Abstract

The use of foams is a promising technique to overcome gas mobility challenges in petroleum reservoirs. Foam reduces the gas mobility by increasing the gas apparent viscosity and reducing its relative permeability. A major challenge facing foam application in reservoirs is its long-term stability. Foam effectiveness and stability depends on several factors and will typically diminish over time due to degradation as well as the foam-rock-oil interactions. In this study, the effect of crude oil on CO2-foam stability and mobility will be investigated using in-house build microfluidics system developed for rapid prescreening of chemical formulations. Two-phase flow emulsification test (oil-surfactant solutions) and dynamic foam tests (in the absence and presence of crude oil) were conducted to perform a comparative assessment for different surfactant solutions. A microfluidics device was used to evaluate the foam strength in the presence and absence of crude oil. The assessment was conducted using five surfactant formulations and different oil fractions. The role of foam quality (volume of gas/total volume) on foam stability was also addressed in this study. The mobility reduction factor (MRF) for CO2-foam was measured in the absence and presence of crude oil using high salinity water and at elevated temperatures. The results indicated that foam stability has an inverse relationship with the amount of crude oil. Crude oil has a detrimental effect on foams, and foam stability decreased as the amount of crude oil was increased. Depending on the surfactant type, the existence of crude oil in porous media, even at very low concentrations of 5% can significantly impact the foam stability and strength. The oil can act as an antifoaming agent. It enters the thin aqueous film and destabilizes it. This resulted in a lower foam viscosity and less stable foams. Thus, the CO2 MRF dropped significantly in the presence of higher oil fractions. This study also demonstrated that in-house assembled microfluidics system allows for a rapid and cost-efficient screening of formulations.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

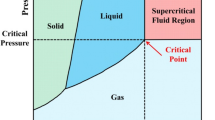

Gas injection is one of the most promising techniques in enhanced oil recovery (EOR) processes (Madathilet al. 2015). Gas injection can aid in maximizing the oil recovery when the injected gas becomes miscible with the reservoir hydrocarbons (Whorton and Kieschnick 1950). The most common gas used for this purpose is carbon dioxide (CO2) as it has low miscibility pressure promoting the swelling of crude oil, and reducing its viscosity and, consequently, enhancing the oil recovery (Slobod and Koch 1953). While CO2 injection has been successful (Hoiland et al. 1986; Brock and Bryan 1989) in mobilizing significant amounts of residual oil, the poor volumetric sweep efficiency is a major challenge associated with this technique. CO2 has a low viscosity and density compared to the reservoir fluids causing the challenges of gravity override and viscous fingering, which lead to poor sweep efficiency (Campbell et al. 1985; Chakravarthy et al. 2004; Masalmeh et al. 2010).

Several methods have been studied and tested to overcome the CO2 mobility challenge including water alternating gas (WAG), in-situ foam generation, and using thickeners to increase the gas viscosity. (Heller et al. 1985, Dandge and Heller 1987, Heller 1994, Enick 1998, Huang et al. 2000, Chakravarthy et al. 2004, Hamilton 2004, AlYousef et al. 2019a, b). One of the widely used techniques to overcome the gas mobility challenge is the in-situ generation of foam. Foam can help in reducing gas mobility by increasing the apparent viscosity of the gas and reducing its relative permeability, thereby improving the gas volumetric sweep efficiency. (Kovscek and Radke 1994; Falls et al. 1988).

Foam is commonly generated using surfactants. However, one of the challenges of using foam generated by surfactants is its long-term stability. Foam stability at reservoir conditions can be affected by many factors including water salinity, reservoir temperature, adsorption of surfactant molecules on rock surfaces, degradation of surfactants, and fluid–fluid interactions (Mannhardt et al. 1993; Yaghoobi 1994; Grigg et al. 2004; Liu et al. 2005; Staszak et al. 2015; Nazari et al. 2017; Skauge et al. 2019; AlYousef et al. 2019a, b). Moreover, the stability of foam can diminish over time due to foam–oil interactions. The oil can act as an antifoaming agent, it enters the thin aqueous films. destabilizes and destroys the film. (Nikolov et al. 1986; Manlowe and Radke 1990; Schramm and Novosad 1990; AlYousef et al. 2017). Depending on the surfactant type, the existence of crude oil in porous media, even at very low concentrations, can significaly impact the foam stability and its strength.

The objective of this work is to evaluate the impact of crude oil on foam stability using a custom-made high pressure and high temperature microfluidics system. Microfluidic technology has provided significant benefits in research and industry across various fields, with a growing track of applications in industrial fluids and chemistries (Saeed et al. 2021). This work demonstrates the utilization of a microfluidic reservoir analogue and presents an approach to rapidly screen and evaluate CO2 foam formulations in the presence of crude oil at a high-temperature (100 °C) condition. Five surfactant solutions were used in this study. Two-phase flow emulsification test (oil-surfactant solutions) and dynamic foam test (in absence and presence of crude oil) were conducted to perform the comparative assessment among different surfactant solutions. Moreover, the mobility reduction factor for CO2-foam was measured in the absence and presence of crude oil at 100 °C.

Materials

Five different surfactants were used in this experimental study. Commercially available cocamidopropyl betaine surfactant (Amphosol CG-50), lauramidopropyl betaine surfactant (Amphosol LB), and cocamidopropyl hydroxysultaine surfactant (Petrostep-SB) used in this study were from Stepan Company (Northfield, USA). Also, tris(2-hydroxyethyl) n-tallow alkyldiaminopropane surfactant (Ethoduomeen T/13), and tallow trimethylpropylenediamine surfactant (Duomeen TTM) both from AkzoNobel (Amsterdam, The Netherlands) were used in this assessment. Table 1 lists the chemical structure of these surfactants. The synthetic brine used in this study had a total dissolved solid (TDS) content of 57,670 ppm, density of 0.99 g/mL, and viscosity of 0.283 measured at 100 °C. More details of the brine compositions can be found in Table 2. The crude oil used had a density of 0.88 g/mL, average viscosity of 3.2 cP measured at 100 °C, and the gas used for foam generation was CO2 with 99.5% purity.

Methodology

The effect of crude oil on foam stability and strength was studied using dynamic foam tests. The major objectives of dynamic foam tests were to ensure the foam formation and to evaluate the effect of crude oil on foam stability and CO2 mobility in porous media. Several assessments were conducted to ensure the solutions are stable at experimental conditions before conducting the dynamic foam tests. Over twenty surfactants were evaluated, only five were selected for this assessment. The shortlisted surfactants are stable in high salinity water at low pH (3.0–3.5) and at 100 °C for over a month. This section describes the procedure used to prepare solutions, measure the oil–water interfacial tension, conduct two-phase emulsification test, and conduct the dynamic foam tests in absence and presence of crude oil.

Aqueous phase preparation

As received from manufacturers, five surfactants listed in Table 1 were dissolved in the brine to produce 0.2 wt.% concentrations and tested for stability at 100 °C for over a month. Stability of surfactants was tested at neutral pH and pH (3.0–3.5) to represent conditions present during CO2 flooding. Surfactant 4 and surfactant 5 are not soluble in brine as is and need to be protonated with acid. Solutions that remained clear, as shown in Fig. 1, without precipitates or phase separation were recorded as stable. There were no tests made for examining decomposition of surfactants. In addition, a bottle-shaking test was conducted after one month to observe if foam was generating. This indicates that surfactant molecules were still present in solutions.

Interfacial tension measurements

KRÜSS Spinning Drop Tensiometer was used to measure the oil–water interfacial tensions. Five 0.2 wt.% surfactant solutions in brine and with the crude oil as the top phase were first aged at 90 °C over 24 h. Then corresponding phases were used for interfacial tension measurements. Measurements were conducted at 90 °C to avoid formation of bubbles. The results were used to better understand the foam stabilization in the presence of the crude oil.

two-phase emulsification test

During the oil effect measurements on foam test, the apparent viscosity change of the foam/oil could be caused by competing of foam, emulsion generation, and oil detrimental effect. In field test, the formation of emulsion during foam flooding is unfavorable as the relative permeability of water and oil could be significantly reduced which can cause remarkable injectivity issues. Therefore, the emulsification test was conducted by a two-phase (surfactant solution-oil) flow and compared to the two-phase flow of brine-oil. This part of the work was aimed to exclude the fact that oil-brine emulsion formation can cause high pressure as observed for foam.

This assessment was conducted using in-house developed microfluidic device depicted in Fig. 2. Uncoated hydrophilic borosilicate glass microfluidic chips with uniform network and reported permeability of 2.55 Darcy were purchased from Micronit Microtechnologies (Enschede, The Netherlands) and used as received. The matrix porosity for uniform network chip is 52% and the pore volume is 2.1 µL. The dimensions of the chip used are 20 × 10 × 0.02 mm. The back pressure of the system was set to 100 psi and experiments were conducted at 100 °C. The total injection velocity was set to 640 ft/day. Three oil fractions were used for emulsification tests: 10, 30, and 50%.

Dynamic foam test

The strength of the CO2 foams produced using the five listed surfactants in the absence and presence of crude oil was measured using the microfluidic device. The main objective of this test was to study the impact of crude oil on foam stability in presence of different amount of oil in porous media. The pressure drop across the microfluidic chip was recorded for the five surfactants in the absence and presence of crude oil. The 0.2 wt.% surfactant solutions in brine were prepared as described previously. The back pressure of the system was set to 100 psi and experiments were conducted at 100 °C. For each test, the microfluidic chip was flushed with several pore volumes of brine to ensure the removal of any trapped air or surfactant inside the system. The baseline experiment was first conducted by co-injecting CO2 and brine at the experimental conditions. In the absence of crude oil, one pore volume of surfactant solution in brine was first injected followed by a co-injection of CO2 and the surfactant solution. The pressure drop across the chip was measured at different foam qualities (volume of gas/total volume): 50, 70, 90, and 95%. The total injection superficial velocity was controlled at 640 ft/day.

In the presence of crude oil, the oil fractional flow test was conducted to check the detrimental oil effect on the CO2 foam stability and strength. The experiment was done with three-phase flow including oil, surfactant solution and CO2 gas. The total superficial velocity was fixed at 640 ft/day and the foam quality was fixed at 80%. The oil fractional flow was changing from 2 to 20% and the pressure drop was measured across the microfluidic chip.

Results and discussion

The interfacial tension measurements for five surfactant solutions with the crude oil were conducted at 90 °C. The results, as shown in Fig. 3, demonstrated that surfactant 4 and surfactant 5 solutions had the lowest interfacial tension values followed by surfactant 1 solution. Also, the results revealed that surfactant 2 solution had the highest interfacial tension value. Compared to the other surfactant solutions, surfactant 3 solution resulted in a moderate interfacial tension reduction. Interfacial tension values for the brine in the absence of the surfactants was 26.9 mN/m. These values are considered relatively high since the surfactants typically used for oil–water interfacial tension reduction can reduce the interfacial tension values up to around 0.001 mN/m.

The two-phase (surfactant solution and oil) flow in porous media was conducted for five surfactant solutions in addition to the brine solution (SW) alone. For all surfactants used, the pressure drop of two-phase flow (surfactant in brine and crude oil) is lower than that of two-phase flow (brine-crude oil), as shown in Fig. 4. The results indicated that no viscous emulsion was formed with the five surfactant solutions. This suggests that (surfactant solutions-oil) emulsions should not contribute to enhancement in foam stability or increase in foam viscosity when foam is tested in the presence of crude oil. The viscosity of generated emulsion, as shown in Fig. 5, increases with oil fraction. According to the interfacial tension measurements reported in Fig. 3, surfactant 5 solution had the lowest interfacial tension value, whereas surfactant 2 solution had the highest interfacial tension value. Amongst the five tested surfactants, the highest pressure drops were observed when surfactant 5 solution was used. In contrast, the lowest pressure drop values were reported when surfactant 2 solution was tested.

The CO2 foam strength produced using five surfactants was measured using microfluidic device. Steady state pressure drop values recorded across the microfluidics chip as a result of the generated foam within the porous structure of microfluidic chip at different qualities are presented in Fig. 6. Higher pressure drops correspond to higher resistance to gas flow and, hence, foams with higher viscosity. Compared to the baseline case (brine/CO2), all surfactants were able to generate foam, and this is reflected on the recorded pressure drops across the microfluidic chip at different foam quality. Also, from the data presented in Fig. 6 it can be seen that surfactant 1, surfactant 3, surfactant 4, and surfactant 5 solutions almost have the same foam strength, same pressure drops observed for different foam qualities. Surfactant 2 solution showed the lowest pressure drops compared to the other surfactant solutions. For most surfactant solutions, the foam strength increased with the foam quality up to 90% quality. Figure 6 also demonstrates that the highest foam strengths for most of the examined surfactants were observed when 90% foam quality was tested.

The CO2 MRF (pressure drop due to foam/pressure drop when brine/CO2 was injected) for each quality was also calculated. Figure 7 reveals that the MRF increases with the foam quality. The highest MRFs for most surfactant solutions were reported when foam was tested at 95% foam quality. Even though the pressure drops were a bit higher for the 90% foam quality than that for 95% quality, but since the MRFs were calculated separately for each quality and the pressure drop for the baseline (brine/CO2) was very low at 95% quality, the MRFs at 95% foam quality were showing the highest values. For most foam qualities, the highest MRFs were reported when surfactant 1, surfactant 3, surfactant 4, and surfactant 5 solutions were used.

The foam strength in the presence of crude oil was evaluated using the abovementioned surfactants at 100 psi and 100 °C. The total superficial velocity was fixed at 640 ft/day due to limitations of the flow meter and the foam quality was fixed at 80%. As shown in Fig. 8, the results of pressure drops across the porous media demonstrate that the presence of crude oil can significantly impact the foam stability. The effect of crude oil on foam stability was conducted using five different oil fractions: 5, 10, 15, and 20%. Surfactant 1 and surfactant 2 solutions were showing very poor foams in presence of crude oil. The pressure drops across the microfluidic chip were lower than that of the baseline experiment (brine/CO2) at all tested oil fractions. The other three surfactants (surfactant 3, surfactant 4, and surfactant 5) showed better foam stability with higher pressure drops than that of the baseline experiment up to around 15% of oil fraction. However, very weak unstable foams were observed when the oil fraction exceeded 15%. These results indicate that the presence of crude oil is a very crucial parameter for foam stabilization and proper surfactants should be selected to generate stable foams in presence of crude oil.

Similar to those in the absence of crude oil, the CO2 MRFs were also calculated in the presence of crude oil. Figure 9 demonstrates that there was no reduction in CO2 mobility when surfactant 1 and surfactant 2 solutions were used. The results also showed that as the oil fraction increased, the CO2 MRF decreased. Surfactant 3 and surfactant 4 solutions were showing the highest CO2 MRF values at 5 and 10% oil fraction. However, the MRFs dropped when higher oil fractions were used.

Compared to the other surfactant solutions, surfactant 1 solution produced relatively stable foams at different foam qualities. However, its ability to stabilize the foam in the presence of crude oil is hindered. This is because of the ability of this solutions to generate an emulsion as it showed the second highest pressure drop for the two-phase flow emulsification test. Although surfactant 2 solution has comparatively the highest interfacial tension value and the lowest pressure drop during the two-phase emulsification test, there was not much reduction in the CO2 (MRF) in the presence of crude oil. This is mainly because this solution was not able to generate strong foams in the absence of crude oil. Surfactant 3 and surfactant 4 solutions were showing relatively stable foam in the absence and presence of crude oil with fractions up to 15%. The results of the two-phase emulsification tests for these two surfactants showed moderate pressure drops across the microfluidic chip compared to the other surfactant solutions. Surfactant 5 solution showed the lowest interfacial tension reduction amongst the other surfactants, and this was in agreement with the two-phase emulsification test where it showed the highest pressure drop compared to the other surfactants due to the formation of emulsion. Even though surfactant 5 solution was able to reduce the CO2 MRF in the absence of crude oil, the ability of this surfactant to create an emulsion resulted in weaker foam stabilization in presence of crude oil.

Conclusions

In this study, a custom-made high pressure and high temperature microfluidics system was used to rapidly evaluate the effect of crude oil on foam stability and strength. Two-phase flow emulsification test (surfactant solutions-oil) and dynamic foam tests (in the absence and presence of crude oil) were conducted. The results demonstrated that:

-

Four of the tested surfactants were able to generate foam using 0.2 wt.% surfactant in high salinity brine (57,670 ppm) and at high temperature (100 °C).

-

There is a good agreement between the results obtained from the two-phase emulsification tests with those obtained from the dynamic foam tests in presence of crude oil.

-

Depending on the surfactant type, the existence of crude oil in porous media, even at very small concentrations of 5%, can significantly impact the foam stability and strength, and hinder the ability of the surfactant to reduce the CO2 mobility.

-

None of the tested surfactants were able to stabilize the foam and reduce the CO2 mobility when the amount of crude oil exceeded 10%.

References

AlYousef ZA, Almobarky MA, Schechter DS (2017) Enhancing the stability of foam by the use of nanoparticles. Energy Fuels 31(10):10620–10627. https://doi.org/10.1021/acs

AlYousef Z, Ayirala S, Gizzatov A, Kokal S 2019a. Evaluating foam stability using tailored water chemistry for gas mobility control applications. presented at the Abu Dhabi international petroleum exhibition & conference, Abu Dhabi, UAE, 11–14 November. SPE-197407-MS. https://doi.org/10.2118/197407-MS.

AlYousef Z, Swaie O, Alabdulwahab A, Kokal, S. 2019b. Direct thickening of supercritical carbon dioxide using CO2-soluble polymer. presented at the Abu Dhabi international petroleum exhibition & conference, Abu Dhabi, UAE, 11–14 November. SPE-197185-MS. https://doi.org/10.2118/197185-MS.

Brock, W. and Bryan, L. 1989. Summary results of CO2 EOR field tests, 1972–1987. presented at the low permeability reservoirs symposium, Denver, Colorado, 6–8 March. SPE-18977-MS. https://doi.org/10.2118/18977-MS.

Campbell BT, Orr FM (1985) Flow visualization for CO2/crude-oil displacements. Soc Petrol Eng J 25(5):665–678. https://doi.org/10.2118/11958-PA

Chakravarthy D, V Muralidharan, E Putra et al. 2004. Application of X-Ray CT for Investigation of CO2 and WAG injection in fractured reservoirs. presented at the canadian international petroleum Conference, Calgary, Alberta, 8–10 June. PETSOC-2004–232. https://doi.org/10.2118/2004-232

Dandge DK, JP Heller, 1987. Polymers for mobility control in co2 floods. presented at the spe international symposium on oilfield chemistry, San Antonio, Texas, 4–6 February. SPE-16271-MS. https://doi.org/10.2118/16271-MS

Enick RM (1998) A literature review of attempt to increase the viscosity of dense carbon dioxide. University of Pittsburgh, Pittsburgh, Pennsylvania

Falls AH, Hirasaki GJ, Patzek TW, Gauglitz DA, Miller DD, Ratulowski T (1988) Development of a mechanistic foam simulator: the population balance and generation by snap-off. SPE Res Eng 3(03):884–892. https://doi.org/10.2118/14961-PA

Grigg RB, Baojun B, Yi L 2004. Competitive adsorption of a hybrid surfactant system onto five minerals, berea sandstone, and limestone. presented at the SPE Annual Technical Conference and Exhibition, Houston, Texas, 26–29 September. SPE-90612-MS. https://doi.org/10.2118/90612-MS.

Hamilton, Robert M. Enick ; Eric J. Beckman ; Andrew. 2004. Inexpensive CO2 Thickening Agents for Improved Mobility Control of CO2 Floods. University of Pittsburgh, Pittsburgh, Pennsylvania (US). https://doi.org/10.2172/968338.

Heller JP (1994) Foams: fundamentals and applications in the petroleum industry. CO2 foams in enhanced oil recovery. ACS Adv Chem (reprint) 242:201–234. https://doi.org/10.1021/ba-1994-0242.ch005

Heller J, Dandge D, Card R et al (1985) Direct thickeners for mobility control of CO2 floods. Soc Petroleum Eng J 25(05):679–686. https://doi.org/10.2118/11789-PA

Hoiland R, Joyner H, and Stalder J 1986 Case history of a successful rocky mountain pilot Co2 flood. presented at the spe enhanced oil recovery symposium, Tulsa, Oklahoma, 20–23 April. SPE-14939-MS. https://doi.org/10.2118/14939-MS.

Huang Z, Shi C, Xu J et al (2000) Enhancement of the viscosity of carbon dioxide using styrene/fluoroacrylat copolymer. Macromolecules 33(15):5437–5442. https://doi.org/10.1021/ma992043+

Kovscek, A. R., C. J. Radke. 1994. Fundamentals of foam transport in porous media. in foams: fundamentals and applications in the petroleum industry, Chap. 3, 115–163. Advances in Chemistry 242, American Chemical Society. https://doi.org/10.1021/ba-1994-0242.ch003

Liu Y, Grigg R, and Bai B 2005 Salinity, pH, and surfactant concentration effects on CO2-Foam. Presented at the SPE International Symposium on Oilfield Chemistry, The Woodlands, Texas, 2–4 February. SPE-93095-MS. https://doi.org/10.2118/93095-MS.

Madathil A, Azrak O, Pearce A et al. 2015. 24 years of successful EOR through immiscible tertiary gas injection. presented at the Abu Dhabi International Petroleum Exhibition and Conference, Abu Dhabi, UAE, 9–12 November. SPE-177689-MS. https://doi.org/10.2118/177689-MS

Manlowe DJ, Radke CJ (1990) A pore-level investigation of foam/oil interactions in porous media. SPE Res Eng 5(04):495–502. https://doi.org/10.2118/18069-PA

Mannhardt K, Schramm L, Novosad J (1993) Effect of rock type and brine composition on adsorption of two foam-forming surfactants. SPE Adv Technol Series 1(01):212–218. https://doi.org/10.2118/20463-PA

Masalmeh Shehadeh K, Heiko Hillgartner, Rifaat Abdul-Munim Al-Mjeni et al. 2010. Simultaneous injection of miscible gas and polymer (SIMGAP) to improve oil recovery and sweep efficiency from layered carbonate reservoirs. presented at the SPE EOR Conference at oil & gas West Asia, Muscat, Oman, 11–13 April. SPE-129645-MS. https://doi.org/10.2118/129645-MS

Nazari N, Tsau J, Barati R (2017) CO2 Foam stability improvement using polyelectrolyte complex nanoparticles prepared in produced water. Energies 10(4):516. https://doi.org/10.3390/en10040516

Nikolov A, Wasan D, Huang D et al. 1986 The effect of oil on foam stability: mechanisms and implications for oil displacement by foam in porous media. presented at the SPE annual technical conference and exhibition, New Orleans, Louisiana, 5–8 October. SPE-15443-MS. https://doi.org/10.2118/15443-MS.

Schramm LL, Novosad JJ (1990) Micro-visualization of foam interactions with a crude oil. Colloid and Surfactants 46(1):21–43. https://doi.org/10.1016/0166-6622(90)80046-7

Skauge A, Solbakken J, Ormehaug P et al (2019) Foam generation, propagation and stability in porous medium. Transp Porous Media 131:5–21. https://doi.org/10.1007/s11242-019-01250-w

Slobod RL HA, Koch Jr. 1953 High-pressure gas injection- mechanism of recovery increase. drilling and production practice, New York, USA. API-53–082.

Staszak K, Wieczorek D, Michocka K (2015) Effect of Sodium Chloride on the Surface and Wetting Properties of Aqueous Solutions of Cocamidopropyl Betaine. J Surfactants Deterg 18(2):321–328. https://doi.org/10.1007/s11743-014-1644-8

Whorton LP, WF Kieschnick 1950 A preliminary report on oil recovery by high-pressure gas injection. drilling and production practice: 247–257, New York, USA. API-50–247.

Yaghoobi H (1994) Laboratory investigation of parameters affecting Co2-foam mobility in sandstone at reservoir conditions. presented at the SPE eastern regional meeting, Charleston, West Virginia, 8–10 November. SPE-29168-MS. https://doi.org/10.2118/29168-MS.

Funding

Work was funded by Aramco.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

On behalf of all the co-authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

AlYousef, Z., Gizzatov, A., AlMatouq, H. et al. Assessment of foam generation and stabilization in the presence of crude oil using a microfluidics system. J Petrol Explor Prod Technol 13, 1155–1162 (2023). https://doi.org/10.1007/s13202-022-01604-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-022-01604-z