 21 illustrates the ideal weights determined for each of the presented groups.

The proposed algorithm was then used to screen EOR methods for 11 oil reservoirs in the southwest of Iran. Most of these reservoirs are carbonate reservoirs. The details of using the method for these reservoirs are fully explained in the next section.

Screening EOR methods for some of the Iranian oil reservoirs using the proposed algorithm

The acquired results raise the question of which of the obtained weights should be utilized to select the optimal enhanced oil recovery technology for a certain reservoir. In order to address this question and provide a general comparison of the results produced from the suggested technique, it was decided to analyze 11 sample reservoirs from the oil-rich regions of the south that were screened in Mashayekhizadeh et al. (2014) study using the method given in this study. The findings of the calculations were then compared to those of the cited paper. The difference in calculating results achieved with each of the two weight groups obtained was also explored. Table 22 contains the list of the corresponding reservoirs and the EOR methods proposed by Mashayekhizadeh et al. (2014) for each reservoir.

After calculating separately for each of the previous two groups, the findings for each reservoir were evaluated. Through careful examination of the obtained data, we have determined that the values obtained for the first group are higher and clearly distinguishable from those obtained for the second group. Table 23 displays the results collected for the R1 reservoir. R1 is a carbonate oil reservoir.

Since the higher values achieved for each of the sets of weights and groups of the corresponding enhanced oil recovery cannot be a solid justification for picking one of the two sets of methods, the set of results obtained and given in the table must be compared to the results of the study supplied by Mashayekhizadeh et al. (2014). Results obtained based on both groups of weights as well as the comparison between the results of the proposed algorithm and the ones determined by Mashayekhizadeh et al. (2014) are provided in Tables 24 and 25. Comparing the results of the calculations using the proposed approach with the method of Mashayekhizadeh et al. (2014) reveals that the first group of acquired methods conforms to the results of Mashayekhizadeh et al. (2014) to a greater extent than 70%.

In conclusion, a comparison of the results obtained from two groups of weights discovered that the higher value calculated for each of the recommended methods of enhanced oil recovery for a particular reservoir can serve as the basis for evaluating that method as the optimal and recommended method for that reservoir.

As discussed in previous sections, the proposed approach is efficient to find the most suitable EOR techniques for an oil reservoir. However, there are challenges and limitations regarding this approach and other screening methods that need to be discussed. Enhanced oil recovery screening is a complex process that needs various data of simulations studies, theoretical and experimental works of a candidate reservoir. By integrating this information, the most appropriate EOR method can be selected. One issue is that very limited information about the past and present successful EOR projects is accessible. Therefore, important information about the candidate reservoir are not considered during the screening process. For example, for finding the applicable EOR methods, production data of the candidate reservoir should be integrated, but current screening methods do not use these data. Another limitation of the proposed approach is that for each reservoir parameter, only a single value can be assigned. However, due to heterogeneity, there is a large variation in most of reservoir parameters such as permeability, saturation, porosity, etc. Considering a single value causes uncertainty to the screening results. Economic issues can highly impact the success of an EOR project. This feature is not considered as an input to the screening approaches and hence, it is a source of uncertainty in the obtained results. Another limitation regarding data-driven screening approaches is the insufficient number of some EOR projects, for example some chemical EOR methods, microbial EOR, etc. Future studies on EOR screening should consider these limitations and challenges.

Conclusions

In this study, application of a new multiple criteria decision-making (MCDM) approach based on VIKOR and Monte-Carlo algorithms in determining the most appropriate enhanced oil recovery (EOR) methods was investigated. The performance of the proposed screening method was analyzed and the obtained results were compared with the results of previous researches. Overall, this research concludes some important findings as follows:

-

The developed approach is new, flexible and simple-to-use, and could predict the appropriate EOR method with acceptable accuracy. The model can also reduce screening time by analyzing various parameters simultaneously

-

As a comprehensive and large database including successful EOR projects around the world was gathered and used to model and test the presented approach, it can be concluded that the proposed model can be applied for reservoirs with wide ranges of properties and different EOR methods

-

The model could also successfully distinguish various categories of EOR techniques for non-observed data. The results were in a very good match with the results of Mashayekhizadeh et al. (2014) work for 11 of Iranian oil reservoirs (non-observed data). CO2 injection is recommended mostly for these Iranian reservoirs

-

The main advantage of the proposed screening approach in this study is that it can be implemented for any oil reservoir, as a fast tool to predict the most suitable enhanced oil recovery method. Another advantage of the presented model is that the obtained results are not biased by the expert's opinion and knowledge. The presented method is also applicable for new field tests. New data can be added to the dataset and the proposed model is upgraded using the new dataset

-

Screening of EOR techniques using the proposed approach and other data-driven models suffers from limitations which could affect the results. These limitations include: deficient input variables, unbalanced and lack of enough data, and also no consideration of economic issues in the used datasets

-

Future studies on using data-driven models for EOR screening should consider the limitations to improve the comprehensiveness and reliability of the obtained results.

Abbreviations

- A :

-

Alternative

- C :

-

Criterion

- \(d\) :

-

Value of the matrix of pairwise comparisons

- \({f}^{+}\) :

-

Best solutions for each criterion

- \({f}^{-}\) :

-

Worst solutions for each criterion

- m :

-

The number of options

- n :

-

Normalized decision matrix

- Q :

-

VIKOR index

- R :

-

Regret measure for alternative f (Represents the option's maximum discomfort from the ideal position)

- \({R}^{*}\) :

-

Regret value represents the option's maximum discomfort from the ideal position

- \({R}^{-}\) :

-

Regret value represents the option's maximum discomfort from the anti-ideal position

- S :

-

Utility measure for alternative f

- \({S}^{*}\) :

-

Usefulness value indicates the option's relative distance from the ideal location

- \({S}^{-}\) :

-

Usefulness value indicates the option's relative distance from the anti-ideal location

- \(V\) :

-

Weight for strategy of maximum group utility

- w :

-

Standard weight

- X :

-

Decision matrix

- ASP:

-

Alkaline/surfactant/polymer

- EOR:

-

Enhanced oil recovery

- MADM:

-

Multiple attribute decision making

- MCDM:

-

Multiple criteria decision making

- MODM:

-

Multiple objective decision making

- SAGD:

-

Steam-assisted gravity drainage

References

Adasani AAL, Bai B (2011) Analysis of EOR projects and updated screening criteria. J Pet Sci Eng 79:10–24

Alemi M, Jalalifar H, Kamali G, Kalbasi M (2010) A prediction to the best artificial lift method selection on the basis of TOPSIS model. J Pet G Eng 1:009–015

AlRassas AM, Thanh HV, Ren S, Sun R, Al-Areeq NM, Kolawole O, Hakimi MH (2022) CO2 sequestration and enhanced oil recovery via the Water alternating gas scheme in a mixed transgressive sandstone-carbonate reservoir: case study of a large middle east oilfield. Energy Fuels 36:10299–10314

Alvarado V, Ranson A, Hernandez K, Manrique E, Matheus J, Liscano T et al (2002) Selection of EOR/IOR opportunities based on machine learning. In: European petroleum conference, society of petroleum engineers, Aberdeen, United Kingdom. Paper Number: SPE-78332-MS

Bang V (2013) A new screening model for gas and water based EOR processes. SPE Enhanced Oil Recovery Conference, Kuala Lumpur, Malaysia. Paper Number: SPE-165217-MS.

Bhatti AA, Raza A, Mahmood SM, Gholami R (2019) Assessing the application of miscible CO2 flooding in oil reservoirs: a case study from Pakistan. J Pet Exp Prod Tech 9:685–701

Bourdarot G, Ghedan SG (2011) EOR Screening criteria as applied to a group of offshore Carbonate oil reservoirs. In: SPE reservoir characterization and simulation conference and exhibition. Paper Number: SPE-148323-MS

Cheraghi Y, Kord S, Mashayekhizadeh V (2021) Application of machine learning techniques for selecting the most suitable enhanced oil recovery method; challenges and opportunities. J Pet Sci Eng 205:108761

Chu MT, Shyu J, Tzeng GH, Khosla R (2007) Comparison among three analytical methods for knowledge communities group-decision analysis. Exp Sys Appl No 33:1011–1024

Diaz D, Bassiouni Z, Kimbrell W, Wolcott J (1996) Screening criteria for application of carbon dioxide miscible displacement in waterflooded reservoirs containing light oil. In: SPE/DOE improved oil recovery symposium, Tulsa, Oklahoma. Paper Number: SPE-35431-MS

Dickson JL, Leahy-Dios A, Wylie PL (2010) Development of improved hydrocarbon recovery screening methodologies. In: SPE improved oil recovery symposium. Paper Number: SPE-129768-MS

Ettinmungon N (2006) Worldwide EOR survey. Oil Gas J 104(15):45–57

Hama MQ (2014) Updated screening criteria for steam flooding based on oil field projects Data. Dissertation, Missouri University of Science and Technology

Jensen T, Harpole K, Østhus A (2000) EOR screening for Ekofisk. In: SPE European petroleum conference, society of petroleum engineers, Paris, France. Paper Number: SPE-65124-MS

Khan M, Raza A, Zahoor MK, Gholami R (2020) Feasibility of miscible CO2 flooding in hydrocarbon reservoirs with different crude oil compositions. J Pet Exp Prod Tech 10:2575–2585

Khazali N, Sharifi M, Ahmadi MA (2019) Application of fuzzy decision tree in EOR screening assessment. J Pet Sci Eng 177:167–180

Khojastehmehr M, Madani M, Daryasafar A (2019) Screening of enhanced oil recovery techniques for Iranian oil reservoirs using TOPSIS algorithm. Energy Rep 5:529–544

Koottungal L (2008) Special report: worldwide EOR survey. Oil Gas J 106(15):47–59

Koottungal L (2012) Worldwide EOR survey. Oil Gas J 110:57–69

Koottungal L (2014) Worldwide EOR survey, Data report. Oil Gas J

Kumar J, Soota T, Sagar Singh G (2015) TOPSIS and VIKOR approaches to machine tool selection. J Sci Res Adv 2:125–130

Mashayekhizadeh V, Kord S, Dejam M (2014) EOR potential within Iran. Spec Top Rev Porous Media Int J 5(4):325–354

Moritis G (1996) EOR worldwide survey. Oil Gas J 94:45–61

Moritis G (1998) Worldwide EOR survey. Oil Gas J

Opricovic S, Tzeng GH (2004) Compromise solution by MCDM methods: a comparative analysis of VIKOR and TOPSIS. Eur J Operat Res No 156(2):445–455

Opricovic S (1998) Multi-criteria optimization of civil engineering systems. Dissertation, Faculty of Civil Engineering, Belgrad

Parada CH, Ertekin T (2012) A new screening tool for improved oil recovery methods using artificial neural networks. In: SPE western regional meeting, society of petroleum engineers. Paper Number: SPE-153321-MS

Rbeawi SA (2013) A view for prospective EOR projects in Iraqi oil fields. Univ J Pet Sci 1(3):39–67

Rivas O, Embid S, Bolivar F (1994) Ranking reservoirs for carbon dioxide flooding processes. SPE Adv Tech Series 2:95–103

Saaty TL (1990) Decision making for leaders: the analytic hierarchy process for decisions in a complex world. RWS publications, Pittsburgh

Saleh L, Wei M, Bai B (2014) Data analysis and novel screening criteria for polymer flooding based on a comprehensive database. In: SPE improved oil recovery symposium, society of petroleum engineers, Tulsa, Oklahoma. Paper Number: SPE-169093-MS

Sheng JJ (2010) Modern chemical enhanced oil recovery: theory and practice. Gulf Professional Publishing, Houston

Sheng JJ (2013) Enhanced oil recovery field case studies. Gulf Professional Publishing, Houston

Sheng JJ (2014) A comprehensive review of alkaline–surfactant–polymer (ASP) flooding. Asia Pac J Chem Eng 9(4):471–489

Standnes DC, Skjevrak I (2014) Literature review of implemented polymer field projects. J Pet Sci Eng 122:761–775

Taber JJ, Martin F, Seright R (1997) EOR screening criteria revisited-part 1: introduction to screening criteria and enhanced recovery field projects. SPE Res Eng 12(03):189–198

Tavana M, Kiani Mavi R, Francisco J, Arteaga S, Rasti Doust E (2016) An extended VIKOR method using stochastic data and subjective judgments. Comp Ind Eng 97:240–247

Teletzke GF, Patel PD, Chen A (2005) Methodology for miscible gas injection EOR screening. In: SPE international improved oil recovery conference in Asia Pacific, society of petroleum engineers, Kuala Lumpur, Malaysia. Paper Number: SPE-97650-MS

Warrlich GM, Waili IH, Said DM, Diri M, Al-Bulushi NIh, Strauss JP et al (2012) PDOS EOR screening methodology for heavy-oil fractured carbonate fields-a Case study. In: SPE EOR conference at oil and gas West Asia, society of petroleum engineers, Muscat, Oman. Paper Number: SPE-155546-MS

Worldwide E (2002) Survey. 2002. Oil Gas J 102(14):53–65

Worldwide E (2004) Survey. 2004. Oil Gas J 102(14):53

Zendehboudi S, Chatzis I, Shafiei A, Dusseault MB (2011) Empirical modeling of gravity drainage in fractured porous media. Energy Fuels 25(3):1229–1241

Zerafat MM, Ayatollahi S, Mehranbod N, Barzegari D (2011) Bayesian Network analysis as a tool for efficient EOR screening. In: SPE enhanced oil recovery conference, society of petroleum engineers, Kuala Lumpur, Malaysia. Paper Number: SPE-143282-MS

Zhang N, Wei M, Fan J, Aldhaheri M, Zhang Y, Bai B (2019) Development of a hybrid scoring system for EOR screening by combining conventional screening guidelines and random forest algorithm. Fuel 256:115915

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors confirm that there are no known conflicts of interest associated with this publication and there has been no significant financial support for this work that could have influenced its outcome.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hajinorouz, M., Alavi, S.E. A new approach based on VIKOR and Monte-Carlo algorithms for determining the most efficient enhanced oil recovery methods: EOR screening. J Petrol Explor Prod Technol 14, 623–643 (2024). https://doi.org/10.1007/s13202-023-01726-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-023-01726-y