Abstract

Shale instability is a significant problem, accounting for approximately 70% of wellbore challenges during drilling operations. To address this issue, shale inhibitors are commonly added to drilling mud to stabilize the encountered shale formations. Ionic liquids and deep eutectic solvents have been recognized as effective shale inhibitors due to their environmental friendliness and effectiveness. However, despite their advantages, these solutions still lack full environmental sustainability, leading researchers to explore more natural alternatives like Natural Deep Eutectic Solvents (NADES). This study focuses on the synthesis and application of a NADES composed of Potassium Chloride (KCl) and glycerine, aiming to enhance the environmental profile and efficacy of shale inhibitors. The NADES was prepared with a 1:8 molar ratio at a temperature of 60 °C. Characterization analyses, including Fourier Transform Infrared and Thermogravimetric Analysis, confirmed the formation of bonds between –(OH) and Cl− and demonstrated the NADES's thermal stability up to 200 °C. Incorporating 3% NADES into water-based mud, prepared following API 13B-1 standards, resulted in significant improvements in mud rheology. Specifically, the addition of 3% NADES reduced filtrate volume by 14.2% and mud cake thickness by 19.2%. Furthermore, the 3% NADES exhibited remarkable inhibition of clay swelling by 69.23% and demonstrated a shale recovery rate of 58%. When compared with 3% KCl and 3% 1-ethyl-3-methylimidazolium chloride (EMIM-Cl), the NADES-based mud outperformed both in terms of efficacy. These findings were further supported by additional analyses, including d-spacing measurements (XRD), Zeta Potential, Surface tension, and Field Emission Scanning Electron Microscopy. Additionally, the rheological behavior of the NADES-based mud aligned with the Yield Power Law at both 25 °C and 100 °C. The study's findings contribute to the advancement of greener drilling practices and highlight the applicability of KCl-based NADES as a potential drilling fluid additive.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

During drilling, a huge percentage of well bore instability issues are associated with the shale formation (Li et al. 2012; Sudharsan and Khare 2022). Shale is a significant sedimentary formation which acts as a source rock as well as reservoir rock (Beg et al. 2021; Rasool et al. 2022a, b, c, d). During drilling, shale failure can occur mainly due to mechanical or chemical reasons (Mkpoikana et al. 2015; Ahmed et al. 2019). The chemical cause behind shale instability is its peculiar chemical composition. Shale contains swelling clays such as smectite and dispersing clays such as illite and kaolinite which on hydration results in shale instability leading to wellbore failure and other drilling hazards (Chu et al. 2019; Abbas et al. 2021; Muhammed et al. 2021). Shale instability results into various wellbore problems such as caving, pipe stucking, bit balling etc. (Akpan et al. 2019; Ahmad et al. 2021).

Basically, shale instability encompasses two phenomena: (1) shale swelling (2) dispersion (Gholami et al. 2018; Liu et al. 2021). Shale swelling or sloughing is merely the expanding of swelling clays when smectite present in shale comes in contact with water while dispersion is mainly the breakdown of shale into smaller fragments which leads to problems like bit balling (Yan et al. 2020; Allawi and Al-Jawad 2021). Oil-based mud (containing oil as base medium) is preferred over water-based mud (containing water as base medium) to drill shale formations as oil-based mud doesn’t contain water that will interact with clay content of the shale which will lead to shale swelling and dispersion(Aramendiz and Imqam 2019; Paswan and Mahto 2020). However, the environmental footprints of oil-based mud are too loud to be utilized as a primary choice thus water-based mud with various inhibitors are used for shale inhibition (Patel et al. 2007; Huang et al. 2018; Okoro et al. 2020).

The most conventional inhibitors are salts such as Potassium Chloride, Calcium Chloride and silicates (Fu et al. 2020; Oseh et al. 2020). The problem with the salts is that they are needed in large amount which makes the disposal of mud ecologically unfavorable while silicates are pH dependent (Gholami et al. 2018; Murtaza et al. 2020). In recent studies, the utilization of ionic liquids as drilling fluid additives is very popular among various research groups as shale inhibitors. Ionic liquids are tunable solvents which are liquid at room temperature and have proven to be capable of interacting with clays and modifying the charge as well as the structure of clay particles which modify their properties (Bavoh et al. 2019, 2020; Zamir et al. 2021; Rasool et al. 2022a, b, c, d).

Rahman et al. (2022) utilized tetramethylammonium chloride (TMACl) and 1-ethyl-3-methylimidazolium chloride (EMIM-Cl) in drilling mud and achieved 23.40% and 15.66% reduction in linear swelling, respectively (Rahman et al. 2022). Khan et al. (2021) utilized Trihexyltetradecyl phosphonium bis(2,4,4-trimethyl pentyl) phosphonate-based ionic liquid and achieved 12.3% shale inhibition as compared to water (Khan et al. 2021). Huang et al. (2020) utilized ionic liquids, i.e., 1-hexyl-3-methylimidazolium bromide and 1,2-bis(3-hexylimidazolium1-yl) ethane bromide using Na-Bt pellets and achieved 86.43% and 94.17% reduction in shale swelling, respectively (Huang et al. 2020). 1-Vinyl-3- dodecylimidazolium bromide and 1-Vinyl-3- tetradecylimidazolium bromide were also used by Yang et al. (2017) and they achieved 16.91% and 5.81% reduction in shale swelling, respectively (Yang et al. 2017). Ofei et al. (2017) used 1-butyl-3-methylimidazolium chloride (BMIM-Cl) in WBM which in turn reduced mudcake thickness up to 50% and decreased YP/PV at all considered temperatures thus improving drilling fluid hydraulics (Ofei et al. 2017). Yang et al. (2017) utilized 1-Vinyl-3-ethylimidazolium bromide and achieved 31.62% reduction in shale swelling with 40.60% shale recovery rate. Luo et al. (2017) used 1-octyl-3- methylimidazolium tetraflouroboreate which resulted into 80% reduction in shale swelling.

Ionic liquids, though they are presented as green solvents, but they are not green in true sense. The most exploited class of ionic liquids in drilling fluids, i.e., imidazolium-based ionic liquids have been found to be toxic and they are generally expensive and non-biodegradable (Flieger and Flieger 2020; Cho et al. 2021). This is when a greener and cheaper alternative of ionic liquids, i.e., Deep Eutectic Solvents (DES)—the fourth generation ionic liquids, came into the picture (de María and Maugeri 2011; Şahin 2019; Singh and Savoy 2020). DES are mere the combination of a hydrogen bond donor and hydrogen bond acceptor which are mixed at particular molar ratio at a specific temperature to get the eutectic mixture (Hayyan et al. 2013; Craveiro et al. 2016). A lot of work has been done in utilization of DES as drilling fluid additives for shale inhibition.

Jia et al. (2019) made significant contributions to the utilization of Deep Eutectic Solvents (DES) as shale inhibitors in drilling mud. They used Propoanoic acid ChCl (1:1), 3-phenyl propanoic acid ChCl (1:2) and 3-mercapto propanoicacid + Itaconic acid + ChCl (1:1:2) based DES and achieved 68%, 58% and 58% bentonite swelling inhibition, respectively (Jia et al. 2019). Rasool et al. (2021a, b) utilized Glycerine: Potassium Carbonate DES. 2:1 for a free style experiment using swelling shale samples and got 87% swelling inhibition (Rasool et al. 2021a, b). Ma (2021) utilized Urea: ChCl based DES and got 67% shale swelling inhibition (Ma et al. 2021). Rasool et al. (2022a) utilized a double action P-D inhibitor combination of Potassium carbonate-based DES and Poly (2-ethyl-2-Oxazoline) hydroxyl terminated polymer in drilling mud and achieved 76% swelling inhibition. The green credentials of DES were put into question when the latest derivative of DES became popular, i.e., natural deep eutectic solvent (NADES) (Vanda et al. 2018; Halder and Cordeiro 2019; Marchel et al. 2022). NADES and DES are chemically and definition wise alike, but the main difference is that NADES is formulated by the naturally occurring hydrogen bond donors and hydrogen bond acceptors such as naturally occurring salts (KCl, CaCl2 etc.) (Paiva et al. 2014; Cunha and Fernandes 2018; Benvenutti et al. 2019). A significant study was conducted where Ascorbic acid-based NADES was used as a shale inhibitor in drilling mud which yielded 77.7% shale swelling inhibition and 87% improved shale recovery (Rasool et al. 2023b). A similar study was conducted for Calcium Chloride-based NADES which is also utilized as a drilling mud additive and has given excellent shale inhibition results (Rasool et al. 2023c).

This study will focus on synthesizing and utilizing KCl-based NADES as additive in drilling fluid for shale stabilization studies and to enhance drilling fluid properties. A detailed characterization study will be conducted to understand the underlying mechanism. The primary objective is to replace KCl, which is a conventional drilling fluid additive for shale stabilization, with KCl-based NADES and recommend it as a potential shale inhibitor. To provide further justification, the performance of the optimized concentration of KCl-NADES in drilling mud will be compared with the same concentration of KCl and 1-Ethyl-3-methylimidazolium chloride (EMIM-Cl). This comparison will test the efficacy of KCl-based NADES as compared to the traditional inhibitor (KCl) and the popular ionic liquid (EMIM-Cl) commonly employed by various researchers in drilling fluids.

KCl and glycerine have been selected as HBD (Hydrogen Bond Donor) and HBA (Hydrogen Bond Acceptors) to formulate the NADES based upon two factors (1) M.H. screening criteria for the selection of DES for shale stabilization studies (Rasool et al. 2022b) (2) Utilizing KCl-based NADES in comparison with KCl alone because KCl is a conventional drilling fluid additive (Hamed and Belhadri 2009; Parizad et al. 2018; Jiang et al. 2019; Ahmed et al. 2020) which is used for improving drilling fluid properties and inhibiting shale swelling. M.H. screening criteria dictates that HBD and HBA should have high hydrogen bond donor and acceptor count and there should be polar functional groups/bonds attached to make an ideal combination for DES/NADES for shale inhibition.

Materials and methods

Materials

Potassium Chloride > 99%, Gylcerine (99 USP), Sodium carbonate > 98%, Sodium Hydroxide pellets, 1-ethyl-3-methylimidazolium chloride > 98% have been procured from Sigma-Aldrich, Malaysia. Sodium Bentonite has been procured from Scomi Oil Tools, Malaysia.

Methods

Synthesis of KCl: glycerine-based NADES

Potassium Chloride and Glycerine have been stirred at different molar ratios to acquire a eutectic mixture. A eutectic mixture is visually substantiated by a homogenous, transparent liquid with no apparent turbidness which implies that HBA and HBD have been mixed at eutectic composition (Martins et al. 2019; Alhadid et al. 2020). Initial experiments have been conducted to observe the temperature dependence of mixing pattern of HBD and HBA. The eutectic mixture ratios have been assessed at three temperatures 50 °C, 70 °C and at 100 °C because as per literature, for most DES, eutectic temperature lies between 50 °C and 80 °C. METTLER Digital Balance has been utilized to weigh the HBD and HBA while Thermo Fisher Hot plate has been used for controlled heating and stirring of HBD and HBA at 100 rpm.

Thermophysical and chemical characterization of NADES

Density, pH, surface tension, viscosity and refractive index of the in-house prepared NADES has been measured between 25 °C and 60 °C mainly because of the equipment constraints. Fourier Transform Infrared (FTIR) is conducted to observe the formation of bond between HBD and HBA and Thermogravimetric Analysis (TGA) of in-house prepared NADES have been conducted to check its candidacy as a drilling fluid additive in high-temperature wells. These all properties have been reported as a part of this research work so that the utilization of novel KCl-based NADES can be made in other applied fields as well.

Bentonite wafer preparation

Bentonite wafers are the preferred choice for studying shale swelling due to the presence of the "smectite" group (clay) in bentonite, which is responsible for the swelling phenomenon in shale. Additionally, obtaining "true" shale core samples is challenging as the coring process renders shale highly unstable, resulting in core samples that are not composed entirely of shale (they may contain sandstone and limestone layers). Furthermore, conducting swelling inhibition experiments on shale outcrops is not feasible since these usually lack the smectite group responsible for shale swelling.

In this research, we utilize refurbished pellets of bentonite measuring approximately 2.54 cm in diameter and weighing 11.5 g of Na-bentonite powder, which are compressed at 1600 psi using a hydraulic press. Before introducing the pellets into the Linear Swell Meter (LSM) environment, their thickness is measured. Subsequently, these pellets are immersed in drilling mud samples, including both the base sample and samples with inhibitors-based mud. The change in pellet thickness is then determined using the linear swell meter, with measurements taken at 60-s intervals over a 24-h period.

The XRD of Sodium bentonite is conducted to know its composition for confirming the presence of smectite group in linear swelling test as shown in Table 1.

Drilling fluid preparation

Drilling fluid has been designed using API 13B-1 standards and the composition of the mud is given in Table 2.

Drilling fluid properties

Various concentrations of NADES-based mud samples (1%, 3%, and 5%) were examined using a FANN Viscometer to record readings at 3 rpm, 6 rpm, 300 rpm, and 600 rpm before and after aging at temperatures of 100 °C and 150 °C. To simulate aging, the mud samples were placed in a rolling oven at a pressure of 1000 psia for 24 h. The obtained data were subsequently utilized to determine the Yield Point (YP) and Plastic Viscosity (PV). The further comparison of the optimized concentration of NADES is conducted with the same concentration of KCl and ionic liquid, i.e., 1-Ethyl-3-methylimidazolium chloride.

The High Pressure High Temperature (HPHT) filtration test is conducted to assess the filtration properties (mud cake thickness and filtrate loss) of drilling fluids under high pressure and high temperature conditions. The test involves preparing a representative sample of the drilling fluid and assembling a filtration cell with a clean filter medium. The cell is then connected to the HPHT apparatus, where the pressure (1000 psia) and temperature (400 °C) are controlled. By measuring the rate at which the drilling fluid filtrate passes through the filter medium, important filtration parameters such as filtrate volume and mud cake thickness can be determined. This test provides valuable insights into the performance of drilling fluids in high-pressure and high-temperature environments, aiding in the optimization of drilling operations. The optimized concentration of NADES is further compared with the same concentration of KCl and 1-Ethyl-3-methylimidazolium chloride (ionic liquid) in terms of filtration properties.

Linear swell meter

The Grace HPHT Linear Swell Meter (M4600) is an advanced piece of equipment capable of directly measuring the swelling phenomenon by monitoring changes in sample thickness. In this study, the LSM is utilized to assess the inhibitory properties of a water-based drilling fluid on shale swelling. The LSM comprises two distinct components: the Wafer Compactor and the Linear Swell Meter (Model: M4600). Bentonite wafers were prepared using the Grace core/wafer compactor, while the main equipment (LSM) was employed to conduct swelling tests and provide real-time swelling data. The optimized concentration of NADES is additionally compared to the equivalent concentrations of KCl and 1-Ethyl-3-methylimidazolium chloride (ionic liquid) to evaluate shale recovery and linear swelling.

Shale recovery test

The shale recovery test, also known as the shale immersion test or shale dispersion test, is conducted to examine the dispersion behavior of shale, which is directly related to its stability. Shale cuttings are separated by filtering them through a 6 BSS mesh sieve and then placed on a 10 mesh sieve. Initially, the cuttings are mixed with both the base fluid and NADES-based drilling fluids in aging cells, followed by subjecting them to hot rolling in an oven. This hot rolling process ensures sufficient contact between the mud and the cuttings. After 16 h, the cuttings are removed from the mud. This entire process causes shale disintegration, resulting in a decrease in the weight of the cuttings.

To analyze the recovery of shale cuttings, the cuttings are filtered out of the mud using a finer mesh screen (40 mesh). They are then thoroughly washed with water and dried in an oven. Subsequently, the recovered cuttings are compared to determine the percentage of shale cuttings recovered from the initial weight. Shale outcrop sample has been obtained from Niah, District of Miri, Sarawak, Malaysia. The shale sample has been subjected to XRD to quantify the clay composition in order to check its candidacy for dispersion/shale recovery test. The clay minerology of shale samples used in this research work is given in Table 3

Surface tension

Surface tension refers to the tension that exists on the surface of a liquid due to cohesive forces. The infiltration of water cations into the micropores of shale is attributed to capillary action, which is directly related to surface tension. In order to determine the surface tension of the drilling fluid samples, an Interfacial Tensiometer (IFT) has been utilized. The IFT serves as a valuable tool in measuring the surface tension by examining the interface between the drilling fluid and another medium. This measurement helps in understanding the interfacial behavior and the effectiveness of the fluid in overcoming the cohesive forces on the liquid surface.

By employing the IFT, the research aims to gain insights into the surface tension properties of the drilling fluid samples. This knowledge can contribute to a better understanding of the behavior of the fluid and its interactions with the shale formations. The NADES's optimized concentration is subjected to a comparison with equivalent concentrations of KCl and 1-Ethyl-3-methylimidazolium chloride (ionic liquid) to analyze surface properties and provide a rationale for the findings.

X-ray diffraction analysis

The d-spacing represents the cumulative interlayer spacing between alumino-silicate layers in clay and one alumino-silicate layer. To examine the intercalation of inhibitors into the bentonite layers, various samples were analyzed using X-ray diffraction (XRD). These samples include dry sodium bentonite, base mud, and wet drilling mud samples containing 1%, 3%, and 5% NADES. XRD analysis was conducted using a benchtop X-ray diffractometer (D2 phaser) operating at a current of 40 mA and 45 kV, with Cu-Kα radiation (λ = 1.54059 Å). This analysis provided XRD peaks for all the wet samples, as well as the dry Na-Bt sample. By applying Bragg's equation, the d-spacing between the crystal lattice planes was determined.

This XRD analysis enables us to investigate the intercalation of inhibitors into the layers of bentonite and assess any changes in the d-spacing. The results contribute to our understanding of the interaction between the inhibitors and the clay mineral structure, shedding light on the effectiveness of the studied inhibitors in modifying the clay's properties. The optimized concentration of NADES is also compared with the corresponding concentrations of KCl and 1-Ethyl-3-methylimidazolium chloride (ionic liquid) to assess d-spacing and provide a justification for the obtained results.

Zeta potential

The Malvern Zetasizer Nano ZSP instrument was utilized to measure the Zeta Potential (Z.P) of the diluted drilling mud samples. Zeta Potential is a crucial parameter that provides insights into the electrical charge and stability of colloidal particles present in the drilling mud.

The Zetasizer Nano ZSP operates based on the principle of electrophoretic light scattering, also known as laser Doppler electrophoresis. In this process, a laser beam is directed at the dispersed particles in the sample. As the particles move under the influence of an applied electric field, they create a Doppler shift in the scattered light, which is then measured by the instrument. By analyzing the frequency shift, the Zeta Potential of the particles can be determined. The drilling mud samples were appropriately diluted to ensure accurate measurements within the instrument's detection range. The diluted samples were then introduced into the Zetasizer Nano ZSP, and the instrument performed the necessary analysis to measure the Zeta Potential.

The obtained Zeta Potential values provide crucial information about the stability and behavior of the drilling mud. It helps assess the likelihood of particle aggregation or dispersion within the fluid, which has implications for its performance during drilling operations.

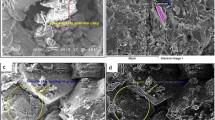

Field Emission Electron Spectroscopy Microscope (FESEM)

A Field Emission Scanning Electron Microscope (FESEM) equipped with Energy Dispersive X-Ray (EDX) analysis capabilities, specifically the Zeiss Supra 55 VP model, was employed to observe and analyze the impact on clay samples before and after exposure to NADES (Natural Deep Eutectic Solvents). The imaging was conducted at a resolution of 500 nm, utilizing electron beam energies of 30 kV and 50 kV. The FESEM enables high-resolution imaging of the clay samples, providing detailed visualizations of their surface morphology and structural characteristics. By comparing the images taken before and after exposure to NADES, researchers gain insights into the effects and interactions of the solvent on the clay material.

By utilizing the FESEM technique, this study aims to investigate the influence of NADES on the clay samples at a microscopic level. The resulting images and elemental analysis data contribute to a comprehensive understanding of the clay-NADES interactions, shedding light on the potential applications and effects of NADES on clay-based materials.

Rheological modeling of KCl-NADES based drilling mud

Rheological modeling is very substantial in drilling fluid hydraulics calculations because it aids in foreseeing the performance of drilling fluid under dynamic conditions. In this research work, rheometer (DHR1) has been used to evaluate shear stress and dynamic viscosity of NADES-WBM at shear rates between 1.48 and 1200 s−1 at 25 °C, 100 °C. Non-Newtonian behaviour is shown by the drilling fluid in which the viscosity shifts with shear rate. There are three major models that are generally utilized to model the behaviour of the drilling mud (Rasool et al. 2022a, b, c, d): (1) Bingham Plastic Law/Model (B.P.L) (2) Power Law/Model (P.L) (3) Yield Power Law or Herschel–Buckley Model (Y.P.L/H.B.M). Further details of the model and curve fitting can be seen in our previous work (Rasool et al. 2022d).

Results and discussion

Preparation of KCl-based NADES

The KCl and glycerine were combined in varying molar ratios until a transparent, turbidity-free, and homogeneous liquid was achieved, indicating the formation of a stable eutectic mixture. The mixing process took place at 60 °C with continuous stirring at 100 rpm. Table 3 and Fig. 1 present the specific molar ratios of KCl and glycerine employed during this experiment, with the eutectic mixture successfully obtained at a ratio of 1:8. The detail synthesis of KCl- NADES (Fig. 1 and Table 4) can be further studied in our previous work (Rasool et al. 2023a).

Thermophysical properties of NADES

As part of this research work, the thermophysical properties of NADES were determined and are reported herein. The properties investigated include density (Fig. 2), pH (Fig. 3), surface tension (Fig. 4), refractive index (Fig. 5), and viscosity (Fig. 6) of the KCl-NADES. At 25 °C, the density was found to be 1.282 g/cc, the pH measured at 5.69, the surface tension recorded as 59.4 mN/m, the refractive index determined as 1.445, and the viscosity measured at 994 cp. The results indicate that KCl-NADES exhibits a slightly acidic nature, with a pH value comparable to that of rainwater. It is worth noting that excessively acidic NADES may not be suitable for use in drilling mud applications, as drilling mud typically performs better in a basic environment. Moreover, the viscosity of KCl-NADES was slightly higher than that of glycerine, while its refractive index was slightly lower than that of glass. These findings contribute to the understanding of the thermophysical properties of KCl-NADES and provide valuable insights for potential applications in various industries, including drilling and fluid systems. The detail physico-chemical characterization of newly prepared NADES can be further studied in our previous work (Figs. 1, 2, 3, 4, 5, 6, 7, 8) (Rasool et al. 2023a).

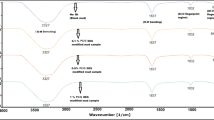

Fourier transform infrared spectroscopy of NADES

The FTIR has been conducted to see the formation of bond between KCl and Glycerine. KCl characteristic peak has been observed at 1394 1/cm, while OH stretching at 3317 1/cm is the adsorbed moisture (Yasar et al. 2019; Rasool et al. 2021a, b). Glycerine shows –OH bending at 1414 1/cm. The corresponding peak shift in NADES is visualized at 1410 1/cm. The change in wavenumber corresponds to shift in electronegative difference which relates to the formation of a new bond. The shift in 1410 1/cm from 1414 1/cm shows glycerine has reacted with KCl and being a hydrogen bond donor –OH group has formulated a bond with chloride in KCl as shown in Fig. 7. Although, the only halide that can make hydrogen bond is Florine but in regime of eutectic mixtures, chloride ions have been found to show hydrogen bond type interaction with hydrogen bond donor as well. This interaction might not be strictly termed as traditional hydrogen bonding, therefore, the better word to describe this dipole–dipole interaction can be coined as "pseudo hydrogen bonding." The decrease in the bending vibration peak frequency of O–H indicates a shift towards a lower frequency, which suggests a strengthening of the hydrogen bond between –OH and Cl− ions. On the other hand, the increase in the stretching vibration peak frequencies of both O–H and C=O bonds can be explained by changes in the local environment and electronic properties of the molecules involved in the hydrogen bond formation. The formation of hydrogen bonds can affect the bond lengths, bond strengths, and electron density distribution, leading to shifts in the peak frequencies.

It is important to note that these spectral changes are influenced by various factors, including intermolecular interactions, molecular geometry, and the presence of other functional groups. Thus, the observed changes in the peak frequencies of O–H and C=O vibrations can provide valuable insights into the nature and strength of hydrogen bonding interactions in the NADES. Figures 7 and 8 are further described in our previous work (Rasool et al. 2023a, b, c).

Thermogravimetric analysis

Thermogravimetric analysis (TGA) was performed on NADES, as depicted in Fig. 8, to evaluate its thermal behavior. Since NADES is utilized as an additive in drilling mud, it is essential for it to maintain its inherent properties even under high-temperature conditions. The observed decrease in the quality of KCl-based NADES (Potassium Chloride- and glycerine-based NADES) before reaching 200 °C can be attributed to the thermal decomposition and volatilization of the components present in the NADES. The results in Fig. 7 indicate that the notable weight loss of NADES initiates after surpassing 200 °C. Figure 7 shows the main decline in the weight of NADES starts after 200 °C. KCl has a melting point of 770 °C so the main reason behind weight loss is the deterioration of glycerin at higher temperatures, i.e., between 200 and 350 °C, glycerine is converted into formaldehyde (Rasool et al. 2021a, b). The temperature for high-temperature wells is approximately 150 °C which shows that KCl-based NADES will not start losing its innate characteristics till 200 °C.

Drilling fluid properties of NADES-based mud

Yield point/plastic viscosity (YP/PV) of the NADES-based mud

Yield Point and Plastic Viscosity ratio is considered as the best indicator of mud rheology as individually they might not contribute significantly towards the results (Rasool et al. 2022a, b, c, d).Yield point is described as the force of attraction existing between colloidal particles of the drilling fluid while plastic viscosity is the force of resistance caused by solid particles and the liquid in the drilling fluid. The cutting carrying capability of the mud can be best described by YP/PV (Abbas et al. 2021, 2022). The rise in YP/PV values usually level the mud flow profile which in turn improves the cutting carrying ability of the mud as shown in Fig. 8. It is also important to note that very extreme values of YP/PV will result into a rise in annular frictional pressure losses, consequently increasing the equivalent circulation density (ECD), which may result into fracturing and other problems resulting into Non-productive Time (NPT) (Rasool et al. 2021a, b). Literature survey shows that YP/PV values ranging between (0.75 – 1)lbm/100 ft2/cp results into good drilling fluid hydraulics without causing any unwanted ECD (Bavoh et al. 2019, 2020; Zamir et al. 2021). Figure 8 shows that the addition of NADES in the mud improves the drilling fluid hydraulic in general and the cutting carrying ability of the mud by reducing the YP/PV value nearer to the optimum range, i.e., (0.75–1)lbm/100 ft2/cp. This is because that NADES just like DES and ionic liquids modify the structure of clay platelets which modifies the mud rheology. For aged samples (100 °C and 150 °C), YP/PV nearly lies into the optimum range.

The diminution in Yield point and Plastic viscosity ratio of the drilling mud with the surge in temperature is the combined effect of various phenomena occurring concomitantly, such as: change in the electrical double layer thickness surrounding the clay particles, waning in the degree of hydration, augmented thermal energy of the clay particles, decline in the viscosity of the colloidal medium along with the increase in clay particles’ dispersion (Rathnaweera et al. 2018; Akpan et al. 2019). At high temperature, bentonite suffers severe dehydration, mechanical shearing, and degradation (Mohammed 2017). The clay platelets, on high temperature, after enduring degradation, come closer to each other and attractive forces are created between them giving the clay platelets a face-to-edge orientation (Wilson and Wilson 2014). The increase in temperature will then lead to the state of agglomeration and flocculation that results into lower rheological properties as shown in Fig. 9a. The ideal YP/PV (yield point/plastic viscosity) value, closest to the optimum range of 0.75–1 lbm/100 ft2/cp, is observed at a concentration of 3% NADES. This concentration of NADES is then compared to the same concentration of KCl and ionic liquids, and the results obtained were quite predictable as shown in Fig. 9b. While both KCl and the ionic liquid improved the YP/PV of the mud, NADES outperformed them, demonstrating the best results when compared to the traditional drilling fluid additive (KCl) and the modern mud additive ionic liquid (EMIM-Cl).

Filtration properties of the NADES-based mud

The results of the HPHT filtration test for both the base sample and NADES-based samples are presented in Figs. 10a and 11a. Notably, the KCl-NADES-based mud exhibited satisfactory performance under HTHP (high-temperature, high-pressure) conditions. When compared to the base sample without any inhibitor, the addition of NADES improved the filtration properties of the mud by reducing both the filtrate volume and mudcake thickness. The growth of a thick mudcake can give rise to several issues, such as drill pipe sticking, which can result in non-productive time (NPT) and wellbore failure. In such situations, thinners are typically incorporated into the drilling mud to decrease the thickness of the mudcake. Interestingly, the presence of NADES in the mud played a role similar to that of a thinner, effectively reducing the mudcake thickness and filtrate volume. This characteristic of NADES can be attributed to its ability to interact with clay platelets, modifying their wettability and subsequently altering the filtration properties of the mud.

Specifically, the 3% NADES-based mud, without undergoing aging, demonstrated the least decline in both mudcake thickness (19.2%) and filtrate volume (14.2%) as shown in Figs. 10 and 11. It is important to note that the elevated aging temperature caused the mud to flocculate and aggregate, resulting in a thicker mudcake and higher filtrate loss, as evident from the figures. Nevertheless, even the NADES-based aged mud samples exhibited superior filtration properties compared to the aged base sample. These findings highlight the effectiveness of NADES in improving the filtration properties of the drilling mud, especially in mitigating mudcake thickness and reducing filtrate volume. The unique characteristics of NADES, including its ability to interact with clay platelets and modify wettability, contribute to its superior performance in maintaining desirable filtration properties under challenging HTHP conditions. At a 3% concentration of NADES, the mud exhibited the thinnest filter cake thickness and lowest filtrate volume. This concentration of NADES was compared to the same concentration of KCl and ionic liquids, and the results were as expected. While both KCl and the ionic liquid improved the filtration properties of the mud, NADES yielded the most favorable outcome when compared to the conventional drilling fluid additive (KCl) and the modern mud additive ionic liquid (EMIM-Cl) as shown in Figs. 10b and 11b.

High pressure high temperature (HPHT) linear swelling test and shale recovery test

The study investigated the impact of KCl-NADES-based mud samples on linear swelling and shale recovery, comparing them to the base drilling fluid, KCl-based and ionic liquid-based mud samples. Figure 12 illustrates the linear swelling behavior, indicating that the base sample (without NADES) exhibited a significant swelling of 52%. However, the addition of NADES in the mud led to a reduction in linear swelling, reaching approximately 30%. The most favorable outcome was achieved with the incorporation of 3% NADES in the drilling mud, resulting in a mere 16% swelling, corresponding to a remarkable 69.23% swelling inhibition.

Figure 13 presents the results of shale recovery. In shale, the presence of illite contributes to shale dispersion, leading to inadequate borehole cleaning and an inefficient drilling process. The base drilling mud samples exhibited an 11% shale recovery rate, while the utilization of 3% NADES yielded the maximum recovery of 58%. The improved shale recovery can be attributed to enhanced shale stabilization facilitated by the interaction between the clay in shale and NADES present in the drilling mud. The shale swelling inhibition capability of NADES can be attributed to its exceptional ability to form hydrogen bonds with clay particles. NADES interacts with negatively charged clay granules, attaching to their surface, and neutralizing the negative charge responsible for attracting water cations into the clay layers. This process effectively stabilizes the shale hydration process. Furthermore, NADES facilitates the removal of water between the hydrated clay layers, as supported by the d-spacing results. It is interesting to note that KCl and ionic liquid improved the swelling inhibition and shale recovery but 3% NADES outperformed these additives. The findings of surface tension and zeta potential analyses align with the experimental results for linear swelling, providing further support for the observed effects.

These results highlight the promising potential of NADES in mitigating shale swelling and improving shale recovery. The interactions between NADES and clay particles play a vital role in stabilizing shale formations and preventing excessive swelling. The comprehensive understanding of these mechanisms is further supported by the results obtained from surface tension and zeta potential measurements.

D-spacing of KCl-based mud

The D-spacing is basically the combined length of interlayer spacing of clay and one alumino-silicate layer (in clay). Figure 14 presents the d-spacing results of dry Sodium Bentonite (Na-Bt), hydrated mud samples and NADES-based mud samples. The results of d-spacing help in understanding the intercalation of water and NADES into clay layers in a better way. The d-spacing of the dry Na-Bt increases with the addition of water into it which shows that water has intercalated between clay layers. However, the addition of NADES into the base mud, decreases the d-spacing which shows NADES possess more affinity towards clay then water thus it has expelled water out of the clay layers, The d-spacing of dry Na-Bt is found to be 12.64 Å which upsurges to 18.01 Å after hydrating the Na-Bt. KCl was further able to remove water from clay layers. Figure 14 shows, 3% Ionic Liquid resulted into more expulsion of water from clay layer as compared to 1% NADES which is in accordance with the results of shale swelling and shale recovery.

The 3% NADES resulted into the maximum elimination of water between the clay layers as shown by the maximum decline in d-spacing of 14.71 Å. However, there is a slight difference in d-spacing of 5% NADES as compared to d-spacing of 3% NADES. This indicates the maximum intercalation of NADES into the clay layers can occur only till 5%. This decrease in d-spacing values depicts that the NADES (inhibitor) have efficiently intercalated between the clay layers and have excluded the water out from the clay layers thus making clay more stable against hydration. The results of d-spacing are in accordance with results of Linear swell meter.

Surface tension of NADES-based mud

Surface tension shows a direct relations to the capillary pressure; however, the relation is not quite straightforward (Pericet-Cámara et al. 2008). The higher the capillary pressure will be at the surface of a shale/clay, the more will be the tendency to water cations to imbibe into the clay layers and result into swelling (Beg et al. 2021). The shale inhibitors can affect surface activity and lower the surface tension, which impedes the water cations to invade into the clay layers. The anti-swelling traits of the clay can be well understood by studying the surface tension of base mud, KCl and ionic liquid and NADES-based mud at various concentration The maximum decline of 36.50% in surface tension had been noted in case of 3% NADES (inhibitor) while 6% decline have been observed for 5% NADES as shown in Fig. 15. The drop in surface tension by NADES is credited to its strong ability to formulate the hydrogen bond with clay, consequently, shifting the contact angle and capillary behaviour which in turn modifies the clay behaviour in presence of water. The results are in accordance with the results of d-spacing and linear swelling.

Zeta potential of NADES-based mud

Zeta Potential (ZP) is defined as the electrokinetic potential that further corresponds to the behaviour of a dispersion (Clogston and Patri 2011). Smectite and Illite clay possess negatively charged surface which is liable to attract water cations into the clay layers, thus causing swelling (Horikawa et al. 1988). The results of Zeta potential depict the effect of inhibitors on thickness of electric double layer of the clay (Rasool et al. 2022a, b, c, d). Figure 16 shows that the inhibitors decrease the electrical double layer thickness which affects the cationic exchange between the inhibitors and the clay. The most significant decline in ZP (just like surface tension and d-spacing) can be seen for 3% NADES, i.e., 53.3%. The most significant reduction of 53.1% causes the maximum decline in Z.P thus affecting the electrical double layer accordingly as shown in Fig. 16. It is also evident that the addition of NADES, no matter the concentration, affects the electrokinetic potential of clay.

Field emission electron spectroscopy microscope of sodium bentonite wafers

The FESEM analysis was conducted on sodium bentonite wafers before and after treatment with NADES to observe any structural changes. Figure 17A presents dry sodium bentonite, where the diameter of a Na-Bt pellet was measured to be 36.1 µm. In Fig. 17B, sodium bentonite treated with water showed an increase in diameter to 54.3 µm. Conversely, NADES-treated bentonite mud exhibited a slight decrease in diameter. This indicates that NADES has expelled water from the alumino-silicate layers, which aligns with the reduction in linear swelling observed in NADES-treated bentonite wafers.

The findings from FESEM images provide further support to the results obtained from d-spacing and Zeta Potential analyses. Together, they demonstrate the impact of NADES treatment on the structure of sodium bentonite and its ability to remove water from the alumino-silicate layers. This contributes to the understanding of the mechanisms underlying the observed decrease in linear swelling in NADES-treated bentonite wafers. These results highlight the potential of NADES as an effective agent for modifying the structure and properties of sodium bentonite. The evidence from FESEM analysis, along with d-spacing and Zeta Potential measurements, strengthens the conclusions drawn from the study.

Rheological modeling of KCl-NADES based drilling mud

Rheological modeling of base sample and 3% NADES mud have been conducted to model its behaviour in dynamic conditions. 3% NADES-based mud sample has been chosen for rheological modeling as the optimum results have been obtained when 3% NADES was added into the mud. Standard deviation (S.D) and Mean Percentage Error (M.P.E) have been computed for the curve fitting and choosing the best fit model. Figures 18 and 19 show the rheological behaviour of base mud at 25 °C and 100 °C while Figs. 20 and 21 show the rheological behaviour of 3% NADES-based mud at 25 °C and 100 °C, respectively. From Figs. 18, 19, 20 and 21, it can be seen that base mud follows Power law at 25 °C and 100 °C while the KCl-NADES based mud follows Y.P.L.

Discussion of results

The use of KCl:Glycerine-based NADES in drilling mud formulations has shown promising results, benefiting drilling operations in multiple ways. NADES, or Natural Deep Eutectic Solvents, are a class of sustainable and environmentally friendly solvents that have gained attention for their unique properties and potential applications in various industries, including the oil and gas sector. In the context of drilling fluids, KCl-based NADES has demonstrated its ability to enhance fluid performance and address key challenges associated with drilling operations. The addition of NADES in the mud formulation improves the transportation of cuttings, which is crucial for maintaining efficient drilling operations. NADES act as effective lubricants, reducing friction between the cuttings and the borehole, thereby facilitating their movement to the surface. This is especially important in high-angle or horizontal drilling, where cuttings can accumulate and hinder the drilling process.

Furthermore, NADES have shown the ability to improve the properties of the mudcake, which is the thin layer of mud that forms on the wellbore wall during drilling. The mudcake serves as a protective barrier, preventing fluid loss into the formation and stabilizing the wellbore. Excessive mudcake thickness can lead to challenges such as drill pipe sticking, increased drilling torque, and compromised wellbore stability. By incorporating NADES, the mudcake thickness can be effectively reduced, mitigating these issues and improving overall drilling efficiency. The effectiveness of KCl:Glycerine-based NADES as a shale inhibitor is another important aspect of their application in drilling muds. Shales are known for their complex mineral composition, consisting of various types of clays such as smectite and illite. These clays are prone to swelling and dispersion when exposed to water-based drilling fluids, leading to wellbore instability and poor borehole cleaning. NADES, through their interactions with clay particles, have shown the ability to mitigate these issues.

The mechanism behind the shale inhibition properties of NADES involves their ability to form hydrogen bonds with clay particles. These bonds result in a modification of the clay's face-to-edge orientation, reducing the clay's affinity for water and thereby minimizing swelling and dispersion (Vryzas et al. 2017). Moreover, NADES possess a stronger affinity for clay particles compared to water, allowing them to displace water molecules between the clay layers. This expulsion of water leads to a stabilization of the shale formation and improved drilling performance. To support these findings, various analytical techniques have been employed. X-ray diffraction (XRD) analysis has provided valuable insights into the structural changes of clay minerals upon interaction with NADES. The XRD results demonstrate alterations in the d-spacing, indicating the intercalation of NADES molecules between the clay layers, which is consistent with the observed shale inhibition effects. Additionally, zeta potential measurements have shed light on the surface charge characteristics of the clay particles in the presence of NADES. The reduction in zeta potential suggests a neutralization of the negative charges on the clay surface, further corroborating the interaction between NADES and clay particles (Yunxiang et al. 2022). Surface tension measurements have also been conducted to investigate the impact of NADES on the interfacial properties of the drilling fluid. The ability of NADES to lower surface tension contributes to improved wetting and fluid flow characteristics and shale inhibiting trait of the drilling mud (Zhong et al. 2011).

In conclusion, the investigation into shale swelling inhibition and drilling fluid improvement has highlighted the effectiveness of KCl and ionic liquids as common inhibitors. However, the introduction of NADES (Natural Deep Eutectic Solvents) as a novel drilling fluid additive has demonstrated superior performance. At a 3% concentration, NADES achieved the lowest filter cake thickness and filtrate volume, outperforming KCl and ionic liquid (EMIM-Cl) based mud. The unique properties of NADES, such as their ability to form hydrogen bonds with clay particles and modify their surface characteristics, have been instrumental in improving drilling fluid properties and inhibit shale swelling. Moreover, NADES' thermal stability and overall performance have positioned it as a promising alternative, offering application flexibility and potential advantages over traditional inhibitors. The findings from analytical techniques such as XRD, zeta potential, and surface tension measurements provide valuable support for the observed effects of NADES on the drilling fluid properties. Continued research and development in this area hold significant potential for advancing the efficiency and sustainability of drilling operations in the oil and gas industry.

Conclusions

The conclusions drawn from this study are as follows:

-

(1)

The Potassium Chloride:Glycerine (KCl:Gly) based Natural Deep Eutectic Solvent (NADES) forms a stable eutectic mixture at a 1:8 ratio, 100 rpm, and 60 °C, with slight acidity and stability up to 200 °C, which is crucial for its application as a drilling fluid additive.

-

(2)

The optimal concentration of 3% KCl:Gly NADES enhances the performance of drilling fluids, improving their rheology and filtration properties, leading to more efficient drilling operations.

-

(3)

The addition of KCl:Gly NADES modifies the interaction between the drilling mud and clay particles, forming hydrogen bonds and altering the face-edge orientation of clay, resulting in improved rheological behavior and enhanced filtration properties, even at elevated temperatures.

-

(4)

The KCl:Gly NADES demonstrates excellent shale inhibition capabilities, effectively reducing the linear swelling of clay up to 69.23% and improving shale recovery up to 58%, thereby contributing to the stability of shale formations during drilling operations.

-

(5)

The KCl:Gly NADES exhibits a higher affinity for clay compared to water, facilitating the expulsion of water from the alumino-silicate layers, as confirmed by d-spacing measurements. This characteristic, combined with its inhibitory properties, makes it a promising candidate as a shale inhibitor in drilling fluids.

Recommendations

Further exploration of different combinations of hydrogen bond donors and acceptors should be conducted to formulate novel NADES. This would enable the discovery of more efficient and effective NADES compositions for use as drilling fluid additives, with enhanced properties for improving drilling operations and shale inhibition. Moreover, extensive research should be carried out to evaluate the performance of these novel NADES compositions in drilling fluid systems under different conditions, such as high temperature and pressure. This will provide valuable insights into their stability and functionality in challenging drilling environments. It is also recommended to investigate into the long-term stability and compatibility of NADES with other drilling fluid additives and components should be conducted. Understanding the interaction between NADES and other additives will help in optimizing the overall drilling fluid formulation and preventing any potential compatibility issues. Lastly, it is recommended to conduct a thorough degradability study of NADES to confirm its green and stability credentials as a green drilling fluid additive.

Abbreviations

- BPL:

-

Bingham Plastic Law

- PV:

-

Plastic Viscosity (cp)

- YP:

-

Yield Point (lbm/100 ft2)

- YPL:

-

Yield Power Law

- ZP:

-

Zeta potential (mV)

- d 001 :

-

Basal spacing (Ao)

- lbm :

-

Pound mass

- Base mud:

-

Drilling mud sample without NADES

- D-spacing:

-

Sum of interlayer spacing and one aluminio-silicate layer in a clay.

- EMIM-Cl:

-

1-Ethyl-3-methylimidazolium chloride

- FESEM:

-

Field Emission Scanning Electron Microscopy

- FTIR:

-

Fourier Transform Infrared Spectroscopy

- Gly:

-

Glycerine/Glycerol/Glycerin

- HBA:

-

Hydrogen bond acceptor

- HBD:

-

Hydrogen bond donor

- KCl:

-

Potassium chloride

- MPE:

-

Mean percentage error

- Na-Bt:

-

Sodium bentonite

- NADES:

-

Natural Deep Eutectic Solvent

- SD:

-

Standard deviation

- S/1:

-

Smectite/illite mixed layer

- USP:

-

United States Pharmacopeia

- XRD:

-

X-ray diffraction

References

Abbas MA, Zamir A, Elraies KA, Mahmood SM, Rasool MH (2021) A critical parametric review of polymers as shale inhibitors in water-based drilling fluids. J Pet Sci Eng 204:108745

Abbas MA, Zamir A, Elraies KA, Mahmood SM, Aslfattahi N, Saidur R, Ahmad M, Rasool MH (2022) Characterization of nano based drilling fluid for shale swelling inhibition. Pet Sci Technol 40:1–27

Ahmad HM, Murtaza M, Kamal MS, Hussain SS, Mahmoud M (2021) Cationic gemini surfactants containing biphenyl spacer as shale swelling inhibitor. J Mol Liq 325:115164

Ahmed HM, Kamal MS, Al-Harthi M (2019) Polymeric and low molecular weight shale inhibitors: a review. Fuel 251:187–217

Ahmed N, Alam M, Salam M (2020) Experimental analysis of drilling fluid prepared by mixing iron (III) oxide nanoparticles with a KCl–Glycol–PHPA polymer-based mud used in drilling operation. J Pet Explor Prod Technol 10(8):3389–3397

Akpan EU, Enyi GC, Nasr G, Yahaya AA, Ahmadu AA, Saidu B (2019) Water-based drilling fluids for high-temperature applications and water-sensitive and dispersible shale formations. J Pet Sci Eng 175:1028–1038

Alhadid A, Mokrushina L, Minceva M (2020) Design of deep eutectic systems: a simple approach for preselecting eutectic mixture constituents. Molecules 25(5):1077

Allawi RH, Al-Jawad MS (2021) Wellbore instability management using geomechanical modeling and wellbore stability analysis for Zubair shale formation in Southern Iraq. J Pet Explor Prod Technol 11(11):4047–4062

Aramendiz J, Imqam A (2019) Water-based drilling fluid formulation using silica and graphene nanoparticles for unconventional shale applications. J Pet Sci Eng 179:742–749

Bavoh CB, Ofei TN, Lal B, Sharif AM, Shahpin MHB, Sundramoorthy JD (2019) Assessing the impact of an ionic liquid on NaCl/KCl/polymer water-based mud (WBM) for drilling gas hydrate-bearing sediments. J Mol Liq 294:111643

Bavoh CB, Ofei TN, Lal B (2020) Investigating the potential cuttings transport behavior of ionic liquids in drilling mud in the presence of sII hydrates. Energy Fuels 34(3):2903–2915

Beg M, Haider MB, Thakur NK, Husein M, Sharma S, Kumar R (2021) Clay-water interaction inhibition using amine and glycol-based deep eutectic solvents for efficient drilling of shale formations. J Mol Liq 340:117134

Benvenutti L, Zielinski AAF, Ferreira SRS (2019) Which is the best food emerging solvent: IL, DES or NADES? Trends Food Sci Technol 90:133–146

Cho C-W, Pham TPT, Zhao Y, Stolte S, Yun Y-S (2021) Review of the toxic effects of ionic liquids. Sci Total Environ 786:147309

Chu Q, Lin L, Zhao Y (2019) Hyperbranched polyethylenimine modified with silane coupling agent as shale inhibitor for water-based drilling fluids. J Pet Sci Eng 182:106333

Clogston JD, Patri AK (2011) Zeta potential measurement. Characterization of nanoparticles intended for drug delivery. Springer, pp 63–70

Craveiro R, Aroso I, Flammia V, Carvalho T, Viciosa M, Dionísio M, Barreiros S, Reis R, Duarte ARC, Paiva A (2016) Properties and thermal behavior of natural deep eutectic solvents. J Mol Liq 215:534–540

Cunha SC, Fernandes JO (2018) Extraction techniques with deep eutectic solvents. TrAC Trends Anal Chem 105:225–239

de María PD, Maugeri Z (2011) Ionic liquids in biotransformations: from proof-of-concept to emerging deep-eutectic-solvents. Curr Opin Chem Biol 15(2):220–225

Flieger J, Flieger M (2020) Ionic liquids toxicity—benefits and threats. Int J Mol Sci 21(17):6267

Fu L, Liao K, Ge J, He Y, Huang W, Du E (2020) Preparation and inhibition mechanism of bis-quaternary ammonium salt as shale inhibitor used in shale hydrocarbon production. J Mol Liq 309:113244

Gholami R, Elochukwu H, Fakhari N, Sarmadivaleh M (2018) A review on borehole instability in active shale formations: interactions, mechanisms and inhibitors. Earth Sci Rev 177:2–13

Halder AK, Cordeiro MND (2019) Probing the environmental toxicity of deep eutectic solvents and their components: an in silico modeling approach. ACS Sustain Chem Eng 7(12):10649–10660

Hamed SB, Belhadri M (2009) Rheological properties of biopolymers drilling fluids. J Pet Sci Eng 67(3–4):84–90

Hayyan A, Mjalli FS, AlNashef IM, Al-Wahaibi YM, Al-Wahaibi T, Hashim MA (2013) Glucose-based deep eutectic solvents: physical properties. J Mol Liq 178:137–141

Horikawa Y, Murray R, Quirk J (1988) The effect of electrolyte concentration on the zeta potentials of homoionic montmorillonite and illite. Colloids Surf 32:181–195

Huang Z, Xu Z, Quan Y, Jia H, Li J, Li Q, Chen Z, Pu K (2018) A review of treatment methods for oil-based drill cuttings. In: IOP conference series: earth and environmental science. IOP Publishing

Huang P, Jia H, Han Y, Wang Q, Wei X, Luo Q, Dai J, Song J, Yan H, Liu D (2020) Designing novel high-performance shale inhibitors by optimizing the spacer length of imidazolium-based bola-form ionic liquids. Energy Fuels 34(5):5838–5845

Jia H, Huang P, Wang Q, Han Y, Wang S, Zhang F, Pan W, Lv K (2019) Investigation of inhibition mechanism of three deep eutectic solvents as potential shale inhibitors in water-based drilling fluids. Fuel 244:403–411

Jiang G, Li X, Zhu H, Yang L, Li Y, Wang T, Wu X (2019) Improved shale hydration inhibition with combination of gelatin and KCl or EPTAC, an environmentally friendly inhibitor for water-based drilling fluids. J Appl Polym Sci 136(22):47585

Khan RA, Murtaza M, Ahmad HM, Abdulraheem A, Kamal MS, Mahmoud M (2021) Development of novel shale swelling inhibitors using hydrophobic ionic liquids and gemini surfactants for water-based drilling fluids. In: SPE middle east oil and gas show and conference, OnePetro.

Li G, Zhang J, Zhao H, Hou Y (2012) Nanotechnology to improve sealing ability of drilling fluids for shale with micro-cracks during drilling. In: SPE international oilfield nanotechnology conference and exhibition, OnePetro

Liu J, Yang Z, Sun J, Dai Z, Lv K, You Q (2021) Experimental investigation on hydration mechanism of Sichuan shale (China). J Pet Sci Eng 201:108421

Luo Z, Wang L, Yu P, Chen Z (2017) Experimental study on the application of an ionic liquid as a shale inhibitor and inhibitive mechanism. Appl Clay Sci 150:267–274

Ma J, Pang S, Zhou W, Xia B, An Y (2021) Novel deep eutectic solvents for stabilizing clay and inhibiting shale hydration. Energy Fuels 35(9):7833–7843

Marchel M, Cieśliński H, Boczkaj G (2022) Deep eutectic solvents microbial toxicity: current state of art and critical evaluation of testing methods. J Hazard Mater 425:127963

Martins MA, Pinho SP, Coutinho JA (2019) Insights into the nature of eutectic and deep eutectic mixtures. J Solution Chem 48(7):962–982

Mkpoikana R, Dosunmu A, Eme C (2015) Prevention of shale instability by optimizing drilling fluid performance. In: SPE Nigeria annual international conference and exhibition, OnePetro

Mohammed AS (2017) Effect of temperature on the rheological properties with shear stress limit of iron oxide nanoparticle modified bentonite drilling muds. Egypt J Pet 26(3):791–802

Muhammed NS, Olayiwola T, Elkatatny S (2021) A review on clay chemistry, characterization and shale inhibitors for water-based drilling fluids. J Pet Sci Eng 206:109043

Murtaza M, Kamal MS, Mahmoud M (2020) Application of a novel and sustainable silicate solution as an alternative to sodium silicate for clay swelling inhibition. ACS Omega 5(28):17405–17415

Ofei TN, Bavoh CB, Rashidi AB (2017) Insight into ionic liquid as potential drilling mud additive for high temperature wells. J Mol Liq 242:931–939

Okoro EE, Ochonma C, Omeje M, Sanni SE, Emetere ME, Orodu KB, Igwilo KC (2020) Radiological and toxicity risk exposures of oil based mud: health implication on drilling crew in Niger Delta. Environ Sci Pollut Res 27(5):5387–5397

Oseh JO, Norddin MM, Muhamad HN, Ismail I, Gbadamosi AO, Agi A, Ismail AR, Blkoor SO (2020) Influence of (3–Aminopropyl) triethoxysilane on entrapped polypropylene at nanosilica composite for shale swelling and hydration inhibition. J Pet Sci Eng 194:107560

Paiva A, Craveiro R, Aroso I, Martins M, Reis RL, Duarte ARC (2014) Natural deep eutectic solvents–solvents for the 21st century. ACS Sustain Chem Eng 2(5):1063–1071

Parizad A, Shahbazi K, Tanha AA (2018) SiO2 nanoparticle and KCl salt effects on filtration and thixotropical behavior of polymeric water based drilling fluid: with zeta potential and size analysis. Results Phys 9:1656–1665

Paswan BK, Mahto V (2020) Development of environment-friendly oil-in-water emulsion based drilling fluid for shale gas formation using sunflower oil. J Pet Sci Eng 191:107129

Patel A, Stamatakis S, Young S, Friedheim J (2007) Advances in inhibitive water-based drilling fluids—can they replace oil-based muds?. In: International symposium on oilfield chemistry, OnePetro

Pericet-Cámara R, Best A, Butt H-J, Bonaccurso E (2008) Effect of capillary pressure and surface tension on the deformation of elastic surfaces by sessile liquid microdrops: an experimental investigation. Langmuir 24(19):10565–10568

Rahman MT, Negash BM, Danso DK, Idris A, Elryes AA, Umar IA (2022) Effects of imidazolium-and ammonium-based ionic liquids on clay swelling: experimental and simulation approach. J Pet Explor Prod Technol 12(7):1841–1853

Rasool MH, Zamir A, Elraies KA, Ahmad M, Ayoub M, Abbas MA (2021a) Investigative review on cutting transportation ability of ionic liquid-based drilling mud. J Hunan Univ Nat Sci 48(2)

Rasool MH, Zamir A, Elraies KA, Ahmad M, Ayoub M, Abbas MA (2021b) Potassium carbonate based deep eutectic solvent (DES) as a potential drilling fluid additive in deep water drilling applications. Pet Sci Technol 39(15–16):612–631

Rasool MH, Ahmad M, Abbas MA (2022a) A double action PD (polymer-deep eutectic solvent) based shale inhibitor in drilling mud. J Adv Res Fluid Mech Therm Sci 99(1):149–157

Rasool MH, Ahmad M, Ayoub M, Zamir A, Abbas MA (2022b) A review of the usage of deep eutectic solvents as shale inhibitors in drilling mud. J Mol Liq 361:119673

Rasool MH, Zamir A, Elraies KA, Ahmad M, Ayoub M, Abbas MA (2022c) A deep eutectic solvent based novel drilling mud with modified rheology for hydrates inhibition in deep water drilling. J Pet Sci Eng 211:110151

Rasool MH, Zamir A, Elraies KA, Ahmad M, Ayoub M, Abbas MA, Ali I (2022d) Rheological characterization of potassium carbonate deep eutectic solvent (DES) based drilling mud. J Pet Explor Prod Technol 12(7):1785–1795

Rasool M, Ahmad M, Hashmi S (2023a) A novel potassium chloride based natural deep eutectic solvent: in-house synthesis and characterization. Moroc J Chem 11(3):11–13

Rasool MH, Ahmad M, Ayoub M, Abbas MA (2023b) A novel ascorbic acid based natural deep eutectic solvent as a drilling mud additive for shale stabilization. Processes 11(4):1135

Rasool MH, Ahmad M, Siddiqui NA, Junejo AZ (2023c) Eco-friendly drilling fluid: calcium chloride-based natural deep eutectic solvent (NADES) as an all-rounder additive. Energies 16(14):5533

Rathnaweera T, Ranjith P, Gu X, Perera M, Kumari W, Wanniarachchi W, Haque A, Li J (2018) Experimental investigation of thermomechanical behaviour of clay-rich sandstone at extreme temperatures followed by cooling treatments. Int J Rock Mech Min Sci 107:208–223

Şahin S (2019) Tailor-designed deep eutectic liquids as a sustainable extraction media: an alternative to ionic liquids. J Pharm Biomed Anal 174:324–329

Singh SK, Savoy AW (2020) Ionic liquids synthesis and applications: an overview. J Mol Liq 297:112038

Sudharsan J, Khare SK (2022) Role of nanocomposite additives in well bore stability during shale formation drilling with water based mud—a comprehensive review. Mater Today Proc 62:6412–6419

Vanda H, Dai Y, Wilson EG, Verpoorte R, Choi YH (2018) Green solvents from ionic liquids and deep eutectic solvents to natural deep eutectic solvents. C R Chim 21(6):628–638

Vryzas Z, Kelessidis VC, Nalbantian L, Zaspalis V, Gerogiorgis DI, Wubulikasimu Y (2017) Effect of temperature on the rheological properties of neat aqueous Wyoming sodium bentonite dispersions. Appl Clay Sci 136:26–36

Wilson M, Wilson L (2014) Clay mineralogy and shale instability: an alternative conceptual analysis. Clay Miner 49(2):127–145

Yan X, Kang Y, You L (2020) Wellbore instability induced by the coupling of high-pH fluid–shale reaction and fracture surface sliding in shale gas wells: experimental and field studies. Energy Fuels 34(5):5578–5588

Yang L, Jiang G, Shi Y, Yang X (2017) Application of ionic liquid and polymeric ionic liquid as shale hydration inhibitors. Energy Fuels 31(4):4308–4317

Yasar S, Alma M, Tosun R, Salan T (2019) Improved by potassium chloride (KCl) dilution predictive ability of attenuated total reflectance Fourier transform infrared (ATR-FTIR) spectroscopy to determine nutrient contents of sunflower meal. J Anim Feed Sci 28(3):282–290

Yunxiang L, Ling L, Wenke Y, Xin L, Han G (2022) Synthesis and evaluation of betaine copolymer filtrate reducer for drilling mud. Clays Clay Miner 70(2):252–269

Zamir A, Elraies KA, Rasool MH, Ahmad M, Ayoub M, Abbas MA, Ali I (2021) Influence of alkyl chain length in ionic liquid based drilling mud for rheology modification: a review. J Pet Explor Prod Technol 12:1–8

Zhong H, Qiu Z, Huang W, Cao J (2011) Shale inhibitive properties of polyether diamine in water-based drilling fluid. J Pet Sci Eng 78(2):510–515

Acknowledgments

The authors would like to acknowledge Drilling Engineering Lab, UTP and Chemical Engineering Department of UTP for providing necessary facilities to conduct experimentations and lab work. Moreover, the authors would also like to acknowledge YUTP Grant 015LC0-326 for providing necessary financial assistance for the project.

Funding

The funding for lab work and postgraduate student involved was provided by YUTP grant No. 015LC0- 326.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors do not have any financial or non-financial interest to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rasool, M.H., Ahmad, M. Revolutionizing shale drilling with potassium chloride-based natural deep eutectic solvent as an additive. J Petrol Explor Prod Technol 14, 85–105 (2024). https://doi.org/10.1007/s13202-023-01700-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-023-01700-8