Abstract

One of the most effective enhanced oil recovery techniques is carbon dioxide (CO2) flooding. It is because of its high oil recovery rate and associated advantage on the environment. CO2 flooding has been broadly used and commercially proven. Depending on the reservoir and operational conditions, it can be implemented either in immiscible or miscible modes. Determining the injection mode depends on the minimum miscibility pressure (MMP). The conventional ways of determining the MMP (slim-tube experiments, supercritical extractor, etc.) are costly and time-consuming. A simulation approach has been deployed to determine the MMP of a synthetic reservoir model using a one-dimension compositional slim-tube model in ECLIPSE300. The MMP was also determined using the group method of data handling (GMDH) and other existing correlations. The MMP determined by slim-tube simulation was ~ 4176 psia. Comparing the MMPs of the correlations to the slim-tube simulation, the correlation by Maklavani et al. (Braz J Pet, 2010) was the most accurate with a mean absolute percentage error (MAPE) of 0.79%. The GDMH and the correlation of Firoozabadi and Khalid had MAPEs of 4.96% and 6.06%, respectively. The GMDH model introduced in this study was not as accurate as the correlation by Maklavani et al. (Braz J Pet, 2010) . The model could be improved, or other machine learning models with improved training and prediction could be deployed to estimate MMP more accurately. A synthetic reservoir model based on literature data was used to investigate the effect of the MMP and injection rate on oil recovery by CO2 flooding. The impact of MMP was investigated by the miscible and immiscible flooding scenarios. The injection rate was varied in each scenario to determine the optimum injection rate. However, the scenarios with optimum injection rates for both miscible and immiscible CO2 injection were compared to a waterflood scenario. The optimum injection rates for miscible and immiscible flooding were 2800 and 2200 Mscf/day, respectively. The oil recovery efficiencies for the optimum miscible and immiscible injection were 48% and 46%, respectively. In this study, miscible flooding proved to be the more effective method in oil recovery. However, considering the difference in oil recovery and the difficulty in achieving miscibility, the immiscible CO2 flooding proves to be the feasible option for improving oil recovery.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Primary recovery often provides access to a small fraction of the reservoir’s total capacity. Following that, the secondary recovery can continue to extract oil to a third or more. Half of a reservoir’s original oil content is still trapped after applying primary and secondary recovery methods, including natural drive mechanisms and water or gas flooding. The Enhanced Oil Recovery (EOR) enables the extraction of most of the remaining oil and extends a field’s life (Verma 2015). Over the years, carbon dioxide flooding has been used widely as one of the most effective enhanced oil recovery methods with associated environmental benefits (Karkevandi-Talkhooncheh et al. 2018). The capillary pressure is zero when complete miscibility is achieved in the CO2 flooding process between injected CO2 and reservoir fluid. Thus, it results in zero oil trapping and higher oil recovery. The most critical factor in determining whether miscibility has been achieved in the reservoir is the minimum Miscibility Pressure (MMP) (Stalkup 1987).

A variety of methods have been suggested to determine the MMP. Experimental methods in measuring the MMP include slim-tube experiment (Yarborough and Smith 1970; Yellig and Metcalfe 1980; Jarrell et al. 2002; Ahmad et al. 2016), vanishing interfacial tension (Rao 1997; Ahmad et al. 2016; Hawthorne et al. 2016; Zhang and Gu 2016), rising bubble apparatus (Christiansen and Kim 1986; Christiansen and Haines 1987; Elsharkawy et al. 1992; Czarnota et al. 2017; Zhang et al. 2018), and supercritical extractor (Rudyk et al. 2009). However, there are limitations in determining the MMP using these experimental methods. The slim-tube experiment is time-consuming, costly, and lacks standard design and procedure (Elsharkawy et al. 1992; Ekundayo and Ghedan 2013; Ahmad et al. 2016). The rising bubble is also known to provide little quantitative information, and the interpretation of the results is subjective (Thomas et al. 1994). The supercritical extractor could also be expensive and rare. Generally, experimental methods could be time-consuming.

Therefore, simulation methods have been deployed by various researchers. Based on the work of Zick (1986), various simulation methods have been proposed (Jaubert et al. 1998a, b, 2002; Maklavani et al. 2010; Fath and Pouranfard 2014; Abdurrahman et al. 2019). Jaubert et al. (1998a) first determined the MMP using slim-tube simulation and showed the method to be more accurate and faster than the 1D simulator. Fath and Pouranfard (2014) and Abdurrahman et al. (2019) also performed the slim-tube simulation in their study using Eclipse 300 and CMG software. Nevertheless, fine-grid computational simulations could suffer from numerical dispersion effects and could also be time-consuming to perform (Yuan et al. 2004). Various correlations have, therefore, been developed from regressions of slim-tube data for the estimation of MMP (Firoozabadi and Khalid 1986; Orr et al. 1993; Johns and Orr 1996; Wang and Orr 2000; Yuan et al. 2004; Yuan and Johns 2005; Maklavani et al. 2010). Correlations are generally less accurate yet are quick and easy to deploy, requiring only a few input parameters. They are, therefore, useful for quick screening of potential CO2 flooding reservoirs and in situations where detailed fluid characterizations are not available.

In this study, a correlation model is developed using the group method of data handling (GMDH) to estimate MMP alongside other correlations by Firoozabadi and Khalid (1986) and Maklavani et al. (2010). The MMPs obtained are compared to those obtained by slim-tube simulation. The injection rate of CO2 is also an essential factor that affects the oil recovery of CO2 flooding. The optimum injection rate must be determined to maximize oil recovery cost-effectively. Therefore, this study also aims at investigating the feasibility of CO2 flooding using a reservoir simulation approach. Therefore, a simulation approach has been deployed in this study to determine the optimum injection rate using Eclipse 300. The effect of MMP is determined via injection at pressures below (immiscible) and above (miscible) the MMP. The injection rates are varied in each of these scenarios to determine the optimum injection rate.

Methodology

Determining MMP by slim-tube simulation

A one-dimensional slim-tube model was simulated using ECLIPSE 300 to determine the MMP. This model is a 10-m-slim-tube test using laboratory units. With a dimension of 200 × 1 × 1 m, this model consists of 200 grid cells. Porosity is set to 0.2 and permeability 2000 mD. A length of 10 m was selected to ensure that miscibility is developed and a 1 cm2 cross-sectional area to reduce the effect of the transition region (Ebrahimi et al. 2012). The MISCIBLE keyword was selected as the solution method, and the FULLIMP (fully implicit solution option) keyword was also chosen as the capillary pressure and relative permeability dependence toward surface tension. The correlation used for slim-tube simulation is by (Stalkup 1987). The injector and producer were placed at the first (1,1,1) and last (200,1,1) grid of the model to keep the bottom-hole pressure (BHP) constant. Figure 1 shows the slim-tube model with the respective well locations. The standard way based on the literature is to end the simulation after injecting 1.2 pore-volume (PV) of injected gas (Shahvaranfard et al. 2009; Salari Sardari and Khorsand Movaghar 2017). Several slim-tube simulations were run at different injection pressures to find the MMP, and the respective recoveries at 1.2 PV were plotted against the pressures (Jarrell et al. 2002).

Determining MMP by correlation of Firoozabadi and Khalid

According to Firoozabadi and Khalid (1986), three parameters affect the multiple-contact miscibility. The three parameters are the number of intermediates, volatility, and temperature. Intermediates composition in the reservoir is defined as C2 through C6, CO2, and H2S. These components enhance the development of miscibility with high concentrations in the reservoir oil. Based on their observation, the exclusion of C6 from the intermediates improved the correlation of MMP. Intermediated in their paper is concluded to be C2 through C5, CO2, and H2S. Another parameter they give is the volatility of the reservoir oil through the vaporization gas condensate process. It shows that light hydrocarbons or more volatile oil are expected to be vaporized at a lower pressure. It is found that the molecular weight of C7+ is accounted for the oil volatility. Higher temperature increases the recovery in the vaporization gas condensate process and thus results in lower MMP. Lastly, the effect of temperature is less obvious, and MMP is inversely related to temperature. The equation for the MMP are as follows:

where \({\text{MMP}}\) = minimum miscibility pressure, \(T\) = temperature (°F), \(C_{{{\text{C}}2}} - C_{{{\text{C}}5}} { }\) = concentration of intermediates, mol%,\(C_{{\text{C2 + }}}\) = molecular weight of heptane plus.

Determining MMP by correlation of Maklavani et. al. (2010)

According to Maklavani et al. (2010), as the heptane plus’ molecular weight increases, the hydrocarbon gas MMP increases. While as the mole fraction of methane and intermediates increase in the oil composition, the hydrocarbon gas MMP will decrease. Furthermore, the MMP reduces when the mole fraction and molecular weight of the ethane plus in the injected gas increases. The correlation is developed by using nonlinear regression. The equation is as follows:

where \({\text{MMP}}\) = minimum miscibility pressure, \(X_{{{\text{C}}2}} - X_{{{\text{C}}6}} { }\) = Intermediate composition in the oil-containing C2–6, CO2 (mole %), \(X_{{{\text{C}}1}} { }\). = Amount of methane in the oil (%), \(T\) = temperature (°F), \(C_{{{\text{C2}}}} - C_{{{\text{C5}}}}\) = concentration of intermediates, mol%, \(M_{{\text{C7 + }}}\) = molecular weight of heptane plus (g/mol), \(Y_{{\text{C2 + }}}\)= Mole percent of C2+ composition in injected gas (%),\(M_{{\text{C2 + }}}\) = Molecular weight of C2+ in injected gas.

Determination of MMP by GMDH correlation

This model is made of two layers to determine the MMP. Initially, ten neurons were connected in the first layer, with only one neuron, N1. Meanwhile, the output is in the second layer, with the MMP value as the only neuron. This correlation shows a significant effect toward MMP on the mole fraction of intermediates (C2–C6) in the oil and the molecular weight of C2+ in the injected gas. The correlation is as follows:

where MMP = Minimum Miscibility Pressure,CC1 = mole fraction of C1, CC2−CC5 = concentration of intermediates, mol%, CC2+ = molecul weight of C2+ of injected gas.

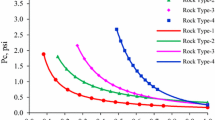

Rock and fluid properties

The modeling requires the assumption and estimation of rock and fluid properties to create a synthetic oil field. Therefore, data selection plays an essential role in ensuring a high-quality model for simulation. For this project, a sensitivity model will be created for manipulating parameters, which are MMP and the injection rate of CO2. A base case model was created first to compare the oil recovery and analyze the effect of the various parameters on oil recovery. The base case chosen for this study is water flooding for secondary recovery due to the regular cases in most countries. Therefore, the base case is a water-flooded reservoir. The base case for this project is based on the screening criteria for the EOR to be applied. Tables 1 and 2 show the criteria used to screen technical data for this model, according to Taber et al. (1997).

Based on the screening criteria, the rock and fluid properties for the model were taken from (Fath and Pouranfard 2014). The rock and fluid properties are presented in Table 3.

Reservoir model

A simple 3-dimensional reservoir model grid of 21 × 5 × 17 (1785 grid block) with a 1900 × 1900 × 250 ft reservoir size is used in a compositional simulator ECLIPSE 300 with eleven-components crude oil from the ECLIPSE library. The components of the crude oil are shown in Table 4. The initial oil in place is measured by simulation as 4.98 MMstb. The three-phase model consists of water, oil, and gas with the miscible option selected. In the PVT section of the model, the 3 Parameter Peng-Robinson equation is specified for the calculation.

A variety of injector and producer pattern layouts were considered. The well pattern needed to be optimized to ensure optimum production from the wells. This study runs the six different well layouts to find the optimum well pattern. The layouts are the direct line drive, staggered line drive, regular five-spot, inverted five-spot, regular seven-spot, and inverted seven-spot. All water flooding well is controlled with the same production and injection control. The total rate control for production is 400 STB/day with a limiting bottom-hole pressure of 1800 psia, while the total rate control for injection is 350 STB/day with a limiting bottom-hole pressure of 3000 psia. Based on the optimization results as shown in Fig. 2 and summarized in Table 5, the inverted five-spot pattern is chosen with the highest field oil efficiency (FOE) of 26.37%. Four producing wells are located at each corner of the reservoir (1,1), (1,5), (21,1), and (21,5). One injector is in the middle of the reservoir at (11,3), as shown in Fig. 3. The simulation was run for three phases of production, which are:

-

1.

Primary recovery: a natural depletion simulation was run to get the first recovery factor compared to secondary and tertiary recovery.

-

2.

Secondary recovery: water flooding is introduced to the reservoir as the secondary recovery method.

-

3.

Tertiary recovery: CO2 injection is introduced to the reservoir.

Results and discussions

Determination of CO2 minimum miscibility pressure

After slim-tube simulation runs at 12 different displacement pressures (3000–6400 psia), the recovery factors at 1.2 PV were determined as presented in Table 6. A plot of the various recoveries against their respective pressures determines the MMP, as shown in Fig. 4. From the plot, the MMP is determined to be ~ 4176 psia. The MMP was also manually calculated using the correlations by Firoozabadi and Khalid (1986) and Maklavani et al. (2010) using Eqs. 1–4, respectively. The MMPs were estimated to be ~ 4429 psia for Firoozabadi and Khalid’s correlation and ~ 4383 psia for the correlation by Maklavani et al. Based on the GMDH correlation, the MMP was estimated to be ~ 4383 using Eq. (5).

A comparison of the MMPs derived from the various methods is shown in Fig. 5. The various MMPs estimated, and their Mean Absolute Percentage Error (MAPE) are summarized in Table 7. As observed in Fig. 5, the MMPs obtained by the correlation of Firoozabadi and Khalid, and the GDMH model varied significantly from the slim-tube simulation’s MMP with MAPE of 6.06% and 4.96%, respectively. On the other hand, the correlation by Maklavani et al (2010). yielded a very close MMP with a MAPE of 0.79%. The correlation by Firoozabadi and Khalid is more accurate for lean gas and nitrogen injection. The correlation produces significant errors when the methane content in the drive gas is significantly lower than 80 mol% (Ali Danesh 1997). The prediction by GDMH could be improved, or other machine learning models with improved training and prediction could be deployed to estimate MMP more accurately. The correlation by Maklavani et al. (2010) is an enhanced model that considers a wide range of parameters that affect MMP. The closeness of the MMP derived from the slim-tube simulation to this improved model means that an MMP of 4176 psia is accurate enough for further analysis.

Reservoir simulation scenarios

The objective of this study is to evaluate the effects of MMP. Thus, it considers the various scenarios, including natural depletion, water flooding, immiscible, and miscible CO2 flooding. All scenarios have to be done with the same pattern, identical operational conditions, and the control for production wells should also be the same.

Natural depletion scenario

The model has four vertical production wells, and the oil production rate was set at 400 STB/day, which is 100 STB/day per well. The BHP was limited to 1800 psia. This model was run for 15 years, from 2015 to 2030, and the result is taken into analysis. Figures 6 and 7 show the natural depletion scenario results. Figure 6 shows the field total oil production (FOPT) and the field reservoir pressure (FPR) declination from 2015 to 2030. The field oil efficiency (FOE) and field oil production rate (FOPR) are also shown in Fig. 7.

As can be seen in these figures, the cumulative oil production (oil recovery) increased until 2020. Beyond this year, there is no further oil production. The cumulative oil production rate remains constant as the oil production rate drops to zero, as seen in Fig. 7. This is due to the depletion of the reservoir pressure, as seen in the FPR curve. Though the simulation continued for 15 years as specified, the oil production halted after the 5th year. Secondary and/or enhanced oil recovery is required to prolong the field's production life. The tremendous decline in the oil production rate shows the effect of pressure depletion on oil recovery. After 15 years of natural depletion, the FPR is 1919 psia. However, the recovery factor after the natural depletion is ~ 15.40%, as seen in Fig. 7. The cumulative oil production for natural depletion is approximately 0.77 MMstb. The variation of the field pressure and the gas-oil ratio is also presented in Fig. 8. The profile shows that the natural drive mechanism was a solution gas drive. This inference is confirmed by comparing this profile to a characteristic solution gas drive profile (Fig. 9) as presented by (Ahmed and McKinney 2011).

Characteristic of solution gas drive (Ahmed and McKinney 2011)

Water flooding scenario

The same model used for natural depletion was used for the water flooding scenario. One injector well is added at the middle of the reservoir with an injection control of 350 STB/day with a limiting bottom-hole pressure of 3000 psia. This model was run as a natural depletion scenario for two years. The water injection well was active in the third year and continued as a water flooding scenario for 13 years. The simulation ended after the 15th year. Water flooding is applied to the reservoir in the secondary recovery to supplement the reservoir pressure and increase oil recovery in the third year after natural depletion. As presented in Figs. 10, 11, the cumulative oil production increased steadily until 2022, the 7th year. After that, though the oil production decreased drastically and the reservoir pressure dropped, the cumulative oil production increased gradually. The injected water displaced the oil toward the producers, as seen in the gradual increase in oil production on the FOPR curve (Fig. 11). At the end of production, the reservoir pressure declined to 1949 psia. As for the total oil production, 1.32 MMstb could be extracted out of the reservoir. This gives a recovery factor of 26.37%, as shown in Fig. 11. The FOPR is constant for seven years, then declines abruptly, followed by fluctuation in the FOPR. The decline in oil production could be attributed to water breakthrough (BT), and the instability in FOPR between years 7 and 9 could be attributed to intermittent oil and water production due to increasing water cuts. The water BT time is, therefore, seven years. In this condition, CO2 injection can be helpful to reduce the pressure drop and increase the recovery factor.

Immiscible displacement of CO2 flooding scenario

The average reservoir pressure is 5830 psia. Therefore, the injection pressure should be greater. Nevertheless, the injection pressure should not exceed the fracture pressure to avoid fracturing and damaging the reservoir's rock. The immiscible CO2 injection pressure was set to 3000 psia, and the same production control is also applied to this scenario. The strategy to run this model is by natural depletion for two years, water flooding for three years, and at year 6, CO2 is injected for the remaining ten years. A total of 15 years of production was simulated for this model. The location of a CO2 injection well has not been changed since the conditions for all the scenarios were maintained. The only variable for optimization was the injection rate. Several simulations were run, and CO2 was injected at different rates of 1000, 1200, 1500, 1800, 2000, 2200, and 2500 Mcf/day for the sake of finding the optimum injection rate for this scenario. The simulation results for immiscible CO2 flooding are presented in Figs. 12 and 13. The results are also summarized in Table 8. From Fig. 12, it could be seen that oil recovery increased with increasing CO2 injection rate. The reservoir pressure also increased beyond that achieved by water flooding with an increasing CO2 injection rate. However, no increase was observed by increasing the CO2 injection rate from 2200 to 2500 Mscf/day. Therefore, the optimum CO2 injection rate was 2200 Mscf/day. It is also observed that with an increased CO2 injection rate, the average field pressure increased until the optimum injection rate (2200 Mscf/day). At the end of the 15 years of production, the recovery factor for this optimum CO2 injection rate was 46.1%. The field reservoir pressure and total oil field production at the end of 15 years of production are 2905 psia and 2.18 MMstb, respectively.

Miscible displacement of CO2 flooding scenario

For the miscible displacement scenario, the production and injection wells were placed the same as the immiscible displacement scenario. The injection pressure was set above the MMP, which is 6000 psia. The bottom-hole pressure for all production wells was set to 1800 psia with a 400 stb/day field production rate and 100 STB/day per well. The injection rate was varied to find the optimum rate for this scenario. The different injection rate used are 1200, 1500, 1800, 2000, 2200, 2500, 2800, and 2900 Mscf/day. The same strategy of CO2 injection used for immiscible displacement is applied for miscible displacement. A total of 15 years was simulated for this model with two years of natural depletion, three years of water flooding, and ten years for CO2 flooding. The oil recovery and the average reservoir pressure for the various miscible CO2 injection scenarios are shown in Figs. 14 and 15, respectively. The results are also summarized in Table 9. As observed in the immiscible displacement scenarios, the oil recovery continuously improved, and average reservoir pressure increased with increasing CO2 injection rate. The optimum injection rate for this displacement was found to be 2800 Mscf/day. The ultimate oil recovery factor is 48% at this optimum rate, and the average reservoir pressure is 5721 psia.

Comparison of scenarios

A comparison between the various scenarios is made. Firstly, the natural depletion is compared to the waterflood scenario, as shown in Fig. 16. As seen from the figure, the field oil production plateau is prolonged for two years more. This is seen in the oil recovery curve maintaining its gradient for two more years compared to natural depletion. The field average pressure curves also show that the pressure decline rate decreased with the water flooding, which is meant to supplement the reservoir pressure while pushing the oil toward the producers. The water flooding also caused substantial oil to be produced during the production decline phase. This shows that it would be economical to implement water flooding as a secondary recovery before the tertiary recovery phase. Therefore, the immiscible and miscible scenarios are compared to the waterflood scenario.

In the previous sections, the optimum injection rates for miscible and immiscible flooding were 2800 and 2200 Mscf/day, respectively. A comparison is made between these scenarios and the water flooding scenario, as presented in Figs. 17 and 18. The results are also summarized in Table 10. The oil recovery from the two optimum CO2 injection scenarios looks pretty close. However, as shown in Table 10, the best immiscible and miscible injection scenarios give 2.18 MMstb and 2.19 MMstb, respectively, while the water flooding gives a field oil total production of 1.32 MMstb. Hence, the miscible CO2 flooding is the best scenario for this reservoir with a recovery factor of 48%, as shown in Fig. 17.

Furthermore, at the end of year 15, the water flooding scenario gives a reservoir pressure of 1949 psia while the immiscible and miscible reservoir pressure of 2905 psia and 5721 psia, respectively. The higher reservoir pressures for the two optimum CO2 injection scenarios over the water flooding scenario are due to the higher CO2 injection rates required while optimizing the injection processes. This shows that the miscible increases the reservoir pressure and thus making it the optimum scenario. However, considering the difference in the oil recoveries and the cost and difficulty in achieving miscible displacement in large oil fields, immiscible flooding seems to be the economically viable means for enhancing oil recovery.

Conclusions

In this study, MMP has been estimated by various methods. The slim-tube simulation used as the standard for comparison yielded an MMP of 4176 psia. A comparison with MMPs estimated by the correlations of Firoozabadi and Khalid (MMP = 4429), Maklavani et al. (MMP = 4209), and a GDMH model (MMP = 4383) revealed that the correlation by Maklavani et al. was more accurate than the GDMH model introduced in this study. The training of the GDMH model could be improved, or machine learning models could be deployed to yield MMP estimation with better accuracy. The study on the effect of injection rate also revealed that the optimum injection rate for the immiscible and miscible CO2 flooding scenarios are 2200 Mscf/day and 2800 Mscf/day, respectively. On the other hand, the effects of MMP on CO2 flooding showed that the best scenario is miscible flooding with 48% oil recovery. At the end of 15 years, the reservoir pressure was 5721 and the total field oil production of 2.19 MMstb. However, miscible displacement is quite difficult to achieve in a massive oil reservoir. Besides, the cost of implementing miscible displacement is higher than immiscible displacement due to the need for a high-pressure injection system. Therefore, the miscible displacement is not feasible from an economic point of view. Since the difference in recovery factor for immiscible and miscible displacement is relatively small, thus the immiscible CO2 flooding scenario is recommended as economically feasible for field application.

Abbreviations

- API:

-

American petroleum institute

- BHP:

-

Bottom-hole pressure

- C7 + :

-

Heptane plus component

- CO2 :

-

Carbon dioxide

- Cn:

-

Alkane with n number of carbons

- EOR:

-

Enhanced oil recovery

- FOE:

-

Field oil efficiency

- FOPR:

-

Field oil production rate

- FOPT:

-

Field oil production total

- FPR:

-

Field pressure

- GDMH:

-

Group method of data handling

- H2S:

-

Hydrogen sulfide

- ICn:

-

Iso alkane

- kH :

-

Horizontal permeability

- kV :

-

Vertical permeability

- MMP:

-

Minimum miscibility pressure

- N2 :

-

Nitrogen gas

- NCn:

-

Normal alkane

- PV:

-

Pore-volume

References

Abdurrahman M, Bae W, Permadi AK (2019) Determination and evaluation of minimum miscibility pressure using various methods: experimental, visual observation, and simulation. Oil Gas Sci Technol d’IFP Energies Nouv 74:55

Ahmad W, Vakili-Nezhaad G, Al-Bemani AS, Al-Wahaibi Y (2016) Experimental determination of minimum miscibility pressure. Procedia Eng 148:1191–1198

Ahmed T, McKinney P (2011) Advanced reservoir engineering. Elsevier, Amsterdam

Ali Danesh A (1997) PVT and phase behavoir of petroleum reservoir. Heriot Watt University, Edinburgh

Christiansen RL, Kim H (1986) Apparatus and method for determining the minimum miscibility pressure of a gas in a liquid. U.S. Patent 4,627,273, 9 Dec 1986

Christiansen RL, Haines HK (1987) Rapid measurement of minimum miscibility pressure with the rising-bubble apparatus. SPE Reserv Eng 2:523–527

Czarnota R, Janiga D, Stopa J, Wojnarowski P (2017) Determination of minimum miscibility pressure for CO2 and oil system using acoustically monitored separator. J CO2 Util 17:32–36. https://doi.org/10.1016/j.jcou.2016.11.004

Ebrahimi A, Khamehchi E, Rostami J (2012) Investigation of hydrocarbon and non-hydrocarbon (CO2, N2) gas injection on enhanced oil recovery in one of the Iranian oil fields. J Pet Explor Prod Technol 2:209–222

Ekundayo JM, Ghedan SG (2013) Minimum miscibility pressure measurement with slim tube apparatus-how unique is the value? In: SPE reservoir characterization and simulation conference and exhibition. OnePetro

Elsharkawy AM, Poettmann FH, Christiansen RL (1992) Measuring minimum miscibility pressure: slim-tube or rising-bubble method? In: SPE/DOE enhanced oil recovery symposium. OnePetro

Fath AH, Pouranfard A-R (2014) Evaluation of miscible and immiscible CO2 injection in one of the Iranian oil fields. Egypt J Pet 23:255–270

Firoozabadi A, Khalid A (1986) Analysis and correlation of nitrogen and lean-gas miscibility pressure (includes associated paper 16463). SPE Reserv Eng 1:575–582

Hawthorne SB, Miller DJ, Jin L, Gorecki CD (2016) Rapid and simple capillary-rise/vanishing interfacial tension method to determine crude oil minimum miscibility pressure: pure and mixed CO2, methane, and ethane. Energy Fuels 30:6365–6372

Jarrell PM, Fox CE, Stein MH, Webb SL (2002) Practical aspects of CO2 flooding. Society of Petroleum Engineers, Richardson

Jaubert J-N, Arras L, Neau E, Avaullee L (1998a) Properly defining the classical vaporizing and condensing mechanisms when a gas is injected into a crude oil. Ind Eng Chem Res 37:4860–4869

Jaubert J-N, Wolff L, Neau E, Avaullee L (1998b) A very simple multiple mixing cell calculation to compute the minimum miscibility pressure whatever the displacement mechanism. Ind Eng Chem Res 37:4854–4859

Jaubert J-N, Avaullee L, Pierre C (2002) Is it still necessary to measure the minimum miscibility pressure? Ind Eng Chem Res 41:303–310

Johns RT, Orr FM (1996) Miscible gas displacement of multicomponent oils. SPE J 1:39–50

Karkevandi-Talkhooncheh A, Rostami A, Hemmati-Sarapardeh A et al (2018) Modeling minimum miscibility pressure during pure and impure CO2 flooding using hybrid of radial basis function neural network and evolutionary techniques. Fuel 220:270–282

Maklavani AM, Vatani A, Moradi B, Tangsirifard J (2010) New minimum miscibility pressure (MMP) correlation for hydrocarbon miscible injections. Braz J Pet Gas 4(1)

Orr FM, Johns RT, Dindoruk B (1993) Development of miscibility in four-component CO2 floods. SPE Reserv Eng 8:135–142

PVTi and ECLIPSE 300. https://studylib.net/doc/8874669/pvti-and-eclipse-300. Accessed 18 Feb 2022

Rao DN (1997) A new technique of vanishing interfacial tension for miscibility determination. Fluid Phase Equilib 139:311–324

Rudyk SN, Søgaard EG, Abbasi WA, Jørgensen LW (2009) Determination of minimum miscibility pressure in supercritical extractor using oil saturated sample. Chem Eng 17:1

Salari Sardari F, Khorsand Movaghar MR (2017) A simulation approach to achieve the best miscible enrichment in gas flooding and chemical injection process for enhanced oil recovery. Asia-Pacific J Chem Eng 12:230–246

Shahvaranfard A, Moradi B, Tahami SA, Gholami A (2009) Evaluation of different flooding scenarios as enhanced oil recovery method in a fractured reservoir: a case study. Braz J Petrol Gas 3(30)

Stalkup FI (1987) Displacement behavior of the condensing/vaporizing gas drive process. In: SPE annual technical conference and exhibition. OnePetro

Taber JJ, Martin FD, Seright RS (1997) EOR screening criteria revisited-Part 1: Introduction to screening criteria and enhanced recovery field projects. SPE Reserv Eng 12:189–198

Thomas FB, Zhou XL, Bennion DB, Bennion DW (1994) A comparative study of RBA, Px, multicontact and slim tube results. J Can Petrol Technol 33(2)

Verma MK (2015) Fundamentals of carbon dioxide-enhanced oil recovery (CO2-EOR): a supporting document of the assessment methodology for hydrocarbon recovery using CO2-EOR associated with carbon sequestration. US Department of the Interior US Geological Survey, Washington, DC

Wang Y, Orr FM Jr (2000) Calculation of minimum miscibility pressure. J Pet Sci Eng 27:151–164

Yarborough L, Smith LR (1970) Solvent and driving gas compositions for miscible slug displacement. Soc Pet Eng J 10:298–310

Yellig WF, Metcalfe RS (1980) Determination and prediction of CO2 minimum miscibility pressures (includes associated paper 8876). J Pet Technol 32:160–168

Yuan H, Johns RT, Egwuenu AM, Dindoruk B (2004) Improved MMP correlations for CO2 floods using analytical gas flooding theory. In: SPE/DOE symposium on improved oil recovery. OnePetro

Yuan H, Johns RT (2005) Simplified method for calculation of minimum miscibility pressure or enrichment. SPE J 10:416–425

Zhang K, Gu Y (2016) Two new quantitative technical criteria for determining the minimum miscibility pressures (MMPs) from the vanishing interfacial tension (VIT) technique. Fuel 184:136–144

Zhang K, Jia N, Zeng F (2018) Application of predicted bubble-rising velocities for estimating the minimum miscibility pressures of the light crude oil–CO2 systems with the rising bubble apparatus. Fuel 220:412–419

Zick AA (1986) A combined condensing/vaporizing mechanism in the displacement of oil by enriched gases. In: SPE annual technical conference and exhibition. OnePetro

Funding

The authors would like to thank the Universiti Teknologi PETRONAS for financial assistance provided through YUTP Grant #015LC0-232.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all the co-authors, the corresponding author states no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ayoub, M.A., Tackie-Otoo, B.N. & Zulkefli, S.H.B. The combined effects of the minimum miscibility pressure and injection rate variations on recovery of co2 flooding in sandstone reservoir. J Petrol Explor Prod Technol 12, 2899–2913 (2022). https://doi.org/10.1007/s13202-022-01480-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13202-022-01480-7